Professional Documents

Culture Documents

CableRail Install Wood

Uploaded by

pierreonthewebCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CableRail Install Wood

Uploaded by

pierreonthewebCopyright:

Available Formats

Step-by-Step Installation for Wood Frames

1

TOOL CHECKLIST

Safety Glasses Work Gloves Pencil Measuring Tape Electric Drill Drill Bits Hammer Cable Cutters or Cut-Off disk Vise-Grip Pliers 7/16'' Wrench Electric Grinder Hacksaw or Electric Reciprocating Saw Cable Lacing Needle

Mark drill hole locations on posts. Drill holes in posts. Hole diameter depends on cable size and type of fitting. See chart below.

Post Quick-C onnect Post Interme diate Po sts

To minimize cable deflection, space cables no more than 3 inches apart and have a post or vertical spacer at least every 3 feet. Also, straight runs of cable (no turns/dips) should not exceed 70 feet. Runs with corners (2 bends at most) should not exceed 40 feet. See Frame Requirements on back page.

(Wood posts only) Insert Protector Sleeves at necessary locations. Tap in until flush. Protector Sleeves prevent abrasion at angled transitions on wood posts (e.g. stair transition posts or outside faces of double corner posts).

1/8 5/16 1/4 3/8 3/16 3/8 1/4 9/16 1/4 7/16 5/16 9/16 If desired, Quick-Connect SS posts may be through drilled at 5/16 and then counter-bored with the recommended Quick-Connect SS drill to countersink the fitting.

Insert the Threaded Terminal through the Terminal end post and attach a flat washer and Snug-Grip Washer-Nut. Spin the nut 2 full turns. Strong resistance will be felt as the SnugGrip threads engage; so hold the Terminal shaft with pliers.

Threade d Term.

Cable S ize

Lace the free end of the cable through the intermediate posts and Quick-ConnectSS end post. Slide-on a flat washer and Quick-ConnectSS fitting until they rest against the face of the post.

Use Beveled Washers for stair termination posts with angled holes. Available for Threaded Terminal and Quick-Connect SS fittings.

Use a Lacing Needle if snagging becomes a problem.

10

Hold the Quick-Connect SS fitting with one hand and pull the cable tight with the other. The fitting automatically locks when you release the cable.

Tighten Snug-Grip Washer-Nuts until you cant flex the cables more than 4 inches apart using your thumb and fingers on one hand. See diagram to the left for tensioning sequence.

Saw off the excess threads as close to the Snug-Grip Washer-Nut as possible. Touch-up with electric grinder. The special Snug-Grip threads prevent the nut from loosening.

Use cable cutters or cut-off disk to trim the excess cable. Grind flush the exposed cable ends with an electric grinder.

Snap on end caps over the exposed Quick-Connect SS fittings and the Snug-Grip WasherNuts. Youre done.

Recommended cable tensioning sequence

11 9 7 5 3 1 2 4 6 8 10 12

Important Note: If using electric or pneumatic tools to tighten the Washer Nuts, spin the nuts very slowly otherwise they will heat-up causing the threads to seize.

Enviro-Magic Cleaner can be applied for lasting protection of stainless steel cable and parts.

Cables can either terminate or run through corner posts

SINGLE WOOD POST* DOUBLE WOOD POSTS

Terminating

Continuous

*Offset drill holes at least 1/2'' if you choose to have cables terminating at a single wood post.

2012 Feeney Inc. File 2012-520

Wood Frame Requirements

Railing frames need to be designed and built strong enough to support the tension of properly installed cables, which is a load in excess of 300 lbs for each cable. Here are some basic guidelines to help you properly prepare your railing frames. These guidelines apply whether you are using 1/8'', 3/16'' or 1/4'' cable (1/4'' cable not recommended for wood frames).

Minimum sizes for all corner and end posts

All other posts should be sized as required for cap rail support strength or for code

4X6 WOOD

3-1/2'' wide, 5-1/2'' thick

CONSTRUCTION CHECKLIST

Space cables no more than 3 inches apart Cap Rail:

Always include a strong, rigid cap rail that is securely fastened to all posts. Cap size is based on load strength needs and local code requirements. Set railing height per local code.

The Basic Frame Design

Spacing From Walls:

Set end posts 3 to 4 inches away from the house/wall face to allow access for attaching cable end fittings.

Cable Spacing:

Maximum 3 inches apart.

Space posts/verticals no more than 3 feet apart Observe minimum end/corner post sizes shown above Securely fasten all posts and cap rails Carefully plan all termination and corner posts for proper clearance, positioning, and maximum cable run lengths Straight runs of cable (no turns/dips) should not exceed 70 feet; runs with corner bends (2 bends at most) should not exceed 40 feet

End Posts:

Use minimum end post sizes noted above, and securely bolt or screw to joists or deck surface.

Wood Blocking

(WOOD FRAMES ONLY):

MAX. 3 FEET

Maximum Post Spacing:

Space all posts and vertical spacers (see below) a maximum of 3 feet apart to minimize any deflection that may occur if the cables are ever forced apart.

Intermediate Posts:

Size all intermediate posts as required for cap rail support strength or for code.

Double Corner Posts:

Underneath the cap rail attach minimum 1x 4 wood blocking between posts to provide additional lateral reinforcement to the posts so that they wont pull out of plumb when the cables are tensioned.

If possible use double corner posts to allow the cable to run continuously through the corners without terminating (see single corner post option below). Securely bolt or screw posts to joists or deck surface and use minimum corner post sizes noted above.

