Professional Documents

Culture Documents

The Hidden Meaning of Water-Cement Ratio: Distance Between Cement Particles Is Fundamental

Uploaded by

mahreza189Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Hidden Meaning of Water-Cement Ratio: Distance Between Cement Particles Is Fundamental

Uploaded by

mahreza189Copyright:

Available Formats

Concrete international / MAY 2008 51

BY DALE P. BENTZ AND PIERRE-CLAUDE ATCIN

The Hidden

Meaning of Water-

Cement Ratio

Distance between cement particles is fundamental

C

oncrete is always characterized by the mass ratio of

water to cement (w/c) in the mixture. Unfortunately, for

most students and many engineers, the w/c is an abstract

number without any particular meaning. Furthermore,

this number is inversely related to concrete strength: the

lower w/c, the greater the strength.

1

People generally

understand and can remember direct relationships better

than inverse relationships.

In fact, w/c has a hidden meaning: its directly linked to

the spacing between cement particles in the cement paste.

The smaller this spacing, the faster the cement hydrates fill

in the gaps between cement particles, the stronger the links

created by these hydrates, and most importantly, the

stronger the concrete. Additionally, the smaller this spacing,

the smaller the sizes of the pores created by self-desiccation

and the larger the stresses generating autogenous shrinkage.

Specifically, the magnitude of the capillary stress

cap

created in the remaining water-filled porosity during self-

desiccation or drying is given by:

cap

=

2 cos

r

(1)

where is the surface tension of the pore solution, is

the contact angle between the pore solution and solids,

and r is the radius of the meniscus in the partially water-

filled pores.

2

Assuming a contact angle of 0 degrees and a

surface tension of 0.072 N/m (0.0049 lb/ft), Table 1

provides values of

cap

for a range of pore radii.

In this article, r will be related to the volume fraction of

water that is within a given distance of any cement particle

surface and examined as a function of both w/c and

cement particle size distribution (PSD). It should be noted

that it may also be possible to directly measure the

internal pressures developing at early ages.

3,4

We believe

the w/c law doesnt look so strange when its considered

that the ratio indirectly represents the spacing between

cement particles in a cement paste. Moreover, the

inverse relationship between w/c and strength is also

easier to understand: the closer the cement particles, the

stronger the concrete.

MATERIALS AND COMPUTATIONAL METHODS

Three cements were selected for analysis of their

water-to-cement distance characteristics at w/c of 0.35

and 0.50. They included:

Cement and Concrete Reference Laboratory (CCRL)

proficiency sample cement 152 issued in January 2004

with a Blaine fineness of 410 m

2

/kg;

5

and

Two ASTM C150

6

Type I/II cements with Blaine fine-

nesses of 310 m

2

/kg and 380 m

2

/kg, respectively, both

from the same manufacturer but made at two different

cement plants.

7

The PSDs of these three cements, found using a laser

diffraction wet method with isopropanol as the solvent,

are shown in Fig. 1. These three cements provide an

interesting contrast. The CCRL cement 152 has a higher

TABLE 1:

CAPILLARY STRESS VERSUS PORE RADIUS

Pore radius Capillary stress

10 m (0.4 mil) 0.014 MPa (2.1 psi)

5 m (0.2 mil) 0.029 MPa (4.2 psi)

2 m (0.08 mil) 0.072 MPa (10.4 psi)

1 m (0.04 mil) 0.14 MPa (21 psi)

0.5 m (0.02 mil) 0.29 MPa (42 psi)

0.2 m (0.008 mil) 0.72 MPa (104 psi)

0.1 m (0.004 mil) 1.4 MPa (210 psi)

0.05 m (0.002 mil) 2.9 MPa (420 psi)

52 MAY 2008 / Concrete international

measured Blaine surface area than the Fine Type I/II

cement. The CCRL 152, however, is actually the slightly

coarser of the two cements, as indicated by the measured

PSD curves shown in Fig. 1 where the CCRL 152 (green)

curve lies to the right of the Fine Type I/II (red) curve,

indicating a coarser PSD.

The water-to-cement distance function was determined

using a previously developed three-dimensional hard core/

soft shell (HCSS) microstructure model.

