Professional Documents

Culture Documents

Bernoulli Theorem Demonstration

Uploaded by

manzahuhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bernoulli Theorem Demonstration

Uploaded by

manzahuhuCopyright:

Available Formats

ABSTRACT The main objectives in this experiment is to investigate the validity of Bernoulli equation when applied to a steady flow

of water in tapered duct and to measure the flow rate and both static and total pressure heads in a rigid convergent or divergent tube known geometry range of steady flow rates.In this experiment,the apparatus used is Bernoullis Theorem Demonstration Apparatus and this apparatus contains of many parts,which are venturi meter,pad of monometer tubes,pump,water tank equipped with valves water controller and water hosts and tubes.The experiment is done after the level of pressure for all the tubes are maintained.Then,the valve is opened to make the flow rate different for three times and the time was recorded when the inductor of the water level reached 3 Liter.When the time was recorded,the reading of pressure level was taken for each tubes A,B,C,D,E, and F.Based on the results taken,it has been analysed that when the speed increases it can only be because the fluid on that section has moved from a region of higher pressure to a region of lower pressure; and if its speed decreases, it can only be because it has moved from a region of lower pressure to a region of higher pressure.Therefore,bernoullis principle is valid for a steady flow in rigid convergent and divergent tube of known geometry for a range of steady flow rates and all the datas are as well calculated.The experiment was completed and successfully conducted.

INTRODUCTION Bernoullis Theorem Demonstration (Model : FM 24) apparatus consists of a classical Venturi made of clear acrylic.A series of wall tappings allow measurement of the static pressure distribution along the converging duct,while a total head tube is provided to traverse along the centre line of the test section.These tappings are connected to a manometer bank incorporating a manifold with air bleed valve.Pressurization of the manometers is facilitated by a hand pump. This unit has been designed to be used with a Hydraulics Bench for students to study the characteristics of flow through both converging and diverging sections.During the experiment,water is fed through a hose connector and students may control the flow rate of the water by adjusting a flow regulator valve at the outlet of the test section. The venture can be demonstrated as a means of flow measurement and the discharge coefficient can be determined.This test section can be used to demonstrate those circumstances to which Bernoullis Theorem may be applied as well as in other circumstances where the theorem is not sufficient to describe the fluid behaviour.

GENERAL DESCRIPTION The unit is mounted on a base board which is to be placed on top of the Hydraulic Bench (Model : FM 110).This base board has four adjustable feet to level the apparatus. The main test section is an accurately machined acrylic venturi of varying circular cross section.It is provided with a number of side hole pressure tappings,which are connected to the manometer tubes on the rig.These tappings allow the measurement of static pressure head simultaneously at each of 6 sections.The tapping positions and the test section diameters are shown in Appendix A.The test section incorporates two unions,one at either end,to facilitate reversel for convergent or divergent testing as illustrated in Figure 1 and Figure 2.

A hypodermic tube,the total pressure head probe,is provided which may be positioned to read the total pressure head at any section of the duct.This total pressure head probe may be moved after slacking the gland nut: this nut should be re-tightened by hand after adjustment.An additional tapping is provided to facilitate setting up.All eight pressure tapings are connected to a bank of pressurized manometer tubes.Pressurization of the manometers is facilitated by connecting any hand pump to the inlet valve on the manometer manifold. The unit is connected to the hydraulic bench using flexible hoses.The hoses and the connections are equipped with rapid action couplings.The flexible hose attached to the outlet pipe which should be directed to the volumetric measuring tank on the hydraulics bench.A flow control valve is incorporated downstream of the test section.Flow rate and pressure in the apparatus may be varied independently by adjustment of the flow control valve and the bench supply control valve.

Please familiarize with the unit before operating the unit.The unit consist of the followings: a. Venturi The venture meter is made of transparent acrylic with the following specifications : Throat diameter : 16 mm Upstream Diameter : 26 mm Designed Flow Rate : 20 LPM

b. Manometer There are eight manometer tubes ; each length 320 mm,for static pressure and total head measuring along the venturi meter. The manometer tubes are connected to an air bleed screw for air release as well as tubes pressurization. c. Baseboard The baseboard is epoxy coated and designed with 4 height adjustable stands to level the venture meter. d. Discharged valve One discharge valve is installed at the venture discharge section for flow rate control. Connections Hose Connections are installed at both inlet and outlet. e. Hydraulic Bench Sump tank : 120 litres Volumetric tank : 100 litres Centrifugal pump : 0.37 kW,50 LPM

