Professional Documents

Culture Documents

DFSV (TIN) PasteurisationOUT

Uploaded by

ChevronelleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DFSV (TIN) PasteurisationOUT

Uploaded by

ChevronelleCopyright:

Available Formats

January 2013

Technical information note

High temperature-short time pasteurisation of milk

High temperature-short time (HTST) pasteurisation is a continuous flow process that heats the milk to a minimum temperature, holds it for the required time, followed by immediate cooling of the milk. The information in this note provides time and temperature parameters for milk heating treatment that will ensure effective pasteurisation. The information is relevant to milk with a fat content of less than 10%, with no added sweeteners (e.g. sucrose or flavoured sugar syrups) or particles (e.g. fruit). Time and temperature combinations to pasteurise products containing high fat, sugar or solids products will need to be validated separately to ensure effective time and temperature combinations for heating are achieved. References are available to assist in calculating equivalent heating treatments.1 The regulated minimum heat process for the holding time and temperature combination of milk pasteurisation in Australia is 72C for 15 seconds as defined in Standard 4.2.4, clause 15 of the Australia New Zealand Food Standards Code.2 The Food Standards Code also provides allowance for: heating using any other time and temperature combination which has equal or greater lethal effect on any pathogenic microorganisms any other process that provides an equivalent or greater lethal effect on any pathogenic microorganisms. The milk is to be immediately cooled after pasteurisation to ensure that the growth of microbial hazards is prevented or reduced. The Code of Practice for Dairy Food Safety requires that unless the milk is to be immediately further processed, the milk is to be cooled to a temperature of 5C or below, or another temperature for which it can be demonstrated will not adversely affect the microbiological safety of the product.3 Milk can be HTST processed at temperatures higher than 72C. To determine the minimum acceptable pasteurisation temperature for holding times of less than 15 seconds, the following equation can be used.1,4 T= 14885 273.1 (log10t + 41.97) Where: T = minimum temperature in C t = minimum holding time in seconds. This equation only applies to temperatures above 72C. Using this equation, alternative minimum holding times and minimum temperatures for a HTST process are listed in Table 1. Table 1 Alternative minimum HTST treatments Min. holding time (Seconds) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Min. temperature (C) 81.6 79.0 77.6 76.5 75.7 75.1 74.6 74.1 73.7 73.3 73.0 72.7 72.4 72.1 72.0

i n tegr i t y & a ssu ra n ce

Page 2

Further details on how milk can be effectively pasteurised using HTST systems is described in Guidelines for Food Safety Validation and Verification of Heat Treatment Equipment and Processes.5

Further information

Further food safety technical information is available at www.dairysafe.vic.gov.au Or contact Dairy Food Safety Victoria on (03) 9810 5900 or info@dairysafe.vic.gov.au

Key points to consider

HTST pasteurisation is a continuous flow process that heats the milk to a minimum temperature, holds it for the required time, followed by immediate cooling of the milk. The regulated minimum heat process for the holding time and temperature combination of milk pasteurisation in Australia is 72C for 15 seconds. The Food Standards Code also allows for heating using any other time and temperature combination or process which has equal or greater lethal effect on any pathogenic bacteria.

References

1. New Zealand Ministry for Primary Industries, Operational Guideline: Dairy Heat Treatments, NZFSA, Wellington, 2003. <http://www.foodsafety.govt.nz/elibrary/industry Operational_Guideline-Provides_Product.pdf> 2. Food Standards Australia New Zealand, Australia New Zealand Food Standards Code: Standard 4.2.4 clause 15 Processing of milk and dairy products, Commonwealth of Australia, Canberra, 2012. <http://www.foodstandards.gov.au/foodstandards/ foodstandardscode.cfm> 3. Dairy Food Safety Victoria. Code of Practice for Dairy Food Safety, Section 5.2.3.2: Storage and Temperature Control, DFSV, Melbourne, 2002. <http://www.dairysafe.vic.gov.au/pdf/DFSV_ CodeOfPractice2002.pdf> 4. HG Kessler, Considerations in relation to some technological and engineering aspects, International Dairy Federation Bulletin, no. 200, 1986. 5. Australian New Zealand Dairy Authorities Committee, Guidelines for Food Safety: Validation and Verification of Heat Treatment Equipment and Processes, Appendix B. Heat treatment equivalence to pasteurisation for common types of dairy produce, ANZDAC, Melbourne 2007. <http://www.dairysafe.vic.gov.au/component/docman/ doc_download/82-anzdac-heat-treatment-equipment->