8

The model has been

used to examine interfacial transition zones in concrete,

9

the use of polymeric fibers to mitigate spalling in high-

performance concrete,

10

and the protected paste volume in

concrete with internal curing.

11

For the current application,

hard (impenetrable) spheres modeled the cement particles

and soft (penetrable) shells surrounding the cement

particles were used to assess the fraction of the total water

volume that was within a specified distance of any cement

particle surface. This assessment was performed using a

three-dimensional sampling grid, with 64 million sampling

points. In addition to the water fractional volume versus

distance function, the program also returns a single 400 x

400 element, color-coded, two-dimensional image from the

simulated three-dimensional microstructure. In the model,

only water and cement are included, as no consideration is

given to either entrained or entrapped air voids.

The distance function provides an indication of the radii

of the menisci that will be initially formed during the

processes of self-desiccation and drying, when occurring

at early ages, as indicated schematically in Fig. 2. The

largest pores will be those centered at locations within the

water-filled capillaries that are farthest from any cement

particle surfaces. These pores will be the first to empty

during self-desiccation or early-age drying. As will be

shown in the results to follow, this spacing is dependent

on both w/c and the specific PSD of the cement. While

simulations are employed in this paper to estimate the water-

to-cement distance function, analytical solutions for spherical

particles, which also require the complete cement PSD as

input, are also readily available.

12

The HCSS model has been

shown to provide equivalent results to the analytical

solution

11

and offers the added advantage of providing a

complete three-dimensional representation of the microstruc-

ture, from which two-dimensional images can be extracted.

A computational volume of 200 x 200 x 200 m (7.9 x 7.9

x 7.9 mil) was employed for the studies presented here.

Using the cement PSDs in Fig. 1 as model input, nearly

300,000 individual particles were needed to produce a w/c

of 0.35 for the Fine Type I/II cement. In the simulations

presented here, the diameters of the cement particles were

limited to be in the range of 0.5 to 100 m (0.02 to 3.9 mil).

For the three PSDs in Fig. 1, microstructures were created

for w/c values of 0.35 and 0.50, corresponding to cement

volume fractions of 0.472 and 0.385, respectively, assuming

a specific gravity of 3.2 for the cements.

RESULTS

A set of example images for the two Type I/II cements at

each of the two different w/c is provided in Fig. 3. The

brightness of the blue color representing the water provides

a relative measure of the water-to-cement distance for each

image. A more quantitative measure of this spacing is

provided by the water-to-cement distance functions shown in

Fig. 4. Clearly, both cement PSD and w/c influence the three-

dimensional spacing distance between cement particles. The

results for the three cements show that Blaine fineness is not

a particularly good indication of the distance function, as

exemplified by comparing the water-to-cement distance

function for the 410 m

2

/kg CCRL 152 cement to that for the

380 m

2

/kg Fine Type I/II cement. Instead, the complete PSD is

required to provide adequate input to the simulation or to

the analytical solution.

12

The size of the largest pores in the matrix, which will

empty first during self-desiccation, can be found by observing

Fig. 1: Measured PSDs for the three cements examined in this

study plotted as probability density functions. Blaine finenesses

are indicated in parentheses (1 m = 0.0394 mil)

Fig. 2: Simplified schematic of relationship between water-to-

cement distance function and radius of first pores emptying

during self-desiccation. x

1

, x

2

, and x

3

represent water shells of

increasing thickness surrounding each cement particle

Concrete international / MAY 2008 53

the distance values corresponding to water volume fractions

of 0.9 and greater. The results for the w/c = 0.50 cement

pastes in Fig. 4 indicate that these largest pores are on the

order of 1.2 to 2 m (0.047 to 0.079 mil) in radius. These radii

generate capillary stresses of about 0.1 MPa (14.5 psi). For

the lower w/c = 0.35 pastes (Fig. 4), these initial pore sizes will

range from about 0.9 to 1.6 m (0.035 to 0.063 mil) in radius,

generating about 25% higher capillary stresses. As the

hydrating cement pastes continue to self-desiccate or lose

additional water to drying, smaller and smaller pores will be

emptied and the capillary stresses will concurrently increase,

possibly exceeding the strength of the material and

producing cracking if local, global, or both types of restraints

are present. Once the first empty pores are produced, the

initial water-to-cement distance function (Fig. 4) will no longer

be valid, but the initial curves should still provide a relative

indication of the progression of pore radii that will become

empty during the self-desiccation or drying process because

the pores are emptied from largest to smallest. Furthermore,

these curves will all be shifted to smaller and smaller

distances as hydration progresses and fills in space

originally filled by water, generally from the original particle

surfaces outward. In addition to containing smaller water-

filled spaces between particles, a finer cement will also

generally hydrate at a faster rate than a coarser one.