AIM/OBJECTIVES To verify experimentally the validity of Bernoullis equation for fluid flow To verify Bernoulli's equation by demonstrating the relationship between pressure head and kinetic head. To measure flow rate and both static and total pressure heads in a rigid convergent/divergent tube of known geometry for a range of steady flow rates. SUMMARY OF THEORY Derivation Using Streamline Coordinates Eulers equation for steady flow along a streamline is

If a fluid particle moves a distance,ds,along a streamline,

Then,after multiplying Equation 3.1 by ds,

Integration of ths equation gives:

The relation between pressure and density must be applied in this equation.For the special case of incompressible flow,p = constant, and Equation 3.6 becomes the Bernoullis Equation.

Restrictions: I. II. III. IV. Steady flow Incompressible flow Frictionless flow Flow along a streamline

Bernoullis Law Bernoullis law states that if a non-viscous fluid is flowing along a pipe of varying cross section, then the pressure is lower at constrictions where the velocity is higher, and the pressure is higher where the pipe opens out and the fluid stagnate.Many people find this situation paradoxical when they first encounter it (higher velocity,lower pressure).This is expressed with the following equation :

Where,

The terms on the left-hand-side of the above equation represent the pressure head (h),velocity head (hv) , and elevation (z), respectively.The sum of these terms is known as the total head (h*).According to the Bernoullis theorem of fluid flow through a pipe,the total head h * at any cross section is constant.In a real flow due friction and other imperfections,as well as measurement uncertainties,the results will deviate from the theoretical ones. In our experimental setup,the centerline of all the cross sections we are considering lie on the same horizontal plane(which we may choose as the datum,z=0, and thus,all the z values are zeros so that the above equation reduces to:

This represents the total head at a cross section. For the experiments,the pressure head is denoted as hi and the total head as h*i, where i represents the cross sections at different tapping points. Static,Stagnation and Dynamic Pressures The pressure,p, which we have used in deriving the Bernoullis equation,Equation 3.7,is the thermodynamic pressure; it is commonly called the static pressure.The static pressure is that pressure which would be measured by an instrument moving with the flow.However,such a measurement is rather difficult to make in a practical situation. As we know,there was no pressure variation normal to straight streamline.This fact makes it possible to measure the static pressure in a flowing fluid using a wall pressure tapping,placed in a region where the flow streamline are straight,as shown in Figure 4(a).The pressure tap is a small hole,drilled carefully in the wall,with its axis perpendicular to the surface.If the hole is perpendicular to the duct wall and free from burrs,accurate measurements of static pressure can be made by connecting the tap to a suitable pressure measuring instrument.

In a fluid stream far from a wall,or where streamline are curved,accurate static pressure measurements can be made by careful use of a static pressure probe,shown in Figure 4(b).Such probes must be designed so that the measuring holes are place correctly with respect to the probe tip and stem to avoid erroneous results.In use,the measuring section must be aligned with the local flow direction. Static pressure probes or any variety of forms are available commercially in sizes as small as 1.5 mm (1/16 in) in diameter.The stagnation pressure is obtained when a flowing fluid is decelerated to zero speed by a frictionless process.In incompressible flow,the Bernoulli Equation can be used to relate changes in speed and pressure along a streamline for such a process.Negleting elevation differences,Equation 3.7 becomes

If the static pressure is p at a point in the flow where the speed is v,then the stagnation pressure,P0, where the stagnation speed, V0, is zero,may be computed from

Therefore,

Equation 3.12 is a mathematical statement of stagnation pressure,valid for incompressible flow.The term V2 generally is the dynamic pressure.Solving the dynamic pressure gives:

Or

Thus,if the stagnation pressure and the static pressure could be measured at a point,Equation 3.14 would give the local flow speed.

Figure 6 : Simultaneous Measurement of Stagnation and Static Pressures

9

Stagnation pressure is measured in the laboratory using a probe with a hole that faces directly upstream as shown in Figure 5.Such a probe is called a stagnation pressure probe (hypodermic probe) or Pitot (pronounced pea-toe) tube.Again,yhe measuring section must be aligned with the local flow direction. We have seen that static pressure at a point can be measured with a static pressure tap or probe (figure 4).If we know the stagnation pressure at the same point,then the flow speed could be computed from Equation 3.14.Two possible experimental setups are shown in Figure 6. In Figure 6(a),the static pressure corresponding to point A is read from the wall static pressure tap.The stagnation pressure is measured directly at A by the total head tube,as shown.(The stem of the total head tube is placed downstream from the measurement location to minimize disturbance of the local flow). Two probes often are combined,as in the Pitot-static tube shown in Figure 6(b).The inner tube is used to measure the stagnation pressure at point B,while the static pressure at C is sensed using the tapping on the wall.In flow fields where the static pressure variation in the streamwise direction is small,the Pitot-static tube may be used to infer the speed at point B in the flow by assuming pB = pc and using Equation 3.14. (Note that when pB procedure will give erroneous results) Remember that the Bernoulli equation applies only for incompressible flow (Mach number,M 0.3). Note : pc ,this

