Professional Documents

Culture Documents

LHV Effect On Output and Heat Rate

Uploaded by

yogacruiseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LHV Effect On Output and Heat Rate

Uploaded by

yogacruiseCopyright:

Available Formats

LHV effect on output and heat rate from GE gas turbine correction curves for both (distillate and

crude oil) LHV reduction (less than ref LHV) will cause output ratio to decrease and vice versa LHV reduction (less than ref LHV) will cause heat rate ratio to increase and vice versa

From Siemens gas turbine correction curves for distillate LHV reduction (less than ref LHV) will cause output ratio to increase and vice versa (opposite to GE curve) LHV reduction (less than ref LHV) will cause efficiency to decrease (heat rate ratio to increase and vice versa) same as GE curves but the Siemens curves in terms of efficiency not HR

In gas turbine engineering hand book (Dr boyce) LHV -430 btu/lb (decrease in LHV) will lead to 0.4% increase in output and -1% ( decrease) heat rate This agree with siemens in output and opposite to both GE and siemns in HR

In Combined-Cycle Gas & Steam Turbine Power Plants ( Rolf Kehlhofer)

The lower heating value (LHV) of the fuel is important because it defines the mass flow of fuel, which must be supplied to the gas turbine. The lower the LHV, the higher the mass flow of fuel required to provide a certain chemical heat input, normally resulting in a higher power output and efficiency. Which agree with Dr boyce book I have noticed that the change in LHV for the same fuel ie distillate is not varying too much and the correction factor for LHV is minor comparing to the inlet temperature but some people look to the LHV as a measure for the quality of the fuel meaning the higher the LHV the better the fuel so reducing the LHV is leading to better performance is confusing. 4 days ago Like CommentFollow Flag More 6 comments

Follow Paul Paul Fernandez, PE The simplistic answer is based on the chemistry of combustion and the thermodynamic properties of the products of combustion. With fuels being primarily carbon and hydrogen, the products of combustion are carbon dioxide and water (neglecting everything else). The difference between HHV and LHV is based on the hydrogen content of your fuel. If your fuel has no hydrogen your products of combustion is pure carbon dioxide. As the hydrogen content increases yuor LHV decreases due to the water vapor as a combustion product from burning hydrogen. Thermodynamics jumps in and says you will not be able to get work from the process of condensing the water vapor in the combustion products, the latent heat of vaporization is not available for work. Not a direct answer to your question, but a basis for LHV vs. HHV. 2 days ago Like

Follow Somnath Somnath Mukherjee Higher the LHV better the fuel as for a given power output for a higher LHV fuel, less fuel mass flow-rate will be required. Difference between HHV and LHV is nicley explained by Paul and it is just the water vapour that is discounted while calculating LHV. 1 day ago Like

Follow Kiran Kiran Rajgor you can read " GAs Turbine Fuels - System Design, Combustion & Operatibility", Turbomachinery Symposium -2010. http://turbolab.tamu.edu/proc/ 1 day ago Like

Follow Brent Brent Homes I always believed that the HHV value (about 6 or 10% higher from LHV for gas and liquid fuels) was the amount of heat contained in the water vapor in the exhaust. The HHV value counted this as usable and the LHV does not, utilizing LHV value is correct for heat rate calcs for GTs and CCGT's as the water vapor heat is never recovered. 1 day ago Like

Follow Mark

Mark Boulden First, watch out for comparisons of performance impacts of LHV variation for liquid fuels. To get very far from 18,300Btu/lb, you typically have to get a little exotic. For example, to get to 19,000Btu/lb you are looking at naptha, and your fuel pumps won't survive due to lack of fuel lubricity unless you have a system specifically designed for that type fuel. To get down to 17,000 Btu/lb, you're looking at residual oil and you're not going to confuse that with distillate. In any case, the fuel volume injected really is very very close to the same because the energy density is not much different from residual oil to naptha. That's why there's typically only one liquid fuel nozzle offered for a turbine model, while the gas fuel nozzles can have significant variation.

Gas fuels are different, especially for recent synthetic gas applications. Particularly in the syngas case, the variation in LHV on a Btu/lb basis is being driven by an inert gas content that is frequently on the order of 65% of the fuel volume and by the hydrogen content. While hydrogen compared to natural gas is high in Btu/lb, it's very low in Btu/ft3. For the inert content (and any emissions control diluent), you are using the gas turbine as a turbo-expander. In this case (including GE curves I've reviewed), LHV going down results in an increase in Output and a decrease in Heat Rate. The predominant impact is on output by a factor of 3:1 to 4:1 for percentage change in Output compared to percentage change in Heat Rate.