7

This

accelerates self-desiccation processes and contributes to

larger capillary stresses at equal ages.

Its interesting to note from Fig. 4 that the ratio of

distances between the two Type I/II cements for any

given value of water volume fraction is less than a factor

of 2. From Eq. (1), an equivalent effect to coarsening

the cement could potentially be achieved by using a

shrinkage-reducing admixture to decrease , as these

chemicals typically reduce surface tension by up to a

factor of 2 and have been used successfully to combat

autogenous shrinkage and plastic shrinkage cracking.

13,14

In some concretes, where neither water-reducing nor high-

range water-reducing admixtures are employed, the cement

particles will have a tendency to flocculate. As shown by the

simulation images in Fig. 5,

7

flocculation will cluster the

cement particles together and thus have a tendency to

increase the water-to-cement distances, leading to larger

pores and lower capillary stresses. Its also shown in Fig. 5

that a cement paste prepared using a coarser cement

contains larger pores, resulting in smaller autogenous

stresses and strains, in agreement with experimental

measurements of these quantities.

7,15

Conversely, the finer

cement will hydrate more quickly, due to its higher exposed

surface area, and exhibit higher strengths, due to both the

smaller pores and its increased hydration rate.

7

A further

complication in concretes and mortars versus pastes will be

the likely presence of interfacial transition zones (ITZs)

9

or

other sources of microstructural inhomogeneities

16

that will

also result in larger local water-to-cement distances. For ITZs,

the extent of the ITZ region is approximately equivalent to

the median cement particle diameter.

9

NEEDS AND PROSPECTUS

As illustrated by the three cements examined in this

study, a complete PSD is critical to accurately determining

a water-to-cement distance function. Unfortunately, no

standard test method for measuring PSD of cement

currently exists. ASTM International C01.25 Subcommittee

on Fineness, however, is working on developing standard

measurement techniques for PSD.

A Web site has been established for performing these

simulations and returning results to the user at http://ciks.

cbt.nist.gov/cementspacing.html. Both a two-dimensional

Fig. 3: Two-dimensional images [200 x 200 m (7.9 x 7.9 mil)] of

(a) Fine Type I/II cement; and (b) Coarse Type I/II cement with w/c =

0.35 (left) and w/c = 0.50 (right). Cement particles are gray and

shades of blue indicate distances of water from nearest cement

particle surface, with lighter blues indicating a greater distance

Fig. 4: Water-to-cement distance function for the three cements

at w/c of 0.35 and 0.50 (1 m = 0.0394 mil)

(a)

(b)

54 MAY 2008 / Concrete international

ACI member Dale P. Bentz is a Chemical

Engineer in the Materials and Construction

Research Division, National Institute of

Standards and Technology, Gaithersburg,

MD. He is a member of ACI Committees 231,

Properties of Concrete at Early Ages; 236,

Material Science of Concrete; and 308,

Curing Concrete. His research interests

include experimental and computer

modeling studies of the microstructure and performance of

cement-based materials. He was a co-recipient of the 2007 ACI

Wason Medal for Materials Research.

image, such as those shown in Fig. 3, and a table of

the water-to-cement distance function are available

as outputs. Its hoped that the availability of such a

computational tool for determining the water-to-cement

distance function will remove some of the hidden

meaning of w/c and provide a concrete demonstration

of the linkages between w/c, cement PSD, and

particle spacing.

References

1. Abrams, D., Design of Concrete Mixtures, Bulletin No. 1,

Structural Materials Research Laboratory, 1918, 20 pp. (available at

http://www. cement.org/pdf_files/LS001.pdf).