Where, U = fluid velocity C = sonic velocity

10

Pressure Varies Along the Pipe A number of factors can cause for pressure to vary along the pipe such as : Friction from the pipes inner surface The diameter of the pipe ; if it is small the pressure is lower because the velocity is increased(Bernoullis Theory) Density of the fluid in the pipe The height of the pipe at which the pipe stands or the height at which the flow through i.e. gravity Turbulence of the fluid

Venturi Meter The venture meter consists of a venturi tube and differential pressure gauge.The venturi tube has a converging portion,a throat and a diverging portion as shown in the figure below.The function of the converging portion is to increase the velocity of the fluid and lower its static pressure.A pressure difference between inlet and throat is thus developed,which pressure difference is correlated with the rate of discharge.The diverging cone serves to change the area of the stream back to the entrance area and convert velocity head into pressure head.

11

Assume incompressible flow and no frictional losses,from Bernoullis Equation

Use of the continuity Equation Q = A1V1 = A2V2,equation (1) becomes

) ]

Ideally,

) ]

)]

However,in the case of real fluid flow,the flow rate will be expected to be less than that given by equation (3.18) because of frictional effects and consequent head loss between inlet and throat.Therefore,

) ]

)]

In metering practice,this non-ideality is accountedby insertion of an experimentally determined discharged coefficient,Cd that is termed as the coefficient of discharge.With Z1 = Z2 in this apparatus,the discharge coefficient is determined as below:

Discharge coefficient,Cd usually lies in the range between 0.9and 0.99.

12

APPARATUS Bernoullis Theorem demonstration unit: Venturi Manometer Baseboard Discharge valve Connections Hydraulic bench Water tank

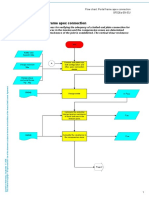

GENERAL OPERATING PROCEDURE General Start-up Procedures The Bernoullis Theorem Demonstration (Model : FM 24) is supplied ready for use and only requires connection to the Hydraulic Bench (Model : FM110 ) as follows: 1. The clear acrylic test section is ensured installed with the converging section upstream. The unions tightened and checked. To dismantle the test suction, the total pressure probe was withdrawn fully before the couplings being released. 2. The apparatus located on the flat top of the bench. 3. A spirit level attached to the baseboard and the unit was level on the top of the bench by adjusting the feet. 4. Water filled into the volumetric tank of the hydraulic bench until approximately 90% full. 5. The flexible inlet tube connected using the quick release coupling in the bed channel. 6. The flexible hose connected to the outlet and it directed into the channel. 7. The outlet flow control partially opened at the Bernoullis Theorem Demonstration Unit. 8. The bench flow control valve, V1 fully closed then the pump switched on. 9. V1 was gradually opened and water allowed to fill until all air has been expelled from the system. 10. All the trapped bubbles checked in the glass tube or plastic transfer tube.

13

To remove air bubbles, the air were bleed out using a pen or screw driver to press the air bleed valve at the top right side of the manometer board.

11. Water flowing into the venturi and discharge into the collection tank of hydraulic bench. 12. The water flow rate proceed to increased it. When all the water flow was steady and there were no trapped bubbles , the discharge valve closed to reduce the flow to the maximum measurable flow rate. 13. Water level in the manometer were in different heights. 14. V1 and outlet control valve adjusted to obtain the flow through the test section and the static pressure profile observed along the converging and diverging sections is indicated on its respective manometers. The total head pressure along the venture tube being measured by traversing the hypodermic tube. Note: the manometer tube connected to the tapping adjacent to the outlet flow control valve is used as a datum when setting up equivalent conditions for flow through test section. 15. The actual flow rate measured by using the volumetric tank with a stop watch.

