Professional Documents

Culture Documents

Ripple Paper

Uploaded by

Shamia SathishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ripple Paper

Uploaded by

Shamia SathishCopyright:

Available Formats

IJCSI International Journal of Computer Science Issues, Vol. 8, Issue 3, No. 2, May 2011 ISSN (Online): 1694-0814 www.IJCSI.

org

533

A New Design for Array Multiplier with Trade off in Power and Area.

Nirlakalla Ravi1, Anchula Satish2, Dr.Talari Jayachandra Prasad3 and Dr.Thota Subba Rao4

1

Research Scholar(SVU), Department of Physics,

2, 3

1, 2, 3

Department of ECE, RGMCET (Autonomous), JNT University-Anantapur, Nandyal, AP-518501, India.

Department of Physics, S.K.University, Anantapur, AP-515003, India.

Abstract

In this paper a low power and low area array multiplier with carry save adder is proposed. The proposed adder eliminates the final addition stage of the multiplier than the conventional parallel array multiplier. The conventional and proposed multiplier both are synthesized with 16-T full adder. Among Transmission Gate, Transmission Function Adder, 14-T, 16-T full adder shows energy efficiency. In the proposed 4x4 multiplier to add carry bits with out using Ripple Carry Adder (RCA) in the final stage, the carries given to the input of the next left column input. Due to this the proposed multiplier shows 56 less transistor count, then cause trade off in power and area. The proposed multiplier has shown 13.91% less power, 34.09% more speed and 59.91% less energy consumption for TSMC 0.18nm technology at a supply voltage 2.0V than the conventional multiplier. Keywords: Array Multiplier, CSA, Full Adder, Power, Delay, Area and Energy Delay Product.

A basic multiplier can be divided into three parts i) partial product generation ii) partial product addition and iii) final addition. In this paper we present a low power design methodology for parallel array multiplier using Carry Save Adder (CSA). The rest of this paper is organized as follows. Section-II presents the total power consumption in CMOS circuits with mathematical expression. Section-III explains the basic structure of an array multiplier with mathematical expression. The methodology of the proposed multiplier with conventional array multiplier is presented in Section-IV. Results of total power, worse case delay and EDP with different technologies is discussed in Section-V. Section-VI is the conclusion of the work.

2. Power Consumption in CMOS VLSI Circuits

There are three main components consumption in digital CMOS VLSI circuits. of power

1. Introduction

Multiplication is an essential arithmetic operation for common Digital Signal Processing (DSP) applications, such as filtering and fast Fourier transform (FFT). To achieve high execution speed, parallel array multipliers are widely used. But these multipliers consume more power. Power consumption has become a critical concern in todays VLSI system design. Hence the designers are needed to concentrate power efficient multipliers for the design of low-power DSP systems. In recent years, several power reduction techniques have been proposed for low-power digital design, including the reduction of supply voltage, multi threshold logic and clock speed, the use of signed magnitude arithmetic and differential data encoding, the parallelization or pipelining of operations, and the tuning of input bit-patterns to reduce switching activity [1].

2.1 Switching Power: consumed in charging and discharging of the circuit capacitances during transistor switching. 2.2 Short-Circuit Power: consumed due to short-circuit current flowing from power supply to ground during transistor switching. This power more dominates in Deep Sub Micron (DSM) technology. 2.3 Static Power: consumed due to static and leakage currents flowing while the circuit is in a stable state. The first two components are referred to as dynamic power, since power is consumed dynamically while the circuit is changing states. Dynamic power accounts for the majority of the total power consumption in digital CMOS VLSI circuits at micron technology [2], [3].