2. Alberty, R.A., and Daniels, F., Physical Chemistry, 5th Edition,

Wiley, New York, 1980, 682 pp.

3. Radocea, A., A Study on the Mechanism of Plastic Shrinkage of

Cement-Based Materials, PhD thesis, Chalmers University of

Technology, Gothenburg, Sweden, 1992, 125 pp.

4. Amziane, S., and Ferraris, C.F., Cementitious Paste Setting

Using Rheological and Pressure Measurements, ACI Materials

Journal, V. 104, No. 2, Mar.-Apr. 2007, pp. 137-145.

5. Cement and Concrete Reference Laboratory Proficiency

Sample Program: Final Report on Portland Cement Proficiency

Samples Number 151 and Number 152, Cement and Concrete

Reference Laboratory, Gaithersburg, MD, Apr. 2004, 65 pp. (available

at http://www.ccrl.us, access verified Mar. 2008).

6. ASTM C150-07, Standard Specification for Portland Cement,

ASTM International, West Conshohocken, PA, 2007, 8 pp.

7. Bentz, D.P.; Sant, G.; and Weiss, J., Early-Age Properties of

Cement-Based Materials: I. Influence of Cement Fineness, Journal of

Materials in Civil Engineering, accepted for publication, 2007.

8. Bentz, D.P.; Garboczi, E.J.; and Snyder, K.A., A Hard Core/Soft

Shell Microstructural Model for Studying Percolation and Transport

in Three-Dimensional Composite Media, NISTIR 6265, U.S. Department

of Commerce, Jan. 1999, 51 pp.

9. Winslow, D.N.; Cohen, M.D.; Bentz, D.P.; Snyder, K.A.; and Garboczi,

E.J., Percolation and Pore Structure in Mortars and Concrete, Cement

and Concrete Research, V. 24, No. 1, Jan. 1994, pp. 25-37.

ACI Honorary Member Pierre-Claude Atcin

is Professor Emeritus of Civil Engineering at

the University of Sherbrooke. He was a

member of ACI Committees 234, Silica

Fume in Concrete, and 363, High-Strength

Concrete. He is a member of the Canadian

Academy of Engineering.

Fig. 5: Two-dimensional slice images [100 x 100 m (3.9 x 3.9 mil)]

from simulated flocculated microstructures for w/c = 0.35 cement

pastes: (a) Coarse Type I/II cement; and (b) Fine Type I/II cement.

Model cement particles are red and model gypsum particles are gray

7

10. Bentz, D.P., Fibers, Percolation, and Spalling of High

Performance Concrete, ACI Materials Journal, V. 97, No. 3, May-June

2000, pp. 351-359.

11. Bentz, D.P., and Snyder, K.A., Protected Paste Volume in

Concrete: Extension to Internal Curing Using Saturated Lightweight

Fine Aggregates, Cement and Concrete Research, V. 29, No. 11, Nov.

1999, pp. 1863-1867.

12. Lu, B., and Torquato, S., Nearest-Surface Distribution

Functions for Polydispersed Particle Systems, Physical Review A,

V. 45, No. 8, Apr. 1992, pp. 5530-5544.

13. Bentz, D.P.; Geiker, M.R.; and Hansen, K.K., Shrinkage-

Reducing Admixtures and Early Age Desiccation in Cement Pastes

and Mortars, Cement and Concrete Research, V. 31, No. 7, July 2001,

pp. 1075-1085.

14. Lura, P.; Pease, B.; Mazzotta, G.B.; Rajabipour, F.; and Weiss,

J., Influence of Shrinkage-Reducing Admixtures on Development of

Plastic Shrinkage Cracks, ACI Materials Journal, V. 104, No. 2, Mar.-

Apr. 2007, pp. 187-194.

15. Bentz, D.P.; Jensen, O.M.; Hansen, K.K.; Olesen, J.F.; Stang, H.;

and Haecker, C.J., Influence of Cement Particle-Size Distribution on

Early Age Autogenous Strains and Stresses in Cement-Based

Materials, Journal of the American Ceramic Society, V. 84, No. 1, Jan.

2001, pp. 129-135.