Bottom line, your LHV effects on Output and Heat Rate are predominantly going to be a result of the variation in required fuel volume. This means the impact for liquid fuels is virtually negligible. For gas fuel, if you do have variability on LHV, the key is whether it's changing due to variation in reactive constituents or variation in inert content. Also for the fuel gas, make sure to watch out for how the vaiation in LHV is relating to the Wobbe index to ensure you stay in the design window for the fuel nozzles. 1 day ago Like Reply privately Flag as inappropriate 1

Follow Ken Ken Walls Mark, very good explanation you have written, particularly the part about the inert portions acting like a turboexpander. The energy contained due to the inert content in the pressurized fuel supply of course has to provide some additional power as it expands out to atmospheric pressure. Also a good explanation of the difference in liquids vs gas, and why.

You might also like

- 5.5 Offshore Platform ProductionDocument14 pages5.5 Offshore Platform Productioneng20072007No ratings yet

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorenciaNo ratings yet

- Gas DehydrationDocument18 pagesGas DehydrationMahendraToratiNo ratings yet

- RefrigerationDocument65 pagesRefrigerationKapil Goyal100% (1)

- Excess Flow ValveDocument2 pagesExcess Flow ValveSyed Waqas HaiderNo ratings yet

- GTL Economics SPE-94380-MSDocument8 pagesGTL Economics SPE-94380-MSWayne MonneryNo ratings yet

- LPG Plants Retrofit 2Document26 pagesLPG Plants Retrofit 2nasir_engrNo ratings yet

- Liquefaction Plant IntroductionDocument27 pagesLiquefaction Plant IntroductionAlex CadareNo ratings yet

- Acid Content DeterminationDocument3 pagesAcid Content DeterminationArmando PerezNo ratings yet

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDocument6 pagesDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaNo ratings yet

- Aspects of Two-Phase Flow RegimesDocument3 pagesAspects of Two-Phase Flow RegimesNITESH SAHNo ratings yet

- SPE-185892-MS ESP-DST Well Testing in A Complex Reservoir in The Barents Sea: Establishing New Methodologies and Lessons LearnedDocument19 pagesSPE-185892-MS ESP-DST Well Testing in A Complex Reservoir in The Barents Sea: Establishing New Methodologies and Lessons LearnedAli100% (1)

- BTX From FCC PDFDocument7 pagesBTX From FCC PDFjosealvaroNo ratings yet

- Pipe Line With Negative Pressure (Siphon Phenomena) : Follow The Natural Contour of The LandDocument8 pagesPipe Line With Negative Pressure (Siphon Phenomena) : Follow The Natural Contour of The LandcharbelNo ratings yet

- Flare Gas Recovery PDFDocument13 pagesFlare Gas Recovery PDFSadad MohamadNo ratings yet

- Liquid Seal Drums: AdvantagesDocument1 pageLiquid Seal Drums: Advantagesbinapaniki6520No ratings yet

- 245 NGL Deethanizer Capacity ExpansionDocument1 page245 NGL Deethanizer Capacity ExpansionRafeek Emad AbdElkader0% (1)

- Aaharya Technologies Aspen Hysys Training ProgramDocument2 pagesAaharya Technologies Aspen Hysys Training Programpavanchem61No ratings yet

- Control Valve Sizing for Multi-Phase Fluid FlowsDocument18 pagesControl Valve Sizing for Multi-Phase Fluid FlowsBuzurjmeherNo ratings yet

- Effective Treatment and Handling of Produced WaterDocument84 pagesEffective Treatment and Handling of Produced Waterc_b_umashankarNo ratings yet

- 111CH0600 ThesisDocument35 pages111CH0600 ThesisAntariksha PattnaikNo ratings yet

- Natural Gas PropertiesDocument18 pagesNatural Gas PropertiesMUHAMMED FUADNo ratings yet

- PDF FileDocument50 pagesPDF FileHussein AyoubNo ratings yet

- 1 s2.0 S0263876299717624 MainDocument7 pages1 s2.0 S0263876299717624 Mainryan123459No ratings yet

- Gas Treatment SLDocument68 pagesGas Treatment SLwahyuriansyahNo ratings yet

- Ejector - DensoDocument5 pagesEjector - DensoMustapha RosyaNo ratings yet

- LNG Operations Manual Final Draft - 010515 - Web PDFDocument34 pagesLNG Operations Manual Final Draft - 010515 - Web PDFSushilNo ratings yet

- 0420 PV 201 Globe Valve Data SheetDocument12 pages0420 PV 201 Globe Valve Data SheetMohamed Farag MostafaNo ratings yet

- PTQ Gas 2011 PDFDocument56 pagesPTQ Gas 2011 PDFIulian BarascuNo ratings yet

- Compressor SurgeDocument3 pagesCompressor SurgeajaysapruNo ratings yet

- Subsea Well Test Flow DiagramDocument1 pageSubsea Well Test Flow DiagramAderobaki GbengaNo ratings yet

- CryoStar PresentationDocument26 pagesCryoStar PresentationLelosPinelos123No ratings yet

- Joule-Thomson (JT) Assembly: Oil and Gas Process and Production EquipmentDocument2 pagesJoule-Thomson (JT) Assembly: Oil and Gas Process and Production EquipmentpedroNo ratings yet

- Pumping Station ConsiderationsDocument16 pagesPumping Station ConsiderationsAKNo ratings yet

- GTC RefiningPetrochemical IntegrationDocument7 pagesGTC RefiningPetrochemical IntegrationKarem Jeanette Saenz BernalNo ratings yet

- FPSO SimposiumDocument34 pagesFPSO SimposiumrodrigoperezsimoneNo ratings yet

- SOLID-LIQUID EXTRACTIONDocument11 pagesSOLID-LIQUID EXTRACTIONFakhirah Ahmad BasriNo ratings yet

- Korf ManualDocument85 pagesKorf Manualzubair1951No ratings yet

- Sop-003-Rvp of Crude Oil LPG and NGLDocument8 pagesSop-003-Rvp of Crude Oil LPG and NGLAmnaKamranNo ratings yet

- Benzene ReductionDocument11 pagesBenzene ReductionzahasherhNo ratings yet

- Activated Carbon Filter Valve Sequence and Operation ChartDocument6 pagesActivated Carbon Filter Valve Sequence and Operation ChartAnujGargNo ratings yet

- LPG Energy IntegrationDocument6 pagesLPG Energy IntegrationBandaru KiranNo ratings yet

- Calculation of Z Factors For Natural Gases Using Equations of State P.M. Dranchuk J.H. Abou-KassemDocument4 pagesCalculation of Z Factors For Natural Gases Using Equations of State P.M. Dranchuk J.H. Abou-KassemAnonymous cCmpclQF6oNo ratings yet

- Natural Gas ProcessingDocument6 pagesNatural Gas ProcessingsgrsthNo ratings yet

- Computers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiDocument13 pagesComputers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiSebastián Castañeda100% (1)

- Effect of Reactor Inlet Temperature in A HydrotreaterDocument5 pagesEffect of Reactor Inlet Temperature in A HydrotreaterAlexNo ratings yet

- Desalter ArticleDocument4 pagesDesalter ArticleAbdus Saboor Khalid100% (1)

- 5 Presentation Corac Downhole Pressure BoostingDocument19 pages5 Presentation Corac Downhole Pressure BoostingEdwin VargadNo ratings yet

- Two-Phase Flashing Flow Methods and Comparisons: J. C. Leung and F. N. NazarioDocument8 pagesTwo-Phase Flashing Flow Methods and Comparisons: J. C. Leung and F. N. NazarioAksheyNo ratings yet

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- Introduction To Compressible FlowDocument14 pagesIntroduction To Compressible Flowram kishor singhNo ratings yet

- Tutorial 7 - HYSYS 4 SolutionDocument6 pagesTutorial 7 - HYSYS 4 SolutionhaziqNo ratings yet

- Exam of Refinery PDF 2Document20 pagesExam of Refinery PDF 2ئارام ناصح محمد حسێن0% (1)

- Circulating Fluidized Bed Boiler (CFB Boiler) How Does It Work and Its PrincipleDocument24 pagesCirculating Fluidized Bed Boiler (CFB Boiler) How Does It Work and Its PrinciplePichai Chaibamrung100% (2)

- LPG TableDocument3 pagesLPG TablekumarNo ratings yet

- Fuel Field ManualDocument18 pagesFuel Field ManualFREDIELABRADORNo ratings yet

- Improving Refinery Fuel Gas CompositionDocument4 pagesImproving Refinery Fuel Gas CompositionAthmane HariziNo ratings yet