General Shut Down Procedures 1. Water supply valve and venturi discharge valve closed. 2. The water supply pump closed. 3. Water drain off from the unit when not in use. Bernoullis Theorem Demonstration Objectives : To demonstrate Bernoullis Theorem Procedures: 1. The general start-up procedures was performed 2. All manometer checked that properly connected to the corresponding pressure taps and were air bubble free. 3. The discharge valve adjusted to high measureable flow rate. 4. After the level stabilized, the water flow rate measured using volumetric method. 5. The hypodermic tube(total head measuring) connected to manometer #H was gently slide , so that its end reached the cross section of the venturi tube at #A. After some time the readings from manometer #H and #A noted down. The reading shiwn by

14

manometer #H was the sum of the static head and velocity heads, i.e the total (or stagnation) head (h*), because the hypodermic tube was held against the flow of the fluid forcing it to a stop (zero velocity). The reading in manometer #A measures just the pressure head (hi) because it was connect to the venturi tube pressure tap, which does not obstruct the flow, thus measuring the flow static pressure. 6. Step 5 repeated for other cross sections (#B,#C,#D,#E,#F). 7. Step 3 to 6 repeated with three other decreasing flow rates by regulating the venturi discharge valve. 8. The velocity , ViB calculated using the Bernoullis equation where ; 9. The velocity , Vic using continuity equation where ;

10. The difference between two calculated velocities were determine

Maintenance and safety precautions 1. It is important to drain all water from the apparatus when not in use. The apparatus should be stored properly to prevent damage. 2. Any manometer tube, which does not fill with water or slow fill, indicates that the tapping or connection of the manometer is blocked. To remove the obstacle, disconnected the flexible connection tube and blow through. 3. The apparatus should not be exposed to any shock and stresses. 4. Always wear protective clothing, shoes, helmet and goggles throughout the laboratory session 5. Always run the experiment after fully understand the unit and procedures.

15

RESULTS Experiment 1 Volume (L) Average Time (min) Flow Rate (LPM) 3 0.17 17.64

Cross section #

Using Bernoulli equation

Using equation

Continuity difference

h* = hH (mm)

hi (mm)

ViB

= Ai =

Vic =

ViB - Vic (m/s)

(m/s) (m2) A B C D E F 216 215 219 208 202 200 192 179 105 160 167 177 0.686 0.840 1.496 0.970 0.829 0.672 5.31 x 10-4 3.66 x 10-4 2.01 x 10

-4

(m/s) 0.554 0.803 1.463 0.936 0.774 0.554 0.132 0.037 0.033 0.034 0.055 0.118

3.14 x 10-4 3.80 x 10-4 5.31 x 10-4

16

Experiment 2 Volume (L) Average Time (min) Flow Rate (LPM) 3 0.25 12.00

Cross section #

Using Bernoulli equation

Using equation

Continuity difference

h* = hH (mm)

hi (mm)

ViB

= Ai =

Vic =

ViB - Vic (m/s)

(m/s) (m2) A B C D E F 184 185 186 182 178 175 174 169 135 160 161 167 0.443 0.560 1.000 0.657 0.578 0.396 5.31 x 10-4 3.66 x 10

-4

(m/s) 0.377 0.546 0.995 0.637 0.526 0.377 0.066 0.014 0.005 0.020 0.052 0.019

2.01 x 10-4 3.14 x 10-4 3.80 x 10-4 5.31 x 10-4

17

Experiment 3 Volume (L) Average Time (min) Flow Rate (LPM) 3 0.42 7.14

Cross section #

Using Bernoulli equation

Using equation

Continuity difference

h* = hH (mm)

hi (mm)

ViB

= Ai =

Vic =

ViB - Vic (m/s)

(m/s) (m2) A B C D E F 173 172 175 170 170 169 168 165 157 162 163 165 0.313 0.371 0.594 0.396 0.371 0.280 5.31 x 10-4 3.66 x 10

-4

(m/s) 0.224 0.325 0.592 0.379 0.313 0.224 0.089 0.046 0.002 0.017 0.058 0.056

2.01 x 10-4 3.14 x 10-4 3.80 x 10-4 5.31 x 10-4

18

CALCULATIONS Experiment 1: Flow rate of water = Sample Calculation (cross section A): Bernoulli equation: ViB = ViB = ViB = 0.686 m/s Continuity equation: Ai = Ai = Ai = 5.34 x 10-4 m2 Vic = Vic = Vic = 0.554 m/s Therefore, the difference is = ViB - Vic = 0.686 m/s - 0.554 m/s = 0.132 m/s