16. Diamond, S., and Landis, E., Microstructural Features of a

Mortar as Seen by Computed Microtomography, Materials and

Structures, V. 40, No. 9, Nov. 2007, pp. 989-993.

Received and reviewed under Institute publication policies.

(a) (b)

You might also like

- The Hidden Meaning of Water-Cement RatioDocument4 pagesThe Hidden Meaning of Water-Cement RatioShazwanShahNo ratings yet

- Future Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresDocument17 pagesFuture Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresSophia LiuNo ratings yet

- Fresh ConcreteDocument57 pagesFresh ConcreteAkshaykumar RathodNo ratings yet

- Leaflet Vandex Crystalline WaterproofingDocument12 pagesLeaflet Vandex Crystalline WaterproofingEngr. Mohammad Moinul HossainNo ratings yet

- Measure Guideline: Transitioning From Three-Coat Stucco To One-Coat Stucco With EPSDocument52 pagesMeasure Guideline: Transitioning From Three-Coat Stucco To One-Coat Stucco With EPSR. akash RajuNo ratings yet

- SM Aqueous Corrosion BookDocument61 pagesSM Aqueous Corrosion BookCassie HewittNo ratings yet

- Material List As Per BOQDocument4 pagesMaterial List As Per BOQzero coolNo ratings yet

- Ipc2022-86922 Progress of Assessment Model Development For DeterminingDocument14 pagesIpc2022-86922 Progress of Assessment Model Development For DeterminingOswaldo MontenegroNo ratings yet

- L4-QAT-087 Method Statement For CCTV & Deflection SurveyDocument10 pagesL4-QAT-087 Method Statement For CCTV & Deflection SurveyrajaNo ratings yet

- South Africa's Standard Specs for Concrete PavingDocument35 pagesSouth Africa's Standard Specs for Concrete PavingPreyolin NaidooNo ratings yet

- م ق ع 5075-1Document13 pagesم ق ع 5075-1Udai SamiNo ratings yet

- Stabilization of Soil Using Fly AshDocument6 pagesStabilization of Soil Using Fly AshIJRASETPublicationsNo ratings yet

- Particle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForDocument5 pagesParticle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForMichele PreghenellaNo ratings yet

- Determination of Water-Cement Ratio of HardenedDocument6 pagesDetermination of Water-Cement Ratio of HardenedMárcio AlvesNo ratings yet

- Aci 124 - 1994Document16 pagesAci 124 - 1994Bhavanishankar ShettyNo ratings yet

- Grab Bars and Accessories Installed in The Bathing Area: Standard Consumer Safety Specification ForDocument5 pagesGrab Bars and Accessories Installed in The Bathing Area: Standard Consumer Safety Specification Forbdr85100% (1)

- Pavement Dowel Bars-WSDoT PDFDocument2 pagesPavement Dowel Bars-WSDoT PDFSankar Cdm100% (1)

- Fundamentals of Concrete LectureDocument51 pagesFundamentals of Concrete LectureUsama ShahidNo ratings yet

- Silica Sand 2Document10 pagesSilica Sand 2Charles Dewey BandaNo ratings yet

- Data Sheet EverGuard TPO 60mil Membrane 342 PDFDocument3 pagesData Sheet EverGuard TPO 60mil Membrane 342 PDFKarina RiveraNo ratings yet

- D6432 16937Document18 pagesD6432 16937prasadNo ratings yet

- ASTM C140 Sampling and Testing Concrete Masonry Units and RelatedDocument24 pagesASTM C140 Sampling and Testing Concrete Masonry Units and RelatedMohamed MeraounaNo ratings yet

- Sp-120-2020 - Final IssueDocument7 pagesSp-120-2020 - Final IssueAhmad Khubaib AdnanNo ratings yet

- LMOSMOOSMMOAMINISNKDocument16 pagesLMOSMOOSMMOAMINISNKRafaelNo ratings yet

- Chemical Resistance of Pipeline Coatings: Standard Test Method ForDocument3 pagesChemical Resistance of Pipeline Coatings: Standard Test Method ForCamilo GuardadoNo ratings yet

- Dealer Price List: International Quality, Hi-Tech PaintsDocument15 pagesDealer Price List: International Quality, Hi-Tech PaintsElango BE100% (1)

