Professional Documents

Culture Documents

Flossmanual3017 3017ss 3077

Uploaded by

Jostin Castillo HurtadoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flossmanual3017 3017ss 3077

Uploaded by

Jostin Castillo HurtadoCopyright:

Available Formats

Part No.

42131 Revised: May 2004

Floss Machine

Model #3017, #3017SS AND #3077

Instruction Manual

Econo-Floss

Floss-Maxx

Cincinnati, OH 45241-4807 USA

Floss Machines

Safety Precautions

All Models #3017, #3017SS, and #3077

Floss Machines

INTRODUCTION

Your Floss Machine warranty is described on the back page of this manual. This does NOT cover the ribbons, bands or motor bearings since, they can be damaged by the operator. After unpacking, check thoroughly for any damage which may have occurred in transit. Claims should be filed immediately with the transportation company. The warranty also does not cover damage that occurs in transit or damage caused by abuse or consequential damage due to the operation of this machine, since it is beyond our control.

ELECTRICAL REQUIREMENTS

The GOLD MEDAL Floss machine requires a 15 amp, 120 volt, 60 cycle electrical service. The power supply cord is equipped with a machine ground (the tubular prong on the male plug). For safety, always plug the machine into a grounded receptacle, which has been tested for proper polarity to insure electrical safety.

BEFORE PLUGGING IN THE MACHINE

Remove all padding and restraints. Lower the shipping bracket so the bell housing "floats" freely on the springs. Unscrew and push down the two knobs on each side of the cabinet top to lower the shipping bracket completely. Make sure the floss ribbon(s) (heating element) located inside the head assembly has not shaken out of the band during transportation. If the ribbon is out of the band, push it back into place manually, before plugging in machine.

CONTROLS AND FUNCTIONS

MAIN SWITCH - Turns motor "on" or "off" and supplies current to the heat switch. HEAT SWITCH - Turns current to the heating element (ribbon) "on" or "off." HEAT CONTROL - Increases or decreases voltage to ribbon wire heating element using a graduated dial.

3

All Models #3017, #3017SS, and #3077

Floss Machines

OPERATING INSTRUCTIONS

The easiest way to make sure you have the right texture sugar with proper flavor and colors is to use GOLD MEDAL FLOSSUGAR. FLOSSUGAR gives good, rich colors and flavors, and does not exceed the color limitations imposed by the Food and Drug Administration. FLOSSUGAR comes in sealed, plastic-coated cartons with handy pouring spouts for filling. If you use your own flavors in cotton candy, make sure they are not gum or starch based; these items burn on the ribbons.

Heat Control Setting Test

1. Follow the guidelines described on page 1 for supplying power to machine. 2. With main switch still OFF, fill floss head. Always fill it 90% full with sugar. This 90% level is necessary to obtain a balanced condition in the floss head. DO NOT OVERFILL! Excessive vibration will occur if overfilled. Before turning the power on, manually turn the head to balance out the sugar. This will eliminate excessive vibration of the head. Important: NEVER add sugar when motor is running. 3. Turn MAIN SWITCH and HEAT SWITCH "ON." 4. Turn heat control knob clockwise to maximum setting to initiate the fastest possible warm up. 5. The machine should start making floss in a few seconds. When the unit starts making floss, you must reduce the heat setting. Turn the heat control knob counter clockwise to eliminate smoking. If you operate the unit at "start up" setting, you will "carbonize" the ribbon.

6.

Once you find the ideal setting for the HEAT CONTROL, operate with the setting near this position each time.

All Models #3017, #3017SS, and #3077

Floss Machines

MAKING FLOSS

Pick a cone; if it sticks in the stack of cones, twist it off the stack. Hold an inch or two of the pointed end of the cone between two fingers and a thumb. With a light flicking action, roll cone in the web of floss building up in the pan. Lift the cone up with the ring of floss attached and rotate the cone to wrap the floss. DO NOT roll floss while the cone is inside the pan. This will pack the floss too tightly. If the floss fails to stick to the cone, pass the cone near the spinner head to pick up a starter of melted sugar. Lift the cone out of the pan and wrap the floss with a "figure eight" movement of the hand. This leaves giant pockets and makes the final product appear larger. Make sure room humidity is not too high, or product will be "heavy".

