Professional Documents

Culture Documents

Application of Conveyors For UG Haulage

Uploaded by

minerito2211Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Conveyors For UG Haulage

Uploaded by

minerito2211Copyright:

Available Formats

Application of Conveyors for Underground Haulage

A G L Pratt1

ABSTRACT

The selection of the ore haulage system is one of the most crucial decisions made in the development of an underground mining project. The haulage system is, once selected, one of the components of a mine that defines its ability to respond to changes in mining inventory and the market conditions for its products. Over the last decade, in Australia at least, this selection process has largely centred on the debate over the merits of shaft and decline truck haulage. Little attention, if any, was given to the application of inclined conveyor haulage as a real alternative to the shaft and truck haulage. This is despite well established precedents for its application in the underground coal industry and some limited applications in underground metalliferous mines. This paper seeks to explore the case for the application of inclined conveyors as a legitimate ore haulage system for underground mines. The case for conveyor haulage is illustrated by an overview of the application of conveyors at some existing operations, and discussion of what conveyors have to offer as a mine haulage system and the issues that are associated with them. Material drawn from the feasibility studies for Newcrests Ridgeway mine and Telfer Deeps Project is presented as case studies that considered selection of inclined conveyor haulage. The purpose of these case studies is to highlight the value of impartially approaching tasks of this type with a robust plan. This plan should be able to respond to issues identified as the task progresses towards the objective of finding the right solution for an ore haulage system.

supervision. There have also been some increases in hoisting speeds as a result of application of fluid mechanics to modelling of the dynamic behaviour of conveyances travelling in the shaft and their response to changes in variables such as air velocity in the shaft. A commitment to shaft haulage represents a significant initial capital cost for a mining project and tends to demand a commensurately larger resource base to justify its selection. In many cases the commitment to a shaft is in addition to an access decline that if not from surface, is from the top of the deposit to the bottom of the shaft. A shaft may also be less flexible in terms of capacity. However, shaft haulage does offer:

low unit operating costs; and provision of a secure route for the delivery of other mine

services; power, communications, primary ventilation, raw water and egress. Against the background of this robust debate little attention, if any, was given to the application of inclined conveyor haulage as a real alternative to either shaft or truck haulage. This is despite well established precedents for its application in the underground coal industry and some limited applications in underground metalliferous mines. On the surface this seems a little surprising given that selection of the haulage system is one of the most crucial decisions made in the development of an underground mining project. The haulage system is, once selected, one of the components of a mine that defines its ability to respond to changes in mining inventory and the market conditions for its products. For this reason it demands a rigorous impartial selection process. This paper seeks to explore the case for the application of inclined conveyors as a legitimate ore haulage system for underground mines. To illustrate what conveyors have to offer as a mine haulage system the status of the conveyor technology is briefly reviewed and its application at some existing operations discussed. Material drawn from Newcrests Feasibility Studies for the Ridgeway and Telfer mines is presented as case studies of considered selection of inclined conveyor haulage.

INTRODUCTION

Over the last decade, in Australia at least, discussion on the selection of haulage systems for underground mines has largely centred on the debate over the merits of shaft and decline haulage. A key driver in this debate over that period is the impressive developments in truck haulage technology that has produced faster, larger capacity trucks for underground mines. The perennial question for projects being one of; how far trucks can keep on doing the job before you need to switch over to shaft haulage? The development of truck haulage technology is now widely agreed to have pushed the operating range for trucks to an operating depth of 1000 m at production rates in the vicinity of 1.5 million tonnes per annum. (Medhurst, 2001; McCarthy, 2001) This compares with operating ranges of 400 and 600 m in the 1970s and 1990s respectively. The enabling technology for improvements in truck performance has been in the areas of engines, braking and control systems. Some believe (Carrick, Guilfoyle and Robertson, 2002) that with further development of the road train style of truck, and the automation of truck fleets, that the operating range has further scope for improvement. Truck haulage is generally considered to offer a project a low initial capital outlay with inherent flexibility provided by the fleet size deployed and the potential for further improvements in technology. In comparison to truck haulage relatively little has changed in the area of shaft haulage; there has been no material change in the mechanical components. The improvement in winder technology, mostly by transfer from other electric drive and control applications, has focused on improved drive systems and automation of ore haulage systems. Most winding systems are now commissioned to operate fully automated with only remote

1. MAusIMM, Divisional Mining Engineer, Project Development, Newcrest Mining Limited, Level 2, Hyatt Business Centre, 30 Terrace Road, East Perth WA 6004. E-mail: pratta@newcrest.com.au

CONVEYOR HAULAGE

Use of conveyors is a common feature of most mining operations. Often their role is limited to a transfer function between bins, chutes and stockpiles, and for the most part this type of installation is well within the capability range of conveyor technology and has a long history. However, conveyor haulage from underground to surface, in metalliferous mines at least, is a more recent application that has appeared in the last ten years (Table 1). In Australia the first of these installations was at the Cadjebut mine. More recently in Australia inclined conveyor haulage systems were installed at:

Revenge mine, Kapok mine, MacArthur River mine, and Ridgeway mine.

Not surprisingly it is the development of technology that has enabled the application of conveyor haulage to be extended so that it is now a serious alternative for haulage from underground to the surface. These improvements in technology (Michaels, 2004) have come in the areas of:

Ninth Underground Operators Conference

Perth, WA, 7 - 9 March 2005

273

A G L PRATT

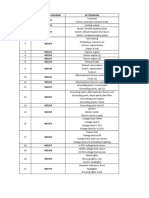

TABLE 1

General specification of some Australian inclined haulage conveyors.

System details Cadjebut Commissioned Length (metres) Inclination Lift (m) Belt strength Belt width (mm) Belt speed (m/s) Rate capacity (t/hr) Drive size (KW) Starter and control 1988 2500 1 in 12 to 6 (8.3 - 16.6%) 200 max Not available 850 2.5 300 2 300 DOL Revenge 1994 1500 1 in 10 to 6 (10 - 16.6%) 185 Not available 1200 1.6 450 1 500 Not available Mine MacArthur River 1995 2680 1 in 5.4 (18.5%) 305 SR3550 900 1.7 470 2 300 Not available Kapok 1996 2400 1 in 6 (16.6%) 400 Not available 630 2.76 200 2 250 DOL with fluid coupling Ridgeway 2002 4000 1 in 5.3 (18.9%) 750 ST2240 ST5500 1050 2.8/3.1 960 2 450 3 630 LRS

Increased belt strengths The introduction of dynamic splice

testing, finite element analysis of splices and the development of high strength steel cord belts of up to ST8000 (8000 kN/m) has allowed designers to develop conveyors with long flights and higher lifts (eg Ridgeways portal conveyor). Goodyear is currently testing ST 10 000 steel cord belt splices. Improved control over starting and stopping loads has also reduced stress and fatigue on belts.

