Professional Documents

Culture Documents

Ac Vector Control

Uploaded by

Amrutha NadarajanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ac Vector Control

Uploaded by

Amrutha NadarajanCopyright:

Available Formats

Simulation of Indirect Vector Controlled Induction Motor Drive

Kulraj Kaur, SSSR Sarathbabu Duvvuri and Shakti Singh Electrical and Electronics Engineering Deptt. , LPU, Jallandhar, Punjab, India Electrical and Inst. Engineering Deptt., Thapar University, Patiala, Punjab, India 3 Electrical and Inst. Engineering, Thapar University, Patiala, Punjab, India E-mail: kulraj.15720@lpu.co.in, sarath.duvvuri@thapar.edu, shakti.singh@thapar.edu

2 1

Abstract

The paper emphasis a solution for induction motor speed control. In this paper we present the simulation results of vector speed control of an induction motor. In this case, indirect methods were simulated using MATLAB (SIMULINK). A squirrel cage induction motor model was used taking the reference coordinates as the rotor magnetic field. The accuracy of results is given by the precision of motor model used. This paper describes the use of the MATLAB simulation toolbox SIMULINK for dynamic modeling of vector controlled motor drive system. The dynamic and transient performance is studied through simulation and the results are presented. The principle of vector control of AC machine enables the dynamic control of AC motors, and induction motors in particular to a performance level comparable to that of a DC machine. The basic equations describing the dynamic behavior of an induction machine in rotating reference frame are designed. Based on these equations the structure of the vector controlled induction motor drive is designed. The procedure is evaluated through extensive computer simulation. The complex nature of the vector controlled scheme places a heavy computational burden on the controller. The power circuit is developed using Insulated Gate Bipolar Transistors (IGBTs). This structure generates the desired reference voltage by acting on both the amplitude and the angle of its components. The motor reaches the reference speed rapidly and without overshoot, load disturbances are rapidly rejected and variations of some of the motor parameters are fairly well dealt with.

Keywords: vector control, induction motor, scalar control, rotor

equations, reference frame

Introduction Modern industrial processes place stringent requirements on industrial drives by way of efficiency, dynamic performance, flexible operating characteristics, ease of diagnostics and communication with a central computer. These coupled with the developments in micro-electronics and power devices have led to a firm trend towards digital control of drives. There is a wide variety of applications such as machine tools, elevators; mill drives etc., where quick control over the torque of the motor is essential. Such applications are dominated by DC drives and cannot be satisfactorily operated by an induction motor drive with constant Volt-Hertz (V/f) scheme. Over the last two decades the principle of vector control of AC

machines has evolved, by means of which AC motors and induction motors in particular, can be controlled to give dynamic performance comparable to what is achievable in a separately excited DC drive. In recent decades, many investigations have been done by researchers to control ac motors similar to that of separately-excited dc machines that lead them to vector control theory [1]. Vector control made the ac drives equivalent to dc drives in the independent control of flux and torque. The major disadvantage of the indirect vector control scheme is that it is machine parameter dependant, since the model of the motor is used for flux estimation. The machine parameters are affected by variations in the temperature and the saturation levels of the machine. Any mismatch between the parameters in the motor and that instrumented in the vector controller will result in the deterioration of performance in terms of steady state error and transient oscillations of rotor flux and torque. These types of oscillations are not desired for some exact uses. Regarding the importance of sensitivity of vector control drive to the motor parameters, many investigations have been carried out in this field. In [2] the effects of rotor resistance and mutual inductance variations on output torque and rotor flux have been discussed qualitatively. In the other work the effect of the machine parameters variations on its outputs, referring to simulation results has been investigated and two techniques for rotor resistance estimation have been described [3]. Krishnan in [4] has derived approximate equations for parameter sensitivity of indirect vector control; and finally in some references, motor parameter estimation and compensation techniques and their effect on machine outputs have been described [5]-[9]. In this paper exact equations of parameter sensitivity have been derived. Using derived equations, the effect of parameter variations on the outputs of the machine can be determined. In the next sections, first the basic equations of indirect vector control are presented, and then sensitivity analysis of this type of control carried out and analytical functions for output torque and rotor flux sensitivity are derived.

Indirect vector control rotor field oriented induction machine The analysis of vector control structures highlights several possibilities to control the instantaneous values of the electromagnetic torque of the induction machine. The position of rotor flux can be estimated directly or indirectly. The

[Page No. 373]

5th IEEE International Conference on Advanced Computing & Communication Technologies [ICACCT-2011] ISBN 81-87885-03-3

indirect estimation schemes of the rotor flux position ensure a good behaviour in all speed range, and they are the common solution in practice. In the indirect method [4], it is necessary to determine the rotor time constant in order to realize effectively the orientation of the rotor flux space vector. This can be seen from the following equations [7]:

dimr + [1 jm r ]imr = is dt

(1)

Where

r =

Lr is the rotor time constant Rr Lr , Rr is the rotor inductance and resistance respectively

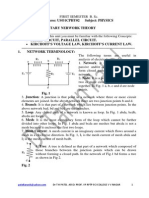

uncoupling the magnetic rotor flux from the torque, a similar behaviour as a separately excited dc motor. This is the basic principle of field orientation control (FOC). The indirect vector speed control with rotor time constant (z,) estimation is shown in figure 2 [6]. In the direct method [5], a rotor flux observer (rotor flux model) is needed in order to implement closed loop flux control such that a reference flux value is set and the estimated flux is the feedback signal. The basic equations describing the dynamic behaviour of an indution machine in a rotating reference frame aligned to the rotor flux axis [1, 2] can be given as (5) Tr (dimr ) / dt + imr = isd

d ( ) / dt = 1 = 1 + 2 = r + isq / Tr imr

Jd (r ) / dt = 2 / 3P[ Lm / (1 + )imr isq mload ]

(6) ( 7)

imr Rotor magnetization current space is - Stator current space vector

m - Electric rotor speed.

Equation (1) is determined taking into consideration the coordinates of the stator, transforming it to the rotor flux coordinates by multiplying with the unit vector e and separating the result into real and imaginary parts, we get

j

As evident in the above equations, the electromagnetic torque is directly proportional to isd component of the stator current, if

imr is kept constant. The ideal method of vector

control implementation is to control the stator current by controlling isq and isd components separately. While a current controlled inverter using hysteresis controller is easy to realise, it has the K te = 1.

dimr dt

+ imr = ids

(2) (3)

3 p Lm following disadvantages: 2 2 Lr

i d = mr = m + qs dt r imr

2. 3.

The switching frequency depends on the nature of the load. The current ripple is high. Performance at higher speeds is unsatisfactory.

Figure 1 shows the current phasor diagram in the rotatory reference frame. The synchronous speed of the stator current space vectors is:

1 = mr +

Where

d dt

(4)

is the torque angle

These disadvantages can be overcome by using a constant switching frequency Pulse Width Modulated (PWM) inverter to control the stator current by a voltage source inverter. This calls for the translation of stator voltage equations to the rotor flux reference frame. The possibility to use the squirrel cage motor in high performance control systems in which a dynamic response similar to that given by dc motor opens up new applications in industry for this type of motors. There exist two vector control methods: The direct field orientation method where field sensors or models are used to calculate the magnitude and position of the rotor flux vector subsequently orienting it in a system of rotatory orthogonal coordinates. The indirect method in which the slip angular speed is used to obtain the position of the rotor flux vector henceforth orienting it.

Figure 1 Phasor diagram representation

In steady state, the torque angle is constant i.e. and the vectors

1 =

mr

is and imr , rotate in synchronism. The components iqs and ids can be controlled independently thus

In both methods, it is necessary to determine correctly the orientation of the rotor flux vector, lack of which leads to degradation in the speed control of the motor. In the indirect method, the rotor flux obtained from an adaptable reference model was compared to a rotor flux obtained from a fixed reference model thus estimating the rotor time constant. This new value is substituted in the oriented field equations thus

[Page No. 374]

Simulation of Indirect Vector Controlled Induction Motor Drive

not disorienting the magnetic field framework that rotates at the same speed as the rotor magnetic flux. The indirect vector controller is derived from the dynamic equations of the induction machine in the synchronously rotating reference frames. The rotor equations of the induction machine are given by:

e e e Rr iqr + pqr + sl dr =0 e e e Rr idr + pdr sl qr =0

Tr =

Lr Rr

(8) (9)

The q and d axis currents are labeled as torque ( iT ) and flux ( i f ) producing components of the stator current phasor, respectively. Tr denotes the rotor time constant. Also using equations (6) to (8), we can summarize the induction machine torque equation as:

Where

e qr

Te =

(10)

e r qr e m qs

sl = s r

3 p Lm 3 p Lm (r iqs ) = r iT = K te r iT 2 2 Lr 2 2 Lr

(18)

=L i +Li

(11) (12)

Where

e e e dr = Lmids + Lr idr

K te is torque constant and is equal to: 3 p Lm K te = 2 2 Lr

(19)

In these equations, the various symbols denote the following: Rr , the referred rotor resistance per phase; Lm , the mutual inductance per phase; Lr , the stator referred rotor self inductance per phase; e

e e and iqr the referred direct and quadrature axes idr

currents, respectively; p, the differential operator; sl , slip speed in rad/sec,

s and r

e e and qr dr

are synchronous speed and electrical rotor are rotor direct and quadrature axes flux

speed both in rad/sec, and linkages ,respectively. The resultant rotor flux is assumed to be on the direct axis, to reduce the number of variables in the equations. Hence, aligning the d axis with rotor flux phasor yields:

e r = dr

Note that the torque is proportional to the product of the rotor flux linkages and the stator q axis current. This resembles the torque expression of dc motor, which is proportional to the product of the field flux linkages and the armature current. If the rotor flux linkage is kept constant, then the torque is simply proportional to the torque producing component of the stator current ( T i ), as in the case of the separately excited dc machine, where the torque is proportional to the armature current when the field current is constant. The rotor flux linkage and torque equations given in (9) and (14), respectively, complete the transformation of the induction machine into an equivalent separately excited dc machine from a control point of view.

(13) (14) (15) Figure 2 Simulation model of indirect vector controlled induction motor drive system simulation and experimentation

e qr =0 e pqr =0

Substituting equations (6) to (8) in (1) and (2) and using equations (4) and (5), the followings are obtained for i f and

sl :

1 [1 + pTr ]r Lm L i sl = m T Tr r if =

Where

e i f = ids e iT = iqs

(16) (17)

Computer modelling and simulation is widely used to study the behaviour of various complex systems. With proper simulation techniques, a significant amount of experimental cost could be saved in the prototype development. Among several simulation software packages, SIMULINK [7] is one of the most powerful techniques for simulating dynamic systems due to its graphical interface and hierarchical structure and in addition SIMULINK uses MATLAB as a Tool for mathematical purposes which further enhances the modelling process. This software permits the design of special user blocks, which can be added to the main library. Figure 3 shows the block diagram in the d-q synchronous reference frame of the reluctance synchronous machine without damper windings, by considering a two pole machine. The vector control aspects are studied using synchronously rotating

[Page No. 375]

5th IEEE International Conference on Advanced Computing & Communication Technologies [ICACCT-2011] ISBN 81-87885-03-3

reference frame. The main part of the dynamic vector controlled reluctance synchronous motor model is the two-axis motor model block which consists of electrical torque, machine voltages and mechanical equations. The (3-2) phase transformation block converts the 3 phase supply to 2-phase but the reverse transformation block converts the 2-phase rotating reference frame into 3-phase stationary equivalent The load torque T is simply represented as a constant value, though it can be represented as a variable quantity. In older to start siniulating the system, the parameters must be known They can be either calculated or measured as in this investigation.The parameters of the motor, used for simulation are as shown in Table. Table I induction machine parameters. S.no. 1 2 3 Parameters Voltage(V) Frequency (Hz) Inertia Value 220 60 0.089

700

600

500

400 speed

300

200

100

-100

0.5 time

1.5

Figure 6 Speed Response with Time Variation

80 60 40 20

c u rre n t

Figure 2 Motor specifications. Table II: Speed Controller S.no 1 2 3 Parameters Proportional gain (Kp) Integral gain (Ki) Derivative gain (Kd) Value 0.5 30 0

0 -20 -40 -60 -80

-100

0.5 time

1.5

Figure 3 Controller parameters.

Figure 7 Torque Variation with time. To validate the simulation results, the prototype of the proposed scheme is worked upon in the laboratory and tests are conducted on it. The motor is run at speed of 1425 rpm in both simulations as well as in experimentation. It can be observed that the simulation results match reasonably with the experimental results. It has been observed that the design of proposed method is flexible for making it suitable for retrofit applications.

Results and Discussions Vector controlled motor (kW) has been simulated and the dynamic responses have been obtained. . The simulation results for speed-time, torque-time and current-time are as shown in figures 3-5 respectively. Figure 3 shows the speed response for the motor with different load torque (T,) when the reference speed is 200 (rad sec) while keeping the voltagefrequency ratio (v/f) constant. Figure 6 shows the starting torque produced by the motor when the motor started from rest, and figure 5 shows the speed /torque characteristics of the drive.

80 60 40 20 0 -20 -40 -60 -80 -100

voltagevsspeed

100% 80% 60% 40% 20% 0% 1 3 5 7 9 11 13 speed voltage

c u r re n t

0.5 time

1.5

Figure 8 Experimental Speed and voltage response Figure 5 Current Responses with Time Variation

[Page No. 376]

Simulation of Indirect Vector Controlled Induction Motor Drive

The experimental set up is shown as under: [3]

[4]

[5] [6]

[7]

[8]

[9]

[10]

[11] Conclusions A design procedure has been given for various control loops of a vector controlled drive. The design procedure is verified using computer simulation. The simulation results helps to decide the hardware and software structure for the vector controlled induction motor drive. The total system includes an electronic controller for the signal processing involved in vector control, PWM inverter, motor and the load. Although the hardware and software have been dealt with in the context of a vector controlled induction motor drive, they are general purpose in nature. These can be used for control of other machine types such as wound field as well as permanent magnet synchronous motors. It is also possible to use the same hardware and software for the implementation of other control schemes like direct self- control of induction machines. The operation of 3.75 KW drive was also investigated experimentally. The simulation has been validated using the actual control of induction motor. The simulation results have been shown a reasonably close agreement with experimental results. The results demonstrate that the drive can be operated in a wide speed and load range.

[12]

[13]

[14]

[15]

[16] References [1] Blaschke F., The Principle of Field Orientation as Applied to the New Transvektor Closed-Loop Control System for Rotating -Field Machines. Siemens Rev., 39, 5, May 1972, pp. 2 17-220. [2] Blaschke F., Das Verfahren der Feldorientierung zur [17]

[18]

Regelung der Drehfeldmaschine Techn. Univ. Braunschweig, Dissertation, 1973. Hasse K., Zur Dynamik drehzahlgeregelter Antriebe mit stromrichtergespeisten Asynchron Kurzschlusslaufermaschinen.Techn. Hochsch. Darmstadt, Dissertation, 1969. Pedro Ponce & Jaime Rodriguez Rivas., Simulation del Control por Campo Orientado de Motores de Induccion. IEEE RVP 97. Bimal K. Bose Power Electronics and Variable Frequency Drives, IEEE Press Pedro Ponce & Jaime Rodriguez Rivas., Estimacion de la Constante de Tiempo del Rotor del Motor de Induccion Mediante un Modelo de Flujo Adaptable del Sistema. IEEE RVP 98, pp. 373-379, Tomo I. Murphy J.M.D. & Turnbull F.G. Power Electronic Control of A.C. Motors, Pergamon also estimates the rotor flux satisfactorily. Press, 1988. Ben-Brahim L., Gastli A., Al-Hamadi M., AutoTuning for Sensorless AC Motor Drive Systems. IEEE Int. Symp. on Ind. Electronics, Bled, Slovenia, 367372, 1999. Onea A, Horga V., Educational Software Environment for Motion Control. Proc. of the IASTED 5th Int. Conf. on Comp. and Adv. Techn. in Education, 334339, 2002. Bhim Singh, A Novel Polygon Based 18-pulse ACDC Converter for Vector Controlled Induction Motor Drive. IEEE transactions vol.22, no.2, March 2007. J. C. Basilio, and S. R. Matos, "Design of PI and PID Controllers with Transient Performance Specification," IEEE. Trans. Education, vol. 45, No.4, pp. 364-370, November 2002. M. M. M. Negm, J. M. Bakhashwain, and M. H. Shwehdi, "Speed Control of a Three-Phase Induction Motor Based on Robust Optimal Preview Control Theory," IEEE Trans. On Energy Conversion, vol. 21, No. I, pp. 77-84, March 2006. M. Bounadja, A. Mellakh i, and B. Belmadani, "A High Performance PWM Inverter Voltage-Fed Induction Machines Drive with an Alternative Strategy for Speed Control," Serbian journal of electrical engineering, vol. 4, No. I, pp. 35-49, June 2007. L. A. Zadeh,"Outline of a New Approach to the Analysis of Complex Systems and Decision Processes", IEEE Trans. Systems , Man, and Cybernetics, No.3, pp. 28-44. B. Singh, G. Bhuwaneswari and V. Garg, "Multipulse improved-power-quality AC-DC converters for vector controlled induction motor drives" , IEE Proc. Electr Power Appl., vol. 153, no. 1, pp. 88-96, Jan. 2006. T. Iwakane et al., "high performance vector controlled AC motor drives, vol.IA 23, no.5, September 1987. J. A. Santisteban, and R. M. Stephan, "Vector control methods for induction machines: an overview," IEEE Trans. On Education, vol. 44, No.2, pp. 170-174,2001. V. Garg, Power Quality Improvements at ac Mains in Variable Frequency Induction Motor Drives, Ph.D. dissertation, Indian Inst. Technol. Delhi, New Delshi, 2006.

