Professional Documents

Culture Documents

Ansi Classes Body Material Selection

Uploaded by

Manh Tien HoangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansi Classes Body Material Selection

Uploaded by

Manh Tien HoangCopyright:

Available Formats

===== ANSI Classes & Body Material Selection ===== ==== ANSI CLASSES ==== It is important that the

valve specifier understands ANSI Class ratings and pres sure ratings; and they must clearly designate the appropriate standard class, sp ecial class, or intermediate class rating when specifying valves. When Valtek designates a valve pressure class according to ANSI B16.34, the foll owing standard designations are generally used: Class 150, 300, 600, 900, 1500 o r 2500. These designations apply to valves with flanged, buttweld, Grayloc, socket weld, or NPT threaded end connections. In addition to the above mentioned classes and end configurations, ANSI B16.34 d esignates a standard Class 4500 for buttwelding end valves. Buttwelding end valv es may also be upgraded to Special Class 150, 300, 600, 900, 1500, 2500, and 450 0. Special Class ratings are available when certain non-destructive examination requirements are met for buttwelding end valves. Properly applied Grayloc-style end connections are also suitable for many high pressure applications. Therefore Valtek offers Special Class and standard Class 4500 valves with Grayloc and but tweld end connections. ANSI B16.34 also permits standard and Special Class 400 ratings with appropriate end connections. Although available by special request, Valtek does not offer t he Class 400 rating as a standard option. ANSI B16.34 also permits the use of intermediate ratings for buttweld end valves . For example: A customer requires a WCB body material for service at 300OF and 6500 psi. ANSI B16.34 provides a method for determining an intermediate rating for this valve (a buttweld end valve) so that it would no t be necessary to require a Class 4500 valve rating (with greater size, weight a nd cost). This method is described in detail in Annex F of ANSI B16.34-1981. Usi ng this example, the method in Annex F would allow the valve specifier to use an intermediate rating of Class 3300. Although designing to intermediate ratings i ncreases engineering time and adds pattern time when castings are required, it m inimizes weight, size and material costs for some applications. The intermediate rating method can also be used to establish pressure classes gr eater that Class 4500. However, the valves specifier must be careful not to inte rpret a 6600 psi pressure rating as a Class 6600 which has a maximum working pre ssure of 13,200 psi. ==== BODY MATERIALS ==== The control valve user normally specifies the body material, which is often the same material as the pipe. The most common choices of body material are carbon s teel, chrome-molybdenum steel and stainless steel. Carbon steel is the most commonly used material for bodies. It handles most noncorrosive liquids and gases up to 800 degrees Fahrenheit for continuous service, or to 1000 degrees Fahrenheit for occasional service. (See ANSI B16.34 for spec ific temperatures and pressures.) Carbon steel can be used for most condensate a nd steam services. Chrome-moly steel l, including such equires corrosion teel and, in some is used for higher temperatures and pressures than carbon stee services as high pressure steam or flashing condensate which r and errosion resistance. Chrome-moly is stronger than carbon s cases, is as strong as stainless steel. It costs less than sta

inless steel, but is not as corrosion resistant. Stainless steel is specified for high temperature services (1000 degrees Fahrenh eit and up) or in corrosive applications. It is more corrosion resistant than ei ther carbon steel or chrome-moly. Special alloyssuch as Hastelloy B and C, Monel, nickel and titaniumare also availa ble. Consideration should be given to the types of material that have been used successfully in the past for similar applications. Valtek is cautious about choosing materials for the user. Except in the most bas ic applications, the control valve user should specify the body materials. Because of the lack of actual correct fluid data, Valtek does not recommend body material or guarantee corrosive resistance or fluid compatibility. Valtek has n o control over fluid composition. Once the body material has been chosen, check the pressure/temperature tables in ANSI B16.34 (found at the end of this section) to determine the application limits for the selected ma terial. The valve body can be cast, forged, wrought or fabricated. Castings are usually the first choice in standard sizes and ratings. Forgings are used for smaller si zed Mark Two valve bodies. (Generally these valves have high pressure ratings1500 , 2500 and 4500 for those special materials not available in castings.) Barstock bodies are recommended when delivery is critical and a casting or forging is no t available. Fabricated bodies are a convenient way to manufacture large angle v alves. Bonnets are generally manufactured from barstock of the same material as the bod y. The exception is smaller (6-inch or less) low pressure chrome-moly valves, wh ere a stainless steel bonnet is normally standard. The basic rule is to specify the general type of bonnet material only, not the ASTM (American Society of Test ing Materials) specification number, because Valtek's standard material varies accordi ng to valve size and pressure rating. Material specification is based upon the ASTM specifications listed in ANSI B16. 34 for standard service valves, and ASME (American Society of Mechanical Enginee rs) specifications. ASME codes are preceded by the letter S, such as SA216-WCB. The tables in this section are from ANSI B16.34 and B16.24 (bronze). They determ ine the valve body's pressure rating, such as Class 150, 300, 600, etc. The design or maximum pressure and temperatures (as given by the control valve user) shoul d be used. Pressure and temperature values may be extrapolated between the lines . The special class tables allow higher pressure and temperature values for weld-end valves with some nondestructive examination of critical areas of the body and b onnet. Table 5-II provides the applicable ASTM codes for Valtek's common body materials. ==== Tables ==== Table 5-I: Valve Body Material Temperature Limits (OF) ^Material ^Lower ^Upper^

|Cast Iron |-20| 410| |Ductile Iron |-20 |650| |*Carbon Steel (Grade WCB) |-20 |1000| |Carbon Steel (Grade LCB) |-50 |650| |Carbon Moly (Grade WC1) |-20 |850| |1-1/4 Cr - 1/2 Mo (Grade WC6) |-20 |1000| |2-1/4 Cr - 1 Mo (Grade WC9) |-20 |1050| |5 Cr - 1/2 Mo (Grade C5) |-20 |1100| |9 Cr - 1 Mo (Grade C12) |-20 |1100| |Type 304 (Grade CF 8) |-425 |1500| |Type 347 (Grade CF8C) |-425 |1500| |Type 316 (Grade CF8M) |-425 |1500| |3-1/2 Ni (Grade LC3) |-150 |650| |Aluminum |-325 |400| |Bronze |-325 |550| |Inconel |600 -325 |1200| |Monel 400 |-325 |900| |Hastelloy B |-325 |700| |Hastelloy C |-325 |1000| |Titanium | |600| |Nickel |-325 |500| |Alloy 20 |-50 |300| //* The carbon phase of carbon steel may be converted to graphite upon long expo sure to temperatures above 775 F. (Check applicable codes for maximum temperature rating of various materials.)// TABLE 5-II: Material Standards {{sizing_selection:valtek:05:table5_2.gif|}} Table 5-III: Valve Body (Pressure Containment) Materials {{sizing_selection:valtek:05:table5_3.gif|}} //* Valtek standard for cast bodies ** Valtek standard for Mark Two bodies//

You might also like

- Ansi-Valve Body Material SelectionDocument3 pagesAnsi-Valve Body Material SelectionsatthukotienNo ratings yet

- 07 - Valves - 1Document8 pages07 - Valves - 1yusuf.yuzuakNo ratings yet

- Valve Trim Material and SpecDocument28 pagesValve Trim Material and SpecRamesh KrishnanNo ratings yet

- Flanges General For DummiesDocument68 pagesFlanges General For DummiesditoNo ratings yet

- Valve Safety With M2 SeriesDocument4 pagesValve Safety With M2 SeriesYang Gul LeeNo ratings yet

- Definition and Details of FlangesDocument39 pagesDefinition and Details of FlangesMohd AmaniNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- API6A Trim Material RatingsDocument5 pagesAPI6A Trim Material RatingsAneez MhdNo ratings yet

- Hydro Static Test Pressure For Flanged FittingsDocument6 pagesHydro Static Test Pressure For Flanged FittingskuntakisNo ratings yet

- Report On API Standard 594Document2 pagesReport On API Standard 594Badar ul Hassan67% (3)

- Codes Standards For YANBU ProjectDocument7 pagesCodes Standards For YANBU ProjectBehçet Serdal CanbazNo ratings yet

- Can-Ulc-S601 StandardDocument10 pagesCan-Ulc-S601 StandardDymac IndiaNo ratings yet

- Api 600 Cast Steel Valves 1: Service FeaturesDocument5 pagesApi 600 Cast Steel Valves 1: Service FeaturesRevanNo ratings yet

- Standards For Pipe LineDocument57 pagesStandards For Pipe Linegopaltry33% (3)

- Applicable Valve StandardsDocument21 pagesApplicable Valve StandardsMatthew KuttikadNo ratings yet

- Flange RatingDocument4 pagesFlange RatingAmit BansalNo ratings yet

- API Valve StandardsDocument6 pagesAPI Valve StandardsFernando PadronNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- CraneDocument32 pagesCranesabes26100% (1)

- Valve Standards in The PetrochemicalDocument5 pagesValve Standards in The PetrochemicalSohaib ZafarNo ratings yet

- Instrument Tubing Selection Guide: Bulletin 4200-TS Revised, June 2004Document4 pagesInstrument Tubing Selection Guide: Bulletin 4200-TS Revised, June 2004tedNo ratings yet

- 01NC0B02Document4 pages01NC0B02raobabar21No ratings yet

- Valve Standards: American Petroleum InstituteDocument6 pagesValve Standards: American Petroleum InstitutejeffNo ratings yet

- List of Awwa StanderdsDocument6 pagesList of Awwa StanderdstadagidsNo ratings yet

- Valve Standards ANSI ASMEDocument0 pagesValve Standards ANSI ASMELuis Alberto Chable GarciaNo ratings yet

- API 5L Pipe SpecificationDocument23 pagesAPI 5L Pipe SpecificationGalo AyalaNo ratings yet

- Piping Guide BookDocument15 pagesPiping Guide BookJagankumar100% (1)

- 01NU0B01Document4 pages01NU0B01raobabar21No ratings yet

- 05 Edge Welded BellowsDocument13 pages05 Edge Welded BellowsAbhishek BasakNo ratings yet

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- Technical Notes (General Specification) FOR Valves (Gate, Globe, Check, Ball, Plug, Needle, Butterfly & Piston Valves)Document30 pagesTechnical Notes (General Specification) FOR Valves (Gate, Globe, Check, Ball, Plug, Needle, Butterfly & Piston Valves)jayakumar100% (1)

- Mechanical Design of Pressure Vessels - Slides PDFDocument29 pagesMechanical Design of Pressure Vessels - Slides PDFYapGwoChaiPatrick100% (1)

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Chock Flow LineDocument24 pagesChock Flow LineTarisahNo ratings yet

- Definition and Details of FlangesDocument23 pagesDefinition and Details of Flangesvishan2kNo ratings yet

- Vessels LDocument34 pagesVessels LMohammed.abudi1996No ratings yet

- Hottappingrequirement1 160722152313 PDFDocument94 pagesHottappingrequirement1 160722152313 PDFadel100% (1)

- Hottappingrequirement1 160722152313Document94 pagesHottappingrequirement1 160722152313ansherina2No ratings yet

- An Overview of The American Petroleum Institute - API - Valve StandardsDocument48 pagesAn Overview of The American Petroleum Institute - API - Valve StandardsazitaggNo ratings yet

- Valves - PresentationDocument119 pagesValves - Presentationkrahul100% (15)

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Piping Material For Hydrogen ServiceDocument4 pagesPiping Material For Hydrogen ServiceALP69No ratings yet

- PipingDocument13 pagesPipingrudiwoworNo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- 600 JSS 2500 001 RevDocument15 pages600 JSS 2500 001 Revhuynhthanhtamga1981No ratings yet

- Plug Valves enDocument24 pagesPlug Valves enAtty AttyNo ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- Valve Standards ANSI BS APIDocument6 pagesValve Standards ANSI BS APInaveenbaskaran1989No ratings yet

- A Pi 6 A Material Trim RatingsDocument4 pagesA Pi 6 A Material Trim RatingsvsajuNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Layout Lau 9 - 26-10Document1 pageLayout Lau 9 - 26-10Manh Tien HoangNo ratings yet

- Clarification For 1749 & 2360 - ProcessDocument1 pageClarification For 1749 & 2360 - ProcessManh Tien HoangNo ratings yet

- SDFSDFDSDSFDocument211 pagesSDFSDFDSDSFManh Tien Hoang100% (1)

- EProcess DO Hydrocyclone Design Basis P1906Document1 pageEProcess DO Hydrocyclone Design Basis P1906Manh Tien HoangNo ratings yet

- Aspen HYSYS UpstreamDocument211 pagesAspen HYSYS UpstreamManh Tien Hoang100% (1)

- 2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedDocument166 pages2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedManh Tien HoangNo ratings yet

- HIPPS Detail EngineeringDocument7 pagesHIPPS Detail EngineeringManh Tien HoangNo ratings yet

- Why Pigs Get StuckDocument16 pagesWhy Pigs Get StuckAmir HoseiniNo ratings yet

- Hysys PrintDocument27 pagesHysys PrintManh Tien HoangNo ratings yet

- Why Pigs Get StuckDocument16 pagesWhy Pigs Get StuckAmir HoseiniNo ratings yet

- Why Pigs Get StuckDocument16 pagesWhy Pigs Get StuckAmir HoseiniNo ratings yet

- Pigging Frequency For DewaxingDocument10 pagesPigging Frequency For DewaxingPNNo ratings yet

- Pigging Frequency For DewaxingDocument10 pagesPigging Frequency For DewaxingPNNo ratings yet

- Controlling Vessels and TanksDocument20 pagesControlling Vessels and TanksAndrew LarsonNo ratings yet

- PM3 - Corrosion StudyDocument8 pagesPM3 - Corrosion StudyManh Tien HoangNo ratings yet

- Cynara - Material Balance SummaryDocument1 pageCynara - Material Balance SummaryManh Tien HoangNo ratings yet

- Materials SelectionasdfsfDocument28 pagesMaterials SelectionasdfsfManh Tien HoangNo ratings yet

- Provision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectDocument41 pagesProvision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectManh Tien HoangNo ratings yet

- CRS For Comment From MoM - 23jan14 (FAS) - IntecseaDocument5 pagesCRS For Comment From MoM - 23jan14 (FAS) - IntecseaManh Tien HoangNo ratings yet

- 11 DMDP A B 1111 001 R4 Instrument CommentDocument1 page11 DMDP A B 1111 001 R4 Instrument CommentManh Tien HoangNo ratings yet

- Thesis Reza MalekzadehDocument180 pagesThesis Reza MalekzadehManh Tien HoangNo ratings yet

- The Lesson Learnt For Piping and MechanicalDocument3 pagesThe Lesson Learnt For Piping and MechanicalManh Tien HoangNo ratings yet

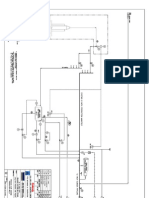

- 2007-4728-03-0100 Rev ASB Process Flow Diagram-Production Wells M PDFDocument1 page2007-4728-03-0100 Rev ASB Process Flow Diagram-Production Wells M PDFManh Tien HoangNo ratings yet

- Cynara - Material Balance SummaryDocument1 pageCynara - Material Balance SummaryManh Tien HoangNo ratings yet

- PFP MaterialsDocument13 pagesPFP MaterialsManh Tien Hoang100% (1)

- Material Stream: To Drain Vessel: ConditionsDocument2 pagesMaterial Stream: To Drain Vessel: ConditionsManh Tien HoangNo ratings yet

- Neotecpipesys V2.5.77.0: - Dh2-Design Case - 1-3 - Rev-Da - HSC 6inch Line (40Mm PP) - 2 ConnectionsDocument28 pagesNeotecpipesys V2.5.77.0: - Dh2-Design Case - 1-3 - Rev-Da - HSC 6inch Line (40Mm PP) - 2 ConnectionsManh Tien HoangNo ratings yet

- BUGEN-00-10-N01-0103 Rev 4 Isolation Philosophy PDFDocument25 pagesBUGEN-00-10-N01-0103 Rev 4 Isolation Philosophy PDFManh Tien Hoang100% (1)

- PVE BD 03 G 002 - Temporary Pig Receiver Typical Drawing - Rev.a.16.05Document1 pagePVE BD 03 G 002 - Temporary Pig Receiver Typical Drawing - Rev.a.16.05Manh Tien HoangNo ratings yet

- Orifice and Chemical Tracer Flow Test Measurements On Production Geothermal Wells PDFDocument1 pageOrifice and Chemical Tracer Flow Test Measurements On Production Geothermal Wells PDFindeskeyNo ratings yet

- Daikin VRV IV Co BrochureDocument52 pagesDaikin VRV IV Co Brochuredokundot100% (1)

- Galvalok INGLESDocument8 pagesGalvalok INGLESsanvel1815No ratings yet

- Technical Data Sheet: High Performance Rail Grease With GraphiteDocument1 pageTechnical Data Sheet: High Performance Rail Grease With GraphiteDon HowardNo ratings yet

- Control of Simple Distillation TowerDocument46 pagesControl of Simple Distillation TowerDian Ardiansyah100% (1)

- Denso Product Catalogue SEPT WEB 2015Document22 pagesDenso Product Catalogue SEPT WEB 2015DianWidodoNo ratings yet

- Combustion CalculationsDocument6 pagesCombustion CalculationsknsaravanaNo ratings yet

- Atoms, Elements & Compounds 1 MS PDFDocument8 pagesAtoms, Elements & Compounds 1 MS PDFClinton ChikengezhaNo ratings yet

- Instrument Engineer B-Tech (Khanna Paper Mill LTD)Document3 pagesInstrument Engineer B-Tech (Khanna Paper Mill LTD)ruhi6727No ratings yet

- Laboratory Safety ContractDocument6 pagesLaboratory Safety Contractwebster gloriagmcNo ratings yet

- Cu Xlpe PVC 0.6 1 KV (N2xa)Document1 pageCu Xlpe PVC 0.6 1 KV (N2xa)Fani Dwi PutraNo ratings yet

- Parts Plastic Mold Design and Preparation ProcessDocument19 pagesParts Plastic Mold Design and Preparation ProcessKodhansNo ratings yet

- ONGAKU Manual SmallerDocument15 pagesONGAKU Manual SmallerEsteban BikicNo ratings yet

- NortonCatalog PortableBeltsDocument2 pagesNortonCatalog PortableBeltsherysyam1980No ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- Masonry Heaters PDFDocument34 pagesMasonry Heaters PDFLucian Leonte0% (1)

- Solid Waste Management - MaloosDocument9 pagesSolid Waste Management - MaloosEdileane Faith SebastianNo ratings yet

- Nt20703 Lab Report Dietary FiberDocument2 pagesNt20703 Lab Report Dietary FiberAmne BintangNo ratings yet

- BMSDocument70 pagesBMSbilal almelegy100% (1)

- Precision Uk Price List 2018 PDFDocument84 pagesPrecision Uk Price List 2018 PDFAmit SinghNo ratings yet

- Nano Material Volumes Applications Holman Lux ResearchDocument29 pagesNano Material Volumes Applications Holman Lux Researchlili_puma100% (2)

- Case 4Document3 pagesCase 4Pavan HegdeNo ratings yet

- Commercial Cooling Load CalculationDocument6 pagesCommercial Cooling Load CalculationMuhammad Kamran MalikNo ratings yet

- Reactive Dye PrintingDocument15 pagesReactive Dye Printingsandipsoni221811No ratings yet

- Pps Seat 163 Seat Ateca EngDocument71 pagesPps Seat 163 Seat Ateca EngManu Fran0% (2)

- Vtu BTD Notes For Pure Substance ChapterDocument24 pagesVtu BTD Notes For Pure Substance ChapterNAVEENNo ratings yet

- Automotive Transmission - Lecture Notes CompleteDocument156 pagesAutomotive Transmission - Lecture Notes CompleteAkshay PundeNo ratings yet

- Cookery 9 (Clean, Sanitize and Store Kitchen Tools and Equipment)Document5 pagesCookery 9 (Clean, Sanitize and Store Kitchen Tools and Equipment)Maureen Madriaga88% (8)

- Curing 4Document588 pagesCuring 4santoruno lupinottiNo ratings yet

- M&E Assignment 3Document12 pagesM&E Assignment 3han0701No ratings yet