And Some Other Options

Vertical Spacers

(OPTIONAL):

I M P O RTA N T N O T E

For railings we recommend spacing the cables no more than 3 inches apart and placing posts or vertical members no more than 3 feet apart. Cable Spacing:

Maximum 3 inches apart.

Slender spacers may be used instead of some of the larger intermediate posts to achieve a more open railing design. These are non-structural members and are only intended to maintain cable spacing and minimize deflection. Examples are 2 x 2 wood strips, 1 metal tubing or 1/4 flat bar. Attach spacers to the cap rail and either the foot rail, deck surface or joists.

MAX. 3 FEET

Foot Rails

(OPTIONAL):

Single Corner Post

(OPTIONAL):

Please note that since building codes vary by state, county and city, our recommendations may not comply with code requirements in all areas. Always consult with your local building department before starting your project.

Foot rails should be spaced no more than 4 inches above the deck surface, or as required by local code, and should be sized as needed for support strength and design appearance.

When terminating on a single corner post, be sure to offset the drill holes at least 1/2'' to allow internal clearance for the cable fittings. Use minimum end post sizes noted above and securely bolt or screw to joists or deck surface.

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Install Geant4Document20 pagesInstall Geant4Nguyễn Thành CôngNo ratings yet

- ZOS 1.12 JES2 New FunctionsDocument53 pagesZOS 1.12 JES2 New FunctionsPatrícia RosaNo ratings yet

- Linha HP COMPAQ PRO 6300 SMALL FORM FACTOR-14269 - Div PDFDocument65 pagesLinha HP COMPAQ PRO 6300 SMALL FORM FACTOR-14269 - Div PDFredepiresNo ratings yet

- Electric Fuel Pump ChecklistDocument11 pagesElectric Fuel Pump ChecklistIzz Bahar100% (1)

- Instrumentationtools Com PLC Program Water Level ControlDocument7 pagesInstrumentationtools Com PLC Program Water Level ControlAlex SalesNo ratings yet

- Kahoot QuestionsDocument48 pagesKahoot QuestionsDavid Diaz RivasNo ratings yet

- Continuum Plain English ReferenceDocument710 pagesContinuum Plain English Referencedontinuum100% (3)

- PT 1 CSS8 2018Document9 pagesPT 1 CSS8 2018Gerean Abeleda-VillasNo ratings yet

- Multilog4: Flow, Pressure Fast Response Temperature Electronic Memory GaugeDocument2 pagesMultilog4: Flow, Pressure Fast Response Temperature Electronic Memory GaugePajaroloco CarpinteroNo ratings yet

- SLM 8 Quarter 4 Week 1 and 2 Parts and Functions of A Motherboard A4Document23 pagesSLM 8 Quarter 4 Week 1 and 2 Parts and Functions of A Motherboard A4Jung-woo KimNo ratings yet

- Doeacc ProspectusDocument13 pagesDoeacc ProspectuskingshukgNo ratings yet

- FileDocument114 pagesFilevaibhav shuklaNo ratings yet

- Transpose Rows To ColumnDocument34 pagesTranspose Rows To ColumnAmit Sharma100% (1)

- 6.04 Cycle Count Unit Test Plan and Test CaseDocument18 pages6.04 Cycle Count Unit Test Plan and Test Caserajesh_talwar_3No ratings yet

- Android App For Student Intimation SynopsisDocument35 pagesAndroid App For Student Intimation SynopsisNatheem SafinNo ratings yet

- IBM Cell Broadband EngineDocument81 pagesIBM Cell Broadband EngineVidya JanarthanamNo ratings yet

- OS Unit 5Document29 pagesOS Unit 5prins lNo ratings yet

- Avocent Vertiv 18.5 Rack Console - BrosuraDocument4 pagesAvocent Vertiv 18.5 Rack Console - BrosuraMarius SimonNo ratings yet

- Esquema InversorDocument18 pagesEsquema Inversorx3roNo ratings yet

- Emacs For WritersDocument23 pagesEmacs For WritersDannyAravenaRiveraNo ratings yet

- Technical Seminar: Electrocardiograph (ECG) Ecg-K Ecg- K・ECG- KDocument60 pagesTechnical Seminar: Electrocardiograph (ECG) Ecg-K Ecg- K・ECG- Kchanlal0% (1)

- DWIN 7-Inch 800x480 LCD SpecDocument3 pagesDWIN 7-Inch 800x480 LCD SpecMatheus Maia Barbosa D. OliveiraNo ratings yet

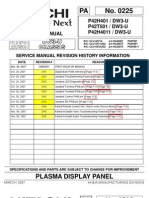

- P42H401Document124 pagesP42H401jangel332045No ratings yet

- EVS7048S-R: 48-HDD Enterprise Video StorageDocument3 pagesEVS7048S-R: 48-HDD Enterprise Video StorageDeltaz AZNo ratings yet

- 50hz Sine PWM Using Tms320f2812 DSPDocument10 pages50hz Sine PWM Using Tms320f2812 DSPsivananda11No ratings yet

- General Questions on Shift Registers and CountersDocument11 pagesGeneral Questions on Shift Registers and CountersakakaNo ratings yet

- RobotStudio 2023-1 Release NotesDocument34 pagesRobotStudio 2023-1 Release Notesduy.nguyen.2501No ratings yet

- Write your first MapReduce program in 20 minutesDocument16 pagesWrite your first MapReduce program in 20 minutesCarlos Roadhouse WienerNo ratings yet

- CARBayes STDocument37 pagesCARBayes STSiswanto HarvardNo ratings yet

- Basic Switch Configuration Guide With ExamplesDocument11 pagesBasic Switch Configuration Guide With ExamplesasalihovicNo ratings yet