19

Experiment 2: Flow rate of water = Sample Calculation (cross section A): Bernoulli equation: ViB = ViB = ViB = 0.443 m/s Continuity equation: Ai = Ai = Ai = 5.34 x 10-4 m2 Vic = Vic = Vic = 0.224 m/s Therefore, the difference is = ViB - Vic = 0.443 m/s - 0.224 m/s = 0.066 m/s

20

Experiment 3: Flow rate of water = Sample Calculation (cross section A): Bernoulli equation: ViB = ViB = ViB = 0.313 m/s Continuity equation: Ai = Ai = Ai = 5.34 x 10-4 m2 Vic = Vic = Vic = 0.377 m/s Therefore, the difference is = ViB - Vic = 0.443 m/s - 0.377 m/s = 0.089 m/s

21

DISCUSSION The objectives of the experiment, which are to investigate the demonstrate the Bernoullis Theorem using Bernoullis Theorem Demonstration unit (model: FM24), to verify experimentally the validity of Bernoullis equation for fluid flow,to verify Bernoulli's equation by demonstrating the relationship between pressure head and kinetic head, and to measure flow rate and both static and total pressure heads in a rigid convergent/divergent tube of known geometry for a range of steady flow rates. Bernoulli's law indicates that, if an inviscid fluid is flowing along a pipe of varying cross section, then the pressure is lower at constrictions where the velocity is higher, and higher where the pipe opens out and the fluid stagnates. Many people find this situation paradoxical when they first encounter it (higher velocity, lower pressure). In this experiment,the pressure difference taken is from hA to hF.The time to collect 3 L water in the tank was determined.Lastly,the flow rate,velocity,dynamic head and total head were calculated using the reading that have got from the experiment.

As fluid flows from a wider pipe to a narrower one, the velocity of the flowing fluid increases. This is shown in all the results tables, where the velocity of water that flows in the tapered duct increases as the duct area decreases, regardless of the pressure difference and type of flow of each result taken. From the analysis of the results, it can be concluded that the velocity of water decrease as the water flow rate decrease. For instance, the velocity difference at cross section A for water

22

flow rate of 17.64 LPM is bigger than velocity difference at cross section A for water flow rate of 12.00 LPM and 7.14 LPM. It also can be concluded that the diameter of the tube will affect the differences in velocity as a bigger tube will cause the differences in velocity become bigger while the smaller tube cause the velocity differences between ViB and Vic to be smaller. There must be some parallax and zero error occur when taking the measurement of each data. One of them is, the observer must have not read the level of static head properly. This will affect the results of the experiment. Moreover, the eyes are not perpendicular to the water level on the manometer. The eyes must be perpendicular to the water level on the manometer so that the parallax error can be reduced in this experiment. Next, the valve and bleed screw should regulate smoothly to reduce the errors.Another error is the bubbles left in the manometer.The bubbles must be removed in the manometer before start the experiment so that it will not affect the results of the experiment. Last but not least,the valve should be controlled slowly to maintain the pressure difference and make sure there is no leakage along the tube to avoid the water flowing out. Therefore, there are some minor effects on the calculations due to the errors. So,the precautions must be taken to reduce the errors in the experiment.

23

CONCLUSION From the experiment conducted,there are different cross sections for the each tubes A,B,C,D,E and F.It results in the varieties values of total or stagnation head (h*) also differ in the value of pressure head(hi).By using Bernoulli equation to calculate the velocity,it can be said as when the pressure of a fluid decreases its speed or its velocity will increased.Based on the results,the theory of Bernoullis was proven.This is exactly following the Bernoullis principle for a steady flow of water and the velocity is increasing along the same channel. Besides,the continuity equation was also used in this experiment. If something moves, it has to go somewhere. This simple fact is just the conservation of mass (this holds unless you're in a nuclear reactor, which converts mass to energy). The conservation of mass results in what's called the continuity equation.Through the results,it can be proved that when the area of the tube increases,the velocity that have been calculated by using continuity equation will decreases.It means that the area and the velocity are inversely proportional to each other.

The second objectives ,where the flow rates and both static and total head pressures in a rigid convergent or divergent of known geometry for a range of steady flow rates are to be calculated,are also achieved through the experiment.

24

RECOMMENDATIONS Repeat the experiment several times to get the average values. Make sure the bubles are fully removed and not left in the manometer. The eyes of the observer should be parallel to the water level on the manometer. The valve should be controlled slowly to maintain the pressure difference. The valve and bleed screw should regulate smoothly to reduce the errors. Make sure there is no leakage along the tube to avoid the water flowing out.