[Page No. 377]

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shop Manual WA380-3LE SN A50001Document758 pagesShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The History of PumpsDocument8 pagesThe History of Pumpsdhanu_aquaNo ratings yet

- SYNOPSIS For Job PortalDocument6 pagesSYNOPSIS For Job PortalAkanksha Verma90% (10)

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- Supplier Deviation Request FormDocument2 pagesSupplier Deviation Request Formjainik shahNo ratings yet

- Add Info B-82974EN 01Document3 pagesAdd Info B-82974EN 01Charles JacobNo ratings yet

- Why and Wherefores of Power System BlackoutsDocument6 pagesWhy and Wherefores of Power System BlackoutsmentongNo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- Gilding Manual PDFDocument14 pagesGilding Manual PDFIva VazNo ratings yet

- GEC - Sample Resume For StudentsDocument2 pagesGEC - Sample Resume For StudentsNiketNo ratings yet

- Wind Load CompututationsDocument31 pagesWind Load Compututationskim suarezNo ratings yet

- Purushothaman.V Head-Technical 9500118390: Kind Attn: Ln. RDocument9 pagesPurushothaman.V Head-Technical 9500118390: Kind Attn: Ln. RsramkmNo ratings yet

- Preliminary Pin-out for 12 Cylinder Engine Control UnitDocument6 pagesPreliminary Pin-out for 12 Cylinder Engine Control UnitSUELENNo ratings yet

- DESIGN II - ChemTran General Reference GuideDocument332 pagesDESIGN II - ChemTran General Reference GuideDebabrata MitraNo ratings yet

- QlassicDocument31 pagesQlassicQila HusinNo ratings yet

- Pump HydraulicsDocument5 pagesPump HydraulicsSiddharth Kharat100% (1)

- 06 - 1 Cutting Tools - 2013 - LRDocument17 pages06 - 1 Cutting Tools - 2013 - LRBaggerkingNo ratings yet

- Instructions For Installation, Operating and Maintenance InstructionDocument30 pagesInstructions For Installation, Operating and Maintenance InstructionmilacronNo ratings yet

- Gas Sensors: Jiturvi Chokshi ENPM-808BDocument27 pagesGas Sensors: Jiturvi Chokshi ENPM-808Banon_44955929No ratings yet

- CNA09016 SGDocument8 pagesCNA09016 SGSatyarth SampathNo ratings yet

- GDCF 2 240 - 2nd - 01 10Document2 pagesGDCF 2 240 - 2nd - 01 10edgardomichligNo ratings yet

- Twice As Sharp Operators ManualDocument34 pagesTwice As Sharp Operators ManualLeonardo CHTZNo ratings yet

- GameBoy Programming ManualDocument298 pagesGameBoy Programming Manualdiceman2037100% (4)

- Whatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Document6 pagesWhatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Kuningan NesiaNo ratings yet

- Bridge Operational ClassificationDocument1 pageBridge Operational ClassificationFrancis DomingoNo ratings yet

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Document22 pagesEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNo ratings yet

- Us01cphy02 Unit 1 2014 THPDocument18 pagesUs01cphy02 Unit 1 2014 THPapi-264723824No ratings yet

- Dedi Kristiawan: Personal DetailDocument5 pagesDedi Kristiawan: Personal DetaildedyNo ratings yet

- Udayanandan, Notes On Tensors PDFDocument56 pagesUdayanandan, Notes On Tensors PDFhristos314No ratings yet

- Green Aviation SeminarDocument19 pagesGreen Aviation SeminarAromalSPillaiNo ratings yet