Professional Documents

Culture Documents

Speed Control System

Uploaded by

Art DoeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Speed Control System

Uploaded by

Art DoeCopyright:

Available Formats

TJ SPEED CONTROL SYSTEM 8H - 1

SPEED CONTROL SYSTEM

CONTENTS

page page

GENERAL INFORMATION SPEED CONTROL SET . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1 ROAD TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DESCRIPTION AND OPERATION SPEED CONTROL SERVO . . . . . . . . . . . . . . . . . . 3

POWERTRAIN CONTROL MODULE . . . . . . . . . . 2 SPEED CONTROL SWITCHES . . . . . . . . . . . . . . 3

SERVO CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . 2 STOP LAMP SWITCH . . . . . . . . . . . . . . . . . . . . . 3

SPEED CONTROL SERVO . . . . . . . . . . . . . . . . . . 1 VACUUM SUPPLY TEST . . . . . . . . . . . . . . . . . . . 3

SPEED CONTROL SOLENOID CIRCUITS . . . . . . 1 VEHICLE SPEED SENSOR . . . . . . . . . . . . . . . . . 3

SPEED CONTROL SWITCHES . . . . . . . . . . . . . . 1 REMOVAL AND INSTALLATION

STOP LAMP SWITCH . . . . . . . . . . . . . . . . . . . . . 2 SERVO CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VACUUM RESERVOIR . . . . . . . . . . . . . . . . . . . . 2 SPEED CONTROL SERVO . . . . . . . . . . . . . . . . . . 4

VEHICLE SPEED SENSOR . . . . . . . . . . . . . . . . . 2 SPEED CONTROL SWITCH . . . . . . . . . . . . . . . . . 5

DIAGNOSIS AND TESTING STOP LAMP SWITCH . . . . . . . . . . . . . . . . . . . . . 5

ON-BOARD DIAGNOSTIC TEST FOR SPEED VACUUM RESERVOIR . . . . . . . . . . . . . . . . . . . . 6

CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . 2 SPECIFICATIONS

OVERSHOOT/UNDERSHOOT FOLLOWING TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . 6

GENERAL INFORMATION vent solenoid and “duty-cycles” the vacuum solenoid

to open the throttle and bring the vehicle up to tar-

INTRODUCTION get speed. When the vehicle is at target speed, it will

The vehicle speed control system is electronically actuate the vent solenoid with the vacuum solenoid

controlled and vacuum operated. The system is de-activated to maintain the vehicle at target speed.

designed to operate between approximately 35 and When the vehicle is above target speed, the PCM will

85 mph (56 and 137 km/h). Following are general “duty-cycle” the vent solenoid with the vacuum sole-

descriptions of the major components in the speed noid still de-activated to close the throttle to return

control system. For diagnosis of the entire speed con- to target speed.

trol system, refer to the appropriate Powertrain

Diagnostic Procedures service manual and the DRB SPEED CONTROL SWITCHES

scan tool. Refer to Group 8W, Wiring Diagrams for Two separate speed control switch modules are

complete circuit descriptions and wiring diagrams. mounted on the steering wheel to the left and right

side of the driver’s airbag module. Within the two

switch modules, five momentary contact switches,

DESCRIPTION AND OPERATION supporting seven different speed control functions

are used. The outputs from these switches are fil-

SPEED CONTROL SERVO tered into one input. The Powertrain Control Module

The servo unit consists of a solenoid valve body, a (PCM) determines which output has been applied

vacuum servo and the mounting bracket. The Power- through resistive multiplexing. The input circuit

train Control Module (PCM) controls the solenoid voltage is measured by the PCM to determine which

valve body. The solenoid valve body controls the switch function has been selected.

application and release of vacuum to the diaphragm A speed control indicator lamp, located on the

of the vacuum servo. A cable connects the servo with instrument panel cluster is energized by the PCM via

the throttle linkage. The servo unit cannot be the CCD Bus. This occurs when speed control system

repaired and is serviced only as a complete assembly. power has been turned ON, and the engine is run-

ning.

SPEED CONTROL SOLENOID CIRCUITS The two switch modules are labeled: ON/OFF, SET,

When all of the speed control parameters are met, RESUME/ACCEL, CANCEL and COAST. Refer to

and the SET button is pressed, the PCM actuates the the owner’s manual for more information on speed

8H - 2 SPEED CONTROL SYSTEM TJ

DESCRIPTION AND OPERATION (Continued)

control switch functions and setting procedures. The PCM speed control circuitry to determine vehicle

individual switches cannot be repaired. If one indi- speed and to maintain speed control set speed.

vidual switch fails, the switch module must be

replaced.