Conveyor haulage has some attributes that give inherent flexibility in its application and these are outlined below:

It is possible to combine access and a haulage conveyor

Improved loading chute design Technology has focussed on

improved transfer of material from bins to conveyor and conveyor to conveyor. This eliminates belt damage and reduces belt wear. mine and the use of belt rip protection ensures that belts are protected from catastrophic damage. operation to better match conveying with mining outputs.

Belt rip protection Mainline conveyors are the lifeline of a Drives Variable speed drives provide flexibility of Maintenance programs Introduction of preventative

maintenance practices and recognition of the role of good housekeeping has contributed to increased life of all conveying components. plus with proper selection of cover rubber and gauge of rubber. Incorporating breaker fabrics also reduces damage to belt carcass.

in the one decline. This decline may initially serve as a platform from which to establish production based on truck haulage and to assess the economic potential of deeper mineralisation. The conveyor would be added later provided sufficient additional reserves were proved. Alternatively a separate conveyor haulage decline may be established from a decline initially utilised for truck haulage, provided that some consideration is given to this opportunity in the design of the initial access decline. A separate conveyor haulage decline can also provide a mining operation with a robust emergency egress trafficable by light vehicles and light trucks. the site to engage or manage a different range of skills and equipment than it requires for other underground development work. Similarly the skills base needed to support the maintenance systems and protocols required for a conveyor are likely to represent an extension of those already available at the mine. Perhaps more importantly in the current climate where there is a shortage of skilled personnel available to the mining industry, these maintenance skills can be sourced from other materials handling industries. This situation contrasts sharply with the situation for shafts; which require specialised skills to develop and maintain that are not in wide general usage in other industries. traverse from the orebody to the treatment plant and thereby eliminate potential for difficult surface topography to impact on the project. In this respect they are similar to truck haulage declines.

Development of a conveyor haulage decline does not require

Improving belt life Belt life has been extended to ten years

Notwithstanding these improvements, the role of engineering risk assessments has also played a part in enabling the application of inclined conveyor haulage from underground. It is by this process that issues and perceived risks associated with inclined conveyor haulage from underground have been identified and management strategies developed for them. Notable amongst these issues and risks are:

Conveyor haulage systems to surface can be designed to

Belt breakage This must be managed by the application of

appropriate maintenance, monitoring systems and provision of physical barriers if required.

The availability for a conveyor system is typically greater

Fire This can be minimised by the use of fire resistant non

than 90 per cent. The components and control systems are robust and well suited to automation, and remote supervision and control.

propagating conveyor belt material. The impact of fire is further reduced by the appropriate design of the primary ventilation system. proper consideration during design (eg location, protection, separation). of belt systems.

Attributes associated with conveyor haulage that may limit their application for mine haulage include:

A tendency to transit larger areas. This requires consideration

Damage by mobile equipment This can be minimised by Guarding Protection of people from the moving components

to be given to the sterilisation of potential mineralisation along the proposed route, assessment of the geotechnical environment and relationship to lease boundaries. In comparison, trucking declines are fairly flexible in their layout and shafts typically need an exclusion zone of 100 m in diameter.

274

Perth, WA, 7 - 9 March 2005

Ninth Underground Operators Conference

APPLICATION OF CONVEYORS FOR UNDERGROUND HAULAGE

A requirement for robust systems to prevent and detect belt

damage. These may include effective chute designs, employment of a multi stage process for removal of tramp steel, verification of no tramp using metal detectors, and embedded belt detection.

Development of maintenance systems that monitor the

condition of the belt installations with the aim of preventing belt failure, treating it as an unacceptable outcome in the same way as failures of hoisting ropes or attachments are treated. The argument that inclined conveyors are clearly becoming part of mainstream haulage solutions for underground mines is supported by the number of inclined haulage conveyor installations that are at various stages of consideration around the world ranging from commissioning to conceptual studies. Some of these are listed below:

The study process applied at Ridgeway and Telfer was similar. Its application at Telfer benefited from information assembled for Ridgeway, including acceptance of the outcomes from conceptual work completed for Ridgeway. The first step in both studies was to consider all conceivable alternatives for haulage systems from underground over a range of likely production rates produced by parallel studies of the application of mining methods. Conceptual studies prepared for these alternatives were intended to allow the selection of a preferred alternative or alternatives. These would be the subject of further, more detailed work in subsequent studies to finalise a selection and specification of the preferred system. The conceptual studies for each haulage alternative included preparation of:

a clear statement of the inputs and assumptions used in the

preparation of each alternative;

Northparkes mine, New South Wales. Newly commissioned

extension of their shaft haulage system.

Ekati Diamond mine, Northwest Territories, Canada. Part of

the development of a new underground mine.

capital and operating cost estimates; an estimate of the electrical supply requirements; first pass construction and commissioning schedules; comment on risks and uncertainties associated with each haulage alternative and scope of additional work required to reduce these; and alternatives.

Jaguar mine, Western Australia. Proposed reinstallation of

the Kapok mine conveyor system at a new project.

Codelco, Chile. Studies for very large capacity systems for

installations at their Chuquicamata and El Teniente mines.

a clear statement of the basis for rejection of some

The spread of haulage systems for underground mines included:

NEWCREST CASE STUDIES Introduction

Newcrest Mining Limited (Newcrest) is an Australian gold mining company with operations in Western Australia, New South Wales, Queensland, and Indonesia. In recent years Newcrest has focused its efforts on the development of gold projects of substantial scale or margin. The Ridgeway and Telfer gold mines are examples of two of these projects. In both projects the resolution of the ore haulage strategy from underground was the subject of comprehensive studies. The circumstances and content of these studies are used to illustrate the potential that inclined conveyors offer as a mine haulage solution. Ridgeway is located 3 km to the north-west of Newcrests Cadia Hill gold mine; an open pit operation situated 25 km to the south of Orange in the NSW Central Tablelands, which commenced operation in 1998. Construction and commissioning of Ridgeway was completed in March 2002 with a projected mine life of 12 years at a nominal production rate of 4.0 million tonnes per annum. This has since increased to 5.6 million tonnes per annum. An inclined conveyor system is used for ore haulage. The Telfer mine is located in the Great Sandy Desert, approximately 400 km east-south-east of Port Hedland, Western Australia. The mine is currently undergoing a redevelopment that involves both open pit and underground mining, and is scheduled to commence processing ore from the open pit in a new treatment plant complex in the October quarter of 2004. Production from the underground mine is expected to commence in the second half of 2005. The projected life of the Telfer operation is 25 years for the open pit with underground lasting 12 years. Haulage studies completed for the underground mine resulted in the selection of a shaft for ore haulage.

truck, shaft hoisting, both crushed and uncrushed, rail, conveyor, pneumatic ore lifting, and hydro-hoisting.