This document is intended to be used as a general guide only and is not a comprehensive statement of all the relevant considerations with respect to your particular circumstances, nor does it comprise, or substitute for, legal or professional advice. DFSV does not guarantee the accuracy, reliability, currency or completeness of the information. DFSV accepts no legal liability arising from, or connected to, any reliance on this document. Dairy food product manufacturers are advised to contact the test kit distributors for updates/changes on the detection limits listed.

i n tegr i t y & a ssu ra n ce

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- New Pair of Glasses Part 1Document18 pagesNew Pair of Glasses Part 1John Ashton80% (50)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Divination Herbs TechniqueDocument3 pagesDivination Herbs Techniquetower1No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pump Life Cycle CostDocument19 pagesPump Life Cycle CostSAMEER100% (3)

- (Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Document48 pages(Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Ahmad Arafa100% (10)

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- My Bully Friends Banged My MotherDocument7 pagesMy Bully Friends Banged My MotherEntertainment and GamingNo ratings yet

- Under Her Towle Samantha 2017 Annas Archive Libgenrs Fic 2013042 PDFDocument217 pagesUnder Her Towle Samantha 2017 Annas Archive Libgenrs Fic 2013042 PDFMaithri MurthyNo ratings yet

- IPG Spring 2014 Cooking TitlesDocument122 pagesIPG Spring 2014 Cooking TitlesIndependent Publishers GroupNo ratings yet

- Sales and DistributionDocument26 pagesSales and DistributionrakesNo ratings yet

- PROBA SCRIS - FILOLOGIE ModelDocument2 pagesPROBA SCRIS - FILOLOGIE Modeljuly JNo ratings yet

- Alberta Dishwashing StandardDocument5 pagesAlberta Dishwashing StandardChevronelleNo ratings yet

- Prfmi 2Document1 pagePrfmi 2ChevronelleNo ratings yet

- 13787, C, EIS, Probes Industrial, BetaDocument2 pages13787, C, EIS, Probes Industrial, BetaChevronelleNo ratings yet

- Prfmi 1Document2 pagesPrfmi 1Jose A LopezNo ratings yet

- Instituto Superior T Ecnico Departamento de Matem Atica Sec C Aode Algebra e An AliseDocument2 pagesInstituto Superior T Ecnico Departamento de Matem Atica Sec C Aode Algebra e An AliseChevronelleNo ratings yet

- Bombas Savino Barbera - Europump CE Marking GuidelineDocument11 pagesBombas Savino Barbera - Europump CE Marking GuidelineChevronelleNo ratings yet

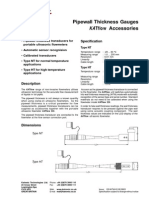

- Pipewall Thickness Gauges Accessories: KatflowDocument1 pagePipewall Thickness Gauges Accessories: KatflowChevronelleNo ratings yet

- Bombas Savino Barbera - Europump Atex GuidelineDocument22 pagesBombas Savino Barbera - Europump Atex GuidelineChevronelleNo ratings yet

- Failure Modes and Effects Analysis (FMEA)Document7 pagesFailure Modes and Effects Analysis (FMEA)DURANLEENo ratings yet

- CatalogDocument0 pagesCatalogChevronelleNo ratings yet

- Bombas Savino Barbera - Europump Atex GuidelineDocument22 pagesBombas Savino Barbera - Europump Atex GuidelineChevronelleNo ratings yet

- BETE Application Intake SheetDocument1 pageBETE Application Intake SheetChevronelleNo ratings yet

- Ultrasonic Flowmeter: Katflow 160Document4 pagesUltrasonic Flowmeter: Katflow 160ChevronelleNo ratings yet

- Accessories: Components & SizesDocument1 pageAccessories: Components & SizesChevronelleNo ratings yet

- Data Sheet Sonometer 30 Kat V10 E0698Document2 pagesData Sheet Sonometer 30 Kat V10 E0698ChevronelleNo ratings yet

- Start WashDocument0 pagesStart WashChevronelleNo ratings yet

- Data Sheet Sonometer 11 Kat V10 E0597Document2 pagesData Sheet Sonometer 11 Kat V10 E0597ChevronelleNo ratings yet

- Data Sheet Sonocontrol 20 Kat V10 E1198Document2 pagesData Sheet Sonocontrol 20 Kat V10 E1198ChevronelleNo ratings yet

- Coin Meter Work Sheet GuideDocument1 pageCoin Meter Work Sheet GuideChevronelleNo ratings yet

- Data Sheet KATflow 110 V10 E0803Document4 pagesData Sheet KATflow 110 V10 E0803Chevronelle100% (1)