1. Grip cone as shown. 2. Break into web of

floss with the cone.

3. Wind the sugar

onto the cone.

4. Lift web of floss from the

pan and roll onto the cone.

5.

6.

7.

8.

DO NOT PUT HANDS OR OBJECTS IN ROTATING SPINNER HEAD. DO NOT FILL SPINNER HEAD WITH SUGAR WHILE IT IS ROTATING. OPERATOR SHOULD WEAR EYE PROTECTION. DO NOT PUT HANDS NEAR ROTATING SPINNER HEAD. USE FLOSS CONE TO COLLECT COTTON CANDY.

All Models #3017, #3017SS, and #3077

Floss Machines

FLOATER ADJUSTMENT

In operation, the floss will collect on the FLOSS STABILIZER (if used). If the floss collects low on the stabilizer, twist the front (leading) edge of the leather floaters down. You get more lift and the floss will collect higher. Form leather floaters as shown. This creates a lifting action to float the floss higher on the outside wall of the floss pan.

SHUT DOWN PROCEDURE

When completing operation for the day (or any prolonged period), run all the sugar out of the floss head. When empty, turn the heat to highest position for approximately one minute to clean the band by baking off remaining sugar. NEVER put water in the floss head.

CLEANING INSTRUCTIONS

Unplug the machine and wait for the floss head to cool down to room temperature. Wipe all surfaces with a clean, damp cloth.

All Models #3017, #3017SS, and #3077

Floss Machines

MAINTENANCE INSTRUCTIONS

All Models #3017, #3017SS, and #3077

Floss Machines

FLOSS BANDS AND RIBBONS

The GOLD MEDAL Floss machine is equipped with a patent pending FLOSS BAND designed to give long life, trouble-free service with little care. DO NOT scratch the band. To clean, unplug the machine and wipe with a damp cloth. GOLD MEDAL Floss Ribbons (heat elements) are made of nickel wire with insulation at the terminal point and on the lead wires. They are designed to be as reliable as the GOLD MEDAL Floss Bands: however, the ribbons must be handled carefully. DO NOT stretch the ribbon or it will not function properly.

Disassembly and Removal 1. 2.

Remove all sugar from the head of the machine before disassembling. If the unit is inoperative, carefully turn the machine on its side and shake the sugar out. Remove the four spinner cap retainer screws and spinner cap. In some cases, the sugar has caused the cap and band to stick together. Applying gentle pressure with the heel of the hand should free the parts for removal. Remove the element lead wire retaining screws with a " (9.5mm) nut driver and remove the element lead wires from the terminals in the floss head. This will allow the band and ribbons to be removed. Remove the band and ribbons. If there is excessive sugar buildup, soak the band and ribbons in hot water until the sugar dissolves. When the sugar has been removed, tap the band in the palm of your hand to loosen the ribbons for removal. Inspect, then clean or replace band and ribbons. The primary reason for ribbon replacement is carbon build up inside the ribbon wire from which the heating element is manufactured. If the ribbon is being cleaned only, an additional hot water soak may help remove some of the carbon buildup.

3. 4.

5.

All Models #3017, #3017SS, and #3077

Floss Machines

TROUBLESHOOTING

LOW PRODUCTION

1. Check for excessive carbon on the ribbons. Follow the instructions for removing and cleaning band and ribbon if needed. 2. Check heat control for correct setting. 3. Check the line voltage. A primary reason for low production and poor equipment performance is low line voltage. Have an electrician check the line voltage and add new lines for all of the various equipment you have plugged into the electric circuit if there is not enough current for the requirement listed on the equipment nameplate. 4. Check the ribbons. For machines with two ribbons, one burned out or shorted ribbon will cut production in half. 5. Foreign objects in the head assembly may short out a ribbon or cause an out-of-balance condition.

