Professional Documents

Culture Documents

1655213-2 2

Uploaded by

Yafiz MalikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1655213-2 2

Uploaded by

Yafiz MalikCopyright:

Available Formats

1655213-2.

2 Page 1 (2)

Exhaust Gas System

B 16 00 0 General

Internal Exhaust Gas System

From the exhaust valves, the gas is led to the exhaust gas receiver where the fluctuating pressure from the individual cylinders is equalized and the total volume of gas led further on to the turbocharger, at a constant pressure. After the turbocharger, the gas is led to the exhaust pipe system. The exhaust gas receiver is cast sections, one for each cylinder, connected to each other, by means of compensators, to prevent excessive stress due to heat expansion. After each cylinder thermosensor for reading the exhaust gas temperature is fitted. The value is indicated by means of the MEG-module (Monitor exhaust Gas Temperature). To avoid excessive thermal loss and to ensure a reasonably low surface temperature the exhaust gas receiver is insulated.

The insulation should be shielded by a thin plating, and should comply with the requirements of the classification society and/or the local authorities.

Exhaust Pipe Dimensions

It should be noted that concerning the maximum exhaust gas velocity the pipe dimension after the expansion bellow should be increased for some of the engines. The wall thickness of the external exhaust pipe should be min. 3 mm.

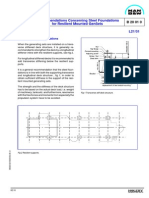

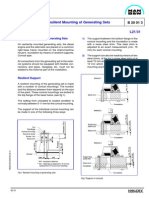

Exhaust Pipe Mounting

When the exhaust piping is mounted, the radiation of noise and heat must be taken into consideration. Because of thermal fluctuations in the exhaust pipe, it is necessary to use flexible as well as rigid suspension points. In order to compensate for thermal expansion in the longitudinal direction, expansion bellows must be inserted. The expansion bellows should preferably be placed at the rigid suspension points. Note: The exhaust pipe must not exert any force against the gas outlet on the engine. One sturdy fixed-point support must be provided for the expansion bellows on the turbocharger. It should be positioned, immediately above the expansion bellow in order to prevent the transmission of forces, resulting from the weight, thermal expansion or lateral displacement of the exhaust piping, to the turbocharger. The exhaust piping should be mounted with a slope towards the gas outlet on the engine. It is recommended to have drain facilities in order to be able to remove condensate or rainwater.

External Exhaust Gas System

The exhaust back-pressure should be kept as low as possible. It is therefore of the utmost importance that the exhaust piping is made as short as possible and with few and soft bends. Long, curved, and narrow exhaust pipes result in higher back-pressure which will affect the engine combustion. Exhaust back-pressure is a loss of energy and will cause higher fuel consumption. The exhaust back-pressure should not exceed 25 mbar at MCR. An exhaust gas velocity through the pipe of maximum 35 m/sec is often suitable, but depends on the actual piping. Holeby will be pleased to assist in making a calculation of the exhaust back-pressure. The gas outlet of turbocharger, the expansion bellows, the exhaust pipe, and silencer, (in case of silencer with spark arrestor care must be taken that the cleaning parts are accessible), must be insulated with a suitable material.

08028-0D\H5250\94.08.12

01.43 - NG

B 16 00 0 General

Exhaust Gas System

1655213-2.2 Page 2 (2)

Position of Gas Outlet on Turbocharger

B 16 02 0 shows turning alternatives positions of the exhaust gas outlet. Before dispatch of the engine from Holeby exhaust gas outlet will be turned to the wanted position. The turbocharger is, as standard, mounted in the front end.

Expansion Bellow

The expansion bellow, which is supplied separately, must be mounted directly on the exhaust gas outlet, see also E 16 01 1-2.

Exhaust Silencer

The position of the silencer in the exhaust gas piping is not decisive for the silencing effect. It would be useful, however, to fit the silencer as high as possible to reduce fouling. The necessary silencing depends on the loudness of the exhaust sound and the discharge from the gas outlet to the bridge wing. The exhaust silencer, see E 16 04 2-3-5-6 is supplied loose with counterflange, gaskets and bolts.

Exhaust Gas Boiler

To utilize the thermal energy from the exhaust, an exhaust gas boiler producing steam or hot water can be installed. Each engine should have a separate exhaust gas boiler or, alternatively, a common boiler with separate gas ducts. Concerning exhaust gas quantities and temperature, see list of capacities D 10 05 0, and engine performance D 10 10 0. The discharge temperature from the exhaust gas boiler should not be lower than 180 C (in order to avoid sulphuric acid formation in the funnel). The exhaust gas boilers should be installed with bypass entering in function at low load operation. The back-pressure over the boiler must be included in the back-pressure calculation.