IJCSI International Journal of Computer Science Issues, Vol. 8, Issue 3, No. 2, May 2011 ISSN (Online): 1694-0814 www.IJCSI.org

534

P iVDDVswing Cload fPi VDD

I isc VDD I l

-------- (1) Where VDD power supply voltage; Vswing - voltage swing of the output which is ideally equal to VDD; Cload load capacitance at node i; f system clock frequency; Pi switching activity at node I; Iisc - short-circuit current at node; Il leakage current. As designing a low power CMOS 1-bit full adder, the emphasis will be on these areas i) to reduce the total number of transistors and the total number of parasitic capacitances in internal nodes to reduce the load capacitance. ii) to lower the switching activity to save the dynamic power consumption. iii) to remove some direct paths from power supply to ground to save the short-circuit power dissipation. iv) to balance each path in the full adder to avoid the appearance of glitches since glitches not only cause a unnecessary power dissipation hut may even lead to a fault circuit operation due to spurious transitions, especially in a low voltage operation system. v) in order to build a low-voltage full adder, all the nodes in the circuit must possess full voltage swing. vi) to build the low-voltage full adder design because the power supply voltage is the crucial factor in reducing power dissipation. In Nanometer scale leakage power dominates the dynamic power and static power due to hot electrons. So the concentration is on to trade off power in parallel multipliers.

In the given example, we have 4-bit multiplier and 4-bit multiplicand. By using the above equation (2) we can generate 4-rows of partial products as shown in the Figure (1).The hardware required for the generation of these partial products is AND gates. Using any adder like Carry Save Adder (CSA), Carry Propagate Adder (CPA) we can add the partial products. In this method we are following Carry Save Addition to add the products. X3 Y3 X1Y3 X2Y2 X3Y1 P4 X2 Y2 X0Y3 X1Y2 X2Y1 X3Y0 P3 X1 Y1 X0Y2 X1Y1 X2Y0 P2 X0 Y0 X0Y1 X1Y0 X 0Y 0

X3Y3

X2Y3 X3Y2

P7 -P6 P5

P1

P0

Fig.1. Multiplier Architecture.

4. Methodology

In the Carry Save Addition method, the first row will be either Half-Adders or Full-Adders. If the first row of the partial products is implemented with Full-Adders, Cin will be considered 0. Then the carries of each FullAdder can be diagonally forwarded to the next row of the adder. The resulting multiplier is said to be Carry Save Multiplier, because the carry bits are not immediately added, but rather are saved for the next stage. In the design if the full adders have two input data the third input is considered as zero. In the final stage, carries and sums are merged in a fast carry-propagate (e.g. ripple carry or carrylook ahead) adder stage [5]. This is the conventional array multiplier with CSA as shown in Figure (2). In the proposed method, we implement all the partial product rows of the multiplier as same as that of the conventional adder (explained above).The final adder which is used to add carries and sums of the multiplier is removed in this method. Then the carries of the multiplier at the final stage is carefully added to the inputs of the multiplier as shown in the Figure (3). The carry of the fourth column of the multiplier is given to the input of the fifth column instead of zero. Then the carry of the fifth column is forwarded to the input of the sixth column so on. In this multiplier the carry of the seventh column of the adder is not neglected, it is considered as Most Significant Bit (MSB) of the multiplier. Due to elimination of four full adders in the final stage power and area can be trade off in the proposed design than that of the conventional array multiplier.

3. Parallel Multiplier

Consider the multiplication of two unsigned n-bit numbers, where X = xn-1, xn-2, x0 is the multiplicand and Y = yn-1,yn-2, ,y0 is the multiplier. The product of these two bits can be written as [4]

P

i 1

n 1

X Y 2

i j 1 j

n 1

(i j )

----------- (2)

X

Y

X 2

Y 2

j 1 j

n 1

i 1 n 1

----- Multiplicand

j

------ Multiplier

IJCSI International Journal of Computer Science Issues, Vol. 8, Issue 3, No. 2, May 2011 ISSN (Online): 1694-0814 www.IJCSI.org

535

Y3 F 0

0 X0

Y2 0 F

Y1 X0 F

Y0 0 X0

X0 F

X1Y3

X1Y2

X1Y1

X1Y0

F X3Y3 0 aF 3b2 X3Y3 0 F

X2Y2 F

X2Y1

X2Y0

X3Y2 a3F

X3Y1 F

X3Y0

0 P3 P2 P1 P0

P7

P6

P5

P4

Fig. 2. Conventional Array Multiplier with CSA.