REFERENCE B.R. Munson, D.F. Young, and T.H. Okiishi,Fundamentals of Fluid Mechanics 3rd ed., 1998, Wileyand Sons, New York

Douglas. J.F., Gasiorek. J.M. and Swaffield, Fluid Mechanics,3rd edition, (1995), Longmans Singapore Publisher.

Giles, R.V., Evett, J.B. and Cheng Lui, Schaumms OutlineSeries Theory and Problems of Fluid Mechanics and Hydraulic,(1994), McGraw-Hill intl

http://www.scribd.com/doc/39165346/Bernoulli-s-Theorem-Distribution-Experiment

25

APPENDICES

26

27

You might also like

- Bernoulli Lab ReportDocument78 pagesBernoulli Lab ReportErraFatiha70% (23)

- Bernoulli's Theorem ExperimentDocument17 pagesBernoulli's Theorem ExperimentMimi Hashim95% (19)

- Bernouli Lab ReportDocument18 pagesBernouli Lab ReportUgeswran Thamalinggam100% (3)

- Lab2FREE AND FORCE VORTEXDocument32 pagesLab2FREE AND FORCE VORTEXjuaxxo50% (2)

- LabDocument6 pagesLabamyNo ratings yet

- Bernoulli's Principle Demonstration (Lab Report)Document17 pagesBernoulli's Principle Demonstration (Lab Report)Arey Ariena94% (110)

- Safety Issues Report - FINAL DRAFTDocument12 pagesSafety Issues Report - FINAL DRAFTCitizens who careNo ratings yet

- Investigate Validity of Bernoulli's TheoremDocument26 pagesInvestigate Validity of Bernoulli's TheoremSaber Minato Azrul100% (1)

- Lab Report 3Document14 pagesLab Report 3Siti Syuhadah0% (1)

- Impact of Jet Lab ReportDocument7 pagesImpact of Jet Lab ReportMohamad Hilmy HaririeNo ratings yet

- Bernoulli's Theorem ExperimentDocument4 pagesBernoulli's Theorem ExperimentT/ROX94% (18)

- Fluids Lab - Experiment 3 - Center of Pressure On A Submerged Plane SurfaceDocument9 pagesFluids Lab - Experiment 3 - Center of Pressure On A Submerged Plane SurfaceJordan Hines72% (25)

- Fluid friction pipe experimentDocument15 pagesFluid friction pipe experimentxxxxx100% (3)

- Full Report Jilin ExplosionDocument19 pagesFull Report Jilin Explosionmanzahuhu67% (3)

- DNV-RU-SHIP Pt.2 Ch.1Document50 pagesDNV-RU-SHIP Pt.2 Ch.1marine matdanNo ratings yet

- Alternators and Starter Motors 2003 PDFDocument106 pagesAlternators and Starter Motors 2003 PDFjovopavlovic100% (4)

- Bernoulli's Theorem Demonstration Lab ReportDocument24 pagesBernoulli's Theorem Demonstration Lab ReportCendolz IssZul50% (2)

- Experiment BernoulliDocument17 pagesExperiment BernoulliHafiniHambali94% (33)

- 12 Experiment #2: Bernoulli'S Theorem DemonstrationDocument12 pages12 Experiment #2: Bernoulli'S Theorem DemonstrationYasir A. Al-ShataifNo ratings yet

- Validates Bernoulli's Theorem in Tapered DuctDocument29 pagesValidates Bernoulli's Theorem in Tapered DuctAnonymous NyvKBWNo ratings yet

- Bernoullis Equation Lab ReportDocument12 pagesBernoullis Equation Lab ReportgeduyoxNo ratings yet

- Table of Content DocDocument17 pagesTable of Content DocjjNo ratings yet

- Orifice and Free Jet Flow: University of NebraskaDocument8 pagesOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- Energy Losses in BendsDocument10 pagesEnergy Losses in BendsAngelica Joyce BenitoNo ratings yet

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremVrushiket PatilNo ratings yet

- Fluid Mechanics Lab Experiment 2Document8 pagesFluid Mechanics Lab Experiment 2SSShakeelNo ratings yet

- Impact of JetDocument7 pagesImpact of JetHeng Xiu KohNo ratings yet

- Impact of JetDocument5 pagesImpact of Jetميسرة33% (3)