EXCESSIVE SMOKE

1. Check heat control setting. After warm up, equipment should make good floss at a reduced setting. Never let the machine operate with the heat so high it produces smoke or if you can smell burned sugar. This condition quickly fills the ribbon with carbonized sugar. 2. Check the product mixture being used. For best results, use nothing with a cornstarch base. 3. Check the band and ribbon for excessive sugar build up and remove if needed as described on page 9 of this manual.

EXCESSIVE VIBRATION

If the equipment is new, verify that shipping bolts have been loosened and packing materials were removed from the machine. When adding sugar to the floss head, always fill it 90% full to obtain a balanced condition in the head and eliminate vibration. DO NOT add sugar with motor running! Check for stretched or uneven suspension springs. Run the sugar completely out, then check for foreign objects or sugar lumps in the head assembly.

All Models #3017, #3017SS, and #3077

Floss Machines

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or the parts list. 2. When ordering, please include part number, part name, and quantity needed. 3. Please include your model name, serial number, and date of manufacture (located on the machine nameplate) with your order. 4. Address all parts orders to:

Parts Department Gold Medal Products Co. 10700 Medallion Drive Cincinnati, Ohio 45241-4807 (800) 543-0862 (513) 769-7676 Fax: (513) 769-8500 E-mail: info@gmpopcorn.com Web Page: www.gmpopcorn.com

or, place orders at:

10

All Models #3017, #3017SS, and #3077

Floss Machines

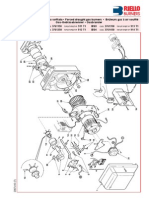

FLOSS MACHINE ASSEMBLY

11

16 19

15

17

7 1

20 18

12

6 8 2

10

11

All Models #3017, #3017SS, and #3077

Floss Machines

PARTS LIST FLOSS MACHINE CABINET ASSEMBLY

Model #3017 Model #3017SS Model #3077

Item # 1 2 3 4

Part No. 47155 22038 67069 42524 42294 42120

Part No. 47155 22038 67069 42524 42294 42120 12600 42448 42150 42567 42798 42558 42556 76026 42283 42190 42119 42125 75328 48649 42436W 42436 42138 42381 49068 55007 42140 47229 42297 48714 48590

Part No. 47155 22038 67069 42524 42294 42120 12600 42448 42150 42567 42798 42558 42556 76026 42561 42190 42119 42125 75328 48649 42436W 42436 42138 42381 49068 55007 42140 47229 42297 48714 48590 Power Supply Cord Handle (2)

Description Molded Recessed Bumper (8)

Springs (3) (Used on Marathon/A.O. Smith Motor Only. ) Springs (3) (Used On Fasco Motor Only. ) Springs (3) ( Used on Baldor/Leeson Motor Only.) Nameplate Bottom Plate Knob, Shipping Saddle (2) Shipping Bracket (2) Switch, On/Off (2) Electronic Heat Control Knob, Electronic Heat Control Strain Relief Spinner Head Complete Bell Housing Motor Mounting Plate Tinnerman Nut 1/4-20 (4) Plastic Bushing, 5/16" (7.9mm) I.D. (2) Motor 120 Volt Brush Holder Assembly (2)- (For 3/8" Wide Brushes.) Brush Holder Assembly (2)- (For 1/4" Wide Brushes.) Brush Holder Cap (4) Inspection Cover (Screws Part No. 74148) Acorn Nut 1/4-20 3/8" Wide Brushes (Measure 3/8" x 1/4") 1/4" Wide Brushes (Measure 1/4" x 1/4") Tinnerman Nut 8-32 (4)