Y0 F

0 X0

Y0 F

0 X0 F

Y0

0 X0

Y0 F

0 X0

F X1Y3 F X2Y3 F X2Y2

F X1Y2 F X 2Y 1

F X1Y1 F X2Y0

F X1Y0

F X3Y3

F X3Y2

F X3Y1

F X3Y0

P7 P6

P5

P4

P3

P2

P1

P0

Fig .3. Proposed Array Multiplier with CSA.

5. Results and Discussions

IJCSI International Journal of Computer Science Issues, Vol. 8, Issue 3, No. 2, May 2011 ISSN (Online): 1694-0814 www.IJCSI.org

536

TotalPower

10 10

TotalPower (Watts)

To show the proposed design very good performance, the design is synthesized with 16-Transistor Full Adder design. Among the Transmission Gate CMOS, Transmission Function Full Adder (TFA), 14-T adders this shows good efficiency in terms of power and delay [6]. The results of the 16-T full adder are as shown in the Table. (1).

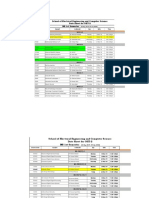

Table.1. Power, Delay and Energy Delay Product of the 16-T Adder.

0 0.0004

Conventional

8 0.0003

Proposed

6 0.0002 4

Technology at (250C) 0.18um 90nm 65nm

16-T Full-Total Power 8.88E-06 1.36E-05 6.15E-06

16-T FullProp-Delay 5.08E-10 5.07E-10 5.06E-10

EDP (JS)

0.0001 2

2.29161E-24 3.49587E-24 1.57462E-24

0.0000

0.18um

0.18um

90nm

90nm

65nm

65nm

Technology

Power, Propagation delays and Energy consumptions are calculated for the conventional array and the proposed multiplier with different technologies using H-Spice to study the performance of the both multipliers shown in Table (2).

Fig. 4. Total Power Comparison.

PropDelay

10 10

Conventional

5.1 Total Power: The total power of these two

multipliers is calculated at a simulation temperature of 250C as shown in Figure 4. The proposed multiplier has shown the power improvement than the conventional for 180nm - 13.91 %, 90nm 13.71% and 65nm 18.59%. In the DSM technology the proposed multiplier show good performance due to less transistor count to avoid more leakage current.

1.20E-009

PropDelay (Sec)

Proposed

4 6.00E-010

0.00E+000

0.18um

0 0.18um

90nm

90nm

65nm

65nm

5.2 Propagation Delay:In the propagation delays of the

two multipliers, the proposed has shown more efficient than the convention shown in Figure 5. The propagation delay is calculated for all inputs and outputs to find the worst case delay.

Technology

Fig. 5. Delay Graph.

EDP

10 10

5.3 Energy Delay Product: The proposed multiplier

shows more efficiency in Energy Delay Product is as shown in Figure 6. It has shown for 180nm 59.91%, 90nm 9.35% and 65nm 29.21% improvement in the energy.

6.00E-022

Conventional

8

EDP (J-S)

4.00E-022

Proposed

2.00E-022

5.4 Transistor count: The proposed multiplier has 56

less transistors than that of the conventional multiplier. These less count can trade off power consumption and area.

0.00E+000

0.18um

0 0.18um

90nm

90nm

65nm

65nm

Technology

Fig. 6. EDP Graph.

IJCSI International Journal of Computer Science Issues, Vol. 8, Issue 3, No. 2, May 2011 ISSN (Online): 1694-0814 www.IJCSI.org

537

Table. 2. Power, Delay and Energy Delay Product of the Conventional and Proposed Multiplier.