DIAGNOSIS AND TESTING

STOP LAMP SWITCH

Vehicles equipped with the speed control option use ROAD TEST

a dual function stop lamp switch. The switch is Perform a vehicle road test to verify reports of

mounted in the same location as the conventional speed control system malfunction. The road test

stop lamp switch, on the brake pedal mounting should include attention to the speedometer. Speed-

bracket under the instrument panel. The PCM mon- ometer operation should be smooth and without flut-

itors the state of the dual function stop lamp switch. ter at all speeds.

Refer to Group 5, Brakes for more information on Flutter in the speedometer indicates a problem

stop lamp switch service and adjustment procedures. which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

SERVO CABLE be corrected before proceeding. Refer to Group 8E,

The speed control servo cable is connected between Instrument Panel and Gauges for speedometer diag-

the speed control vacuum servo diaphragm and the nosis.

throttle body control linkage. This cable causes the If a road test verifies a system problem and the

throttle control linkage to open or close the throttle speedometer operates properly, check for:

valve in response to movement of the vacuum servo • A Diagnostic Trouble Code (DTC). If a DTC

diaphragm. exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

POWERTRAIN CONTROL MODULE • A misadjusted brake (stop) lamp switch. This

The speed control electronic control circuitry is could also cause an intermittent problem.

integrated into the Powertrain Control Module • Loose, damaged or corroded electrical connec-

(PCM). The PCM is located in the engine compart- tions at the servo. Corrosion should be removed from

ment. The PCM speed control functions are moni- electrical terminals and a light coating of Mopar

tored by the On-Board Diagnostics (OBD). All OBD- MultiPurpose Grease, or equivalent, applied.

sensed systems are monitored by the PCM. Each • Leaking vacuum reservoir.

monitored circuit is assigned a Diagnostic Trouble • Loose or leaking vacuum hoses or connections.

Code (DTC). The PCM will store a DTC in electronic • Defective one-way vacuum check valve.

memory for certain failures it detects. See On-Board • Secure attachment of both ends of the speed con-

Diagnostic Test For Speed Control System in this trol servo cable.

group for more information. The PCM cannot be • Smooth operation of throttle linkage and throttle

repaired and must be replaced if faulty. body air valve.

• Failed speed control servo. Do the servo vacuum

VACUUM RESERVOIR test.

A vacuum reservoir is used to supply the vacuum

CAUTION: When test probing for voltage or conti-

needed to maintain proper speed control operation

nuity at electrical connectors, care must be taken

when engine vacuum drops, such as in climbing a

not to damage connector, terminals or seals. If

grade while driving. A one-way check valve is used in

these components are damaged, intermittent or

the vacuum line between the reservoir and the vac-

complete system failure may occur.

uum source. This check valve is used to trap engine

vacuum in the reservoir. On certain vehicle applica-

tions, this reservoir is shared with the heating/air- ON-BOARD DIAGNOSTIC TEST FOR SPEED

conditioning system. The vacuum reservoir cannot be

CONTROL SYSTEM

repaired and must be replaced if faulty.

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the speed control

VEHICLE SPEED SENSOR

system, making sure they are operational. A Diagnos-

The Vehicle Speed Sensor (VSS) is a pulse genera-

tic Trouble Code (DTC) is assigned to each input and

tor mounted to an adapter near the transmission out-

output circuit monitored by the On-Board Diagnostic

put shaft. The sensor is driven through the adapter

(OBD) system. Some circuits are checked continu-

by a speedometer pinion gear. The VSS pulse signal

ously and some are checked only under certain con-

to the speedometer/odometer is monitored by the

ditions.

TJ SPEED CONTROL SYSTEM 8H - 3

DIAGNOSIS AND TESTING (Continued)

For DTC information, refer to Diagnostic Trouble

Codes in Group 25, Emission Control System. This

will include a complete list of DTC’s including DTC’s

for the speed control system.

VEHICLE SPEED SENSOR

For diagnosis and testing of the Vehicle Speed Sen-

sor (VSS), refer to the appropriate Powertrain Diag-

nostic Procedures service manual. Also refer to the

DRB scan tool.