The evaluation process aimed to ensure that decisions were made based on a rational and rigorous analysis of what options might be applicable in different circumstances. This meant that once an option was rejected it would remain so, and it would not be returned for consideration in later stages. The evaluation process considered the following elements:

distribution, scale, and tenor of mineralisation as it is known,

and as it may develop;

geotechnical setting; topography of the overlying surface and location of existing

facilities;

robustness of the underlying technology, precedence for its

application, upgradeability in the future; in the underlying assumptions;

assessment of risk and opportunities sensitivity to changes costs capital and operating; and comment on additional work required to reduce uncertainties

and risks associated with preferred alternatives. Prior to the preparation of conceptual studies a preliminary evaluation was completed of the conceivable alternatives and their application at each site. This resulted in the elimination of:

Hydro hoisting of crushed rock This technology has not

been applied to hard rock mining with lifts of the depth required at either Ridgeway or Telfer. any significant capacity or depth.

Case studies

The objective for haulage studies at Ridgeway and Telfer was to select a flexible, efficient and cost effective method of ore haulage from underground. The battery limits for the haulage studies were from the orepass tip through to the delivery of ore to a run of mine (ROM) stockpile adjacent to the process plant.

Pneumatic ore lifting (POL) POL has not been proven for Rail haulage This approach is commonly applied in

mountainous areas where the mine is accessed by adits. This was not applicable at either Ridgeway or Telfer.

Ninth Underground Operators Conference

Perth, WA, 7 - 9 March 2005

275

A G L PRATT

Vertical conveyors The application of vertical or high angle

conveyors is limited to a few hundred metres. The vertical Flexoturn conveyor which was installed at Porgera and had one of the highest lifts in the world at 200 m (Paelke, 1993), is an example of this type of duty.

For Ridgeway conceptual haulage studies were completed for:

truck haulage to the treatment plant; underground crushing and shaft hoisting to surface and the

use of a surface conveyor system to transport ore to the treatment plant;

Ridgeway

The project evaluation phase for the Ridgeway mine included development of a decline that provided access for drilling and bulk sampling of the deposit. The decline was sized and located so that it would be the main access for any future mining operation, and could, if required, support truck haulage operation. As in the initial stages of the project, the strategy for ore haulage from the mine was left open pending selection of a mining method. Assessment of the treatment options for Ridgeway ore indicated that a standalone plant was more economically attractive than modifying the Cadia Hill treatment plant to accept Ridgeway ore. This was due to a significant loss of recovery when Ridgeway ore was processed in Cadia Hill treatment plant; the ore requiring a finer grind for optimum ore recoveries. Prior to evaluating the merits of haulage systems at Ridgeway the various alternatives for the location of the Ridgeway treatment plant were reviewed. The alternatives considered included:

hoisting of uncrushed ore to surface, with surface crushing at

Ridgeway and surface haulage by conveyor to the treatment plant; and

underground crushing and inclined conveyor haulage to the

treatment plant. In all cases the battery limits of the studies were from a loading or tipping point through to a surface run of mine (ROM) stockpile adjacent to the treatment plant. The structure of these studies relied on common estimates for components such as; orepass systems, and underground and surface crushing. Each alternative was estimated for a mine operating at 2.0 Mtpa, and to test sensitivity of each alternative was also estimated at 1.5 Mtpa and 4.0 Mtpa (Figure 1). The truck haulage alternative included a series of suboptions:

two-way haulage in the existing decline; haulage one-way in the existing decline and the other way in

a new decline; and

haulage both ways in a new decline.

The shaft options considered hoisting of material crushed underground and hoisting of uncrushed, but sized, material. Initial studies of the inclined conveyor alternative were based on a series of three conveyors. Use of a single conveyor was considered but rejected. While technically feasible, although at the leading edge, the belt carcass strength required resulted in an excessive capital cost in comparison to the use of shorter conveyors. These comparisons showed that conveyor haulage had the lowest overall life of mine operating cost. This proved true across the spread of production rates investigated. The initial capital cost was lowest for truck haulage using the existing decline. However the higher operating cost of the truck haulage

locating a separate treatment plant at Ridgeway; either above

the Cadia Valley, or within the Cadia Valley; and

a position adjacent to the Cadia Hill mines treatment plant

further down the Cadia Valley. The site adjacent to the Cadia Hill treatment plant was selected. Capital savings were identified from the shared infrastructure. Operating cost savings resulted from the relatively small number of additional personnel required to operate a processing facility adjacent to, and integrated with, the existing Cadia Hill mine plant. This study also considered the preservation of maintenance access and retention of an area allocated for expansion of the Cadia plant itself.

250

27Mt reserve 24Mt reserve

Costs ($M)

C U

200 150 100 50 0

276

on ve yo nc r1 H ru sh oist .5M ed in tp g H a 1. oi 5 st M i tp Tr ng a 1. uc 5 ki M ng tp C on 1.5 a M ve U yo t pa nc r H ru sh ois 2M tp tin ed a g H 2 oi st Mt Tr ing pa 2 uc ki Mtp n C on g 2 a M v ey U t nc or pa H ru sh ois 4M tp tin ed a g H 4 oi st Mt Tr ing pa 4 uc ki Mtp ng a 4M tp a

Total Capital Cost

LOM Operating Cost

FIG 1 - Comparison of some of the haulage alternatives for Ridgeway.

Perth, WA, 7 - 9 March 2005

Ninth Underground Operators Conference

APPLICATION OF CONVEYORS FOR UNDERGROUND HAULAGE

options quickly eroded this advantage. Furthermore the practicality of truck haulage from 800 to 1000 m depth at 4 Mtpa is questionable. Based on the outcome of this conceptual study conveyor haulage was selected as the preferred alternative. Another factor recognised in this selection was that, despite limited precedents for the application of conveyor haulage to surface from underground, there was significant technical support for this decision. Conveyor technology is driven by a very large range of applications and this demand had resulted in significant advances in design and construction of belts and drive systems for conveyors. Subsequent studies of conveyor systems resulted in selection of two conveyors for the Feasibility Study (Figure 2). The Ridgeway ore handling system can be summarised as follows:

This permitted easy clean up of spillage from under the conveyors. The tail end loading points, take-ups and drive support structures are floor mounted. The portal location and decline layout for the conveyor considered:

geotechnical conditions at the portal and along the route of

the decline;

potential for flooding from the Cadiangullong Creek; and interference from potential open pit mining areas.