- University of Mauritius: Faculty of Engineering Mechanical & Production Engineering DepartmentDocument17 pagesUniversity of Mauritius: Faculty of Engineering Mechanical & Production Engineering Departmenthansley100% (1)

- Impact of A JetDocument11 pagesImpact of A JetMuhammad Hakim Jaffar0% (1)

- Energy Losses in Bends and FittingsDocument11 pagesEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- Fluid Mechanics Lab 3.1Document13 pagesFluid Mechanics Lab 3.1mahmoudNo ratings yet

- Metacentric HeightDocument26 pagesMetacentric Heightlindzay100% (1)

- Flow Meter Demonstration Lab ReportDocument21 pagesFlow Meter Demonstration Lab Reportmhd badhrul bin baharNo ratings yet

- LAB REPORT - Discharge Over WeirsDocument9 pagesLAB REPORT - Discharge Over WeirsLuli LolNo ratings yet

- Venturi Meter 1Document13 pagesVenturi Meter 1Da Champ CenaNo ratings yet

- Bernoilli's Principle Lab ReoprtDocument2 pagesBernoilli's Principle Lab ReoprtJohnConor100% (2)

- Bernoulli's PrincipleDocument8 pagesBernoulli's PrincipleMD Atiqur Rahman Faisal100% (1)

- Losses in BendsDocument5 pagesLosses in BendsAnonymous hWMDyBFGc1100% (1)

- CE 2020 - Fluid Mechanics LaboratoryDocument67 pagesCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamNo ratings yet

- Bernoulli Lab ReportDocument18 pagesBernoulli Lab ReportRam Krishna Singh80% (15)

- Full Report Bernoulli Experiment TiqaDocument19 pagesFull Report Bernoulli Experiment TiqaAtiqah Samad100% (5)

- Hydrostatic forces on immersed plane surfacesDocument9 pagesHydrostatic forces on immersed plane surfacesEssam Ahmed Abd MeguidNo ratings yet

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- FULL REPORT Flow Over WeirDocument18 pagesFULL REPORT Flow Over WeirShahrul Ikram0% (1)

- Comparing Flow Measurement Methods Using Bernoulli's Equation and Continuity EquationDocument3 pagesComparing Flow Measurement Methods Using Bernoulli's Equation and Continuity EquationRazali RamlanNo ratings yet

- Hydrostatic Pressure LabDocument12 pagesHydrostatic Pressure LabMuhammadShah100% (1)

- V Notch PracticalDocument13 pagesV Notch PracticalAnushaBheenuck0% (2)

- 6-Energy Loss in BendsDocument12 pages6-Energy Loss in BendsMaysara Maawia Mukhtar60% (10)

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Document19 pagesSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaNo ratings yet

- Metacentric HeightDocument4 pagesMetacentric Heightanil chejaraNo ratings yet

- BROAD CRESTED WEIR LABORATORY EXPERIMENTDocument12 pagesBROAD CRESTED WEIR LABORATORY EXPERIMENTSyafiq Roslan75% (4)

- Impact of A Water JetDocument5 pagesImpact of A Water JetAnirban SardarNo ratings yet

- How Jet Angles Affect Fluid ForcesDocument11 pagesHow Jet Angles Affect Fluid Forcesjoshx12No ratings yet

- Orifice & Free Jet FlowDocument6 pagesOrifice & Free Jet FlowMohamedElkikiNo ratings yet

- Lab Report 4Document7 pagesLab Report 4api-300265822100% (1)

- Marcet BoilerDocument7 pagesMarcet BoilerSt Oong100% (1)

- (Exp # 5) Energy Losses in BendsDocument16 pages(Exp # 5) Energy Losses in BendshamZA17% (12)

- Thermal Fluid Lab Semester 6 Bernoulli's Theorem DemoDocument22 pagesThermal Fluid Lab Semester 6 Bernoulli's Theorem DemoEason OngNo ratings yet

- FM 24 ManualDocument18 pagesFM 24 ManualMohd Nor SollehanNo ratings yet

- Bernoulli Equation Full ReportDocument6 pagesBernoulli Equation Full ReportChala1989No ratings yet

- Bernoulli S Principle Demonstration Lab ReportDocument17 pagesBernoulli S Principle Demonstration Lab ReportpehweihaoNo ratings yet

- Lab 2 Bernoulli's EquationDocument12 pagesLab 2 Bernoulli's EquationDário Da SilvaNo ratings yet