- Adelaide Pointe Aquatic Biota Bottom Substrate ReportDocument43 pagesAdelaide Pointe Aquatic Biota Bottom Substrate ReportWZZM NewsNo ratings yet

- 5 Concrete and Reinforcement: 5.1 GeneralDocument73 pages5 Concrete and Reinforcement: 5.1 Generalahmed alyNo ratings yet

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceDocument3 pagesFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- Gestion Del AguaDocument378 pagesGestion Del Aguaedwin gabrielNo ratings yet

- Materials For Bridge Deck Waterproofing Membrane SystemsDocument2 pagesMaterials For Bridge Deck Waterproofing Membrane SystemstenNo ratings yet

- Conceptual and Visual Understanding of Hydraulic Head and Groundwater FlowDocument68 pagesConceptual and Visual Understanding of Hydraulic Head and Groundwater Flowboussalem hindNo ratings yet

- Non-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried ApplicationsDocument5 pagesNon-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried ApplicationsLito EstimosNo ratings yet

- Astm C39Document8 pagesAstm C39Raphael ReisNo ratings yet

- Silicone Rubber PropertiesDocument15 pagesSilicone Rubber PropertiesSh.nasirpurNo ratings yet

- Experimental Study of Glass Fiber Reinforced Concrete (GFRCDocument17 pagesExperimental Study of Glass Fiber Reinforced Concrete (GFRCbheshNo ratings yet

- Fiberglass Manholes: Sanitary Sewer LinesDocument10 pagesFiberglass Manholes: Sanitary Sewer LinesshagogalNo ratings yet

- Astm C121C121M-20Document1 pageAstm C121C121M-20Tensile TestingNo ratings yet

- VELOSIT-Watertight-Concrete AF Egy Army Corps of EngineersDocument33 pagesVELOSIT-Watertight-Concrete AF Egy Army Corps of EngineersHsaam HsaamNo ratings yet

- D 6412 - D 6412m - 99 Rdy0mtivrdy0mtjnDocument4 pagesD 6412 - D 6412m - 99 Rdy0mtivrdy0mtjnMarceloNo ratings yet

- Challenges and solutions in machining advanced ceramicsDocument48 pagesChallenges and solutions in machining advanced ceramicsShashank GowdaNo ratings yet

- Condition Assessment of SeawallsDocument7 pagesCondition Assessment of SeawallsJIBEESH01No ratings yet

- IndustrialDocument462 pagesIndustrialTamagnsewNegnNo ratings yet

- Avery Dennison T-11500 Retroreflective Sheeting Test ReportDocument18 pagesAvery Dennison T-11500 Retroreflective Sheeting Test ReportEws EnggNo ratings yet

- Astm D422-63 Reap 2002Document8 pagesAstm D422-63 Reap 2002Boris AguilarNo ratings yet

- WWR 500-R-10 - Manual of Standard PracticeDocument38 pagesWWR 500-R-10 - Manual of Standard PracticePeterWayNo ratings yet

- Ytl Cement - Kursb 1Document1 pageYtl Cement - Kursb 1الهادي الياس100% (1)

- Pipeline Technology Conference 2020: GRP Piping FailuresDocument14 pagesPipeline Technology Conference 2020: GRP Piping FailuresEnrico Manfrinato100% (1)

- Plastic waste as fine aggregate in self-compacting mortarsDocument7 pagesPlastic waste as fine aggregate in self-compacting mortarsNicolas PitaNo ratings yet

- List of Approved ProductsDocument82 pagesList of Approved ProductskavNo ratings yet

- Epoxy-Siloxan Avantaje - PSX 700SG Whitepaper FinalDocument4 pagesEpoxy-Siloxan Avantaje - PSX 700SG Whitepaper FinalGeorgianaNo ratings yet

- As 2205.2.1 - 2003 (R2018)Document9 pagesAs 2205.2.1 - 2003 (R2018)jesoneliteNo ratings yet

- Mass Foundations ConcreteDocument7 pagesMass Foundations ConcreteChris RetardoNo ratings yet