Technology

Array Multiplier type

Total Power (Watts)

Total Power Percentage (%) 13.91 13.71 18.59

Prop-Delay (Sec)

PropDelay Percentage (%) 34.09 1.12 0.52

0.18um 90nm 65nm

Conventional Proposed Conventional Proposed Conventional Proposed

2.4628E-04 2.1200E-04 3.8089E-04 3.2864E-04 2.0514E-04 1.6699E-04

1.6490E-09 1.0867E-09 8.3947E-10 8.3000E-10 1.1040E-09 1.0982E-09

Energy Delay Product (EDP) JS 6.6968E-22 2.6841E-22 2.5002E-22 2.2664E-22 2.8451E-22 2.0139E-22

EDP No.of Transistors Percentage (%) 59.91 9.35 29.21 376 (Conventioal) 320 (Proposed)

6. Conclusion

In this paper we have proposed a new design for low power, high performance and low area based array multiplier with out RCA. It shows the same functionality than the conventional adder. For higher bit multiplication it shows better power and area saving. For example, in the proposed 4x4 multiplier it saves 56 MOS transistors. For TSMC 0.18um it saves 13.91% of total power, 34.09% of more speed and 59.91% less energy consumption. To study the performance of the multiplier, it is synthesized with different technologies.

N.Ravi holds B.Sc degree in electronics at Osmania Degree College-Kurnool, S.K. University, Anantapur, Andhra PradeshIndia in 1998. He obtained Masters Degree in Physics (Solid State Physics) at S.K.University, Anantapur, AP- India in 2001. He is pursuing Ph.D in VLSI Design from Sri Venkateswara University, Tirupati, AP. He is presently working at Rajeev Gandhi memorial College of Engg & Technology, Nandyal, Andhra Pradesh-India as

An Assistant professor & Head in the department of Physics. His area of interest includes VLSI, Solid State Physics and Nanotechnology. Dr.T.Jayachandra Prasad is a Principal and Professor of ECE at Rajeev Gandhi Memorial College of Engg & Technology, Nandyal, Andhra Padesh-India Dr.T.Subba Rao is a Professor in the department of Physics, Sri Krishnadevaraya University, Anantapur, Andhra Pradesh-India.

References

[1]

A. P. ChandrakashanandR. Brodcrsen, Low Power Digital CMOS Design, Kluwer. Academic Publisher, 1996.

[2] S. Devadas, S. Malik, A survey of optimization techniques targeting low power VLSI circuits, in Proc. 32nd ACM/IEEE Design Automation Conf., 1995, pp. 242247. [3] A. P. Chandrakasan, S. Sheng, R. W. Bordersen, Lowpower CMOS digital design, IEEE J. Solid-State Circuits, vol. 27, pp. 473484, Apr. 1992. [4] Jan M. Rabaey, Anantha Chandrakasan and Borivoje Nikolic, Digital Integrated Circuits- Adesign Perspective ,second edition,PHI-2004

[5] M.-C. Wen, S.-J. Wang and Y.-N. Lin, Low-power parallel multiplier with column bypassing, Electronics Letters 12th May 2005 Vol. 41 No. 10. [6] Jin-Fa Lin, Yin-Tsung Hwang, Member, IEEE, Ming-Hwa Sheu, Member, IEEE, and Cheng-Che Ho, A Novel HighSpeed and Energy Efficient 10-Transistor Full Adder Design, IEEE Tran on Circuits and SystemsI: Regular Papers, Vol. 54, no. 5, May 2007, pp. 1050-1059.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 6.5.3-IQAC Minutes of The Meeting-1Document37 pages6.5.3-IQAC Minutes of The Meeting-1Shamia SathishNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AGENDADocument2 pagesAGENDAShamia SathishNo ratings yet

- DownloadDocument1 pageDownloadShamia SathishNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BrochureDocument1 pageBrochureShamia SathishNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 6.5.3-IQAC Minutes of The Meeting-2Document37 pages6.5.3-IQAC Minutes of The Meeting-2Shamia SathishNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 17.08.2022 - Industrial Seminar - Attendance SheetDocument2 pages17.08.2022 - Industrial Seminar - Attendance SheetShamia SathishNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Consolidated NewDocument122 pagesConsolidated NewShamia SathishNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Letter of IntentDocument1 pageLetter of IntentShamia SathishNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Vote of Thanks Speech For Nirmalites DayDocument1 pageVote of Thanks Speech For Nirmalites DayShamia SathishNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- V.S.B. College of Engineering Technical Campus, CoimbatoreDocument1 pageV.S.B. College of Engineering Technical Campus, CoimbatoreShamia SathishNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- V.S.B. College of Engineering Technical Campus, CoimbatoreDocument3 pagesV.S.B. College of Engineering Technical Campus, CoimbatoreShamia SathishNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- AM ProblemsDocument13 pagesAM Problemspad pestNo ratings yet

- Name List - Iv EceDocument2 pagesName List - Iv EceShamia SathishNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Thread by @JoelGiftson17 On Thread Reader App - Thread Reader AppDocument4 pagesThread by @JoelGiftson17 On Thread Reader App - Thread Reader AppShamia SathishNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Ec8552 Computer Architecture and OrganizationDocument67 pagesEc8552 Computer Architecture and OrganizationShamia SathishNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- S.sheryl LessonDocument1 pageS.sheryl LessonShamia SathishNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- ChatLog Webinar On AI - Cyber Security 2020 - 06 - 27 11 - 59Document6 pagesChatLog Webinar On AI - Cyber Security 2020 - 06 - 27 11 - 59Shamia SathishNo ratings yet

- 01.B.E.civil Pages 6 9Document4 pages01.B.E.civil Pages 6 9Shamia SathishNo ratings yet

- AICTE SubjectDocument1 pageAICTE SubjectShamia SathishNo ratings yet

- 01.B.E.civil Pages 6 9Document4 pages01.B.E.civil Pages 6 9Shamia SathishNo ratings yet

- Ec8351 Electronic Circuits I MCQDocument72 pagesEc8351 Electronic Circuits I MCQShamia SathishNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ec8791 Embedded and Real Time SystemsDocument41 pagesEc8791 Embedded and Real Time Systemsthirsh ragavNo ratings yet

- Ec8551 Communication NetworksDocument53 pagesEc8551 Communication NetworksShamia SathishNo ratings yet

- AICTE SubjectDocument1 pageAICTE SubjectShamia SathishNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- DPSD, B-Sec Unit Test II-,Srikamatchi.mDocument12 pagesDPSD, B-Sec Unit Test II-,Srikamatchi.mShamia SathishNo ratings yet

- Assignment For EdcDocument2 pagesAssignment For EdcShamia SathishNo ratings yet

- Erts Internal Retest 1Document3 pagesErts Internal Retest 1Shamia SathishNo ratings yet

- Library Books I Have ReadDocument2 pagesLibrary Books I Have ReadShamia SathishNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- God Makes PreparationsDocument16 pagesGod Makes PreparationsShamia SathishNo ratings yet

- List of Funding AgenciesDocument1 pageList of Funding AgenciesShamia Sathish100% (1)

- Eaton Fireman Switch Safety First Sol30x Flyer fl003001 en UsDocument5 pagesEaton Fireman Switch Safety First Sol30x Flyer fl003001 en UsRadu IonescuNo ratings yet

- Multimeter Parts and FunctionsDocument3 pagesMultimeter Parts and FunctionsDavid Dela CruzNo ratings yet

- Storz Endoflator Insufflation Unit - Service ManualDocument102 pagesStorz Endoflator Insufflation Unit - Service ManualAnonymous 58LGc3No ratings yet

- Arria 10 HandbookDocument334 pagesArria 10 HandbookIswear WangNo ratings yet

- MX25L8006E, 3V, 8Mb, v1.2Document53 pagesMX25L8006E, 3V, 8Mb, v1.2Md. Nahid AlamNo ratings yet