5 6 7 8 9 10 11 12 13

12600 42448 42150 42567 42798 42558 42556 76026 42283 42190 42119 42125 75328

14 15 16 17 18 19 20

48649 42436W 42436 42138 42381 49068 55007 42140 47229 42297 48714 48590

* Surge Protector *

Motor Spacer (4)

Relay 120V DPST-NO

* Not Shown

12

All Models #3017, #3017SS, and #3077

Floss Machines

PARTS LIST FLOSS MACHINE HEAD ASSEMBLY

Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Model #3017 Model #3017SS Model #3077 Part No. Part No. Part No. 42283 42283 42561 42045 (2) 42045 (2) 42045 (4) 43166 43166 43166 42284 42284 42284 43165 43165 42517 42279 42279 42565 42162 42162 42162 20054 20054 20054 20010 20010 20010 42126 42126 42126 48041 48041 48041 42041 (2") 42041 (2") 42199 (2 3/4") 42192 42192 42192 42311 42311 42311 42127 42127 42127 74143 74143 74143 42215 42215 42215 74125 74125 74125 42305 42305 42305 42437 42437 42437 42281 42281 42281 Description Spinner Head Complete 8-32 x 1/4 HX HD Whizlock Spinner Cap, High Capacity Spinner Head Bottom Only 5 1/2" Floss Band 5" Ribbon, 120V Terminal Guard, Phenolic Bottom Washer, Phenolic Leather Floater (2) Slip Ring 3/8" Wide (2) Acorn Nut, Nylon Screw, #10-24 x 2" Screw, #8-32 x 5/8 PH PAN Set Screw, 1/4-20 x 2" Slip Ring Stud (2) Hex Nut, #10-32 (4) #10 External Tooth Washer (4) Set Screw, 1/4-20 x 3/8" Terminal Assembly (2) Upper Spinner Head Lower Spinner Head

13

All Models #3017, #3017SS, and #3077

Floss Machines

ELECTRICAL SCHEMATIC

A.O. SMITH

14

All Models #3017, #3017SS, and #3077

Floss Machines

ELECTRICAL SCHEMATIC

FASCO MOTOR

15

All Models #3017, #3017SS, and #3077

Floss Machines

ELECTRICAL SCHEMATIC

MARATHON MOTOR

16

All Models #3017, #3017SS, and #3077

Floss Machines

WARRANTY

WE WARRANT to the original purchaser the Gold Medal equipment sold by us to be free from defects in material or workmanship under normal use and service. Our obligation under this warranty shall be limited to the repair or replacement of any defective part for a period of six (6) months from the date of sale to the Original Purchaser with regard to labor and two (2) years with regard to parts and does not cover damage to the equipment caused by accident, alteration, improper use, voltage, abuse, or failure to follow instructions. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR PART, INCLUDING THE IMPLIED WARRANTY OF MERCHANTIBILITY. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. We neither assume, nor authorize any other person to assume for us, any other obligation or liability in connection with the sale of said GOLD MEDAL equipment or any part thereof. The term Original Purchaser as used in this warranty shall be deemed to mean that person, firm, association, or corporation who was billed by the GOLD MEDAL PRODUCTS COMPANY, or their authorized distributor for the equipment. THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS COMPANY AT 1-800543-0862 TO DISCUSS WITH OUR SERVICE REPRESENTATIVE THE EQUIPMENT PROBLEM, AND, IF NECESSARY, FOR INSTRUCTIONS CONCERNING THE REPAIR OR REPLACEMENT OF PARTS. NOTE: This equipment is manufactured and sold for commercial use only.