SPEED CONTROL SWITCHES

For complete speed control system diagnosis, refer

to the appropriate Powertrain Diagnostic Procedures

manual. To test each of the speed control switches

only, refer to the following:

WARNING: BEFORE ATTEMPTING TO DIAGNOSE,

REMOVE OR INSTALL ANY AIRBAG SYSTEM OR

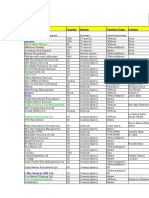

RELATED STEERING WHEEL AND STEERING COL- Fig. 1 Speed Control Switch Continuity Tests

UMN COMPONENTS, YOU MUST FIRST DISCON-

access to reservoir, refer to Vacuum Reservoir Remov-

NECT AND ISOLATE THE BATTERY NEGATIVE

al/Installation in this group. Disconnect vacuum line

(GROUND) CABLE. WAIT 2 MINUTES FOR SYSTEM

at reservoir and connect a hand-operated vacuum

CAPACITOR TO DISCHARGE BEFORE FURTHER

pump to reservoir fitting. Apply vacuum. Reservoir

SYSTEM SERVICE. FAILURE TO DO SO COULD

vacuum should not bleed off. If vacuum is being lost,

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

replace reservoir.

AND POSSIBLE PERSONAL INJURY.

(5) Verify operation of one-way check valve and

(1) Disconnect negative battery cable. Wait 2 min- check it for leaks.

utes for airbag system capacitor to discharge. (a) Locate one-way check valve. The valve is

(2) Remove the two speed control switch modules located in vacuum line between vacuum reservoir

from steering wheel. Refer to the removal/installation and engine vacuum source. Disconnect vacuum

section for procedures. hoses (lines) at each end of valve.

(3) Check continuity of each individual speed con- (b) Connect a hand-operated vacuum pump to

trol switch module as shown in chart (Fig. 1). If OK, reservoir end of check valve. Apply vacuum. Vac-

reinstall switch. If not OK, replace switch module uum should not bleed off. If vacuum is being lost,

assembly. replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

STOP LAMP SWITCH vacuum source end of check valve. Apply vacuum.

For continuity checks and switch adjustment, refer Vacuum should flow through valve. If vacuum is

to Group 5, Brakes. not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

VACUUM SUPPLY TEST apply vacuum. If vacuum will not hold, diaphragm

(1) Disconnect vacuum hose at speed control servo within check valve has ruptured. Replace valve.

and install a vacuum gauge into the disconnected

hose. SPEED CONTROL SERVO

(2) Start engine and observe gauge at idle. Vac- For complete speed control system diagnosis, refer

uum gauge should read at least ten inches of mer- to the appropriate Powertrain Diagnostic Procedures

cury. manual. To test the speed control servo only, refer to

(3) If vacuum is less than ten inches of mercury, the following:

determine source of leak. Check vacuum line to The engine must be started and running for the

engine for leaks. Also check actual engine intake following voltage tests.

manifold vacuum. If manifold vacuum does not meet (1) Start engine.

this requirement, check for poor engine performance (2) Disconnect 4–way electrical connector at servo.

and repair as necessary. (3) Turn speed control switch to ON position.

(4) If vacuum line to engine is not leaking, check (4) Check for battery voltage at pin–3 of wiring

for leak at vacuum reservoir. To locate and gain harness 4–way connector (Fig. 2). This is the 12 volt

8H - 4 SPEED CONTROL SYSTEM TJ

DIAGNOSIS AND TESTING (Continued)

feed from the stoplamp switch. When the brake pedal To “unlearn” the overshoot/undershoot condition,

is depressed, voltage should not be present at pin–3. the vehicle operator has to press and release the set

If voltage is not present with brake pedal not button while maintaining the desired set speed with

depressed, check for continuity between servo and the accelerator pedal (not decelerating or accelerat-

stop lamp switch. Also check stop lamp switch ing), and then turn the cruise control switch to the

adjustment. Refer to Group 5, Brakes for procedures. OFF position (or press the CANCEL button if

(5) Connect a small gauge jumper wire between equipped) after waiting 10 seconds. This procedure

the disconnected servo harness 4–way connector must be performed approximately 10–15 times to

pin–3, and pin–3 on the servo. Check for battery volt- completely unlearn the overshoot/undershoot condi-

age at pins–1, 2 and 4 of the servo. If battery voltage tion.

is not at these pins, replace the servo.