- Data Sheet Sonocontrol 11 Kat V10 E0698Document2 pagesData Sheet Sonocontrol 11 Kat V10 E0698ChevronelleNo ratings yet

- Ultrasonic Flowmeter: Katflow 160Document4 pagesUltrasonic Flowmeter: Katflow 160ChevronelleNo ratings yet

- Data Sheet KATflow 140 V09 E0803Document6 pagesData Sheet KATflow 140 V09 E0803ChevronelleNo ratings yet

- Data Sheet KATflow 10 Kat V10 E0100Document2 pagesData Sheet KATflow 10 Kat V10 E0100ChevronelleNo ratings yet

- Pressure-Based Sprayer Plumbing DiagramsDocument1 pagePressure-Based Sprayer Plumbing DiagramsChevronelleNo ratings yet

- Coin Meter Work Sheet: 3 Stack Rotary SwitchDocument1 pageCoin Meter Work Sheet: 3 Stack Rotary SwitchChevronelleNo ratings yet

- Flowmeter Based Sprayer Plumbing Diagrams: Console Should Be Ground Speed OrientedDocument1 pageFlowmeter Based Sprayer Plumbing Diagrams: Console Should Be Ground Speed OrientedChevronelleNo ratings yet

- Penns Restaurant Canton22 MenuDocument2 pagesPenns Restaurant Canton22 MenunuzunetNo ratings yet

- Temas Língua Inglesa IIIDocument22 pagesTemas Língua Inglesa IIIClenagela Paes RibeiroNo ratings yet

- BovontoDocument12 pagesBovontoThoufiq Umar JNo ratings yet

- Committee MembersDocument6 pagesCommittee MembersAmman FinsNo ratings yet

- 2023 Question Bank - ENGLISHDocument16 pages2023 Question Bank - ENGLISHruyuzaki256No ratings yet

- Font - NobelDocument3 pagesFont - NobelRafa RoderoNo ratings yet

- The Metric System: ConversionsDocument4 pagesThe Metric System: ConversionsEnrique Ruiz HonoratoNo ratings yet

- Past Simple Elementary Grammar Exercises 21 04 PDFDocument4 pagesPast Simple Elementary Grammar Exercises 21 04 PDFVera AtanasovaNo ratings yet

- Terrace BBQ MenuDocument12 pagesTerrace BBQ Menuvasim88No ratings yet

- Substance Abuse StudyDocument7 pagesSubstance Abuse StudyWXYZ-TV Channel 7 DetroitNo ratings yet

- Experiment 4 Aldehydes and Ketones: Preparation and Qualitative AnalysisDocument10 pagesExperiment 4 Aldehydes and Ketones: Preparation and Qualitative AnalysisRom PeDrazaNo ratings yet

- Experiment 6: Spectrophotometric Determination of Iron in A Vitamin TabletDocument6 pagesExperiment 6: Spectrophotometric Determination of Iron in A Vitamin TabletMoisés PonceNo ratings yet

- PepsiCoâ ™s Distribution & Logistics OperationsDocument16 pagesPepsiCoâ ™s Distribution & Logistics OperationsPriyesh DoshiNo ratings yet

- Test de Evaluare IniţialăDocument4 pagesTest de Evaluare IniţialăAndreea PaulaNo ratings yet

- Adopt 5 Cycle 1 TextDocument2 pagesAdopt 5 Cycle 1 Textapi-95700766No ratings yet

- 2 - Restaurants and Bars VocabDocument10 pages2 - Restaurants and Bars VocabMaria Helena SantosNo ratings yet

- Afrocabaret Ii: Music in The Mouse House LyricsDocument19 pagesAfrocabaret Ii: Music in The Mouse House LyricsjonathanNo ratings yet

- Soal Penyisihan Kmsi 2023 B.inggris Level 1 (Type B)Document5 pagesSoal Penyisihan Kmsi 2023 B.inggris Level 1 (Type B)Ranna Iswi AnggitaNo ratings yet

- GV BrochureDocument4 pagesGV BrochureNatural Soy FoodsNo ratings yet

- APP Titan MPS Applications Notebook 010773BDocument214 pagesAPP Titan MPS Applications Notebook 010773BJeny Zuñiga100% (1)

- Clean, Well-Lighted Place, A - SparkNotesDocument13 pagesClean, Well-Lighted Place, A - SparkNotesStuSantNo ratings yet

- ASKODocument33 pagesASKOlauraNo ratings yet

- D167-Standard Test Method For Apparent and True Specific Gravity and Porosity of Lump Coke PDFDocument3 pagesD167-Standard Test Method For Apparent and True Specific Gravity and Porosity of Lump Coke PDFAyaNo ratings yet