GOLD MEDAL PRODUCTS COMPANY 10700 Medallion Drive Cincinnati, Ohio 45241-4807 USA www.gmpopcorn.com Phone: 1-800-543-0862 Fax: 1-800-542-1496

17

All Models #3017, #3017SS, and #3077

You might also like

- Prearrangements for Detergent & Rinse Aid InjectionDocument84 pagesPrearrangements for Detergent & Rinse Aid InjectionJostin Castillo Hurtado50% (2)

- Zanussi WarewashingDocument0 pagesZanussi WarewashingJostin Castillo HurtadoNo ratings yet

- CMA-44 Electrical DiagramsDocument3 pagesCMA-44 Electrical DiagramsJostin Castillo Hurtado0% (1)

- Install and Operate CMA-66 DishwasherDocument26 pagesInstall and Operate CMA-66 DishwasherJostin Castillo HurtadoNo ratings yet

- WT830 & WT850 Parts ManualDocument13 pagesWT830 & WT850 Parts ManualJostin Castillo HurtadoNo ratings yet

- Manual Avavajillas Champion Dh1000engDocument80 pagesManual Avavajillas Champion Dh1000engJostin Castillo HurtadoNo ratings yet

- WT30 Parts ManualDocument9 pagesWT30 Parts ManualJostin Castillo HurtadoNo ratings yet

- Usa Dishwasher Tech. TrainingDocument68 pagesUsa Dishwasher Tech. TrainingJostin Castillo Hurtado50% (2)

- NHT60 EspecificacionDocument4 pagesNHT60 EspecificacionJostin Castillo HurtadoNo ratings yet

- CMA-44 Owners Manual Rev 2.15BDocument27 pagesCMA-44 Owners Manual Rev 2.15BJostin Castillo HurtadoNo ratings yet

- Sa 20Document9 pagesSa 20Jostin Castillo HurtadoNo ratings yet

- CMA-44 Parts Manual Rev 2.16BDocument27 pagesCMA-44 Parts Manual Rev 2.16BJostin Castillo HurtadoNo ratings yet

- Gulliver BSF Ts0059uk01Document20 pagesGulliver BSF Ts0059uk01Jostin Castillo HurtadoNo ratings yet

- Gulliver BS1FDocument3 pagesGulliver BS1FJostin Castillo HurtadoNo ratings yet

- 3-1071199A Vantage 17 CFSDocument0 pages3-1071199A Vantage 17 CFSJostin Castillo HurtadoNo ratings yet

- Sa 20Document9 pagesSa 20Jostin Castillo HurtadoNo ratings yet

- WFP14S Wfp14Sc: Unit InformationDocument2 pagesWFP14S Wfp14Sc: Unit InformationJostin Castillo HurtadoNo ratings yet

- Riello Gulliverbs1bs2bs3bs4sparepartslistDocument4 pagesRiello Gulliverbs1bs2bs3bs4sparepartslistJostin Castillo HurtadoNo ratings yet

- Waring - Flat Warranty Labor 0841 - 001Document2 pagesWaring - Flat Warranty Labor 0841 - 001Jostin Castillo HurtadoNo ratings yet

- Waring Authorized Service Application 0554 - 001Document3 pagesWaring Authorized Service Application 0554 - 001Jostin Castillo HurtadoNo ratings yet

- Floss Manual 3024Document17 pagesFloss Manual 3024Jostin Castillo HurtadoNo ratings yet

- Parts Diagram HGB146Document3 pagesParts Diagram HGB146Jostin Castillo HurtadoNo ratings yet

- Salter Brecknell 200eDocument47 pagesSalter Brecknell 200eHugo MagallanesNo ratings yet

- Cornado 2258eDocument22 pagesCornado 2258eJostin Castillo HurtadoNo ratings yet

- Flossmanual3030 3317 3030EXDocument19 pagesFlossmanual3030 3317 3030EXJostin Castillo HurtadoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Name: Mariano, Marionne M. PRDE152L Community Dentistry 2 LaboratoryDocument3 pagesName: Mariano, Marionne M. PRDE152L Community Dentistry 2 LaboratoryMarionne MarianoNo ratings yet

- Diagnosis and Treatment of Periodontal Disease ExplainedDocument53 pagesDiagnosis and Treatment of Periodontal Disease ExplainedSunny MaviNo ratings yet

- OralhealthlessonsDocument11 pagesOralhealthlessonsapi-373503406No ratings yet

- Dental Provider's Oncology Pocket Guide: Special Care For ChildrenDocument10 pagesDental Provider's Oncology Pocket Guide: Special Care For Childrenمحمد عبدالهادي إسماعيلNo ratings yet

- Lesson PlanDocument4 pagesLesson Planpsuliongrl1659No ratings yet

- Treatment Plan 3Document7 pagesTreatment Plan 3api-399400413No ratings yet

- Plaque ControlDocument11 pagesPlaque ControlFadwa El-FeituriNo ratings yet

- Brochure GC Tooth Mousse AdultsDocument6 pagesBrochure GC Tooth Mousse AdultsCikw KuzhaNo ratings yet

- Pontic and RetainersDocument36 pagesPontic and RetainersIbrahim mohamoudNo ratings yet

- 11 Going To The DentistDocument7 pages11 Going To The DentistElizabeth UrbinaNo ratings yet

- Oral Health ProgramDocument11 pagesOral Health Programapi-233877887No ratings yet

- Qtp4y0x1 4Document33 pagesQtp4y0x1 4DentalBoardNo ratings yet

- Camp Tanner Song BookDocument115 pagesCamp Tanner Song Bookapi-256941284100% (1)

- Flossing For A Healthier HeartDocument3 pagesFlossing For A Healthier HeartPaula MaquilonNo ratings yet

- Ndodontics: Rubber Dam Frames and AccesoriesDocument5 pagesNdodontics: Rubber Dam Frames and AccesoriesFaber SidabutarNo ratings yet

- Estethic DentistreDocument639 pagesEstethic DentistreAdrian Venegas Melo100% (1)

- GUBB USA grooming range categoriesDocument16 pagesGUBB USA grooming range categoriesAhsan DharNo ratings yet

- m71019 - Ingles I GuiasDocument8 pagesm71019 - Ingles I GuiasJennifer MezaNo ratings yet

- The Bed Uncovered BookDocument222 pagesThe Bed Uncovered BookBRIDGET EMENUWENo ratings yet

- Grade School Dental Health PresentationDocument4 pagesGrade School Dental Health Presentationqwerty123No ratings yet

- Knowledge, Attitude and Practices On Oral Health of Public School Children of Batangas CityDocument10 pagesKnowledge, Attitude and Practices On Oral Health of Public School Children of Batangas CityAsia Pacific Journal of Multidisciplinary ResearchNo ratings yet

- Dental Hygiene: Healthy Smiles Lesson PlanDocument3 pagesDental Hygiene: Healthy Smiles Lesson PlangggregorieNo ratings yet

- WEEK 4. Treatment of Stage I-III Periodontitis. Clinical Practice Guidelines. Supportive Periodontal CareDocument37 pagesWEEK 4. Treatment of Stage I-III Periodontitis. Clinical Practice Guidelines. Supportive Periodontal CarebbNo ratings yet

- India's Oral Healthcare Industry Growing Despite Low PenetrationDocument3 pagesIndia's Oral Healthcare Industry Growing Despite Low PenetrationSaranya KRNo ratings yet

- Adpie Paper For WeeblyDocument23 pagesAdpie Paper For Weeblyapi-366538835No ratings yet

- Case Study 2Document31 pagesCase Study 2api-548943155No ratings yet

- Plaque ConDocument31 pagesPlaque ConKruti PatelNo ratings yet

- How To Conduct A Focus GroupDocument13 pagesHow To Conduct A Focus GroupJerome JosephNo ratings yet

- Post Op InstructionsDocument5 pagesPost Op InstructionsAmar Bhochhibhoya0% (1)

- Preventive Care Checklist Form ExplanationsDocument3 pagesPreventive Care Checklist Form ExplanationsKak KfgaNo ratings yet