The trunk conveyor is driven at its head end. The take up is by winch and located near the head end. Belt installation and changing are carried out at the tail end of the conveyor. Belt reels are transported to the tail end of the trunk conveyor via the Ridgeway access decline. The portal conveyor drive and belt change facilities are located on the surface between the portal and the stacker. This is the longer of the two conveyors and having these facilities on surface reduced the amount of conveyor belt and size of components to be transported underground. The Cadiangullong Creek runs between the conveyor portal and ROM stockpile location. The portal conveyor is mounted on an elevated structure above the one in 100 year flood level. The majority of the surface portion of the conveyor is ground mounted (Figure 3). The original design criterion for the conveyor system was 780 tph based on 70 per cent utilisation and three per cent moisture (4.6 Mtpa). Following a review of upgradeability, and completion of design, the final system capacity was 960 tph (Table 2). This was achieved with little increase in capital (Table 3). The fire fighting and protection systems included the selection of belts with a self-extinguishing cover and a moderate wear rate. At transfer points an automatic detection system was installed with automatic or remote actuation of the foam equipment. As the conveyor decline is a minor intake airway, a remote control ventilation door was placed near the tail end of the conveyor. In the event of a fire on the portal or trunk conveyor the door can be closed to stop the spread of smoke through the mine.

Crushing consisting of underground crushing station with a

rock breaker.

Tramp metal removal consisting of an apron feeder, and

two sacrificial conveyors. These conveyors are fitted with metal detectors and magnets for removal of tramp metal. material to the surface. These belts are designated as the trunk and portal conveyors. With the exception of the last 350 m of the portal conveyor these belts are located underground.

Haulage conveyors two conveyors in series that convey

Surface ROM stockpile fed by a radial stacker that can be

slewed and luffed to form a kidney shaped stockpile. The stacker and ROM layout allowed waste from underground hauled on the same system to be placed to one side and rehandled to the waste dump by loaders and trucks.

Various configurations for the decline cross-section were considered based on different positions for the conveyor within the cross-section. The selected configuration allowed for access alongside the belt in a 6.0 m by 4.0 m decline. The bulk of the conveyor is hung from the back of the conveyor incline with a nominal clearance of 1.3 m to the underside of the conveyor.

FIG 2 - Ridgeway conveyor layout.

Ninth Underground Operators Conference

Perth, WA, 7 - 9 March 2005

277

A G L PRATT

FIG 3 - Section through the portal conveyor showing the location of Cadiangullong Creek.

TABLE 2

Ridgeway conveyor haulage system.

Conveyor data Belt name Length (m) Belt strength (kN) Inclination Width (mm) Belt speed (m/s) Drive size (KW) Starter and control Belt #1 Collection conveyor CV101 30 PN1000/5 Flat 2000 0.65 15 DOL Belt #2 Picking conveyor CV102 40 PN1000/5 Flat 2000 0.65 15 DOL Belt #3 Trunk conveyor CV103 1197 ST2240 1 in 5.3 (18.9%) 1050 2.8 2 450 LRS Belt #4 Portal conveyor CV104 2870 ST5500 1 in 5.3 (18.9%) 1050 3.1 3 630 LRS Belt #5 Stacker CV105 40 4PN250 -6 to +15 (10.5 to 27%) 1050 1.75 55 VVVF

TABLE 3

Ridgeway conveyor costs.

Capital costs Decline Conveyor Total Operating cost @ 5.6 Mtpa Units $M $M $M $/tonne Actual 15.7 16.4 32.1 0.76 Based on 03/04 and includes 0.38 $/tonne to repair major system failures Comments Decline includes the boxcut, portal and additional near surface ground support Includes the trunk, portal and stacking conveyors

To guard against the hazards associated with belt failure on one of the inclined conveyors, concrete protection bulkheads were constructed at the tail of each inclined conveyor to prevent the belt rolling back and damaging down slope facilities. Maintenance and online systems to prevent belt breakage included:

belt rip system detection (embedded loops); monthly belt scans (magnetic signature to detect broken

cords, corrosion and splice damage); and cover damage).

high levels of belt inspection and maintenance (prevent top

278

Perth, WA, 7 - 9 March 2005

Ninth Underground Operators Conference

APPLICATION OF CONVEYORS FOR UNDERGROUND HAULAGE

How has Ridgeways conveyor haulage system performed?

Overall the performance of the Ridgeways conveyor haulage system, to date, could be rated as very good; the system has operated mainly at 840 tph:

Hydraulic take-ups function reasonably well, but are

currently being reviewed for a functional system change (eg make them a bit smarter).

Telfer

The existing underground operation at Telfer is accessed via a decline from within the Main Dome open pit. The re-establishment of open pit mining and the selection of sublevel caving meant a large proportion of this decline needed to be replaced during the early part of the mine life. Upper sections are lost to the open pit and parts of the lower section are lost to the cave. Therefore haulage studies for Telfer needed to consider opportunities for alternatives that combined access and haulage functions. The re-development of the Telfer Mine includes the construction of a new treatment plant. Separate studies determined that the best location was to the west of the Main Dome open pit (Figure 4). Conceptual haulage studies completed for Telfer underground included: Shaft hoisting by: single skip and counter weight, conventional drum winding with skips in balance, and a friction winder with skips in balance.

Conveyor system was originally designed for 70 per cent

utilisation. Monthly utilisations in the low 80 per cent region have been achieved.

Maintenance and inspections have maintained system integrity

at a high level. The standards required for these large systems cannot be underestimated (eg a winder maintenance regime, not a traditional mill conveyor maintenance regime).

What were the issues?

Notwithstanding the high level of performance achieved, the system did experience a number of issues:

During commissioning, wax from the belt manufacture

transferred to, and built up on, the idlers. Idlers were pressure cleaned several times to remove the build-up.

Initial gearboxes on the portal conveyor have all failed and

are being replaced. The underlying problems relate to gearbox manufacture and quality issues.

Initial holdbacks on the portal conveyor failed. These were

replaced with units of approximately twice the holdback capacity.

Conveyor haulage to surface via: dedicated haulage ramp

(similar to the Ridgeway haulage conveyor ramp at a gradient of one in 5.3), and a combined haulage and access ramp (at a gradient of nominally one in seven). The access ramp included in this alternative would be the main travel way for personnel and equipment in and out of the mine. The application of these haulage scenarios was considered for production rates between 1.5 and 6 Mtpa. Operating and capital cost estimates were prepared for alternatives and the subalternatives within this range at four throughput tonnages; 1.5 tpa, 3 Mtpa, 4.5 Mtpa, and 6 Mtpa.

Load sharing between the drives has been a minor issue. The

ultimate system for starting and load sharing is a Variable Voltage Variable Frequency (VVVF), however this option is expensive. Trimming resistors have been added to the motors at Ridgeway to improve load sharing. Poor load sharing leads to high rates of pulley lagging wear.

West Do Open me Pit

Telfer Shaft

Old Plant & Offices

t& Plan New e Site Offic

New Pad O R M

me D o it n i Ma en P Op

FIG 4 - Telfer site.

Ninth Underground Operators Conference

Perth, WA, 7 - 9 March 2005

279

A G L PRATT

Other haulage systems considered and rejected included:

Trucking benchmarking revealed that trucking from depths

in excess of 650 m was not economically viable over the range of production rates considered.

project schedule, capital required for access and ventilation, and preliminary assessment of risk and opportunities.

This assessment of the mine haulage options indicated that:

Uncrushed shaft haulage previous studies for Ridgeway, at

similar production rates to those considered at Telfer, had concluded that it was desirable to crush underground. As there were no variables at Telfer that were materially different from those at Ridgeway, for this level of study, the same conclusion was accepted as valid at Telfer. That is, underground crushing:

haulage shaft and access decline had the lowest life of mine

costs;

combined conveyor haulage and access decline was not

significantly more costly, and might have some schedule advantages over the decline access and shaft haulage option;

guarantees the material size to be handled to the surface; reduces the size of equipment required to transport the

material to the surface;

separate conveyor haulage and access declines did not appear

to offer any advantage over the either of cases noted above; and

minimises spillage; and allows the use of more conventional ore handling plant

and improves system reliability.

haulage and mine access via a single shaft installation had

the highest capital and operating costs, and preliminary schedules indicate that it would take the longest to deliver. The option of a haulage and access shaft was rejected based on the results of this analysis. However, the differences between the remaining three mine haulage options considered were not large:

Hoisting

Several configurations were reviewed. These included a single skip, skip/counterweight and balanced skip winding. The single skip option requires very high torque, which increased the peak demand on the power supply. The skip/counterweight combination, while decreasing the torque, is not an optimal solution due to its inefficient cycle time. As a result, the study focused on balanced winding alternatives. Both double drum and friction winders were reviewed. Limitations on rope strengths constrain conventional double drum winders to a production rate of 4.5 Mtpa at the proposed depths of 1100 m. Friction winders (Koep) are capable of meeting the full range of tonnages at this depth and were selected for capital and operating cost estimates. For the winder duty a double drum hoisting system will be more costly.

capital costs were all within $10 M range of each other and

the spread of operating cost was small; and

the gap between a haulage shaft option and the haulage

conveyor options was close enough to prevent a definitive selection to be made at this stage. Further studies were recommended to better define the shaft and conveyor haulage cases. These focused on better definition of:

capital and operating costs; construction schedules; a more extensive assessment of the risks and opportunities

associated with each option; and

efficiencies associated with minimising the range of different

types of mining activities required on a remote mining site. The objective for these subsequent haulage studies was to complete sufficient work to identify a preferred ore haulage strategy for Telfer Deeps. Three options were considered:

Conveyor haulage

Newcrest was well prepared to consider the application of conveyor haulage at Telfer based on experience with the selection, and engineering, of an inclined haulage conveyor for Ridgeway. At the time of the conceptual studies for Telfer the conveyor decline at Ridgeway was being developed. The conceptual studies completed focused on determining the technical viability for the minimum number of conveyor flights to transfer the ore from underground. The use of a single conveyor flight was considered and rejected; this configuration was not technically feasible for the higher tonnage rates. The difference in the capital cost estimates between two and three flights of conveyors was minimal. The difference between two and three flights was in the order of $1 M for total estimates ranging from $45 to $55 M. This indicated that other factors such as the relationship between the geometry of the conveyor and the deposit may have a more important influence. As part of this study a range of decline cross-sections and conveyor installations were also reviewed (Figure 5). The purpose of this review was to investigate the merits of the various arrangements with respect to excavation profile and operability and maintainability under each of the scenarios considered.

shaft haulage with an access decline, conveyor haulage with a separate access decline, and conveyor haulage without a separate access decline.

However, refinement of concepts and estimates provided little additional insight into differences between options. The studies completed merely confirmed the technical feasibility of the concepts identified for conveyor and shaft haulage from underground at Telfer. The total capital cost estimates prepared for each concept indicated that they were not sufficiently different in their order of magnitude to allow a clear selection of a preferred strategy (Table 4).

TABLE 4

Telfer haulage alternatives, comparative project costs.

Haulage alternatives @ 4 Mtpa Hoisting Inclined conveyor Combined access and conveyor decline Capital cost estimates ($M) Fixed plant 84.1 79.9 82.8 Mining 92.7 103.0 95.0 Total 176.8 182.9 177.8 Operating cost estimate ($/t) 1.79 1.82 1.85

Shaft hoisting versus conveyor haulage

A comparative assessment of shaft and conveyor options was prepared and considered:

power supply characteristics,

280

Perth, WA, 7 - 9 March 2005

Ninth Underground Operators Conference

APPLICATION OF CONVEYORS FOR UNDERGROUND HAULAGE

Not to scale

FIG 5 - Some of the conveyor arrangements and cross-sections considered at Telfer.

Coupled with these studies, benchmarking of similar conveying and hoisting systems world wide for operating costs and technology was also undertaken. Benchmarking costs proved impossible for conveying and inconclusive for hoisting. The general outcome for conveyor technology was that while there are many equivalent component installations for conveyors, Ridgeway was the closest equivalent total underground system and with a vertical lift 750 m. Hoisting on the other hand, has numerous examples of systems in Australia and around the world; both smaller and larger than system proposed for Telfer and all performing satisfactorily.

Additional engineering assessments

Recognition of the potential for extensions of the mineralisation at Telfer to the west and below the proposed SLC operation, were only just becoming evident and resulted in further haulage studies. These aimed to assess the impact on the haulage alternatives of:

Moving haulage systems for the conveyor or shaft 700 m

further west of the SLC to position it clear of potential mineralisation. Options considered included moving the haulage system away, or moving both the haulage and the crusher systems.

Ninth Underground Operators Conference

Perth, WA, 7 - 9 March 2005

281

A G L PRATT

Increasing the production rate to 6 to 7 Mtpa, if required, and

establishing ore handling systems at depths up to 400 m deeper than the nominal 1055 m depth used in studies to date. In the cases with the crusher station remote from the SLC, truck haulage from chutes on orepasses adjacent to the SLC was proposed. The comparative studies considered: capital costs, sensitivity to schedule and development rates, assumption for delivery of key operational functions, access to future mineralisation, varying geotechnical conditions and capacity to increase production. The analysis demonstrated that:

deepening the shaft and moving the existing crusher, or

providing a new crushing/shaft loading installation and developing a new truck haulage level below the new ore zone.

CONCLUSION

The idea that there is a correct haulage solution for each deposit implies that the true extent and potential of a deposit is sufficiently understood at the commencement of the development of the deposit. The reality is that for many mine owners it may be prohibitively expensive, or strategically simply just not an option, to prove up sufficient deeper resource to a level of confidence that will enable a fully informed decision on the selection of correct haulage strategy to be made at the start of a project. In this regard selection of the haulage system has some risk. The underlying uncertainty cannot be designed out of the project and it needs to be identified and contingency plans established to increase the capacity of the mine haulage system. Consideration of the use of conveyor haulage may provide some projects with a basis for a contingency plan. The process adopted by Newcrest to examine haulage strategies illustrated how selection of an optimum haulage system might be approached and how inclined conveyor haulage featured in haulage studies at Ridgeway and Telfer. At Ridgeway, selection of a conveyor, while it was not quite a no brainer, was not a very demanding task. This installation has been at the very heart of the operations ability to ramp up and develop its production rate beyond the capacities envisaged in the Feasibility Study. The haulage studies for Telfer clearly identified resilience in terms of the capability and economics of conveyor haulage systems to meet the demands of serving a deep mining operation. In this instance there was no material economic difference between shaft or conveyor haulage and it was the uncertainty over the Newcrests ability to sterilise enough country to accommodate a conveyor that was the telling difference. However, the process applied was able to deal with these issues in a balanced analytical way. Furthermore, the haulage study demonstrated that the preferred solution is still the optimum should the underground resource increase.

the change from ore transfer by LHD to truck haulage

between the SLC and the crusher had no material impact on the result;

the combination of shaft and access decline has the smallest

physical impact on the orebody and the flexibility to be extended if further economic ore is intersected at depth;

the main disadvantage of the conveyor system was the large

footprint created by the development required and a lack of flexibility if other economic ore zones were identified;

the single decline option combining truck haulage and access

functions had the lowest capital cost; and

the conveyor options both offered a similar outcome to the

shaft and access decline option in terms of efficiency. A shaft, with an adjacent crusher and an access decline, was selected as the preferred alternative for ore haulage for Telfer Deeps. The proposed location of the shaft and crusher provided a significant degree of flexibility. A range of future scenarios are possible and these include:

trucking up to the crusher adjacent to the shaft as an

alternative to deepening the shaft;

construction of a satellite crusher installation to serve a new

ore zone or a depth extension of Telfer Deeps, and using an inclined conveyor to transfer crushed material to the shaft; and

FIG 6 - Operating ranges for haulage system from underground.

282

Perth, WA, 7 - 9 March 2005

Ninth Underground Operators Conference

APPLICATION OF CONVEYORS FOR UNDERGROUND HAULAGE

There is now range of underground mining projects that are currently considering, or are implementing, inclined conveyor haulage systems. This represents a significant change in the level of interest in the application of conveyors. Some of these operations will provide the underground mining industry with some much needed benchmarks to assess, and develop, the application of inclined conveyors for haulage from underground to surface (Figure 6). It appears certain that inclined conveyor haulage is set to become part of the mainstream in terms of underground haulage and offers a flexible alternative to truck and shaft haulage.

ACKNOWLEDGEMENTS

The author wishes to thank the management of Newcrest for permission to publish this paper and gratefully acknowledges the assistance of colleagues at Newcrest and Maunsell Australia in its preparation. Particular thanks go to Peter Ellen and Peter Choules of Maunsell Australia.

REFERENCES

Arancibia, E and Flores, G, 2004. Design for the underground mining at Chuquicamata orebody, scope engineering stage, in Proceedings MassMin 2004 (eds: A Karzulovic and M A Alfaro) (Editec Ltd: Santiago).

Carrick, P, Guilfoyle, K and Robertson, A, 2002. Road trains underground the alternative trucking system, in Proceedings Eighth Underground Operators Conference, pp 285-291 (The Australasian Institute of Mining and Metallurgy: Melbourne). Flores, G, 2004. Personal communication, August. Hersant, D, 2004. Mine design of The Argyle underground project, in Proceedings MassMin 2004 (eds: A Karzulovic and M A Alfaro) (Editec Ltd: Santiago). Kerr, P, 2002. Independent decline haulage at Kanonwna Belle gold mines, in Proceedings Eighth Underground Operators Conference, pp 285-291 (The Australasian Institute of Mining and Metallurgy: Melbourne). McCarthy, P, 2001. Decline flexibility reduces funding risk, Australias Mining Monthly, May:44. Medhurst, G, 2001. Time to examine options for more deeply, Australias Mining Monthly, April:72-76. Michaels, C, 2004. Personal communication, August. Newcrest Mining Limited, 1999. Ridgeway Mine feasibility study. Newcrest Mining Limited, 2002. Telfer Project feasibility study. Paelke, J W,1993. Gold mine operates 203 m vertical Flexoturn System, Bulk Soilds Handling, 13(2):297-300. Quinn, M, 2004. Conveyor to cut costs at Jaguar, Mining News, 12 August. Steven, R B, 2003. Replacing C-6 conveyor belt at Kennecott Utah Copper, Bingham Canyon Mine, in Proceedings Beltcon 12 Conference, July, Johannesburg, South Africa. Yez, P, 2004. New mine level project at El Teniente, in Proceedings MassMin 2004, pp 421-428 (eds: A Karzulovic and M A Alfaro) (Editec Ltd: Santiago).

Ninth Underground Operators Conference

Perth, WA, 7 - 9 March 2005

283

You might also like

- Shaft or DeclineDocument10 pagesShaft or DeclineElias ArayaNo ratings yet

- Selecting Shaft or DeclineDocument8 pagesSelecting Shaft or DeclineluisparedesNo ratings yet

- Incline Haulage TrucksDocument2 pagesIncline Haulage Trucksgarves007No ratings yet

- Issue110 Evolution MiningTrucksDocument4 pagesIssue110 Evolution MiningTrucksluisparedesNo ratings yet

- Modelling of In-Pit Crusher Conveyor AlternativesDocument8 pagesModelling of In-Pit Crusher Conveyor AlternativesJosue GonzalezNo ratings yet

- IPCC System OverviewDocument19 pagesIPCC System OverviewBadar Hayat100% (1)

- High Angle Conveyor Offers Mine Haulage SavingsDocument20 pagesHigh Angle Conveyor Offers Mine Haulage SavingsZiggy Gregory100% (1)

- High Angle Conveyor Offers Mine Haulage SavingsDocument27 pagesHigh Angle Conveyor Offers Mine Haulage SavingsJDNo ratings yet

- Gate Mining 2007-2019 PapersDocument220 pagesGate Mining 2007-2019 PapersAarya raj singh RanawatNo ratings yet

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pages10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulNo ratings yet

- Alternative Process Flow For Underground Mining OpDocument14 pagesAlternative Process Flow For Underground Mining OpEduardo MenaNo ratings yet

- Pneumatic and Slurry Transport Design CalculationsDocument51 pagesPneumatic and Slurry Transport Design CalculationsDondon Irig100% (1)

- Short Term Gain For Long Term PainDocument10 pagesShort Term Gain For Long Term PainPutro Asta Nagara100% (1)

- Counter Current LeachingDocument4 pagesCounter Current Leachingbelter99100% (1)

- The Backacter: Transportation of Excavator Section Towards SlipwayDocument5 pagesThe Backacter: Transportation of Excavator Section Towards SlipwayAditi BazajNo ratings yet

- Cyanide DestructionDocument11 pagesCyanide DestructionISMAEL RAMIREZNo ratings yet

- Inclined Belt Conveyors For Underground Mass Mining OperationsDocument6 pagesInclined Belt Conveyors For Underground Mass Mining OperationsIsmaelNo ratings yet

- Application of Highwall Mining in IndiaDocument12 pagesApplication of Highwall Mining in IndiaSatish kumarNo ratings yet

- Air CannonDocument9 pagesAir Cannonkarthikraja21100% (1)

- Blast Fume Clearance Reentry TimesDocument8 pagesBlast Fume Clearance Reentry TimesYuni_Arifwati_5495No ratings yet

- Belt Conveyor IsmDocument16 pagesBelt Conveyor IsmPrasenjit ChoudhuryNo ratings yet

- Economics of Haul Road ConstructionDocument8 pagesEconomics of Haul Road Constructionhendri sulistiawan100% (1)

- Chapter 2: Literature ReviewDocument14 pagesChapter 2: Literature ReviewShahadat HossainNo ratings yet

- BenchFill VillaescusaDocument10 pagesBenchFill VillaescusaFredd_AlvaroNo ratings yet

- Investigative Methods for Controlling Groundwater Flow to Underground Mine WorkingsDocument45 pagesInvestigative Methods for Controlling Groundwater Flow to Underground Mine WorkingsJamealNo ratings yet

- 1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineDocument1 page1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineYeimsNo ratings yet

- Natural Ventilation Explained in MinesDocument16 pagesNatural Ventilation Explained in Minesalwcastillo100% (2)

- AI Solution for Dragline PlanningDocument25 pagesAI Solution for Dragline PlanningAditya HimanshuNo ratings yet

- Size ReductionDocument12 pagesSize ReductionPCarolina50% (2)

- 2011 Cost Models SectionDocument56 pages2011 Cost Models Sectionoduk odbayarNo ratings yet

- Gold Operations - PresentationDocument79 pagesGold Operations - PresentationChristian TewodrosNo ratings yet

- Attrition Scrubbers Provide Intense Scrubbing Action at High DensitiesDocument39 pagesAttrition Scrubbers Provide Intense Scrubbing Action at High DensitiesVic Andres E. AracenaNo ratings yet

- BWEDocument16 pagesBWEMas YoanNo ratings yet

- Mining Innovation 8apr2016Document57 pagesMining Innovation 8apr2016cdkuea100% (1)

- Energy Saving Belt ConveyorDocument11 pagesEnergy Saving Belt ConveyorVINCENZOVECCHIO100% (1)

- 015chapter 14 Koepe Friction HoistsDocument14 pages015chapter 14 Koepe Friction HoistsWahyu Dwi AgustianNo ratings yet

- Crushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDocument24 pagesCrushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDanny Joaquin Flores CruzNo ratings yet

- Destruction of cyanide waste solutions using oxidationDocument10 pagesDestruction of cyanide waste solutions using oxidationBrent WoottonNo ratings yet

- TFMPelayoLopezGRUO PDFDocument91 pagesTFMPelayoLopezGRUO PDFshivakumar bairojuNo ratings yet

- Highwall MiningDocument10 pagesHighwall MininghendrawanNo ratings yet

- Mine Ventilation Systems ExplainedDocument22 pagesMine Ventilation Systems ExplainedMatías Ignacio Fuentes BustamanteNo ratings yet

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocument22 pagesFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNo ratings yet

- List of Mining BooksDocument34 pagesList of Mining BooksTurtasNo ratings yet

- Coal Mining Methods - EMFI SummaryDocument0 pagesCoal Mining Methods - EMFI SummaryCharles BinuNo ratings yet

- Comparision of CrusherDocument6 pagesComparision of CrusherVeerasamy SureshbabuNo ratings yet

- Angle of Repose: Instructions (Read These Carefully or You Will Have To Redo Your Responses!)Document6 pagesAngle of Repose: Instructions (Read These Carefully or You Will Have To Redo Your Responses!)Rohit GadekarNo ratings yet

- Research and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalDocument12 pagesResearch and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalKarthii Aju100% (1)

- Stockpile SegregationDocument2 pagesStockpile SegregationEdwin BatallanosNo ratings yet

- SAIL BSBK Visit Docx-15.06. R-1rtfDocument7 pagesSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Centrifuge PDFDocument11 pagesCentrifuge PDFسراء حيدر كاظمNo ratings yet

- Mine Ventilation System PDFDocument22 pagesMine Ventilation System PDFADRIAN NURHADINo ratings yet

- Appendix 20 - Cyanide Facility Decommissioning Plan (ICM Code Principle 5) For Kalgoorlie Consolidated Gold MinesDocument38 pagesAppendix 20 - Cyanide Facility Decommissioning Plan (ICM Code Principle 5) For Kalgoorlie Consolidated Gold MinesPaipinpokoNo ratings yet

- Lecture 4Document11 pagesLecture 4yogesh shindeNo ratings yet

- Material Handling-Contents Volume IIDocument9 pagesMaterial Handling-Contents Volume IItafakor100% (1)

- Schedule 90 Days Haul RoadRev ADocument4 pagesSchedule 90 Days Haul RoadRev AMario CordovaNo ratings yet

- 4 main mining methods & their impactsDocument4 pages4 main mining methods & their impactssunilsinghmNo ratings yet

- RailveyorDocument43 pagesRailveyorpecampbe100% (2)

- Automation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980From EverandAutomation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980J. O'SheaNo ratings yet

- NPV or IRR - Why Not BothDocument5 pagesNPV or IRR - Why Not Bothminerito2211No ratings yet

- 05 Strategic Mine Planning 1Document39 pages05 Strategic Mine Planning 1minerito22110% (1)

- Conveyor System at South BulgaDocument5 pagesConveyor System at South Bulgaminerito2211No ratings yet

- Applying Risk Analysis To Asses Economic Viability To UG Golden Sunlight MineDocument10 pagesApplying Risk Analysis To Asses Economic Viability To UG Golden Sunlight Mineminerito2211No ratings yet

- MisUse of MonteCarlo Simulation in NPV Analysis-DavisDocument5 pagesMisUse of MonteCarlo Simulation in NPV Analysis-Davisminerito2211No ratings yet

- Geostatistical Design of Infill Drilling ProgramsDocument10 pagesGeostatistical Design of Infill Drilling Programsminerito2211No ratings yet

- Feasibility Studies - Scope and AccuracyDocument8 pagesFeasibility Studies - Scope and Accuracyminerito2211No ratings yet

- Application of Whittle 4D To Risk Manag. in OP OptimisationDocument12 pagesApplication of Whittle 4D To Risk Manag. in OP Optimisationminerito22110% (1)

- Application of Whittle 4D To Risk Manag. in OP OptimisationDocument12 pagesApplication of Whittle 4D To Risk Manag. in OP Optimisationminerito22110% (1)

- Block Size Selection in OPDocument8 pagesBlock Size Selection in OPminerito2211No ratings yet

- Planning and Design of Surface MinesDocument6 pagesPlanning and Design of Surface Minesminerito2211No ratings yet

- Economic Modelling and Its Application in Strategic PlanningDocument12 pagesEconomic Modelling and Its Application in Strategic Planningminerito2211100% (1)

- Use of Monte Carlo Simluations For Operations ManagementDocument4 pagesUse of Monte Carlo Simluations For Operations Managementminerito2211100% (1)

- Mining Grade ControlDocument6 pagesMining Grade Controlminerito221175% (8)

- Evolution of Strategic LTP at Anglo PlatinumDocument6 pagesEvolution of Strategic LTP at Anglo Platinumminerito2211No ratings yet

- Optimization of Shovel-Truck System in OPDocument7 pagesOptimization of Shovel-Truck System in OPminerito2211100% (1)

- Chapter 20Document70 pagesChapter 20minerito2211No ratings yet

- XPAC7 Autocheduler Training GuideDocument64 pagesXPAC7 Autocheduler Training Guideminerito2211100% (8)

- Service Bulletin Trucks: Oil and Filters, Volvo ComponentsDocument14 pagesService Bulletin Trucks: Oil and Filters, Volvo ComponentsmattkidoNo ratings yet

- Cold In-Place Recycling Using Foamed BitumenDocument14 pagesCold In-Place Recycling Using Foamed BitumenBijay Krishna DasNo ratings yet

- 075 - EN - PS - 90553307 - Endt Co AssuredDocument2 pages075 - EN - PS - 90553307 - Endt Co AssuredRizky FajarNo ratings yet

- ISO-Certified HDPE Pipe ManufacturerDocument4 pagesISO-Certified HDPE Pipe Manufacturerdhopat kalpeshNo ratings yet

- Annual Scooter H&R Inc SDP: Certificate of Motor InsuranceDocument1 pageAnnual Scooter H&R Inc SDP: Certificate of Motor InsuranceEdi0% (1)

- Mass & Balance - Long BriefDocument20 pagesMass & Balance - Long BriefTarik MerryleesNo ratings yet

- Technical Service Bulletin 10R80 - Illuminated Mil - Dtcs P0741 and P1744 - Built On or Before 20-Nov-2017 20-2117Document3 pagesTechnical Service Bulletin 10R80 - Illuminated Mil - Dtcs P0741 and P1744 - Built On or Before 20-Nov-2017 20-2117Alex Maceira GraterolNo ratings yet

- Can Air Asia Sustain Its SuccessDocument2 pagesCan Air Asia Sustain Its SuccesstennydeNo ratings yet

- Chapter 3 Relief For Capital Allowance - StudentDocument48 pagesChapter 3 Relief For Capital Allowance - StudentAng ZhitingNo ratings yet

- 7462TWENDocument4 pages7462TWENMUHAMAD AWISSNo ratings yet

- Section 55 - Electrical System - Chapter 12Document40 pagesSection 55 - Electrical System - Chapter 12احمد الشبراوى الشبراوىNo ratings yet

- Keterangan Wiring DiagramDocument3 pagesKeterangan Wiring DiagramandraNo ratings yet

- Utilization of Flight Simulator in AviationDocument5 pagesUtilization of Flight Simulator in AviationSamuel ANo ratings yet

- Hot Central Plant Recycling Methods and EquipmentDocument7 pagesHot Central Plant Recycling Methods and EquipmentharNo ratings yet

- Ibo 5Document12 pagesIbo 5vinodh kNo ratings yet

- B15S-5 SB1086 E18 PDFDocument412 pagesB15S-5 SB1086 E18 PDFGORDNo ratings yet

- F23 Q3 - RLP Policy - 02-11-2022 - 03-05-35Document2 pagesF23 Q3 - RLP Policy - 02-11-2022 - 03-05-35huzaifa ShakirNo ratings yet

- Accessibility Design Manual - 2-Architechture - 1-RampsDocument4 pagesAccessibility Design Manual - 2-Architechture - 1-RampsSiriwat PatchimasiriNo ratings yet

- 12 Answer Key InglesDocument2 pages12 Answer Key InglesDianalid CubasNo ratings yet

- Comparison of national approaches to flexible pavement design with cold recycled asphalt basesDocument11 pagesComparison of national approaches to flexible pavement design with cold recycled asphalt basesEvert Mosqueira NdgNo ratings yet

- RC Box Culvert & U-Ditch: DescriptionDocument1 pageRC Box Culvert & U-Ditch: DescriptionAgung Mahendra STNo ratings yet

- Virtual Court - HomeDocument2 pagesVirtual Court - HomeShashwat BhageriaNo ratings yet

- A320 MEL 23 Sep 2019Document1,424 pagesA320 MEL 23 Sep 2019Ahmed Badi100% (1)

- Submarine Navigation LightsDocument1 pageSubmarine Navigation Lightsrianto wibowoNo ratings yet

- ANNUAL REPORT 2018 2019 Final Version December 2020Document75 pagesANNUAL REPORT 2018 2019 Final Version December 2020PrithviNo ratings yet

- Operation and Maintenance Manual - R934B (EN)Document192 pagesOperation and Maintenance Manual - R934B (EN)min thet100% (1)

- 28 COROLLA / AURIS OVERALL ELECTRICAL WIRING DIAGRAMDocument1 page28 COROLLA / AURIS OVERALL ELECTRICAL WIRING DIAGRAMvarenziaNo ratings yet

- GLA PresentationDocument34 pagesGLA Presentation徐东No ratings yet

- LVT Reference List - Imperial Version: (Issued June 2018)Document2 pagesLVT Reference List - Imperial Version: (Issued June 2018)apa apaapaNo ratings yet

- GIS Presentation VietnamDocument116 pagesGIS Presentation VietnamNguyen Duy KhuongNo ratings yet