REMOVAL AND INSTALLATION

SPEED CONTROL SERVO

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Disconnect vacuum line at servo (Fig. 3).

(3) Disconnect electrical connector at servo.

(4) Disconnect servo cable at throttle body. Refer to

Servo Cable Removal/Installation in this group.

(5) Remove 2 mounting nuts holding servo cable

sleeve to bracket (Fig. 3) or (Fig. 4).

(6) Pull speed control cable sleeve and servo away

from servo mounting bracket to expose cable retain-

ing clip (Fig. 4) and remove clip. Note: The servo

mounting bracket displayed in (Fig. 4) is a typical

bracket and may/may not be applicable to this model

vehicle.

Fig. 2 Servo 4–Way Harness Connector

(6) Turn ignition switch to OFF position. Check for

continuity between disconnected servo harness

4–way connector pin–4 and a good ground. There

should be continuity. If not OK, repair open circuit to

ground as required.

OVERSHOOT/UNDERSHOOT FOLLOWING SPEED

CONTROL SET

If the operator repeatedly presses and releases the

set button with their foot off of the accelerator (a “lift

foot set” to begin speed control operation), the vehicle

may accelerate and exceed the desired set speed by

up to 5 MPH (8 km/h) and then decelerate to less

than the desired set speed before finally achieving

the desired set speed.

The Speed Control has an adaptive strategy that

compensates for vehicle-to-vehicle variations in speed

control cable lengths. When the speed control is set Fig. 3 Speed Control Servo Location

with the vehicle operators foot off of the accelerator (7) Remove servo from mounting bracket.

pedal, the speed control thinks there is excessive

speed control cable slack and adapts. If the lift foot INSTALLATION

sets are continually used, the speed control over- (1) Position servo to mounting bracket.

shoot/undershoot condition will develop. (2) Align hole in cable connector with hole in servo

pin. Install cable-to-servo retaining clip.

TJ SPEED CONTROL SYSTEM 8H - 5

REMOVAL AND INSTALLATION (Continued)

Fig. 4 Servo Cable Clip Remove/Install—Typical

(3) Insert servo mounting studs through holes in

servo mounting bracket. Fig. 5 Speed Control Switch Remove/Install

(4) Install servo mounting nuts and tighten to 8.5

N·m (75 in. lbs.). (3) Install switch mounting screw and tighten to

(5) Connect vacuum line at servo. 1.5 N·m (14 in. lbs.) torque.

(6) Connect electrical connector at servo. (4) Install airbag module. Refer to Group 8M, Pas-

(7) Connect servo cable to throttle body. Refer to sive Restraint Systems for procedures.

Servo Cable Removal/Installation in this group. (5) Connect negative battery cable to battery.

(8) Connect negative battery cable to battery.

(9) Before starting engine, operate accelerator STOP LAMP SWITCH

pedal to check for any binding. Refer to Stop Lamp Switch in Group 5, Brakes for

removal/installation and adjustment procedures.

SPEED CONTROL SWITCH

SERVO CABLE

WARNING: BEFORE ATTEMPTING TO DIAGNOSE,

REMOVE OR INSTALL ANY AIRBAG SYSTEM OR REMOVAL

RELATED STEERING WHEEL AND STEERING COL- (1) Disconnect negative battery cable at battery.

UMN COMPONENTS YOU MUST FIRST DISCON- (2) Using finger pressure only, remove cable con-

NECT AND ISOLATE THE BATTERY NEGATIVE nector by pushing connector off the throttle body

(GROUND) CABLE. WAIT 2 MINUTES FOR SYSTEM bellcrank pin (Fig. 6). DO NOT try to pull cable

CAPACITOR TO DISCHARGE BEFORE FURTHER connector off perpendicular to the bellcrank

SYSTEM SERVICE. FAILURE TO DO SO COULD pin. Connector will be broken.

RESULT IN ACCIDENTAL DEPLOYMENT AND POS- (3) Two squeeze tabs are located on sides of speed

SIBLE PERSONAL INJURY. control cable at cable locking plate (Fig. 7). Squeeze

the tabs together and push cable out of cable locking

plate.