- As 4155.11-1993 Test Methods For General Access Floors Test For Dynamic Rolling Loads With The Tread Made FroDocument2 pagesAs 4155.11-1993 Test Methods For General Access Floors Test For Dynamic Rolling Loads With The Tread Made FroSAI Global - APACNo ratings yet

- Sikatherm® Foam 45 IN: Product Data SheetDocument4 pagesSikatherm® Foam 45 IN: Product Data SheetTarun KumarNo ratings yet

- ASTM C 1260 Expansion LimitsDocument12 pagesASTM C 1260 Expansion Limitsheisin1865No ratings yet

- LIST of APPROVED PRODUCTS For Use in Public Water Supply in The United KingdomDocument78 pagesLIST of APPROVED PRODUCTS For Use in Public Water Supply in The United Kingdomdeaji SetiawanNo ratings yet

- Primal TT 615 Rheology ModifierDocument3 pagesPrimal TT 615 Rheology ModifierNelson LozanoNo ratings yet

- 1 - The Importance of The Water-Cement and Water-Binder RatiosDocument11 pages1 - The Importance of The Water-Cement and Water-Binder RatiosPurandhar ReddiNo ratings yet

- Engineering PaperDocument15 pagesEngineering PaperDubistWhiteNo ratings yet

- 1-X Lift Liner CatalogueDocument6 pages1-X Lift Liner Cataloguemahreza189No ratings yet

- 1 - Grinding Media Catalogue PDFDocument14 pages1 - Grinding Media Catalogue PDFmahreza189No ratings yet

- Energy and PowerDocument69 pagesEnergy and PowerFahadullah Khan AfridiNo ratings yet

- High-temperature refractory brick made from magnesia-chromite raw materialsDocument1 pageHigh-temperature refractory brick made from magnesia-chromite raw materialsmahreza189No ratings yet

- 6-SD Reference ListDocument5 pages6-SD Reference Listmahreza189No ratings yet

- General InformationDocument1 pageGeneral Informationmahreza189No ratings yet

- Kiln Shell CoolingDocument4 pagesKiln Shell CoolingjmpbarrosNo ratings yet

- Kiln StabilityDocument6 pagesKiln Stabilityraobabar21No ratings yet

- 1-X Win CatalogueDocument6 pages1-X Win Cataloguemahreza189No ratings yet

- Irjet V2i151 PDFDocument9 pagesIrjet V2i151 PDFmahreza189No ratings yet

- New Developments in Monolithic ProductsDocument59 pagesNew Developments in Monolithic Productsmahreza189100% (1)

- Refractory brick composition and propertiesDocument1 pageRefractory brick composition and propertiesmahreza189No ratings yet

- General InformationDocument1 pageGeneral Informationmahreza189No ratings yet

- High-temperature refractory brick made from magnesia-chromite raw materialsDocument1 pageHigh-temperature refractory brick made from magnesia-chromite raw materialsmahreza189No ratings yet

- High-strength refractory concrete with silica glass and sol bondingDocument1 pageHigh-strength refractory concrete with silica glass and sol bondingmahreza189No ratings yet

- Didomur B52V-03 M: General InformationDocument1 pageDidomur B52V-03 M: General Informationmahreza189No ratings yet

- High-strength refractory concrete with silica glass and sol bondingDocument1 pageHigh-strength refractory concrete with silica glass and sol bondingmahreza189No ratings yet

- Divasil: General InformationDocument1 pageDivasil: General Informationmahreza189No ratings yet

- Compac Sol F53G-6: General InformationDocument1 pageCompac Sol F53G-6: General Informationmahreza189No ratings yet

- Compac Sol F53 6Document1 pageCompac Sol F53 6mahreza189No ratings yet

- Carsit Sol A10mb 15 PDFDocument1 pageCarsit Sol A10mb 15 PDFmahreza189No ratings yet

- Compac Sol B82-6: General InformationDocument1 pageCompac Sol B82-6: General Informationmahreza189No ratings yet

- Compac Shot F49S-6: General InformationDocument1 pageCompac Shot F49S-6: General Informationmahreza189No ratings yet