- How PLC Reads The Data From Field TransmittersDocument5 pagesHow PLC Reads The Data From Field TransmitterslampfievNo ratings yet

- HTS-32 Panasonic Feature - ManualDocument80 pagesHTS-32 Panasonic Feature - ManualWaldirNo ratings yet

- Lab 08Document17 pagesLab 08salloum18No ratings yet

- Excel Document Tutorial For BeginnersDocument2 pagesExcel Document Tutorial For BeginnersSehar KhanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TAL Dub II User Manual ENDocument6 pagesTAL Dub II User Manual ENjohnnyNo ratings yet

- System Module FSMFDocument23 pagesSystem Module FSMFjirox123No ratings yet

- Sinclair I and Um Controller Ccm30 enDocument30 pagesSinclair I and Um Controller Ccm30 enNecko VejzaNo ratings yet

- Nanotechnology in ElectronicsDocument28 pagesNanotechnology in ElectronicsAbhishek RajNo ratings yet

- Getting Started Wp-8xx7Document199 pagesGetting Started Wp-8xx7Pedro BortotNo ratings yet

- AN15932AADocument1 pageAN15932AARicardo Banegas ValleNo ratings yet

- Radio Link Failure EventDocument1 pageRadio Link Failure EventriadelectroNo ratings yet

- Verizon Lte Network Extender User Guide July2020Document38 pagesVerizon Lte Network Extender User Guide July2020Timeko PerezNo ratings yet

- Bti TFT Aem v2 Gauge 1 0Document20 pagesBti TFT Aem v2 Gauge 1 0xe tevNo ratings yet

- Inspection and Cleaning Procedures For Fiber Optic ConnectionsDocument23 pagesInspection and Cleaning Procedures For Fiber Optic Connectionsnaveed4k143No ratings yet

- Matrix 2000 Standalone Inverter C A4size PDFDocument2 pagesMatrix 2000 Standalone Inverter C A4size PDFYoYoRamezNo ratings yet

- Rf/Rfs & RL/RLS: Class HDocument2 pagesRf/Rfs & RL/RLS: Class HFrank SemenukNo ratings yet

- M29F400T M29F400B: 4 Mbit (512Kb x8 or 256Kb x16, Boot Block) Single Supply Flash MemoryDocument34 pagesM29F400T M29F400B: 4 Mbit (512Kb x8 or 256Kb x16, Boot Block) Single Supply Flash MemorykokotnoNo ratings yet

- Volume51 Number4Document60 pagesVolume51 Number4torinomgNo ratings yet

- TelcoBriges SS7 Spec SheetDocument2 pagesTelcoBriges SS7 Spec Sheetapi-3833851No ratings yet

- RC51, RC52 & RC53 Signal Conditioners: Installation, Operation and Maintenance ManualDocument44 pagesRC51, RC52 & RC53 Signal Conditioners: Installation, Operation and Maintenance ManualArmando AguilarNo ratings yet

- Philips Fw-c1 Fw-c10 SM EuropeDocument87 pagesPhilips Fw-c1 Fw-c10 SM Europenullvoice84No ratings yet

- Block Diagram of Digital Computer:: MicroprocessorDocument25 pagesBlock Diagram of Digital Computer:: MicroprocessorRobotrixNo ratings yet

- MSK Minimum-Shift KeyingDocument2 pagesMSK Minimum-Shift KeyingfiraszekiNo ratings yet

- TQM250NB06CR: Taiwan SemiconductorDocument7 pagesTQM250NB06CR: Taiwan Semiconductorn tanevarNo ratings yet

- Instruction Manual Universal Fieldbus-Gateway Unigate CM - ProfibusDocument62 pagesInstruction Manual Universal Fieldbus-Gateway Unigate CM - ProfibusFakhri GhrairiNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- Cyber War: The Next Threat to National Security and What to Do About ItFrom EverandCyber War: The Next Threat to National Security and What to Do About ItRating: 3.5 out of 5 stars3.5/5 (66)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (55)