01.43 - NG

08028-0D\H5250\94.08.12

You might also like

- Windlass & Mooring Winch Brake Holding Test LogDocument1 pageWindlass & Mooring Winch Brake Holding Test LogYafiz MalikNo ratings yet

- Life Raft Check List: Company Forms and Check ListsDocument1 pageLife Raft Check List: Company Forms and Check ListsYafiz MalikNo ratings yet

- Mooring Winch Test: Company Forms and Check ListsDocument1 pageMooring Winch Test: Company Forms and Check ListsYafiz MalikNo ratings yet

- Fire Extinguisher Check List: Company Forms and Check ListsDocument3 pagesFire Extinguisher Check List: Company Forms and Check ListsYafiz MalikNo ratings yet

- Life Boat Equipment Check List: Company Forms and Check ListsDocument2 pagesLife Boat Equipment Check List: Company Forms and Check ListsYafiz MalikNo ratings yet

- Cargo Venting System Inspection Log: Device Name & Number Inspected Cleaned Lubricated Replaced Screens InitialsDocument1 pageCargo Venting System Inspection Log: Device Name & Number Inspected Cleaned Lubricated Replaced Screens InitialsYafiz MalikNo ratings yet

- Life Jacket Check List: Company Forms and Check ListsDocument1 pageLife Jacket Check List: Company Forms and Check ListsYafiz MalikNo ratings yet

- Designation of Cylinders I 00 15 0: 1607568-0.2 Page 1Document1 pageDesignation of Cylinders I 00 15 0: 1607568-0.2 Page 1Yafiz MalikNo ratings yet

- Fire Hose Station Check List: Company Forms and Check ListsDocument1 pageFire Hose Station Check List: Company Forms and Check ListsYafiz MalikNo ratings yet

- Basic Symbols For Piping I 00 25 0Document3 pagesBasic Symbols For Piping I 00 25 0Yafiz MalikNo ratings yet

- Lifting Instruction: Lifting of Complete Generating SetsDocument1 pageLifting Instruction: Lifting of Complete Generating SetsYafiz MalikNo ratings yet

- Standard Spare Parts: For Guidance Demands Extent According To The Requirements ofDocument2 pagesStandard Spare Parts: For Guidance Demands Extent According To The Requirements ofYafiz MalikNo ratings yet

- Mooring System Check List Steam: Company Forms and Check ListsDocument1 pageMooring System Check List Steam: Company Forms and Check ListsYafiz MalikNo ratings yet

- Loss / Contamination of Cargo Check List: Company Forms and Check ListsDocument1 pageLoss / Contamination of Cargo Check List: Company Forms and Check ListsYafiz MalikNo ratings yet

- Preservation of Spare Parts and ToolsDocument1 pagePreservation of Spare Parts and ToolsYafiz MalikNo ratings yet

- Engine PerformanceDocument1 pageEngine PerformanceYafiz MalikNo ratings yet

- Exhaust Gas Emission: 1655210-7.1 Page 1Document1 pageExhaust Gas Emission: 1655210-7.1 Page 1Yafiz MalikNo ratings yet

- List of Capacities: Engine Driven PumpsDocument1 pageList of Capacities: Engine Driven PumpsYafiz MalikNo ratings yet

- Preservation of Diesel Engine Before DispatchDocument1 pagePreservation of Diesel Engine Before DispatchYafiz MalikNo ratings yet

- Heat Balance: Load (%)Document1 pageHeat Balance: Load (%)Yafiz MalikNo ratings yet

- Fitting Instructions For Resilient Mounting of Gensets L16/24 L21/31Document4 pagesFitting Instructions For Resilient Mounting of Gensets L16/24 L21/31Yafiz MalikNo ratings yet

- Nox Emission: 1687134-1.0 Page 1Document1 pageNox Emission: 1687134-1.0 Page 1Yafiz MalikNo ratings yet

- Water Washing of Turbocharger - Compressor B 15 05 1: 1639499-6.0 Page 1Document1 pageWater Washing of Turbocharger - Compressor B 15 05 1: 1639499-6.0 Page 1Yafiz MalikNo ratings yet

- Recommendations Concerning Steel Foundations For Resilient Mounted GensetsDocument1 pageRecommendations Concerning Steel Foundations For Resilient Mounted GensetsYafiz MalikNo ratings yet

- 1679743-4 2Document1 page1679743-4 2Yafiz MalikNo ratings yet

- Starting of Engine: 1655204-8.5 Page 1Document1 pageStarting of Engine: 1655204-8.5 Page 1Yafiz MalikNo ratings yet

- Test Running of Gensets On Do: 1356501-5.5 Page 1Document1 pageTest Running of Gensets On Do: 1356501-5.5 Page 1Yafiz MalikNo ratings yet

