Professional Documents

Culture Documents

A New Fuzzy Logic Based Space Vector Modulation Approach On Direct Torque Controlled Induction Motors

Uploaded by

CS & ITOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A New Fuzzy Logic Based Space Vector Modulation Approach On Direct Torque Controlled Induction Motors

Uploaded by

CS & ITCopyright:

Available Formats

A NEW FUZZY LOGIC BASED SPACE VECTOR MODULATION APPROACH ON DIRECT TORQUE CONTROLLED INDUCTION MOTORS

Fatih Korkmaz, smail Topalolu and Hayati Mamur

Department of Electrical and Electronics Engineering ankr Karatekin University, 18200, ankr, TURKEY

fkorkmaz@karatekin.edu.tr

ABSTRACT

The induction motors are indispensable motor types for industrial applications due to its wellknown advantages. Therefore, many kind of control scheme are proposed for induction motors over the past years and direct torque control has gained great importance inside of them due to fast dynamic torque response behavior and simple control structure. This paper suggests a new approach on the direct torque controlled induction motors, Fuzzy logic based space vector modulation, to overcome disadvantages of conventional direct torque control like high torque ripple. In the proposed approach, optimum switching states are calculated by fuzzy logic controller and applied by space vector pulse width modulator to voltage source inverter. In order to test and compare the proposed DTC scheme with conventional DTC scheme simulations, in Matlab/Simulink, have been carried out in different speed and load conditions. The simulation results showed that a significant improvement in the dynamic torque and speed responses when compared to the conventional DTC scheme.

KEYWORDS

Direct torque control, Fuzzy logic control, Space vector modulation, Induction motor control,

1. INTRODUCTION

In electromechanic systems, Direct torque control (DTC) of induction motor is well-known control scheme which provides fast dynamic response compared with other control schemes like field oriented control (FOC). DTC has been proposed for induction motor control in 1985 by Takahashi [1] and similar idea that the name of Direct Self Control devoloped in 1988 by Depenbrock [2]. Over the past years, DTC has gained great attention due to its advantages like simple structure, robustness to parameters variations, fast dynamic response, not need to current regulators...etc. However, like every control scheme, DTC has some disadvantages too. If we want to sort out some of these disadvantages; difficulty to control torque and flux at very low speed, high current and torque ripples, variable switching frequency behavior and high sampling frequency needed for digital implementation. In order the overcome these disadvantages many researchers have been researching on the DTC drive and they can grouped under several headings:

Sundarapandian et al. (Eds) : ICAITA, SAI, SEAS, CDKP, CMCA-2013 pp. 161169, 2013. CS & IT-CSCP 2013 DOI : 10.5121/csit.2013.3813

Computer Science & Information Technology (CS & IT)

162

Using different switching techniques and inverter topologies [3-7] Using artificial intelligence on different sections of system [8-9] Using different observer models [10-11]

In this paper, a new fuzzy logic based space vector modulation method has been proposed to improve torque behavior of induction motor on the DTC scheme. The fuzzy logic controller in the proposed method rates of flux and torque errors and describes optimum space vector to minimize flux and torque errors. The experimantal studies have performed with dSPACE 1103 controller board to performance testing of the proposed control method. . In Section II of this paper, the basic principles of DTC has shortly introduced and in Section III, detailed information about the proposed method has presented. Section IV presents the experimental results of the the proposed method. Finally, conclusion has given in Section V.

2. DIRECT TORQUE CONTROL

In conventional DTC scheme, the control of an induction motor involves the direct control of stator flux vector by applying optimum voltage switching vectors of the inverter . For this control, the stator current should be decoupled two independent components as flux and torque components like dc motors. The clarke transformation method is uses in this decoupling process in the DTC scheme. The DTC bases on the selection of the optimum voltage vector which makes the flux vector rotate and produce the demanded torque. In this rotation, the amplitude of the stator flux vector remains in hysteresis band limits[12]. Stator flux linkage vector is estimated using (8)-(10).

= (V Rs i )dt , = (V R s i )dt ,

2 = + 2 .

(1) (2)

(3)

Where is stator flux vector, v and v stator voltages two phase components, i and i line currents in - reference frame and Rs describes stator resistance. The electromagnetic torque of the induction machine can be calculated as given in Eq. 7

Te =

3 p ( i i ). 2

(4)

Where, p is the number of pole pairs. In DTC scheme, stator flux rotate trajectory devided six region and well- defined of stator flux region is directly affects on control performance and calculation of stator flux vector region as given in Eq. 8.

= tan 1 (

).

