Professional Documents

Culture Documents

213000

Uploaded by

Kukuh WidodoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

213000

Uploaded by

Kukuh WidodoCopyright:

Available Formats

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers

Page 1 of 9

P!"# 1.1 .1

G$N$"!L SUMMARY Section Includes: .1 Materials and installation for pac aged fire pumps for use !"en !ater pressure ser#ing facilit$ is inade%uate.

1.2

RELATED SECTIONS .1 Section 01 &' 21 Construction()emolition *aste Management and )isposal. .2 Section 21 12 01 Standpipe and +ose ,ssem-l$. .3 Section 21 13 13 *et Pipe Sprin ler S$stems. .' Section 21 13 1. )r$ Pipe Sprin ler S$stems. ./ Section 23 0/ 0/ Installation of Pipe *or . .. Section 23 0/ 19.01 0"ermometers and Pressure 1auges 2 Piping S$stems. REFERENCES .1 ,merican 3ational Standards Institute(3ational Fire Protection ,ssociation 4,3SI(3FP,5 .1 .2 ,3SI(3FP, 206 Standard for t"e Installation of Stationar$ Pumps for Fire Protection. Material Safet$ )ata S"eets 4MS)S5.

1.3

+ealt" Canada(*or place +a7ardous Materials Information S$stem 4*+MIS5 .1

1.4 .1

SYSTEM DESCRIPTION )esign 8e%uirements: .1 .2 Select fire pump to satisf$ fire protection s$stem re%uirements and ,3SI(3FP, 20. *ater suppl$: .1 Conduct flo! and pressure test of !ater suppl$ in #icinit$ of pro9ect to o-tain criteria for -asis of design including 3PS+ a#aila-le6 and in accordance !it" ,3SI(3FP, 20. .2 :ase design on ,3SI(3FP, 20.

1.5 .1

SUBMITTALS Product )ata: .1 Su-mit manufacturer;s printed product literature6 specifications and datas"eet in accordance !it" Section 01 33 00 2 Su-mittal Procedures. .1 Su-mit t!o copies of *or place +a7ardous Materials Information S$stem 4*+MIS5 Material Safet$ )ata S"eets 4MS)S5 in accordance !it" Section 01 33 00 2 Su-mittal Procedures.

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers S"op )ra!ings: .1

Page 2 of 9

.2

Su-mit s"op dra!ings in accordance !it" Section 01 33 00 2 Su-mittal Procedures .1 S"op dra!ings. Indicate: .1 Materials. .2 Finis"es. .3 Met"od of anc"orage .' 3um-er of anc"ors. ./ Supports. .. 8einforcement. .& ,ssem-l$ details. .< ,ccessories. .9 Indicate "$draulic and electrical c"aracteristics including 3et Positi#e Suction +ead 43PS+5 re%uired6 ma e and model num-er. .2 Pro#ide po!er and control diagrams.

1.6 .1 =ualit$ assurance su-mittals: su-mit follo!ing in accordance !it" Section 01 33 00 2 Su-mittal Procedures. .1 0est reports: .1 Su-mit certified test reports for pac aged fire pumps from appro#ed independent testing la-oratories6 indicating compliance !it" specifications for specified performance c"aracteristics and p"$sical properties. .2 0est eac" pump(dri#er pac age at factor$ to pro#ide detailed performance data and to demonstrate compliance !it" ,3SI(3FP, and specification. Su-mit certified test cur#es for appro#al of >!ner?s 8epresentati#e. .3 0est "$drostaticall$ to meet re%uirements of fire protection s$stem to !"ic" it !ill -e connected. Certificates: su-mit certificates signed -$ manufacturer certif$ing t"at materials compl$ !it" specified performance c"aracteristics and p"$sical properties. Instructions: su-mit manufacturer;s installation instructions. Manufacturer;s Field 8eports: manufacturer;s field reports specified. Su-mit maintenance and engineering data for incorporation into manual specified in Section 01 &< 00 2 Closeout Su-mittals in accordance !it" ,3SI(3FP, 20.

.2 .3 .' .2 .1 1.7 .1

Closeout Su-mittals:

QUALITY ASSURANCE =ualifications: .1 .2 Installer: certified 9ourne$person in pac aged fire pump installations !it" documented e@perience appro#ed -$ manufacturer.

+ealt" and Safet$:

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers .1

Page 3 of 9

)o construction occupational "ealt" and safet$ in accordance !it" Section 01 3/ 29.0. 2 +ealt" and Safet$ 8e%uirements.

1.8 .1

MAINTENANCE A@tra Materials: .1 Furnis" spare parts for eac" pump in accordance !it" Section 01 &< 00 2 Closeout Su-mittals and as follo!s: .1 >ne set of pac ing. .2 >ne casing 9oint gas et.

1.9 .1

DELIVERY, STORA E, AND !ANDLIN Pac ing6 s"ipping6 "andling and unloading: .1 .2 .2 )eli#er6 store and "andle in accordance !it" Section 01 .1 00 2 Common Product 8e%uirements. )eli#er6 store and "andle materials in accordance !it" manufacturer;s !ritten instructions. Construction()emolition *aste Management and )isposal: separate !aste materials for reuse and rec$cling in accordance !it" Section 01 &' 21 2 Construction()emolition *aste Management and )isposal.

*aste Management and )isposal: .1

P!"# 2 2.1 .1 .2 .3 .' ./

P"%&'(#S FIRE PUMP Pac aged6 BCC listed and la-eled #ertical s"aft tur-ine or "ori7ontal s"aft centrifugal fire pump and controller. )ri#er: electric6 totall$ enclosed6 fan cooled motor or diesel internal com-ustion engine complete !it" storage -atteries6 starting e%uipment and controls. Mounting: install pump and dri#er on common -ase. Materials and construction: to ,3SI(3FP, 20. Capacit$: as indicated to satisf$ fire protection s$stem re%uirements and 3FP,: .1 .2 .3 .' Flo! rate: as indicated. Pressure: as indicated. 3PS+: as indicated. Speed: as indicated. Fire pump -$pass fitted !it" s"ut off #al#es and c"ec #al#es. ,udi-le and #isual suction side alarm.

..

,ccessories to ,3SI(3FP, 20 re%uirements and in addition: .1 .2

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers .3

Page ' of 9

>SDE #al#es on suction and s"ut off #al#es on disc"arge6 electricall$ super#ised. Suppl$ for installation -$ ot"ers. Si7e anc"or -olts to !it"stand seismic 7one acceleration and #elocit$ forces.

.&

,nc"or -olts and templates: .1 .2

2.2 .1 .2

PRESSURE MAINTENANCE "#OC$EY% PUMP 1eneral: "ori7ontal6 tur-ine close2coupled6 or multi2stage electricall$ dri#en centrifugal pump and controller. Capacit$: as indicated to satisf$ fire protection s$stem re%uirements and 3FP,: .1 .2 .3 .3 Flo! rate: as indicated. Pressure: as indicated. Speed: as indicated.

,ccessories: to ,3SI(3FP, 20. ELECTRIC MOTOR DRIVEN FIRE PUMP&CONTROLLER

2.3 .1

Main com-ined manual and automatic controller for s%uirrel cage induction motor2dri#en fire pump6 full #oltage or reduced #oltage6 auto2transformer6 closed transition or soft start(stop. Starting6 accommodated in drip2proof CS, enclosure 36 completel$ !ired and tested -$ manufacturer -efore s"ipment from factor$6 for pumps o#er 2/ "p use reduced #oltage or soft start(stop. 0o 3FP, 3o. 206 and BCC listed for fire pump control. 8ating: +orsepo!er as indicated .00 F6 3 p"ase6 .0 +7. Controller microprocessor -ased capa-le of -eing energi7ed automaticall$ t"roug" pressure s!itc" or manuall$ -$ e@ternall$ opera-le "andle. Pressure s!itc" set to cut in and out as determined on site. Minimum running period timer set to eep motor in operation !"en started automaticall$6 for minimum period of 1 minute for eac" 10 "p of motor rating6 -ut not to e@ceed & min.6 automatic !ee l$ test. Pilot lamp to indicate circuit -rea er closed and po!er a#aila-le. Indi#idual alarm contacts rela$ to energi7e audi-le and #isi-le alarm t"roug" independent source of po!er to indicate circuit -rea er open 6 po!er failure and p"ase re#ersal. ,larm and signal de#ices in controller and in remote location to indicate trou-le on controller and pumping unit. ,mmeter test lin and #oltmeter test studs. Manual selector station6 t!o positions6 mar ed G,utomaticG and G3on2,utomaticG. Means on controller to operate alarm signal continuousl$ !"ile pump is running. Mar GFI8A PBMP C>308>CCA8G.

.2 .3 .'

./ .. .& .< .9 .10 .11

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers

Page / of 9

.12 .13

*"ere multiple pumps are pro#ided6 indicate area or 7one ser#ed -$ eac" pump controller. )igital )ispla$ for .1 .2 .3 .' ./ .. .& .< .9 S$stem fre%uenc$ Cine2to2line #oltages Cine2to2line amperages Alapsed run time Pressure s$stem settings Pump starting failure >#er current pro-lem Bnder current pro-lem Pressure transmitter pro-lem Po!er a#aila-le S$stem trou-le P"ase re#ersal Co! s$stem pressure

.1'

,nnciator for .1 .2 .3 .'

2.4 .1

EN INE DRIVEN FIRE PUMP &CONTROLLER ,utomatic engine2dri#en microprocessor -ased fire pump controller: to 3FP, 3o. 20 and e%uipped as follo!s: .1 .2 .3 .' Pressure2s!itc" transducer start. Fire protection e%uipment start. Main ac po!er failure rela$ connected eit"er to start engine or to actuate remote trou-le alarm. Common local alarm -ell and indi#idual trou-le lamps or annuciator to indicate: .1 Co! oil pressure. .2 +ig" cooling !ater temperature. .3 Angine failure to start. .' S"ut do!n from o#er speed. ./ S"ut do!n from pump operation. .. S"ut do!n from trou-le on controller or engine. .& S"ut do!n from loss of ac po!er. .< :atter$ failure for eac" -atter$. .9 :atter$ c"arger failure. .10 Co! suction .11 Co! fuel le#el .12 *ater reser#oir lo! .13 *ater reser#oir empt$ .1' Co! pump room temperature .1/ +ig" fuel le#el

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers

Page . of 9

./ ..

.& .< .9 .10 .11 .12 .13 .1' .1/ .1. .1& .1< .19 .20 .21 .22 .23 .2' .2/

.2. .2&

.2<

.1. Main s!itc" in auto .1& Angine run .1< Failure !"en running Pro#ision for selecta-le automatic alternate use of t!o separate storage -atteries. *it" alarm if -atter$ fails and pre#ention of use of defecti#e -atter$ on startup. Intermittent cran ing of engine !it" loc 2out if engine fails to start on . cran periods of appro@imatel$ 1/ s duration separated -$ / rest periods of appro@imatel$ 1/ s duration. Pro#ision for loc 2out alarm if a -atter$ is disconnected or -ecomes inoperati#e. Selector s!itc" to -$pass rela$ circuits and pro#ide for manual starting. Pro#ision for 10 s dela$ed start. Se%uential timing de#ice. Circuits for #arious engine mounted de#ices suc" as automatic c"o es6 anti2 dieseling solenoid #al#e6 cooling !ater line solenoid #al#e. 0iming rela$ for automatic stop. *ee l$ timer for automatic !ee l$ test run. 8emote start s!itc" rela$. ,uto2manual6 selector. G,utoG position indicating lamp. Manual6 start2stop pus"-uttons. 8ecording pressure gauge !it" & da$ c"art. 0!o -uilt2in automatic -atter$ c"argers. 0ransformer to feed 11/ F panel. Control ca-inet strip "eater. 3AM, 38 enclosure. Mar GFI8A PBMP C>308>CCA8G. *"ere multiple pumps are pro#ided6 indicate area or 7one ser#ed -$ eac" pump controller. 8emote alarm contacts rated at 10 amp6 12/ F,C for: .1 >#erspeed .2 Fail to start .3 Co! oil pressure .' +ig" coolant temperature ./ Failure !"en running Pro#ision for deluge #al#e6 start6 remote. >perator control panel and annunciator to incorporate .1 Indi#idual c"arger #oltmeter and ammeter readout6 c"arger mode indication. .2 Indi#idual cut2in6 cut2out and s$stem pressure. .3 Camp test(silence6 run test6 print and paper feed test -uttons. .' Indi#idual -atter$ manual cran pus" -utton. Controller to s"ut do!n engine for lo! oil pressure or "ig" coolant temperature during e@ercise c$cle -ut restart in case of !ater pressure drop.

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers .29 .30

Page & of 9

Angine o#erspeed s"utdo!n !it"out time dela$ and loc out until manuall$ reset. Include lo! fuel le#el float s!itc"6 "ig" fuel le#el float s!itc"6 lo! pump room temperature t"ermostat6 lo! suction pressure s!itc" mounted inside controller.

2.5 .1 .2

AUTOMATIC TRANSFER S'ITC! *"en automatic transfer s!itc" is re%uired include in 3AM, 3 enclosure mec"anicall$ attac"ed to full ser#ice fire pump control enclosure. Indi#idual dr$ alarm contacts for .1 .2 .3 .' .3 .1 .2 .3 .' ./ .. 1enerator start. Isolating s!itc" in off position. ,utomatic transfer s!itc" in normal position. ,utomatic transfer s!itc" in emergenc$ po!er position. Foltage sensing eac" p"ase of normal po!er suppl$ for generator start contact. Foltage and fre%uenc$ of emergenc$ po!er source to transfer to emergenc$ po!er. 0iming function to o#erride momentar$ normal outages. 0iming function to dela$ transfer to normal po!er suppl$. 0iming function to allo! generator cool do!n after retransfer to normal po!er. Foltage sensing on all p"ases of normal po!er to retransfer to normal po!er.

0ransfer s!itc" to -e pro#ided !it"

2.6 .1 .2 .3 .'

DUAL FIRE PUMP CONTROLLER Consists of lead and stand-$ fire pump controllers complete !it" automatic transfer s!itc"es in 3AM, 3 enclosure. A%uip !it" separate normal and emergenc$ po!er feeders si7ed for one pump. Pressure sensing de#ice for eac" controller onl$. >ne pump allo!ed to start and run at a time. Controllers and transfer s!itc"es to -e complete !it" features specified in 2.3 and 2.'.

2.7 .1

FIRE PUMP REMOTE ALARM PANEL Fire pump remote alarm panel: to 3FP, 3o. 206 s"eet steel6 !all mounting6 finis"ed red6 "inged front access door. ,udi-le and #isual alarm e%uipment indicating pump po!er failure6 pump operating6 super#isor$ po!er failure6 controller engine trou-le. Coloured indicating lamps6 pus"-uttons6 gong6 control rela$s6 terminals6 completel$ factor$ installed and !ired. Aac" a-normal pump condition to lig"t appropriate lamp and to sound audi-le gong alarm. 1ong to -e pus" -utton silenced6 lig"t to remain on until a-normal condition remo#ed6 e@cept t"at in e#ent of super#isor$ po!er suppl$ failure6 gong cannot -e silenced until suppl$ restored.

.2

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers $)$('#I%N MANUFACTURER(S INSTRUCTIONS

Page < of 9

P!"# 3 3.1 .1

Compliance: compl$ !it" manufacturer;s !ritten recommendations or specifications6 including product tec"nical -ulletins6 "andling6 storage and installation instructions6 and datas"eet. INSTALLATION

3.2 .1 .2 .3 .' ./ 3.3 .1

Install in accordance !it" BCC listing6 ,3SI(3FP, 206 manufacturer;s instructions and appro#ed s"op dra!ings. Install engine cooling s$stem. Insulate e@"aust s$stem6 cooling s$stem muffler in accordance !it" Section 21 0& 19 2 0"ermal Insulation for Piping. ,lign pump and motor s"afts to !it"in manufacturer;s recommended clearances prior to start2up. *iring to perform in accordance !it" manufacturer;s instructions and applica-le codes. FIELD QUALITY CONTROL Manufacturer;s Field Ser#ices: .1 >-tain !ritten report from manufacturer #erif$ing compliance of *or 6 in "andling6 installing6 appl$ing6 protecting and cleaning of product and su-mit Manufacturer;s Field 8eports as descri-ed in P,80 1 2 SB:MI00,CS. Pro#ide manufacturer;s field ser#ices consisting of product use recommendations and periodic site #isits for inspection of product installation in accordance !it" manufacturer;s instructions. Sc"edule site #isits6 to re#ie! *or 6 as directed in P,80 1 2 =B,CI0E ,SSB8,3CA. Field test eac" fire pump6 dri#er and controllers in accordance !it" ,3SI(3FP, 20. 0esting s"all include: .1 Ferification of proper installation s$stem initiation ad9ustment and fine tuning. .2 Ferification of t"e se%uence of operations and alarm s$stems. 0esting to -e !itnessed -$ aut"orit$ "a#ing 9urisdiction. )e#elop6 !it" >!ner?s 8epresentati#e?s assistance6 detailed instructions for > D M of t"is installation.

.2

.3 .2

Site 0ests: .1

.2 .3 3.4 .1

CLEANIN Proceed in accordance !it" Section 01 &' 11 2 Cleaning.

Issued 2008/03/ 8

NL Master Specification Guide for Public Funded Buildings Section 21 30 00 Fire Pumps and Controllers

Page 9 of 9

.2

Bpon completion and #erification of performance of installation6 remo#e surplus materials6 e@cess materials6 ru--is"6 tools and e%uipment. COMMISSIONIN

3.5 .1 .2 .3

Field test eac" fire pump6 dri#er and controllers in accordance !it" ,3SI(3FP, 20. 0esting to -e !itnessed -$ aut"orit$ "a#ing 9urisdiction. Pro#ide >!ner assistance6 detailed instructions for > D M of t"is installation.

$N& %F S$(#I%N

You might also like

- Dual 1×30 Multiplexer Card: 60 Differential Channels, Automatic CJC w/3720-ST AccessoryDocument2 pagesDual 1×30 Multiplexer Card: 60 Differential Channels, Automatic CJC w/3720-ST AccessoryKukuh WidodoNo ratings yet

- 2711p Um001 - en PDocument16 pages2711p Um001 - en PKukuh WidodoNo ratings yet

- GCP-30 Series: Genset Control Package Mains & Generator Protection & ControlDocument4 pagesGCP-30 Series: Genset Control Package Mains & Generator Protection & ControlKukuh WidodoNo ratings yet

- Fire CS1140 ManualDocument8 pagesFire CS1140 ManualshebabgNo ratings yet

- PCF 25A Miniature Power PC Board Relay Catalog EntryDocument2 pagesPCF 25A Miniature Power PC Board Relay Catalog EntryKukuh WidodoNo ratings yet

- Optimize Simple Machines with Modicon M218 Logic ControllerDocument7 pagesOptimize Simple Machines with Modicon M218 Logic ControllerKukuh WidodoNo ratings yet

- SD Card-1Document22 pagesSD Card-1Kukuh WidodoNo ratings yet

- Panelview Plus Terminals: Catalog Number 2711P 400, 600, 700, 1000, 1250, 1500 Terminals User ManualDocument246 pagesPanelview Plus Terminals: Catalog Number 2711P 400, 600, 700, 1000, 1250, 1500 Terminals User ManualJaime Flores CaballeroNo ratings yet

- Installation Manual: Paralleling and Protection Unit Type PPUDocument26 pagesInstallation Manual: Paralleling and Protection Unit Type PPUKukuh WidodoNo ratings yet

- Danfoss VLT5000 Data Sheet PDFDocument62 pagesDanfoss VLT5000 Data Sheet PDFKukuh WidodoNo ratings yet

- CautionDocument543 pagesCautionKukuh WidodoNo ratings yet

- E 4980 A Sample ProgramDocument26 pagesE 4980 A Sample ProgramKukuh WidodoNo ratings yet

- ATV61 71 FDR Function With M340Document16 pagesATV61 71 FDR Function With M340Kukuh WidodoNo ratings yet

- 207 05Document60 pages207 05Kukuh WidodoNo ratings yet

- ATV71 Modbus Integrated en 1755863 03Document45 pagesATV71 Modbus Integrated en 1755863 03Feri HandoyoNo ratings yet

- Reg Use ModbusDocument31 pagesReg Use ModbusKukuh WidodoNo ratings yet

- 28521-871.01.12-D (MSB1layout Oneline)Document9 pages28521-871.01.12-D (MSB1layout Oneline)Kukuh WidodoNo ratings yet

- Modbus Master CommunicationDocument3 pagesModbus Master CommunicationKukuh WidodoNo ratings yet

- 28521-871.01.11-A (MSB Spec Data)Document1 page28521-871.01.11-A (MSB Spec Data)Kukuh WidodoNo ratings yet

- 28521-871.01.10-B (MSB Design Descri..)Document9 pages28521-871.01.10-B (MSB Design Descri..)Kukuh WidodoNo ratings yet

- Rfvlslo: Assembly Drawing Sr1 SeriesDocument8 pagesRfvlslo: Assembly Drawing Sr1 SeriesKukuh WidodoNo ratings yet

- 100 - Miclyn Opal Drawing - 100 (Electrical)Document31 pages100 - Miclyn Opal Drawing - 100 (Electrical)Kukuh WidodoNo ratings yet

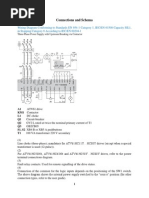

- Connections and SchemaDocument7 pagesConnections and SchemaKukuh WidodoNo ratings yet

- ReadmeDocument16 pagesReadmeKukuh WidodoNo ratings yet

- Filosofi Program On Magelis To Altivar 61Document1 pageFilosofi Program On Magelis To Altivar 61Kukuh WidodoNo ratings yet

- enDocument8 pagesenKukuh WidodoNo ratings yet

- Simatic Working With STEP 7Document112 pagesSimatic Working With STEP 7Slavisa LejicNo ratings yet

- Control WordDocument2 pagesControl WordKukuh WidodoNo ratings yet

- 2011123012494154130Document8 pages2011123012494154130Kukuh WidodoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Renewable Energy FinanceDocument9 pagesRenewable Energy Financeapi-19973582No ratings yet

- Customer Course CatalogDocument108 pagesCustomer Course CatalogSanghwi HwangNo ratings yet

- MAN - ME-GI Dual Fuel A Technical, Operational and Cost-Effective Solution For Ships Fuelled by GasDocument32 pagesMAN - ME-GI Dual Fuel A Technical, Operational and Cost-Effective Solution For Ships Fuelled by GasjhonNo ratings yet

- Standard method of calculation for TEWIDocument5 pagesStandard method of calculation for TEWITEndai BangajenaNo ratings yet

- Automatic Sprinkler Systems Acceptance Test Checklist NFPA 13Document3 pagesAutomatic Sprinkler Systems Acceptance Test Checklist NFPA 13duchoang5000100% (1)

- Ventilation in Hospital ProjectsDocument18 pagesVentilation in Hospital ProjectsMAGDY KAMELNo ratings yet

- Company Catalogue HAUG enDocument14 pagesCompany Catalogue HAUG enjshdlhNo ratings yet

- ThermodynamicsDocument10 pagesThermodynamicsمحمد لقمانNo ratings yet

- Marine product range oil-gas-fired steam hot-water boilersDocument2 pagesMarine product range oil-gas-fired steam hot-water boilersJunMamauagDelaCruz0% (1)

- GTG-1 GTG-2: A-Shift B-Shift C-Shift A-Shift B-Shift C-ShiftDocument3 pagesGTG-1 GTG-2: A-Shift B-Shift C-Shift A-Shift B-Shift C-Shiftcksharma68No ratings yet

- Specification & Drawings: EH-500F, 750F, 1000FDocument6 pagesSpecification & Drawings: EH-500F, 750F, 1000FIPSRS TEKNISINo ratings yet

- Lab 1 Heat PumpDocument17 pagesLab 1 Heat PumpZack MalikNo ratings yet

- 250 MW Fuel Cell PlantDocument2 pages250 MW Fuel Cell PlantGomolemoGumzNtlailaneNo ratings yet

- Solar Power Plant: Components, Working and ApplicationsDocument8 pagesSolar Power Plant: Components, Working and ApplicationsSatyam KumarNo ratings yet

- Air Standard Power CycleDocument24 pagesAir Standard Power Cycle24sandeep24No ratings yet

- Thermodaynamics Lab 1Document11 pagesThermodaynamics Lab 1Kabo Busanang100% (2)

- VRV/VRF: Variable Refrigerant Volume/Variable Refrigerant FlowDocument18 pagesVRV/VRF: Variable Refrigerant Volume/Variable Refrigerant FlowDesai SiddhiNo ratings yet

- NFPA 13, 13R and 13D Sprinkler Design/Installation Comparison ChartDocument2 pagesNFPA 13, 13R and 13D Sprinkler Design/Installation Comparison Chartefac7100% (1)

- Innio Jenbacher j420 Brochure 210x297mm RZ Screen Ijb-122001-EnDocument5 pagesInnio Jenbacher j420 Brochure 210x297mm RZ Screen Ijb-122001-EnOwais JatoiNo ratings yet

- RRI School of Performance Air-Fuel RatiosDocument4 pagesRRI School of Performance Air-Fuel RatiosAntonio Renato CrespoNo ratings yet

- Explosion Occurance in CFBC Boiler and Necessary OperationsDocument6 pagesExplosion Occurance in CFBC Boiler and Necessary OperationsAnudeep ChittluriNo ratings yet

- SB MultiVIV HighStaticDucted ARNU543BRA4!8!15 20150904103919Document2 pagesSB MultiVIV HighStaticDucted ARNU543BRA4!8!15 20150904103919ags387No ratings yet

- DuctulatorDocument44 pagesDuctulatorgeorgeNo ratings yet

- Flare Gas Ignition System: For Oil and Gas Producing Facilities and Petrochemical PlantsDocument2 pagesFlare Gas Ignition System: For Oil and Gas Producing Facilities and Petrochemical Plantsdebasish bhowmickNo ratings yet

- The Power of Steam: Planing and Sales Certuss Dampfautomaten GMBH & Co. KGDocument24 pagesThe Power of Steam: Planing and Sales Certuss Dampfautomaten GMBH & Co. KGPrisca Rojas CandelarioNo ratings yet

- Brayton CycleDocument6 pagesBrayton CycleMǾhămed Tăwfiķ100% (1)

- Ibrahim KhoswanDocument253 pagesIbrahim KhoswanazzamNo ratings yet

- STEAG Training Calendar 2021-2022Document32 pagesSTEAG Training Calendar 2021-2022Chandra Kumar100% (1)

- Data Sheet Bellows and U LoopsDocument1 pageData Sheet Bellows and U Loopsdhanu_lagwankarNo ratings yet