- Physical Treatment - FiltrationDocument25 pagesPhysical Treatment - FiltrationmanzahuhuNo ratings yet

- Technology Description (ENT)Document2 pagesTechnology Description (ENT)manzahuhuNo ratings yet

- Lab Report Project 4 Production of Propylene GlycolDocument2 pagesLab Report Project 4 Production of Propylene GlycolmanzahuhuNo ratings yet

- Laplace TransformationDocument7 pagesLaplace TransformationnualdinNo ratings yet

- Lab Report Control...Document3 pagesLab Report Control...manzahuhuNo ratings yet

- Lab Report Control...Document3 pagesLab Report Control...manzahuhuNo ratings yet

- Mechanism of Rotary DryerDocument2 pagesMechanism of Rotary DryermanzahuhuNo ratings yet

- NMR ExperimentDocument16 pagesNMR Experimentmanzahuhu100% (1)

- Marcet Boiler Lab ReportDocument4 pagesMarcet Boiler Lab ReportJohnConor98% (40)

- Bernoulli'sDocument19 pagesBernoulli'smanzahuhuNo ratings yet

- Siemens Syngas Capable TurbinesDocument8 pagesSiemens Syngas Capable TurbinesAlasdair McLeodNo ratings yet

- Rate Analysis-KalikaDocument35 pagesRate Analysis-KalikaPujan Amit Gurung100% (1)

- CrackingDocument20 pagesCrackingNiaz Ali KhanNo ratings yet

- Allotropes of Phosphorus (White and Red)Document3 pagesAllotropes of Phosphorus (White and Red)Mayette Rose SarrozaNo ratings yet

- Lecture 10 - Recovery Recrystallication and Grain GrowthDocument22 pagesLecture 10 - Recovery Recrystallication and Grain GrowthsimNo ratings yet

- Foundry Shop Tools and ProcessesDocument37 pagesFoundry Shop Tools and ProcessesAsmitaNo ratings yet

- Hilton EMEA Energy Water-Efficient Design Companion Guide - Final - V - 1.0Document41 pagesHilton EMEA Energy Water-Efficient Design Companion Guide - Final - V - 1.0virtechNo ratings yet

- Venezuela Asfalto Modificado PDFDocument12 pagesVenezuela Asfalto Modificado PDFkarenNo ratings yet

- Mil DTL 46027JDocument23 pagesMil DTL 46027JmurphygtNo ratings yet

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsDocument4 pagesVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshNo ratings yet

- R5000 PriceInfoSheetDocument2 pagesR5000 PriceInfoSheetDominique OnealNo ratings yet

- Lab Design Accomodation and Environment, Ms. Sonam Bansal, Head, Nestle Quality CentreDocument37 pagesLab Design Accomodation and Environment, Ms. Sonam Bansal, Head, Nestle Quality CentrePranay KumarNo ratings yet

- Gis 145kv 4Document18 pagesGis 145kv 4tafseerahmedNo ratings yet

- Dlab Ms-H280-ProDocument3 pagesDlab Ms-H280-ProAntoNo ratings yet

- Advantages of Precast Concrete ConstructionDocument12 pagesAdvantages of Precast Concrete Constructionvalerie samarNo ratings yet

- Cavitation and Pump NPSHRDocument39 pagesCavitation and Pump NPSHRRicardo BarrosNo ratings yet

- Understanding Defects in High Integrity Die Castings - EJ VinarcikDocument11 pagesUnderstanding Defects in High Integrity Die Castings - EJ Vinarcikoğuz kağanNo ratings yet

- Directorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubDocument238 pagesDirectorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubnewprojectsNo ratings yet

- Vibro CompactionDocument2 pagesVibro CompactionVpln SarmaNo ratings yet

- Retrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life ExtensionDocument7 pagesRetrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life Extension王阳No ratings yet

- ActuatorsDocument6 pagesActuatorsFam ChumNo ratings yet

- SF026a-Flow Chart Portal Frame Apex ConnectionDocument3 pagesSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevNo ratings yet

- FAA 8083 30 - Ch09Document26 pagesFAA 8083 30 - Ch09William LoNo ratings yet

- Ductile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringDocument7 pagesDuctile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringKASHFI UDDINNo ratings yet

- Nitoflor EU5 PDFDocument4 pagesNitoflor EU5 PDFriverwilliamsNo ratings yet

- Public Review Draft 2394Document82 pagesPublic Review Draft 2394Johan SetiawanNo ratings yet