- Resilient Mounting of Generating SetsDocument2 pagesResilient Mounting of Generating SetsYafiz MalikNo ratings yet

- 1679743-4 2Document1 page1679743-4 2Yafiz MalikNo ratings yet

- Compressed Air System B 14 00 0: Design of External System InstallationDocument1 pageCompressed Air System B 14 00 0: Design of External System InstallationYafiz MalikNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pyramid - Adventurous Occupations - Computer Expert (For Gurps 4e)Document5 pagesPyramid - Adventurous Occupations - Computer Expert (For Gurps 4e)answeringthecalNo ratings yet

- LM361Document8 pagesLM361api-3825669No ratings yet

- PYTHON For Class9Document5 pagesPYTHON For Class9AuraNo ratings yet

- SO-1431-C Instructor User Guide Kongsberg Offshore Vessel SimulatorDocument182 pagesSO-1431-C Instructor User Guide Kongsberg Offshore Vessel SimulatorYuriyNo ratings yet

- Power Supply ExportDocument513 pagesPower Supply ExportAlexandru OrghiciNo ratings yet

- ABAP-CDS-FIORI Interview Question 2023Document6 pagesABAP-CDS-FIORI Interview Question 2023125diptiNo ratings yet

- Office 2013 Activation ProcedureDocument2 pagesOffice 2013 Activation ProcedureChandra KanthNo ratings yet

- Electrical Machines and Power-Electronic Systems For High-Power Wind Energy Generation ApplicationsDocument38 pagesElectrical Machines and Power-Electronic Systems For High-Power Wind Energy Generation ApplicationsmmrNo ratings yet

- AWS Cost OptimisationDocument49 pagesAWS Cost OptimisationeraviraltiwariNo ratings yet

- 3PoleContactors Digital PDFDocument17 pages3PoleContactors Digital PDFGunnie PandherNo ratings yet

- Capr-Ii 2013Document46 pagesCapr-Ii 2013Pramod DhaigudeNo ratings yet

- BSC Computer Science Syllabus NepDocument17 pagesBSC Computer Science Syllabus NepBhagya SarathyNo ratings yet

- 01 A18 Electronic Control SystemDocument136 pages01 A18 Electronic Control Systemkibreaa100% (6)

- Antonio Garcia ResumeDocument2 pagesAntonio Garcia Resumeapi-518075335No ratings yet

- Dellemc Poweredge Raid Controller h745 DatasheetDocument2 pagesDellemc Poweredge Raid Controller h745 DatasheetAndres MartinezNo ratings yet

- Himanshu Pandey Organic Chemistry Solutions PDFDocument2 pagesHimanshu Pandey Organic Chemistry Solutions PDFvishveswar choudharyNo ratings yet

- Mama Star Pricelist (Autorecovered)Document27 pagesMama Star Pricelist (Autorecovered)AkohItoNo ratings yet

- Wireless Network ArchitectureDocument52 pagesWireless Network Architecturekkpandyaji2013No ratings yet

- Lesson 2Document22 pagesLesson 2Duy LươngNo ratings yet

- Huawei Optix RTN 950a DatasheetDocument4 pagesHuawei Optix RTN 950a DatasheetFREDERICK QUISPE HIPOLITONo ratings yet

- GSM 100 BTDocument37 pagesGSM 100 BTRamiro Daniel RulopNo ratings yet

- ST-4000D Manual011312Document11 pagesST-4000D Manual011312Winder GomezNo ratings yet

- SJ-20141127113509-001-ZXSDR R8872A (HV1.0) Product Description - 732736Document20 pagesSJ-20141127113509-001-ZXSDR R8872A (HV1.0) Product Description - 732736Rehan Haider JafferyNo ratings yet

- PUAN Internship Program 2023Document10 pagesPUAN Internship Program 2023Asim SultanNo ratings yet

- Notes-Chapter 1Document5 pagesNotes-Chapter 1Echa LassimNo ratings yet

- DS Neptune NPT-1200Document2 pagesDS Neptune NPT-1200Deepak Kumar Singh100% (1)

- Harrier - 7inch - Infotainment - ManualDocument99 pagesHarrier - 7inch - Infotainment - Manuallio mareNo ratings yet

- ASM2 - Database - GCS200218Document22 pagesASM2 - Database - GCS200218Scott AvenNo ratings yet

- Gods Cab ManualDocument11 pagesGods Cab ManualKenneth CastilloNo ratings yet

- Toyota Celica 94-95 & Corolla 93-95 Trouble CodeDocument2 pagesToyota Celica 94-95 & Corolla 93-95 Trouble CodeKike22No ratings yet