- Comprit A91g 6Document1 pageComprit A91g 6mahreza189No ratings yet

- Compac Shot B84 3Document1 pageCompac Shot B84 3mahreza189No ratings yet

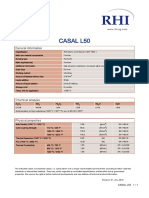

- Casal L50: General InformationDocument1 pageCasal L50: General Informationmahreza189No ratings yet

- COMPAC SOL A100-15 Refractory CastableDocument1 pageCOMPAC SOL A100-15 Refractory Castablemahreza189No ratings yet

- Compac shot F49-6 refractory concreteDocument1 pageCompac shot F49-6 refractory concretemahreza189No ratings yet

- Compac shot F49-6 refractory concreteDocument1 pageCompac shot F49-6 refractory concretemahreza189No ratings yet

- Compac Shot B84 3Document1 pageCompac Shot B84 3mahreza189No ratings yet

- RB450G Trouble ShootingDocument9 pagesRB450G Trouble Shootingjocimar1000No ratings yet

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusNo ratings yet

- Phenomenal Consciousness and Cognitive Access: ResearchDocument6 pagesPhenomenal Consciousness and Cognitive Access: ResearchAyşeNo ratings yet

- Individual Moving Range (I-MR) Charts ExplainedDocument18 pagesIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- Company Profile HighlightsDocument7 pagesCompany Profile HighlightsRaynald HendartoNo ratings yet

- Confirmation Form: Pillar Regional Conference (NCR)Document1 pageConfirmation Form: Pillar Regional Conference (NCR)Llano Multi-Purpose CooperativeNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaNurha ZizahNo ratings yet

- TCBE - Conversation Skills TemplateDocument10 pagesTCBE - Conversation Skills TemplateAryoma GoswamiNo ratings yet

- Radiograph Evaluation ChecklistDocument2 pagesRadiograph Evaluation ChecklistZulfadli Haron100% (1)

- Tomas Del Rosario College: Department: EDUCATIONDocument12 pagesTomas Del Rosario College: Department: EDUCATIONveehneeNo ratings yet

- 713 Catalog PagesDocument2 pages713 Catalog PagesJosé AcostaNo ratings yet

- Margin Philosophy For Science Assessment Studies: EstecDocument11 pagesMargin Philosophy For Science Assessment Studies: EstecFeyippNo ratings yet

- Astm A105, A105mDocument5 pagesAstm A105, A105mMike Dukas0% (1)

- U-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishDocument76 pagesU-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishszerenguettiNo ratings yet

- 1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFDocument11 pages1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFBonnie JamesNo ratings yet

- Scan & Pay Jio BillDocument22 pagesScan & Pay Jio BillsumeetNo ratings yet

- READING 4.1 - Language and The Perception of Space, Motion, and TimeDocument10 pagesREADING 4.1 - Language and The Perception of Space, Motion, and TimeBan MaiNo ratings yet

- Maths Note P1 and P3Document188 pagesMaths Note P1 and P3Afeefa SaadatNo ratings yet

- GCSE H3 02g4 02 3D TrigonometryDocument2 pagesGCSE H3 02g4 02 3D TrigonometryAndrei StanescuNo ratings yet

- Holacracy FinalDocument24 pagesHolacracy FinalShakil Reddy BhimavarapuNo ratings yet

- Hackathon Statements V1Document10 pagesHackathon Statements V1AayushNo ratings yet

- Technology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural ProductsDocument14 pagesTechnology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural Productslana del rey100% (1)

- Proposed - TIA - 1392 - NFPA - 221Document2 pagesProposed - TIA - 1392 - NFPA - 221Junior TorrejónNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- Inventory ManagementDocument60 pagesInventory Managementdrashti0% (1)

- SEM 3037E Tower Piping.Document52 pagesSEM 3037E Tower Piping.Kodali Naveen KumarNo ratings yet

- Demand Performa For Annual DemandDocument10 pagesDemand Performa For Annual DemandpushpNo ratings yet

- Calculating Molar MassDocument5 pagesCalculating Molar MassTracy LingNo ratings yet

- Influence of Oxygen in Copper - 2010Document1 pageInfluence of Oxygen in Copper - 2010brunoNo ratings yet