REMOVAL (4) Unclip cable from cable guide at valve cover

(1) Disconnect and isolate negative battery cable (Fig. 7).

from battery. (5) Disconnect servo cable at servo. Refer to Speed

(2) Remove airbag module. Refer to Group 8M, Control Servo—Removal/Installation.

Passive Restraint Systems for procedures.

(3) From underside of steering wheel, remove INSTALLATION

speed control switch mounting screw (Fig. 5). (1) Attach end of cable to speed control servo.

(4) Remove switch from steering wheel and unplug Refer to Speed Control Servo Removal/Installation.

electrical connector. (2) Install cable into cable locking plate (snaps in).

(3) Install cable connector at throttle body

INSTALLATION bellcrank pin (snaps on).

(1) Plug electrical connector into switch. (4) Clip cable to cable guide at valve cover.

(2) Position switch to steering wheel. (5) Connect negative battery cable to battery.

8H - 6 SPEED CONTROL SYSTEM TJ

REMOVAL AND INSTALLATION (Continued)

VACUUM RESERVOIR

The vacuum reservoir is located under the vehicle

battery tray (Fig. 8).

Fig. 8 Vacuum Reservoir Removal/Installation

REMOVAL

(1) Remove battery and battery tray. Refer to

Group 8A, Battery for procedure.

(2) Disconnect vacuum supply line at reservoir

(Fig. 8).

(3) Remove screw securing reservoir to inner

fender.

(4) Remove reservoir from vehicle.

INSTALLATION

Fig. 6 Servo Cable to Bellcrank—Remove/Install (1) Position reservoir to vehicle and install mount-

ing screw.

(2) Tighten screw to 1.2 N·m (10 in. lbs.) torque.

(3) Connect vacuum line to reservoir.

(4) Install battery and battery tray. Refer to Group

8A, Battery.

SPECIFICATIONS

TORQUE CHART

Description Torque

Servo Mounting Bracket-to-Servo

Nuts . . . . . . . . . . . . . . . . . . . .8.5 N·m (75 in. lbs.)

Speed Control Switch Mounting

Screws. . . . . . . . . . . . . . . . . . .1.5 N·m (14 in. lbs.)

Vacuum Reservoir Mounting

Screw . . . . . . . . . . . . . . . . . . .1.2 N·m (10 in. lbs.)

Fig. 7 Squeeze Tabs at Cable Locking Plate

(6) Before starting engine, operate accelerator

pedal to check for any binding.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Wiper and Washer SystemsDocument14 pagesWiper and Washer SystemsArt DoeNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- TJ Starting Systems 8B - 1Document10 pagesTJ Starting Systems 8B - 1Art DoeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Vehicle Theft and Security SystemsDocument6 pagesVehicle Theft and Security SystemsArt DoeNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Turn Signal and Hazard Warning SystemsDocument6 pagesTurn Signal and Hazard Warning SystemsArt DoeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SteeringDocument34 pagesSteeringArt DoeNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Passive Restraint SystemsDocument12 pagesPassive Restraint SystemsArt DoeNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Tires and WheelsDocument10 pagesTires and WheelsArt DoeNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- SuspensionDocument16 pagesSuspensionArt Doe100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Vehicle Identification Number Decoding Chart: Position Interpretation Code DescriptionDocument10 pagesVehicle Identification Number Decoding Chart: Position Interpretation Code DescriptionArt DoeNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lamps: Lamp DiagnosisDocument16 pagesLamps: Lamp DiagnosisArt DoeNo ratings yet

- Lamps 1Document12 pagesLamps 1Art DoeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Lubrication and MaintenanceDocument12 pagesLubrication and MaintenanceArt DoeNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Horn SystemsDocument4 pagesHorn SystemsArt DoeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Instrument Panel SystemsDocument30 pagesInstrument Panel SystemsArt DoeNo ratings yet

- Electrically Heated SystemsDocument6 pagesElectrically Heated SystemsArt DoeNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cooling SystemDocument32 pagesCooling SystemArt DoeNo ratings yet

- Exhaust System and Intake ManifoldDocument10 pagesExhaust System and Intake ManifoldArt Doe100% (1)

- Frame and Bumpers 1Document2 pagesFrame and Bumpers 1Art DoeNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Frame and BumpersDocument14 pagesFrame and BumpersArt DoeNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Emisipn Control SystemsDocument4 pagesEmisipn Control SystemsArt Doe100% (1)