(5)

These estimated values are compared to reference values and the resultant errors are applied to the hysteresis comparators. Two different hysteresis comparators, as flux and torque comparators, generate other control parameters on the DTC scheme. Flux hysteresis comparator is two level type while torque comparator is tree level type. According to the hysteresis comparators outputs,

163

Computer Science & Information Technology (CS & IT)

the estimated angle of flux linkage and using a switching table, optimum voltage vectors are selected and applied to the inverter. The basic schematic representation of DTC scheme for an induction motor is shown in Figure 1.

Figure 1. Conventional DTC scheme

3. THE FUZZY BASED SVM-DTC

The objective of space vector pulse width modulation technique is to obtain the demanded output voltage, Uout, by instantaneously combination of the switching states corresponding the basic space vectors (Figure 2.)[13].

Figure 2. Basic space vectors

U out can be obtained as Eq. 6. by applying the inverter in switching states U x and U x + 60 or U x 60 for the time periods, T1 and T2 periods of time respectively. 1 U out ( nT ) = (T1U x + T2U x 60 ) (6) T

Computer Science & Information Technology (CS & IT)

164

It must be pointed out that the sum of T1 and T2 periods should be less than or equal to total sampling time period, T. If T1 + T2 T , than the inverter needs to be in pasive vectors,

0 000 or 0111 states, for the rest of the total time period that pasive time period can be named T0 . Thus, the calculation of total time period is given in Eq. 7. T1 + T2 + T0 = T

Therefore, Eq. 6 becomes Eq. 7 in the following,

(7)

TU out = T1U x + T2U x 60 + T0 (0 000 or 0111 )

From Eq. 8., we get Eq. 9. for T1 and T2 .

(8)

[T1

T2 ] = T [U x

U x 60 ]

U x 60 ]1U out

1

(9)

where [U x

is the normalized decomposition matrix for the sector.

Assume the angle between U out and U x is from Figure 3, it can be also obtained Eq. 10. and Eq. 11. for the T1 and T2 [13].

T1 = 2T U out cos( + 30) T2 = 2T U out sin( )

(10) (11)

Figure 3. The Simulink block diagram the proposed scheme

The proposed fuzzy based SVM-DTC scheme includes a fuzzy logic controller to produce optimum control vector. The optimum control vector angle is calculated by fuzzy logic controller with instantaneously flux and torque errors. On this calculation, fuzzy logic rates both errors and produces necessary change in vector angle for next step. Then, calculated optimum vector angle applied to discrete space vector pulse width modulation block (DSV-PWM) and DSV-PWM generates switching signals. The Simulink block diagram of the proposed system is given in Figure 3.

165

Computer Science & Information Technology (CS & IT)

The membership functions of fuzzy logic controller flux-torque inputs and angle output can be seen in Figure 4. Table 1. describes rule table of fuzzy logic controller.

Figure 4. Flux, torque and angle membership functions Table 1. Rule table of fuzzy logic controller Flux Rules BD BD SD Torque 0 SI BI -135 -165 0 165 135 SD -105 -135 0 135 105 SI -75 -45 0 45 75 BI -45 -15 0 15 45

Computer Science & Information Technology (CS & IT)

166

4. SIMULATIONS

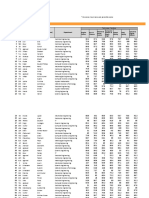

In order to evaluate the effectiveness of the proposed fuzzy logic based SVM-DTC method simulation works have been carried out in Matlab/Simulink software. The DTC scheme and the induction machine used in the simulation works have the parameters given in Table 2.

Table 2. Induction Machine and Simulation parameters IM and Simulation Parameters Inverter bus voltage (V) Rated Power (kW) Stator resistance () Stator inductance(H) Pole pairs Sampling time (s) Flux reference (Wb) 400V 4 1.405 0.0058 2 50 0.8

Some tests have been carried out to compare the performances of the proposed fuzzy logic based dSV-PWM DTC (FL-dSV-PWM) with conventional DTC (C-DTC). In order to compare the performances with the C-DTC and the proposed FLSVM-DTC on induction motor drive different speed and load range applied to the induction motor. The dynamic performances of the schemes are performed by applying step change on load, 0Nm to 10 Nm, at 0,5. sec. In first step of the simulation studies, the induction motor has been tested at rated speed with two different load conditions. The simulation results of speed and torque responses at 1500 rpm reference are shown in Figure 5. and Figure 6., respectively.

(a)

Figure 5. Speed curves of motor at 1500 rpm a) C-DTC

(b)

b) FLSVM-DTC

167

Computer Science & Information Technology (CS & IT)

(a)

(b)

Figure 6. Torque curves of motor at 1500 rpm a) C-DTC b) FLSVM-DTC

According to the speed and torque curves which given in Figure 5. and Figure 6., the motor has reached the reference speed at 0,075. sec. for both control scheme. So, it can be said that there are no difference between C-DTC and FLSVM-DTC and the motor has almost same performance at transient conditions for both control scheme. However, the main differences have appeared at steady state conditions. It can be seen that, with the FLSVM-DTC instantaneous speed fluctuations and torque ripples of the motor are reduced significantly. In the second step of simulation studies, the motor has been at low speed with two different load conditions. The simulation results of speed and torque responses at 250 rpm reference are shown in Figure 7. and Figure 8., respectively.

(a) Figure 7. Speed curves of motor at 250 rpm a) C-DTC b) FLSVM-DTC

(b)

Computer Science & Information Technology (CS & IT)

168

(a) Figure 8. Torque curves of motor at 250 rpm a) C-DTC b) FLSVM-DTC

(b)

According to the speed and torque curves which given in Figure 7. and Figure 8., the motor has reached the reference speed at 0,02. sec for both control scheme and still no difference at transient conditions. If we need to compare of steady state conditions of the motor for both control scheme, it must be pointed out that the FLSVM-DTC controlled motor has better performance as lesser torque ripples and speed fluctuations.

5. CONCLUSIONS

In this paper, a new fuzzy logic based space vector modulation technique has been proposed for direct torque controlled induction motor drives. The numerical simulations have been carried out to verify the proposed technique under different load and speed conditions. The numerical simulations proves that torque and speed responses of the motor are significantly improved with the proposed technique. The torque ripples of the motor are lesser about % 40, in parallel, the speed fluctuations are reduced according to conventional direct torque control technique. Moreover, the hyseteresis controllers and look-up table that used in conventional scheme are removed. Thus, switching frequency is maintained constant and the complexity of the scheme has been reduced.

REFERENCES

[1] [2] [3] [4] [5] I. Takahashi and T. Noguchi , A new quick-response and high efficiency control strategy of an induction motor IEEE Transactions on Industrial Applications, vol.I A-22 , no.5, pp. 820827, 1986. M. Depenbrock, Direct self control of inverter-fed induction machines IEEE Transactions in Power Electronics, vol. PE-3, vo. 4, pp. 420429, 1988. B. Xu and X. Zhang , Design of a new Direct Torque Control in induction motor Control and Decision Conference, (CCDC '09), P.53975400. 2009. D. Casadei, G. Serra and A. Tani, The use of matrix converters in direct torque control of induction machines IEEE Trans. on Industrial Electronics, vol.48, no.6, pp. 10571064, 2001. Batna University, Improvement in DTC-SVM of AC Drives Using a New Robust Adaptive Control Algorithm International Journal of Control, Automation, and Systems, vol. 9, no. 2, pp.267-275, 2011. D. Casadei, G. Serra and A. Tani, Implentation of a direct torque control algorithm for induction motors based on discrete space vector modulation IEEE Trans. on Power Electronics, vol.15, no. 4, pp. 769777, 2000.

[6]

169 [7]

Computer Science & Information Technology (CS & IT) K.-B. Lee and F. Blaabjerg, Improved Direct Torque Control for Sensorless Matrix Converter Drives with Constant Switching Frequency and Torque Ripple Reduction International Journal of Control, Automation, and Systems, vol. 4, no. 1, pp.113-123, 2006. S. Benaicha, F. Zidani, R.-N. Said, M.-S.-N. Said, Direct Torque with Fuzzy Logic Torque Ripple Reduction Based Stator Flux Vector Control Computer and Electrical Engineering, (ICCEE '09), vol.2, pp. 128133, 2009. N. Sadati, S. Kaboli, H. Adeli, E. Hajipour and M. Ferdowsi, Online Optimal Neuro-Fuzzy Flux Controller for DTC Based Induction Motor Drives Applied Power Electronics Conference and Exposition (APEC 2009), P.210215. 2009. Z. Tan, Y. Li and Y. Zeng, A three-level speed sensor-less DTC drive of induction motor based on a full-order flux observer Power System Technology, Proceedings. PowerCon International Conference, vol. 2, pp. 1054- 1058, 2002. G. Ya and L. Weiguo, A new method research of fuzzy DTC based on full-order state observer for stator flux linkage Computer Science and Automation Engineering (CSAE), 2011 IEEE International Conference, vol. 2, pp.104-108, 2011. P. Vas, Sensorless vector and direct torque control Oxford University Press, 2003. Zhenyu Yu "Space-Vector PWM With TMS320C24x/F24x Using Hardware and Software Determined Switching Patterns" Texas Ins. Application Report, SPRA524, pp. 5., 1999.

[8]

[9]

[10]

[11]

[12] [13]

Authors

Fatih Korkmaz was born in Krkkale, Turkey, in 1977. He received the B.T., M.S., and Doctorate degrees in in electrical education, from University of Gazi, Turkey, respectively in 2000, 2004 and 2011. His current research field includes Electric Machines Drives and Control Systems smail TOPALOGLU was born in Adana, Turkey, in 1983. He received the B.Sc , M.Sc. and Ph.D degrees in electrical education from University of Gazi in 2007,2009 and 2013, respectively. His current research interests include Computer aided design and analysis of conventional and novel electrical and magnetic circuits of electrical machines, sensors and transducers, mechatronic systems Hayati Mamur was born in Bolu, Turkey, in 1974. He received the B.Sc , M.Sc. and Ph.D degrees in electrical education from University of Gazi in 1996,2005 and 2013, respectively. His research interests include automatic control, SCADA, PLC, microcontroller, DSP control applications, renewable energy, and thermoelectric modules.

You might also like

- International Journal of Game Theory and Technology (IJGTT)Document2 pagesInternational Journal of Game Theory and Technology (IJGTT)CS & ITNo ratings yet

- Call For Papers-The International Journal of Ambient Systems and Applications (IJASA)Document2 pagesCall For Papers-The International Journal of Ambient Systems and Applications (IJASA)CS & ITNo ratings yet

- Ijait CFPDocument2 pagesIjait CFPijaitjournalNo ratings yet

- Graph HocDocument1 pageGraph HocMegan BellNo ratings yet

- Free Publications : Scope & TopicsDocument2 pagesFree Publications : Scope & TopicscseijNo ratings yet

- International Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Document3 pagesInternational Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Anonymous w6iqRPANo ratings yet

- International Journal of Game Theory and Technology (IJGTT)Document2 pagesInternational Journal of Game Theory and Technology (IJGTT)CS & ITNo ratings yet

- International Journal On Cloud Computing: Services and Architecture (IJCCSA)Document2 pagesInternational Journal On Cloud Computing: Services and Architecture (IJCCSA)Anonymous roqsSNZNo ratings yet

- Call For Papers-The International Journal of Ambient Systems and Applications (IJASA)Document2 pagesCall For Papers-The International Journal of Ambient Systems and Applications (IJASA)CS & ITNo ratings yet

- International Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Document3 pagesInternational Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Anonymous w6iqRPANo ratings yet

- Ijait CFPDocument2 pagesIjait CFPijaitjournalNo ratings yet

- The International Journal of Ambient Systems and Applications (IJASA)Document2 pagesThe International Journal of Ambient Systems and Applications (IJASA)Anonymous 9IlMYYx8No ratings yet

- Graph HocDocument1 pageGraph HocMegan BellNo ratings yet

- International Journal of Game Theory and Technology (IJGTT)Document2 pagesInternational Journal of Game Theory and Technology (IJGTT)CS & ITNo ratings yet

- Ijait CFPDocument2 pagesIjait CFPijaitjournalNo ratings yet

- Graph HocDocument1 pageGraph HocMegan BellNo ratings yet

- Free Publications : Scope & TopicsDocument2 pagesFree Publications : Scope & TopicscseijNo ratings yet

- International Journal of Game Theory and Technology (IJGTT)Document2 pagesInternational Journal of Game Theory and Technology (IJGTT)CS & ITNo ratings yet

- International Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)Document2 pagesInternational Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)ijscaiNo ratings yet

- Ijait CFPDocument2 pagesIjait CFPijaitjournalNo ratings yet

- Call For Papers-The International Journal of Ambient Systems and Applications (IJASA)Document2 pagesCall For Papers-The International Journal of Ambient Systems and Applications (IJASA)CS & ITNo ratings yet

- Graph HocDocument1 pageGraph HocMegan BellNo ratings yet

- International Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Document3 pagesInternational Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Anonymous w6iqRPANo ratings yet

- Free Publications : Scope & TopicsDocument2 pagesFree Publications : Scope & TopicscseijNo ratings yet

- International Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Document3 pagesInternational Journal of Chaos, Control, Modelling and Simulation (IJCCMS)Anonymous w6iqRPANo ratings yet

- International Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)Document2 pagesInternational Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)ijscaiNo ratings yet

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonNo ratings yet

- International Journal of Peer-To-Peer Networks (IJP2P)Document2 pagesInternational Journal of Peer-To-Peer Networks (IJP2P)Ashley HowardNo ratings yet

- International Journal of Security, Privacy and Trust Management (IJSPTM)Document2 pagesInternational Journal of Security, Privacy and Trust Management (IJSPTM)ijsptmNo ratings yet

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Retail Analysis WalmartDocument18 pagesRetail Analysis WalmartNavin MathadNo ratings yet

- Permutation Vs CombinationDocument4 pagesPermutation Vs CombinationSaleh RehmanNo ratings yet

- Solution StochiometryDocument23 pagesSolution StochiometryAnthony AbesadoNo ratings yet

- Certification of Anti-Seismic Devices According To The European Standard EN 15129:2009: Tasks For Manufacturers and Notified BodiesDocument9 pagesCertification of Anti-Seismic Devices According To The European Standard EN 15129:2009: Tasks For Manufacturers and Notified BodiesRobby PermataNo ratings yet

- Bibliometry of Radiography Bachelor Theses in University of MaiduguriDocument7 pagesBibliometry of Radiography Bachelor Theses in University of MaiduguriInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Session ManagementDocument4 pagesSession ManagementahamedyaseenNo ratings yet

- Qualifications: Stephanie WarringtonDocument3 pagesQualifications: Stephanie Warringtonapi-268210901No ratings yet

- Project Execution PlanDocument69 pagesProject Execution PlanGraco Calle100% (6)

- Advanced Java SlidesDocument134 pagesAdvanced Java SlidesDeepa SubramanyamNo ratings yet

- ExtPascal Advanced Configuration Complete Eng v4Document31 pagesExtPascal Advanced Configuration Complete Eng v4jofreezeNo ratings yet

- Delegate Handbook: The National Final of The Evatt Trophy CompetitionDocument19 pagesDelegate Handbook: The National Final of The Evatt Trophy Competitionevatt2012No ratings yet

- Diamondfreezemel32r E82eenDocument11 pagesDiamondfreezemel32r E82eenGILI RELIABILITYNo ratings yet

- Sustainability Indicators: Are We Measuring What We Ought To Measure?Document8 pagesSustainability Indicators: Are We Measuring What We Ought To Measure?yrperdanaNo ratings yet

- MCQ in Engineering Economics Part 11 ECE Board ExamDocument19 pagesMCQ in Engineering Economics Part 11 ECE Board ExamDaryl GwapoNo ratings yet

- Labacha CatalogueDocument282 pagesLabacha CatalogueChaitanya KrishnaNo ratings yet

- Nonverbal Communication (BAS105 UNIT-4)Document16 pagesNonverbal Communication (BAS105 UNIT-4)sachinnonofficialmailNo ratings yet

- فص یروئت Queuining TheoryDocument47 pagesفص یروئت Queuining Theorycampal123No ratings yet

- Zerkle Dalcroze Workshop HandoutDocument2 pagesZerkle Dalcroze Workshop HandoutEricDoCarmoNo ratings yet

- Eng 1: Communication Arts: Talisay City CollegeDocument14 pagesEng 1: Communication Arts: Talisay City CollegeDennis SocuanoNo ratings yet

- Research Methods SESSIONS STUDENTS Abeeku PDFDocument287 pagesResearch Methods SESSIONS STUDENTS Abeeku PDFdomaina2008100% (3)

- English II Homework Module 6Document5 pagesEnglish II Homework Module 6Yojana DubonNo ratings yet

- How To Use SQL Servers Extended Events and Notifications White Paper 24902Document20 pagesHow To Use SQL Servers Extended Events and Notifications White Paper 24902Santosh KadamNo ratings yet

- Discourse Analysis: Understanding How We Understand.: Ey WordDocument7 pagesDiscourse Analysis: Understanding How We Understand.: Ey WordTommy NickelsonNo ratings yet

- Innoventure List of Short Listed CandidatesDocument69 pagesInnoventure List of Short Listed CandidatesgovindmalhotraNo ratings yet

- 2998 1-Emt Fibre Optic Cable-Cat LRDocument32 pages2998 1-Emt Fibre Optic Cable-Cat LRsubramanyaNo ratings yet

- French DELF A1 Exam PDFDocument10 pagesFrench DELF A1 Exam PDFMishtiNo ratings yet

- Philippines Research PaperDocument6 pagesPhilippines Research Paperhxmchprhf100% (1)

- Rigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187Document9 pagesRigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187tavis80No ratings yet

- Success Story of Amit Kumar Singh UPSC 2010 BatchDocument5 pagesSuccess Story of Amit Kumar Singh UPSC 2010 BatchvishalkkkkNo ratings yet