- Boiler and Steam BasicsDocument7 pagesBoiler and Steam BasicsJanneth Herrera FloresNo ratings yet

- CombustionDocument15 pagesCombustionvietrossNo ratings yet

- Ethanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesFrom EverandEthanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesNo ratings yet

- Hipot Testing Dielectric Strength Test EepDocument14 pagesHipot Testing Dielectric Strength Test EepyogacruiseNo ratings yet

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- Steam BlowingDocument6 pagesSteam BlowingS V NAGESHNo ratings yet

- XA Manual-V1.2Document72 pagesXA Manual-V1.2Mohamed Elsayed100% (1)

- Ge DGCM Field Rtu CatalogDocument12 pagesGe DGCM Field Rtu CatalogyogacruiseNo ratings yet

- Vibration Guidelines C132530Document1 pageVibration Guidelines C132530yogacruiseNo ratings yet

- Honeywell Chart Recorder QuestionDocument1 pageHoneywell Chart Recorder QuestionyogacruiseNo ratings yet

- Calculation Sheet of Bus Protection Unit 3 FinalDocument17 pagesCalculation Sheet of Bus Protection Unit 3 Finalyogacruise100% (1)

- Boiler Feed Pump KSBDocument9 pagesBoiler Feed Pump KSByogacruiseNo ratings yet

- EDG TestDocument6 pagesEDG Testyogacruise100% (1)

- Protection Relay of Generator TestDocument6 pagesProtection Relay of Generator Testyogacruise100% (2)

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- Refractory Repair Procedure GuideDocument3 pagesRefractory Repair Procedure Guideyogacruise50% (2)

- Stiffness Coefficients For Nozzles in API 650 Tanks - 2Document8 pagesStiffness Coefficients For Nozzles in API 650 Tanks - 2yogacruise100% (2)

- Harga Batubara Acuan April 2012Document6 pagesHarga Batubara Acuan April 2012satuiku100% (1)

- SS 310 Temperature Limit AlternativesDocument3 pagesSS 310 Temperature Limit AlternativesyogacruiseNo ratings yet

- Magnetrol Level Flow Tech HandbookDocument44 pagesMagnetrol Level Flow Tech HandbookDelfinshNo ratings yet

- Budget For FEED of An Onshore Oil FieldDocument1 pageBudget For FEED of An Onshore Oil FieldyogacruiseNo ratings yet

- What Code To Design Chlorine TankDocument3 pagesWhat Code To Design Chlorine TankyogacruiseNo ratings yet

- Non Metallic Expansion JointDocument2 pagesNon Metallic Expansion JointyogacruiseNo ratings yet

- Pure Argon For Non Carbon SteelDocument3 pagesPure Argon For Non Carbon SteelyogacruiseNo ratings yet

- Zirconium IdentificationDocument2 pagesZirconium IdentificationyogacruiseNo ratings yet

- Manhole On Weld SeamDocument1 pageManhole On Weld SeamyogacruiseNo ratings yet

- WUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangDocument4 pagesWUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangyogacruiseNo ratings yet

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 pagesIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruiseNo ratings yet

- 3 Heating Load Calculation: 3.1 Heat Transmission LossDocument14 pages3 Heating Load Calculation: 3.1 Heat Transmission LossyogacruiseNo ratings yet

- Chimney RateDocument6 pagesChimney RateyogacruiseNo ratings yet

- Expansion Bellows Leak RepairDocument1 pageExpansion Bellows Leak RepairyogacruiseNo ratings yet

- Instrument Cable LayoutDocument2 pagesInstrument Cable LayoutyogacruiseNo ratings yet

- Surge Gas Pilene Cross CountryDocument2 pagesSurge Gas Pilene Cross CountryyogacruiseNo ratings yet

- Optimizing Combustion Chamber Design to Reduce NOx EmissionsDocument19 pagesOptimizing Combustion Chamber Design to Reduce NOx EmissionsYummy BeatsNo ratings yet

- NishthaDocument8 pagesNishthahappy happy0% (2)

- EQUIPMENT INSPECTION STATUS UPDATE FOR PELLETIZER & ISBLDocument45 pagesEQUIPMENT INSPECTION STATUS UPDATE FOR PELLETIZER & ISBLnkvonNo ratings yet

- Industrial Valve Manufacturer in India - SpecialityvalveDocument5 pagesIndustrial Valve Manufacturer in India - SpecialityvalvespecialityvalveNo ratings yet

- Hydrogen GeneratorDocument4 pagesHydrogen GeneratorsaleempetrochemicalNo ratings yet

- Characteristics of ExplosivesDocument4 pagesCharacteristics of ExplosivesMerced Baneza Cahuana100% (1)

- Continuous Cast Copper Rod Plant Pre-Feasibility ReportDocument13 pagesContinuous Cast Copper Rod Plant Pre-Feasibility Reportadelafuente2012No ratings yet

- Hydrogen Will Never Be A Full Solution To Our Green Energy Problems (Contradict)Document2 pagesHydrogen Will Never Be A Full Solution To Our Green Energy Problems (Contradict)LauraNo ratings yet

- Tata Power CompanyDocument5 pagesTata Power Companylaloo01No ratings yet

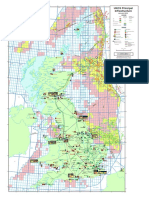

- Map of UKCS InfrastructureDocument1 pageMap of UKCS InfrastructureN ShepherdNo ratings yet

- Gathering CenterDocument9 pagesGathering CenterAnbalagan Prabhu100% (3)

- COOK Moppet Valve BrochureDocument2 pagesCOOK Moppet Valve BrochureYurizki LhzNo ratings yet

- CH 3 Matter WebquestDocument2 pagesCH 3 Matter Webquesttownsenr94No ratings yet

- Pipeline Design PDFDocument437 pagesPipeline Design PDFgilbertotiburcio100% (2)

- 4100 + Statics PDFDocument19 pages4100 + Statics PDFRahul KaushalNo ratings yet

- ORTON - Company Profile 31-12-09Document14 pagesORTON - Company Profile 31-12-09Fabrizio DelledonneNo ratings yet

- CSEC Chemistry January 2018 P1 PDFDocument11 pagesCSEC Chemistry January 2018 P1 PDFShalini K86% (7)

- CHPTR 1 - Ds Chauhan Non Conventional Energy ResourcesDocument17 pagesCHPTR 1 - Ds Chauhan Non Conventional Energy ResourcesAkash Singh33% (3)

- Gas Piping Building Services 1Document21 pagesGas Piping Building Services 1abinayaNo ratings yet

- Injection Well ProblemsDocument12 pagesInjection Well Problemsdriller2250% (2)

- MEDREG Gas Infrastructure Map April 2018Document41 pagesMEDREG Gas Infrastructure Map April 2018Mircea IspasNo ratings yet

- Experimental Study On The Behaviour of Buried Flexible Plastic PipeDocument10 pagesExperimental Study On The Behaviour of Buried Flexible Plastic PipeDom Ram DrdNo ratings yet

- British Petroleum: Pramit Pratim Ghosh - 17 Krishnakumar J - 25 Abinash Nayak - 34Document23 pagesBritish Petroleum: Pramit Pratim Ghosh - 17 Krishnakumar J - 25 Abinash Nayak - 34Sujit MishraNo ratings yet

- MQ135-Air QualityDocument5 pagesMQ135-Air Qualitysupport ubicuoNo ratings yet

- Year 12 Homework Ideal Gas, Empirical Formula QuestionsDocument8 pagesYear 12 Homework Ideal Gas, Empirical Formula QuestionsCat ShannonNo ratings yet

- Exergetic Life Cycle Analysis of Hydrogen Production and Storage Systems For Automotive ApplicationsDocument9 pagesExergetic Life Cycle Analysis of Hydrogen Production and Storage Systems For Automotive Applicationsxinyi zhangNo ratings yet

- Burbank, Osage County Oil Field Recovery HistoryDocument50 pagesBurbank, Osage County Oil Field Recovery HistoryPercival Wulfric BrianNo ratings yet

- Industrial Waste ManagementDocument2 pagesIndustrial Waste ManagementUmma SabiraNo ratings yet

- CHP Presentation Cat Gas and Diesel Generator Sets Performance Cost and Application DifferencesDocument77 pagesCHP Presentation Cat Gas and Diesel Generator Sets Performance Cost and Application DifferencesripalNo ratings yet

- Biodiesel Production: Nubuor Richmond Nii Addotey & Howels SamuelDocument33 pagesBiodiesel Production: Nubuor Richmond Nii Addotey & Howels SamuelNubuor Richmond Nii Addotey100% (1)