- Wiring DiagramsDocument246 pagesWiring DiagramsArt DoeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- ClutchDocument14 pagesClutchArt DoeNo ratings yet

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoeNo ratings yet

- Wiring DiagramsDocument246 pagesWiring DiagramsArt DoeNo ratings yet

- Turn Signal and Hazard Warning SystemsDocument6 pagesTurn Signal and Hazard Warning SystemsArt DoeNo ratings yet

- Charging SystemDocument8 pagesCharging SystemArt DoeNo ratings yet

- Vehicle Theft and Security SystemsDocument6 pagesVehicle Theft and Security SystemsArt DoeNo ratings yet

- Wiper and Washer SystemsDocument14 pagesWiper and Washer SystemsArt DoeNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Tires and WheelsDocument10 pagesTires and WheelsArt DoeNo ratings yet

- SuspensionDocument16 pagesSuspensionArt Doe100% (1)

- Award Report TemplateDocument3 pagesAward Report Templatechriscivil12No ratings yet

- CP R77.20 EndpointSecurity AdminGuideDocument168 pagesCP R77.20 EndpointSecurity AdminGuideMSNo ratings yet

- File Handling in C PDFDocument86 pagesFile Handling in C PDFDeepak ShakyaNo ratings yet

- Presentation STAAD ProDocument47 pagesPresentation STAAD ProjosephfelixNo ratings yet

- Greenhouse Project Interim ReportDocument26 pagesGreenhouse Project Interim ReportMuneek ShahNo ratings yet

- Dem 1Document12 pagesDem 1Vicks BTBNo ratings yet

- GemDocument23 pagesGemMukesh KumarNo ratings yet

- Quad Exclusive or Gate: PD CC oDocument7 pagesQuad Exclusive or Gate: PD CC oHungChiHoNo ratings yet

- Peach TreeDocument36 pagesPeach TreeSana MeerNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Presented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainDocument57 pagesPresented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainAnis VohraNo ratings yet

- Uber Strategy TeardownDocument44 pagesUber Strategy Teardownskouti9100% (3)

- 953CDocument24 pages953CVictor M. Mejia Diaz0% (1)

- Axial Piston Fixed Motor AA2FM Series 6x: AmericasDocument30 pagesAxial Piston Fixed Motor AA2FM Series 6x: AmericasKaian OliveiraNo ratings yet

- Company Name Country Service Function/Type Contact: RigzoneDocument4 pagesCompany Name Country Service Function/Type Contact: RigzonekokabawaNo ratings yet

- Pressostato SUCO - 0159Document3 pagesPressostato SUCO - 0159Hugo Lemos ArthusoNo ratings yet

- Topray Tpsm5u 185w-200wDocument2 pagesTopray Tpsm5u 185w-200wThanh Thai LeNo ratings yet

- Fuzzy LogicDocument27 pagesFuzzy LogicvibhutiNo ratings yet

- IP10G-CLI User Guide Version 6.7 March2011Document124 pagesIP10G-CLI User Guide Version 6.7 March2011JorgIVariuS100% (1)

- AAAC - All Aluminum Alloy ConductorDocument5 pagesAAAC - All Aluminum Alloy ConductoralejandraNo ratings yet

- KW Tedder LeafletDocument32 pagesKW Tedder Leafletinfo4826No ratings yet

- Zombie RPGDocument30 pagesZombie RPGBo100% (3)

- An Introduction To Java Programming 3Document179 pagesAn Introduction To Java Programming 3Aleksandar Dutina100% (2)

- Questions & Answers On EDC OverviewDocument89 pagesQuestions & Answers On EDC Overviewkibrom atsbhaNo ratings yet

- Catia MaualDocument44 pagesCatia MaualSai Venkatesh.0% (1)

- OODMSDocument8 pagesOODMSvanikkdi76No ratings yet

- Humboldt Triaxial Equipment Guide-LR0417Document21 pagesHumboldt Triaxial Equipment Guide-LR0417Dilson Loaiza CruzNo ratings yet

- RC Design EC2 v1.9Document64 pagesRC Design EC2 v1.9mohammed alebiedNo ratings yet

- Litografia Soft LithographyDocument33 pagesLitografia Soft Lithographyrfm147No ratings yet

- JDocument4 pagesJapi-299173937No ratings yet

- Linux InterviewDocument35 pagesLinux InterviewTao FengNo ratings yet

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet