Professional Documents

Culture Documents

Track Design Handbook

Uploaded by

Tilahun SarkaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Track Design Handbook

Uploaded by

Tilahun SarkaCopyright:

Available Formats

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 2 of 9

Issue record

Issue Date Comments

1 Mar 1996 Supersedes GC/EH0049 and CE HB3

1A Dec 1997 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

2 Dec 1999 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

3 April 2000 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

4 Aug 2000 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

5 J une 2001 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

6 Feb 2002 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

7 Feb 2003 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

8 Aug 2004 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

9 J une 2006 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

10 Feb 2007 For details of changes see Issue 10, February 2007 (NR/SP/TRK/0049)

11 J une 2008

Preferred Geometries and Configurations of S&C according to usage

are provided for the first time (sheet J .1.1).

Values in tables in Section A verified/corrected. Structure Gauging

Sheets re-formatted and now include Temporary Works and TENs

Routes. New sheet (A.8.9b) on Construction of On-Track Plant

Calibration Sidings. New sheet (A.9.2) on Gauge Transition between

CEN60 plain line and 1432mm gauge track.

Majority of formulae/equations in Section C rationalised.

New sheets (D.8.1 & 2) on Level Crossing Surface Systems.

Minor corrections and updates to a number of data sheets. Several

sheets withdrawn (use RE/PW drawings instead).

The Briefing Note gives further detail of changes to each data sheet.

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 3 of 9

Compliance

This Network Rail Company standard is mandatory and shall be complied with by Network

Rail and its contractors if applicable from 26 August 2008.

When this standard is implemented, it is permissible for all projects, which have formally

completed GRIP Level 4, to continue to comply with the Issue of any relevant Network Rail

Standards current when GRIP Level 4 was reached and not to comply with requirements

contained herein unless the designated Standard Owner has stipulated otherwise in the

accompanying Briefing Note.

Reference Documentation

See section 3.

Disclaimer

In issuing this document for its stated purpose, Network Rail makes no warranties, express

or implied, that compliance with all or any documents it issues is sufficient on its own to

ensure safe systems of work or operation. Users are reminded of their own duties under

health and safety legislation.

Supply

Copies of documents are available electronically, within Network Rails organisation. Hard

copies of this document may be available to Network Rail people on request to the relevant

controlled publication distributor. Other organisations may obtain copies of this document

from IHS (Technical Indexes Ltd) tel: 01344 328039.

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 4 of 9

Contents

1 Purpose 5

2 Scope 5

3 Reference documentation 5

4 Alternative Designs 5

5 Issue of data sheets 5

6 Summary of handbook sections 5

7 Index list of data sheets 6

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 5 of 9

1 Purpose

This specification gives the requirements for the design of track alignments and layouts.

Information provided on track geometry, the mathematics of track layouts, switch & crossing

(S&C) assemblies, sleepers and rail fastenings is intended to result in designs that take

proper account of the speed of traffic.

2 Scope

The specification applies to all track alignment and layout design carried out for use in

Network Rail infrastructure.

3 Reference documentation

NR/L2/TRK/2500 Technical Approval in the Design of Track Infrastructure.

4 Alternative Designs

This specification sets out both maximum and recommended normal values for track

geometry parameters to be used in track alignment and layout designs. The designs of

Network Rails standard range of S&C are based on these values.

Preferred Geometries and Configurations of S&C are tabulated on sheet J .1.1.

Alternative designs of S&C, or of other components or methods having a bearing on track

geometry, may be approved for use subject to demonstration of acceptable values; and

there being an accepted business benefit from so doing. The approval process is set out in

Network Rail Company Procedure NR/L2/TRK/2500 Technical Approval in the Design of

Track Infrastructure.

5 Issue of data sheets

The data sheets, which follow, are numbered, as sheets rather than pages, in a separate

series. Revised or additional sheets will not be issued individually: the complete Track

Design Handbook will be re-issued, and each re-issue will incorporate a revised index as

well as the sheets themselves.

6 Summary of handbook sections

Section A Track Geometry

Section B Requirements for Speed

Section C Permanent Way Mathematics

Section D Selection of Components and/or Systems

Section E Assemblies

Section F Miscellaneous

Section G Other publications

Section H Obsolescent and Historic Data

Section J Switch & Crossing (S&C) Design Fundamentals

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 6 of 9

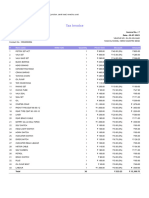

7 Index list of data sheets

NR60,

Vertical,

General

Rev. Date

Section A Geometry

A.1.1 Switch and crossing design philosophy General 4 06/08

A.1.2 Switch and crossing design philosophy NR60 NR60 6 06/06

A.1.3 Vertical S&C switch details Vertical 2 06/08

A.1.4 NR60 Inclined S&C switch details NR60 5 06/08

A.2.1 Standard Circular Curve Turnouts leads and radii Vertical 3 06/08

A.2.2 Circular Curve Turnouts setting out offsets Vertical 1 06/08

A.2.3 Standard Circular Curve Turnouts leads and radii NR60 9 06/08

A.2.4 Standard Circular Curve Turnouts leads and radii NR60 2 06/08

A.3.1 Standard Transitioned Turnouts leads and radii Vertical 2 02/07

A.3.2 Transitioned Turnouts setting out offsets Vertical 2 06/08

A.3.3 Standard Transitioned Turnouts & Crossovers leads and radii NR60 9 06/08

A.4.1 Leads and Radii across Standard Track Interval 1970 Vertical 1 06/08

A.4.2 Leads and Radii across Standard Track Interval 1970 NR60 6 06/08

A.5.1 Diamonds - Leads and Radii 1 Vertical 4 06/08

A.5.2 Diamonds - Leads and Radii 2 Vertical 2 06/08

A.6.1 Standard Double J unctions from Tracks at 1970 Interval Vertical 2 06/08

A.6.2 Standard Tandem Turnouts Radii, leads and offsets to crossing noses Vertical 1 06/08

A.6.3 Standard Scissors Crossovers Vertical 1 06/08

A.6.4 Standard Double J unctions from Straight Tracks at 1970 Interval NR60 6 02/07

A.6.5 Standard Single J unctions from Straight Tracks at 1970 Interval NR60 7 02/07

A.6.7 Standard Slips: Single and Double Vertical 1 06/08

A.6.8 Obtuse Crossings and Switch Diamonds Openings at Knuckle Vertical 08/04

A.7.1 End and Centre Throw General 3 06/08

A.7.2 Centre Throw (Static) of Coaches built to C1 gauge, Appendix A, on

Vertical Switches

Vertical 03/96

A.7.3 Centre Throw (Static) of Coaches with 16m Bogie Centres (Type B) on

Vertical Switches

Vertical 03/96

A.7.4 End Throw (Static) of Type A and Type B Coaches on Vertical Switches Vertical 03/96

A.7.5 Buffer Locking Considerations 1 12/99

A.8.1a Standard Structure Gauge 2 06/08

A.8.1b Temporary Works Structure Gauge New 06/08

A.8.1c Special TENs Structure Gauge New 06/08

A.8.2 Track Intervals 2 08/04

A.8.3 Gradients HMRI Requirements Sheet withdrawn J une 2008 06/08

A.8.4 Electrical Clearances 25kV 1 12/99

A.8.5 Design of Layouts for 25kV Overhead Electrified Lines 1 6 06/06

A.8.6 Design of Layouts for 25kV Overhead Electrified Lines 2 1 12/99

A.8.7 Relationship of Conductor Rail to Standard Load Gauge 03/96

A.8.8 Conductor Rail Positioning at Switches 6 06/08

A.8.9a Sidings Layouts and Geometry Requirements 3 06/08

A.8.9b Construction of On-Track Plant Calibration Sidings New 06/08

A.8.10 Passing Clearances 1 1 12/99

A.8.11 Passing Clearances 2 1 02/07

A.8.12 Passing Clearances 3 03/96

A.8.13 Platform Structure Standards 03/96

A.8.14 Platform Alignments and Lengths 1 06/08

A.9.1 Gauge Widening on Plain Line Curves 3 02/07

A.9.2 Gauge Transition between 1438mm and 1432mm gauge track New 06/08

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 7 of 9

NR60,

Vertical,

General

Rev. Date

Section B Requirements for Speed

B.1.1 Definitions for curving rules 2 02/02

B.2.1 Curving design values Cant and Rate of Change of Cant 5 02/07

B.2.2 Curving design values Cant Deficiency 7 06/08

B.2.3 Curving design values Rate of Change of Cant Deficiency 3 06/06

B.2.4 Curving design values Guidance on Circular Curves 2 06/08

B.2.5 Curving design values Guidance on Transitions 1 06/08

B.3.1 Curve Formulae 1 12/99

B.3.2 Speeds through turnouts Equivalent Radius Formulae 2 06/01

B.3.3 Maximum Speeds through Follow-on Crossovers and Turnouts Vertical 2 08/04

B.3.4 Principle of Virtual Transition 1 12/99

B.3.5 Compound Curves, Reverse Curves 2 06/01

B.3.6 Transition Lengths in Relation to Speed, Cant and Deficiency 2 08/04

B.3.7 Speeds Through Turnouts with Track Reversing to Parallel Main Line 1 1 12/99

B.3.8 Speeds Through Turnouts with Track Reversing to Parallel Main Line 2 Vertical 1 12/99

B.3.9 Speeds Through Turnouts with Track Reversing to Parallel Main Line 3 NR60 1 06/01

B.3.10 Maximum speeds through follow-on crossovers and turnouts NR60 5 06/08

B.3.11 Maximum Speeds for Short Switches and Complex S&C 02/07

B.4.1 Vertical Curves 3 06/06

B.4.2 Vertical Curves Formulae 1 08/04

B.4.3 Compensating and Equivalent Gradients due to Curved Track 1 12/99

B.5.1 Two Levelling 2 06/08

B.5.1 (continued) Two Levelling 1 02/07

Section C Permanent Way Mathematics

C.1.1 Permanent Way Mathematics 1 1 06/08

C.1.2 Permanent Way Mathematics 2 1 06/08

C.1.3 Permanent Way Mathematics 3 1 06/08

C.1.4 Permanent Way Mathematics 4 03/96

C.1.5 Permanent Way Mathematics 5 03/96

C.1.6 Permanent Way Mathematics 6 1 06/08

C.1.7 Permanent Way Mathematics 7 1 06/08

C.1.8 Permanent Way Mathematics 8 1 06/08

C.2.1 Transition Curves Straight to Circular Curve (and vice-versa) 03/96

C.2.2 Transition Curves Circular Curve to Circular Curve 03/96

C.2.3 Transition Curves Circular Curve to Circular Curve 03/96

C.2.4 Transition Curves Reverse Curves 03/96

C.2.5 Transition Curves Clothoid Spirals 2 06/06

C.2.6 Transition Curves Bloss Form 12/99

C.2.7 Transition Curves Bloss Form Comparison to Cubic Parabola 12/99

C.3.1 Centre-Line Setting Out for S&C 1 Vertical 1 12/99

C.3.2 Centre-Line Setting Out for S&C 2 NR60 5 02/07

Section D Selection of Components and/or Systems

D.1.1 Rail section designations 2 02/07

D.2.1 Rail Section CEN60E1 4 06/06

D.2.2 Rail Section CEN60E1A1 1 06/06

D.2.3 Rail Section CEN56E1 1 06/06

D.2.4 Rail Section CEN54E1A1 1 06/06

D.2.5 Rail Section CEN33C1 1 06/06

D.2.6 Standard Rail Lengths 3 06/06

D.2.8 Rail Section 60E2 06/06

D.3.1 Rail End Drilling and Bonding Sheet withdrawn J une 2008 95,113A 06/08

D.4.1 Rail Pads, Clips and Insulators 1 1 06/08

D.4.2 Rail Pads, Clips and Insulators 2 2 06/08

D.4.3 Rail Pads, Clips and Insulators 3 2 06/08

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 8 of 9

NR60,

Vertical,

General

Rev. Date

D.5.1 Standard Timber Lengths 03/96

D.5.2 Standard Timbering of Turnouts Sheet withdrawn J une 2008 Vertical 06/08

D.5.3 Extended Bearer Lengths for Point Motors (formerly Sheet D.6.3) 1 02/03

D.6.1 Insulated Rail J oints 2 06/08

D.6.2 Positioning of Insulated Rail J oints 03/96

D.7.1 Trap Points and Vehicle Retardation 3 02/07

D.7.2 Interlaced Retarder Trap Points Vertical 1 08/04

D.7.3 Sand Drags 1 1 08/04

D.7.4 Sand Drags 2 2 02/07

D.8.1 Level Crossing Surface Systems 1 New 06/08

D.8.2 Level Crossing Surface Systems 2 New 06/08

Section E Assemblies

E.1.1 Switches - Full Depth Rail and Timber Lengths Vertical 2 06/08

E.1.2 Switches - Full Depth Slide Baseplates Sheet withdrawn J une 2008 Vertical 06/08

E.2.1 Switches - Shallow Depth Rail and Timber Lengths Vertical 3 06/08

E.2.2 Switches - Shallow Depth Slide Baseplates Sheet withdrawn J une 08 Vertical 06/08

E.3.1 Common Crossings Rail Lengths for Turnouts and Crossovers Vertical 03/96

E.4.1 Common Crossings Baseplates and Timber Spacings for Built-Up and

Part-Welded Crossings 1

Vertical 03/96

E.4.2 Common Crossings Baseplates and Timber Spacings for Built-Up and

Part-Welded Crossings 2

Vertical 03/96

E.4.3 Cast Centre Block Crossings 1, EAE Type Common crossings Vertical 1 06/01

E.4.4 Cast Centre Block Crossings 2, EAE Type Common crossings Vertical 1 06/01

E.4.5 Cast Centre Block Crossings 3, EAE Type Common crossings Vertical 1 06/01

E.4.6 Cast Centre Block Crossings 4, EAE type Obtuse crossings Vertical 1 06/01

E.4.7 Cast Centre Block Crossings 5, EAE type Obtuse crossings Vertical 06/01

E.5.1 Obtuse Crossings 1 in 4.75 to 1 in 8 Vertical 1 12/99

E.6.1 Cast Manganese Crossings, Single Lead Turnouts 1, EAE Type Vertical 03/96

E.6.2 Cast Manganese Crossings, Single Lead Turnouts 2, EAE Type Vertical 03/96

E.6.3 Cast Manganese Crossings, Double J unctions, N1/N5, EAE Type Vertical 03/96

E.6.4 Cast Manganese Crossings, Double J unctions, N2, EAE Type Vertical 03/96

E.6.5 Cast Manganese Crossings, Double J unctions, N3 Obtuse, EAE Type Vertical 03/96

E.6.6 Cast Manganese Crossings, Double J unctions, N4, EAE Type Vertical 03/96

E.6.7 Cast Manganese Crossings, Scissors Common Crossing, N6,

EAE Type

Vertical 03/96

E.6.8 Cast Manganese Crossings, Scissors Saddle, N7, EAE Type Vertical 03/96

E.6.9 Cast Manganese Crossings, Scissors Common, N8, EAE Type Vertical 03/96

E.6.10 Cast Manganese Crossings, Scissors Compound Crossing, N6/N7,

EAE Type

Vertical 03/96

E.6.11 Cast Manganese Crossings, Common Crossing for 1 in 7.5 Single &

Double Slips, EAE Type

Vertical 03/96

E.6.12 Cast Manganese Crossings, Obtuse Crossing for 1 in 7.5 Single &

Double Slips, EAE Type

Vertical 03/96

E.6.13 Cast Manganese Crossings of Manoir Industries 1 Vertical 03/96

E.6.14 Cast Manganese Crossings of Manoir Industries 2 Vertical 1 06/01

E.6.15 Cast Manganese Crossings of Manoir Industries 3 Vertical 03/96

E.6.16 Cast Manganese Crossings of Manoir Industries 4 Vertical 1 12/99

E.6.17 Cast Steel Vees for Common and Obtuse Crossings EAE Type Vertical 06/01

E 7.1 Identification Markings of Edgar Allens Cast Crossings 1 06/08

E.7.2 Identification Markings of Manoir Industries Outreaus Cast Crossings 03/96

E.8.1 Check Rails 1 Types 1 & 2 and Special Applications Vertical 1 06/01

E.8.2 Check Rails 2 High Speed Sheet moved to Section H.3 Feb 07 Vertical

E.8.3 Check Rails 2 Positioning in Relation to Crossing Nose Vertical 1 06/01

E.8.4 Check Rails 3 Using CEN33C1 Rail Profile 06/06

E.8.5 Check Rails 4 NR60 S&C NR60 5 06/06

E.9.1 Swing Nose Crossings Vertical 2 06/06

Ref: NR/L2/TRK/2049

Issue: 11

Date: 01 J une 2008

Compliance Date 26 August 2008

Page 9 of 9

NR60,

Vertical,

General

Rev. Date

E.10.1 S&C Baseplates 1 (Types VA and V) Vertical 03/96

E.10.2 S&C Baseplates 2 (Types VB and VC) Vertical 1 12/99

E.10.3 S&C Baseplates 3 (Types VD and CV) Vertical 1 12/99

E.11.1 Concrete Bearers, Size and Weight Vertical 2 08/04

E.11.2 Concrete Bearers 2, Layout Types Availability Sheet wdrawn J une 08 Vertical 1 12/99

E.12.2 Switch Diamonds Full Depth Strengthened 1 Vertical 1 06/01

E.12.3 Switch Diamonds Full Depth Strengthened 2 Vertical 1 06/01

E.12.4 Switch Diamonds Shallow Depth Strengthened 1 Vertical 1 06/01

Section F Miscellaneous

F.1.1 Identification of Pandrol Baseplates 1 2 06/08

F.1.2 Identification of Pandrol Baseplates 2 3 06/08

F.2.1 Identification of Concrete Sleepers Chaired/Baseplated Types 03/96

F.2.2 Identification of Concrete Sleepers Fastenings 1 06/01

F.2.3a-d Identification of Concrete Sleepers Direct Fastening Types 1 06/08

F.2.4a-b Identification of Concrete Sleepers Special Types & Shallow Depth 1 06/08

F.2.5a-b Identification of Concrete Sleepers post-1996 designs 4 06/08

F.3.1 Standard Method of Measurement of S&C 03/96

F.4.1 Standard Symbols for use on Layout Drawings 1 1 06/08

F.4.2 Standard Symbols for use on Layout Drawings 2 03/96

F.4.3 Standard Symbols for use on Layout Drawings 3 1 06/08

F.5.1 Adjustment Switches & Welds Adjacent to Non-Ballasted Underbridges 12/99

F.6.1 Weights of Components and S&C Units 03/96

F.7.1 S&C Detail Drawing Aide-Memoir 1 03/96

F.7.2 S&C Detail Drawing Aide-Memoir 2 1 06/08

F.9.1 Calculation of Leads and Lags in Curved J ointed Track 03/96

Section G Other Publications

G.1.1 List of Other Relevant Publications (Sheet withdrawn Feb 07) 1

Section H Obsolescent and Historic data

H.1.1 Rail section BS95RBH Bullhead 12/99

H.2.5 Speeds through turnouts FB

Inclined

12/99

H.3.1 Switch diamonds: Vertical S&C Full-depth, non-strengthened Vertical 12/99

H.3.2 Check Rails: Vertical S&C High Speed Vertical 02/07

H.4.1 RT60 Switch Details RT60 02/07

H.4.2 RT60 Diamonds Leads and Radii 1 RT60 1 06/08

H.4.3 RT60 Diamonds Leads and Radii 2 Sheet withdrawn J une 2008 RT60

H.4.4 RT60 Double J unctions from Straight Tracks at 1970 Interval RT60 02/07

H.4.5 RT60 Single J unctions from Straight Tracks at 1970 Interval RT60 02/07

Section J Switch & Crossing (S&C) Design Fundamentals

J .1.1 Preferred Geometries and Standard Configurations of S&C 2 06/08

J .1.2 Standard Configurations of S&C for Running Lines

Construction Codes

new 06/08

J .2.1 S&C Layout Design 4 06/08

J .2.2 Siting of S&C 1 2 06/06

J .2.3 Siting of S&C 2 02/02

J .3.1 Design Considerations Speeds Through S&C 4 06/08

J .4.1 Types of S&C Unit 1 3 06/08

J .4.2 Types of S&C Unit 2 3 06/08

J .4.3 Rail J oints, Bearers, and Checking Arrangements 4 06/08

J .5.1 Measurement of Crossing Angles 02/02

J .5.2 Measurement of Lead Lengths and Track Intervals 2 06/08

Track Design Handbook NR/L2/TRK/2049

Sheet 1 of 202

Network Rail

Index

A.1.1: Switch and Crossing Design Philosophy - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A.1.2: Switch and Crossing Design Philosophy - NR60 S&C . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

A.1.3: CEN56E1 Vertical S&C Switch Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

A.1.4: NR60 Inclined S&C Switch Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A.2.1: CEN56E1 Vertical S&C - Standard Circular Curve Turnouts - Leads & Radii . . . . . . . . 10

A.2.2: CEN56E1 Vertical S&C Circular Curve Turnouts - Setting Out Offsets . . . . . . . . . . . . . 11

A.2.3: NR60 Inclined S&C Standard Circular Curve Turnouts - Leads and Radii . . . . . . . . . . . 12

A.2.4: NR60 Inclined S&C Standard Circular Curve Turnouts - Leads and Radii . . . . . . . . . . . 13

A.3.1: CEN56E1 Vertical S&C Standard Transitioned Turnouts and

Crossovers - Leads and Radii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

A.3.2: CEN56E1 Vertical S&C Transitioned Turnouts - Setting Out Offsets . . . . . . . . . . . . . . . 15

A.3.3: NR60 Inclined S&C Standard Transitioned Turnouts & Crossovers - Leads and Radii . 16

A.4.1: CEN56E1 Vertical S&C Leads and Radii Across Standard (1970) Track Interval . . . . . 17

A.4.2: NR60 Inclined S&C Leads and Radii Across Standard (1970) Track Interval . . . . . . . . 18

A.5.1: CEN56E1 Vertical S&C Diamonds - Leads and Radii - 1 . . . . . . . . . . . . . . . . . . . . . . . . 19

A.5.2: CEN56E1 Vertical S&C Diamonds - Leads and Radii - 2 . . . . . . . . . . . . . . . . . . . . . . . . 20

A.6.1: CEN56E1 Vertical S&C Standard Double Junctions from Tracks at 1970 Interval . . . . . 21

A.6.2: CEN56E1 Vertical S&C Standard Tandem Turnouts - Radii, Leads and

Offsets to Crossing Noses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

A.6.3: CEN56E1 Vertical S&C Standard Scissors Crossovers . . . . . . . . . . . . . . . . . . . . . . . . . 23

A.6.4: NR60 Inclined S&C Standard Double Junctions from Straight Tracks at 1970 Interval . 24

A.6.5: NR60 Inclined S&C Standard Single Junctions from Straight Tracks at 1970 Interval . . 25

A.6.7: CEN56E1 Vertical Standard S&C Slips - Single and Double . . . . . . . . . . . . . . . . . . . . . 26

A.6.8: CEN56E1 Vertical S&C Obtuse Crossings and Switch Diamonds

- Openings at Knuckle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

A.7.1: End and Centre Throw - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

A.7.2: Centre Throw (Static) of Coaches Built to C1 Gauge Appendix A on Vertical Switches . 29

A.7.3: Centre Throw (Static) of Coaches with 16 m Bogie Centres (Type B) on

Vertical Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

A.7.4: End Throw (Static) of Type A and Type B Coaches on Vertical Switches . . . . . . . . . . . 31

A.7.5: Buffer Locking Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

A.8.1a: Standard Structure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

A.8.1a (continued): Notes on Standard Structure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

A.8.1b: Temporary Works Structure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

A.8.1b (continued): Notes on Temporary Works Structure Gauge . . . . . . . . . . . . . . . . . . . . . . 36

A.8.1c: Special TENs Structure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A.8.1c (continued): Notes on the Special TENs Structure Gauge . . . . . . . . . . . . . . . . . . . . . . . 38

A.8.2: Track Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A.8.4: Electrical Clearances - 25 kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

A.8.5: Design of Layouts for 25kV Overhead Electrified Lines - 1 . . . . . . . . . . . . . . . . . . . . . . . 41

A.8.6: Design of Layouts for 25kV Electrified Lines - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.8.7: Relationship of Conductor Rail to Standard Load Gauge . . . . . . . . . . . . . . . . . . . . . . . . 43

A.8.8: Conductor Rail Positioning at Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.8.9a: Sidings - Layouts and Geometry Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.8.9b: Construction of On-Track Plant Calibration Sidings . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

A.8.10: Passing Clearances - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Revision Date:

Track Design Handbook NR/L2/TRK/2049

Sheet 2 of 202

Network Rail

A.8.11: Passing Clearances - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

A.8.12: Passing Clearances - 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

A.8.13: Platform Structure Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

A.8.14: Platform Alignments and Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

A.9.1: Gauge Widening on Plain Line Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

A.9.2: Gauge Transition - between CEN60 plain line and 1432mm gauge track . . . . . . . . . . . 53

B.1.1: Definitions for Curving Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

B.2.1: Curving Design Values - Cant and Rate of Change of Cant . . . . . . . . . . . . . . . . . . . . . . 55

B.2.2: Curving Design Values - Cant Deficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

B.2.3: Curving Design Values - Rate of Change of Cant Deficiency . . . . . . . . . . . . . . . . . . . . . 57

B.2.4: Curving Design Values - Guidance on Circular Curves . . . . . . . . . . . . . . . . . . . . . . . . . 58

B.2.5: Curving Design Values - Guidance on Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

B.3.1: Curve Formulae . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

B.3.2: Speeds Through Turnouts - Equivalent Radius Formulae . . . . . . . . . . . . . . . . . . . . . . . 61

B.3.3: Speeds Through CEN56E1 Vertical Follow-on Turnouts & Crossovers . . . . . . . . . . . . . 62

B.3.4: Principal of Virtual Transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

B.3.5: Compound Curves, Reverse Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

B.3.6: Transition Lengths in Relation to Speed, Cant & Deficiency . . . . . . . . . . . . . . . . . . . . . . 65

B.3.7: Speeds Through Turnouts with Track Reversing To Parallel Main - 1 . . . . . . . . . . . . . . 66

B.3.8: Speeds Through Turnouts with Track Reversing to Parallel Main - 2 . . . . . . . . . . . . . . . 67

B.3.9: Speeds Through Turnouts with Track Reversing to Parallel Main - 3 . . . . . . . . . . . . . . . 68

B.3.10: Speeds Through NR60 Follow-on Turnouts & Crossovers . . . . . . . . . . . . . . . . . . . . . . 69

B.3.11: Maximum Speeds for Short Switches and Complex S&C . . . . . . . . . . . . . . . . . . . . . . . 70

B.4.1: Vertical Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

B.4.2: Vertical Curves Formulae . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

B.4.3: Compensating and Equivalent Gradients due to Curved Track . . . . . . . . . . . . . . . . . . . 73

B.5.1: Two-Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

B.5.1 (continued): Two-Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

C.1.1: Permanent Way Mathematics - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

C.1.2: Permanent Way Mathematics - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

C.1.3: Permanent Way Mathematics - 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

C.1.4: Permanent Way Mathematics - 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

C.1.5: Permanent Way Mathematics - 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

C.1.6: Permanent Way Mathematics - 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

C.1.7: Permanent Way Mathematics - 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

C.1.8: Permanent Way Mathematics - 8 (Calculation of Diamonds) . . . . . . . . . . . . . . . . . . . . . 83

C.2.1: Transition Curves - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

C.2.2: Transition Curves - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

C.2.3: Transition Curves - 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

C.2.4: Transition Curves - 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

C.2.5: Transition Curves - 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

C.2.6: Transition Curves - 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

C.2.7: Transition Curves - 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

C.3.1: CEN56E1 Vertical - Centreline Setting Out for S&C . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

C.3.2: NR60 Inclined - Centreline Setting Out for S &C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

D.1.1: Rail Section Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

D.2.1: Rail Section - CEN60E1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

D.2.2: Rail Section - CEN60E1A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Revision Date:

Track Design Handbook NR/L2/TRK/2049

Sheet 3 of 202

Network Rail

D.2.3: Rail Section - CEN56E1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

D.2.4: Rail Section - CEN54E1A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

D.2.5: Rail Section - CEN33C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

D.2.6: Standard Rail Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

D.2.8: Rail Section 60E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

D.3.1: Rail End Drilling and Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

D.4.1: Rail Pads, Clips & insulators - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

D.4.2: Rail Pads, Clips and Insulators - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

D.4.3: Rail Pads, Clips and Insulators - 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

D.5.1: Standard Timber Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

D.5.3: Extended Bearer Lengths for Point Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

D.6.1: Insulated Rail Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

D.6.2: Positioning of Insulated Rail Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

D.7.1: Trap Points and Vehicle Retardation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

D.7.2: Interlaced Retarder Trap Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

D.7.3: Sand Drags - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

D.7.4: Sand Drags - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

D.8.1: Level Crossing Surface Systems - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

D.8.2: Level Crossing Surface Systems - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

E.1.1: CEN56E1 Rail & Timber Lengths for Full Depth Vertical Switches . . . . . . . . . . . . . . . . 115

E.2.1: CEN56E1/CEN54E1A1 Rail & Timber Lengths for Shallow Depth Vertical Switches . 116

E.3.1: CEN56E1 Vert S&C - Common Crossings - Rail Lengths for Turnouts & Crossovers . 117

E.4.1: CEN56E1 Vert S&C Common Crossings - Baseplates & Timber Spacings for

Built-Up & Part Welded Crossings - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

E.4.2: CEN56E1 Vert S&C Common Crossings - Baseplates & Timber Spacings for

Built-Up & Part-Welded Crossings - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

E.4.3: Cast Centre Block Crossings - Baseplate Designations & Spacings - 1 . . . . . . . . . . . . 120

E.4.4: Cast Centre Block Crossings - Baseplate Designations & Spacings - 2 . . . . . . . . . . . . 121

E.4.5: Cast Centre Block Crossings - Baseplate Designations & Spacings - 3 . . . . . . . . . . . . 122

E.4.6: Cast Centre Block Crossings - Baseplate Designations & Spacings - 4 . . . . . . . . . . . . 123

E.4.7: Cast Centre Block Crossings - Baseplate Designations & Spacings - 5 . . . . . . . . . . . . 124

E.5.1: CEN56E1 Vertical S&C - Obtuse Crossings - 1 in 4.75 to 1 in 8 . . . . . . . . . . . . . . . . . 125

E.6.1: Cast Manganese Crossings - Single Lead Turnouts - 1 (LH or RH) . . . . . . . . . . . . . . . 126

E.6.2: Cast Manganese Crossings - Single Lead Turnouts - 2 (LH or RH) . . . . . . . . . . . . . . . 127

E.6.3: Cast Manganese Crossings - Common Crossings for Double Junctions . . . . . . . . . . . 128

E.6.4: Cast Manganese Crossings - Common Crossings for Double Junctions . . . . . . . . . . . 129

E.6.5: Cast Manganese Crossings - Obtuse Crossings for Double Junctions . . . . . . . . . . . . 130

E.6.6: Cast Manganese Crossings - Common Crossings for Double Junctions . . . . . . . . . . . 131

E.6.7: Cast Manganese Crossings - Common Crossings for Scissors Crossover . . . . . . . . . 132

E.6.8: Cast Manganese Crossings - Saddle Crossings for Scissors Crossover . . . . . . . . . . . 133

E.6.9: Cast Manganese Crossings - Common Crossings for Scissors Crossover . . . . . . . . . 134

E.6.10: Cast Manganese Crossings - Combined Saddle Crossings for Scissors Crossover . 135

E.6.11: Cast Manganese Crossings - Common Crossings Single and Double Slips . . . . . . . 136

E.6.12: Cast Manganese Crossings - Obtuse Crossings for Single and Double Slips . . . . . . 137

E.6.13: Cast Manganese Common Crossings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

E.6.14: Cast Manganese Common Crossings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

E.6.15: Cast Manganese Common Crossings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

E.6.16: Cast Manganese Common Crossings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

E.6.17: Cast Steel Vees for Common and Obtuse Crossings . . . . . . . . . . . . . . . . . . . . . . . . . 142

Revision Date:

Track Design Handbook NR/L2/TRK/2049

Sheet 4 of 202

Network Rail

E.7.1: Identification Markings of Edgar Allens Cast Crossings . . . . . . . . . . . . . . . . . . . . . . . . 143

E.7.2: Identification Markings of Manoir Industries Cast Crossings . . . . . . . . . . . . . . . . . . . . 144

E.8.1: Check Rails - 1: Vertical S&C - Types 1 & 2 and Special Applications . . . . . . . . . . . . . 145

E.8.3: Check Rails - 2: Vertical S&C - Positioning in Relation to Crossing Nose . . . . . . . . . . 146

E.8.4: Check Rails - 3: Using CEN33C1 Rail Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

E.8.5: Check Rails - 4: NR60 Inclined S&C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

E.9.1: CEN56E1 Vertical S&C - Swing Nose Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

E.10.1: CEN56E1 Vertical S&C - Baseplates - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

E.10.2: CEN56E1 Vertical S&C - Baseplates - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

E.10.3: CEN56E1 Vertical S&C - Baseplates - 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

E.11.1: CEN56E1 / CEN54E1A1 Vertical S&C - Concrete Bearers - Size & Weight . . . . . . . 153

E.12.2: CEN56E1 Vertical S&C - Switch Diamonds, Full Depth, Strengthened - 1 . . . . . . . . . 154

E.12.3: CEN56E1 Vertical S&C - Switch Diamonds, Full Depth, Strengthened - 2 . . . . . . . . . 155

E.12.4: CEN56E1 / CEN54E1A1 Vertical S&C - Switch Diamonds,

Shallow Depth, Strengthened - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

F.1.1: Identification of Pandrol Baseplates - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

F.1.2: Identification of Pandrol Baseplates - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

F.2.1: Identification of Concrete Sleepers - Chaired / Baseplated types . . . . . . . . . . . . . . . . . 159

F.2.2: Identification of Concrete Sleepers (Fastenings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

F.2.3a: Identification of Concrete Sleepers - Direct Fastening Types - 1 . . . . . . . . . . . . . . . . 161

F.2.3b: Identification of Concrete Sleepers - Direct Fastening Types - 2 . . . . . . . . . . . . . . . . 162

F.2.3c: Identification of Concrete Sleepers - Direct Fastening Types - 3 . . . . . . . . . . . . . . . . 163

F.2.3d: Identification of Concrete Sleepers - Direct Fastening Types - 4 . . . . . . . . . . . . . . . . 164

F.2.4a: Identification of Concrete Sleepers - Special Types & Shallow Depth 1 . . . . . . . . . . . 165

F.2.4b: Identification of Concrete Sleepers - Special Types & Shallow Depth 2 . . . . . . . . . . . 166

F.2.5a: Identification of Concrete Sleepers - Post 1996 Designs - 1 . . . . . . . . . . . . . . . . . . . . 167

F.2.5b: Identification of Concrete Sleepers - Post 1996 Designs - 2 . . . . . . . . . . . . . . . . . . . . 168

F.3.1: Standard Method of Measurement of S&C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

F.4.1: Standard Symbols for use on Layout Drawings - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

F.4.2: Standard Symbols for use on Layout Drawings - 2 (Crossings) . . . . . . . . . . . . . . . . . . 171

F.4.3: Standard Symbols for use on Layout Drawings - 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

F.5.1: Minimum Distance for Welds adjacent to Non-Ballasted Underbridges . . . . . . . . . . . . 173

F.6.1: Weights of Components and S&C Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

F.7.1: S&C Detail Drawing Aide-Memoire - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

F.7.2: S&C Detail Drawing Aide-Memoire - 2 continued from Sheet F.7.1. . . . . . . . . . . . . . . . 176

F.9.1: Calculation of Leads and Lags in Curved Jointed Track . . . . . . . . . . . . . . . . . . . . . . . . 177

G.1.1: List of Relevant Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

H.1.1: Rail Section - BS95RBH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

H.2.5: BR109/BS110A/BS113A FB Inclined S&C, 1435 mm Gauge:

Speeds Through Turnouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

H.3.1: CEN56E1 Vertical S&C - Switch Diamonds Full Depth, Non-strengthened . . . . . . . . . 181

H.3.2: Check Rails: Vertical S&C - High Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

H.4.1: RT60 Inclined S&C Switch Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

H.4.2: RT60 Inclined S&C Diamonds - Leads and Radii - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 184

H.4.4: RT60 Inclined S&C Double Junctions from Straight Tracks at 1970 Interval . . . . . . . . 185

H.4.5: RT60 Inclined S&C Single Junctions from Straight Tracks at 1970 Interval . . . . . . . . . 186

Revision Date:

Track Design Handbook NR/L2/TRK/2049

Sheet 5 of 202

Network Rail

J.1.1: Preferred Geometries and Standard Configurations of S&C . . . . . . . . . . . . . . . . . . . . . 187

J.1.2: Standard Configurations of S&C - Construction Codes . . . . . . . . . . . . . . . . . . . . . . . . . 193

J.2.1: S&C Layout Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

J.2.2: Siting of S&C - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

J.2.3: Siting of S&C - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

J.3.1: Design Considerations - Speeds Through S&C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

J.4.1: Types of S&C Unit - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

J.4.2: Types of S&C Unit - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

J.4.3: Rail Joints, Bearers and Checking Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

J.5.1: Measurement of Crossing Angles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

J.5.2: Measurement of Lead Lengths and Track Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Revision Date:

Track Design Handbook NR/L2/TRK/2049

Sheet 6 of 202

Network Rail

Revision 4 Date: June 2008

A.1.1: Switch and Crossing Design Philosophy - General

Turnouts

Design of turnouts

By definition, a turnout is handed left or right, the reference being to the direction of the turnout line from the

through or main line. The creation of a track layout will define the hand of switches required, the turnout can then

be designed by applying the various lead lengths of the standard elements.

Normally a left handed turnout will have left hand switches but in some instances, where the majority of the traffic

takes the turnout route, switches of an opposite hand are installed to provide a smoother alignment through the

turnout.

Hand of switches

To determine the hand of a turnout observe, from a position in advance of the switch toes looking towards the

common crossing - if the right hand stock rail has a set or kink in it at the switch toe, then by definition, it is a right

hand turnout. Similarly, a left hand stock rail with a set will define a left hand turnout. In the very rare instance of

both stock rails having a very small set, the turnout would be defined as equal split - this design is discouraged as it

involves non-standard manufacturing processes.

Measurement of lead lengths

See Sheet J.5.2.

Speed calculations

The calculations required to establish the maximum speed over a particular layout/curve/turnout/etc., (detailed on

various sheets in this handbook) will produce a specific speed in km/h. This must be converted to mph by dividing by

1.609344, as all speed restrictions in the UK are quoted in mph. It is important to realise that when rounding the

resultant figure to a multiple of 5 mph (the increments used), no upward rounding is permitted. Hence a

calculated figure of say 24.6 mph MUST be rounded down to 20 mph. Failure to do so would result in an excess of

cant deficiency/rate of change beyond the permitted limits.

Track Design Handbook NR/L2/TRK/2049

Sheet 7 of 202

Network Rail

Revision 6 Date: June 2006

A.1.2: Switch and Crossing Design Philosophy - NR60 S&C

Basis of NR60 Series Geometry

NR60 geometry is identical to the earlier RT60 geometry. However, NR60 S&C uses components of a single

converged design; whereas RT60 components varied between the S&C manufacturers. NR60 uses 60E2 rail profile,

RT60 used CEN60E1 rail. CEN60E1A1 switch rail is used in both.

The NR60 series is a range of turnouts, crossovers and junctions incorporating principles of geometry which offer

good ride quality while reducing impact forces. They have been optimised for mixed traffic including high speed

tilting trains above 125 mph.

The range of configurations is described in more detail on Sheets A.1.4, A.2.3, A.2.4 & A.3.3, and includes:-

Transitioned turnouts - for turnouts, crossovers, and single and double junctions;

Natural (and circular curve) turnouts - for turnouts and junctions where space is restricted or geometry dictates.

The main principles on which the range is based are as follows:-

Switches have a clothoidal entry curve which minimises the angle of attack and consequently reduces lateral

wheel impact forces.

In the transitioned turnouts, a comfortable ride is assured by a clothoidal transition from the switch curve to the

straight at the crossing; the crossing area is designed with straight alignment on all 4 legs - improving the ride

through the crossover road.

Principles Adopted for Standard Turnout Configurations

1. Design maximum speeds are based upon useable increments in miles per hour (i.e. 25, 30, 35 mph etc.).

2. Maximum allowable cant deficiency values, as set out in sheet B.2.2, are used in the determination of switch

radii and initial crossing angles.

3. Crossing angles are rounded up to the nearest of a whole number (e.g. 1 in 17, 1 in 17, I in 17 etc.).

However, many CEN56E1 and all NR60 crossing angles will be quoted as decimals (1 in 17.25, 1 in 17.5 etc.).

4. Based on the rounded-up crossing angle the final switch and turnout radii, transition and lead lengths, and

general geometry are determined.

General Parameters (see Sheets B.2.1 to B.2.4)

Rails inclined at 1 in 20 and set at 1435 mm nominal track gauge within fully welded layouts.

Maximum cant deficiency of 110 mm at speeds up to 105 mph, and 85 mm above that.

Maximum rate of change of cant deficiency of 80 mm/sec (with an exceptional value of 93.33 mm/sec applied to

transitioned turnouts).

Track Design Handbook NR/L2/TRK/2049

Sheet 8 of 202

Network Rail

Revision 2 Date: June 2008

A.1.3: CEN56E1 Vertical S&C Switch Details

NOTES

1. All dimensions are in millimetres, gauge is 1432 mm.

2. All angles shown are in centre-line measure.

3. HV planing length includes 3000 mm of straight from the toe.

4. The origin of the AVT switch radius occurs at 22.75992 mm outside the running edge of the main line.

5. For details of rail lengths and timbers for full depth switches, see sheet E.1.1.

6. For details of rail lengths and timbers for shallow depth switches, see E.2.1.

7. For vertical S&C all radii shown are to the running edge of the high, or outer, rail.

8. * True value of 1 in 32.365 crossing is 32.3648889.

Switch

type

Natural

angle

1 in

Turnout

Speed

mph

Length

of

planing

P

Planing radius

R1

Switch

radius

R2

Toe to origin

of switch

curve

T

Lead

length.

Toe to IP

L2

Heel offset

H

Toe to

heel

L1

Heel angle

1 in

Entry angle

1 in

AV 7 20 2900 196 750.16 141 052 1542.98208 18 505 278.53865 7317 15.904403 59.669887

AVT 8 2900 196 750.16 186 936.65 2988.02322 20 288 219.55314 6527 19.633740 59.669886

BV 8 20 3500 230 724.78 184 012 1574.84848 21 337 289.16004 8737 17.830694 80.586548

CV 9.25 25 4250 287 251.45 245 767 1615.10392 24 877 372.99182 11 920 18.143969 110.266503

DV 10.75 30 5200 367 038.30 331 687 1613.80233 29 174 297.86830 12 440 23.590631 156.854444

EV 15 40 7000 739 696.30 645 116 2503.06229 40 457 302.69882 17 257 32.639808 189.846820

FV 18.5 50 8550 1 137 066.68 980 920 3168.39649 49 816 293.04404 20 807 40.907497 225.888333

SGV 21 60 10 150 1 398 518.18 1 263 740 3150.95190 56 993 299.41963 24 357 45.935453 306.055765

GV 24 70 11 600 1 826 293.27 1 650 380 3600.16188 65 136 300.77672 27 907 52.376332 349.842595

HV 32.365* 90 17 495 3 000 716.00 3 000 716 3000.35326 89 693 291.75251 38 843 71.709978 500.059376

S

w

itc

h

R

a

d

iu

s

R

2

P

la

n

in

g

R

a

d

iu

s

R

1

H

L2

L1

T

o

e

T

Origin of switch radius

(except AVT)

70

IP

1432

Heel angle

Entry angle

P

la

n

in

g

L

e

n

g

th

P

Track Design Handbook NR/L2/TRK/2049

Sheet 9 of 202

Network Rail

Revision 5 Date: June 2008

A.1.4: NR60 Inclined S&C Switch Details

Referring to the figure below, the clothoidal entry curve forms the tangent with the straight stock rail at A and merges

with the switch radius R at B, where the offset is 12 mm. The shift of the switch radius is 3 mm. For practical

purposes, a straight tangent is taken from the point C where the offset to the transition is 3 mm, and projected back

to the stock rail at point T, which is the mathematical switch toe.

Switch details

Positioning of Switch Heels

NOTES

1. All dimensions are in millimetres.

2. Switch Radii shown above are to the running edge of the high, or outer, rail of curve. Radii shown on

subsequent sheets for NR60 geometry are to centre line.

Switch

designation

Natural

crossing

angle

Turnout

speed mph

Switch

radius

R (R6)

Length of

straight at

toe

T - C (L1)

Entry angle

1 in ~

Length of

transition at

toe

C - B (L2)

Headcut

length

Flexing

length

NR60C 8.25 25 195 647 788 263 1389 5497 10 580

NR60D 9.5 30 259 192 907 302 1599 6327 11 230

NR60E 12.5 40 448 216 1193 398 2102 8320 14 480

NR60F 15.75 50 711 167 1503 501 2648 10 480 17 080

NR60SG 20.25 65 1 175 135 1932 644 3404 13 471 20 330

NR60G 23.5 75 1 582 360 2241 747 3950 15 632 22 280

NR60H 31.25 100 2 797 591 2980 993 5251 20 783 30 080

Switch designation Switch curve origin to heel Heel to toe Heel angle 1 in N

NR60C 11 129.663 11 430.014 17.564647

NR60D 11 237.949 11 583.654 23.053150

NR60E 14 962.163 15 416.757 29.948284

NR60F 19 867.924 20 440.557 35.787745

NR60SG 27 698.972 28 435.061 42.419327

NR60G 27 446.977 28 301.106 57.647184

NR60G Trans 31.25 31 346.649 32 200.778 50.476757

NR60H 36 514.040 37 648.303 76.613595

A

T

R

C

3mm

B

12mm

R

S

t

r

a

i

g

h

t

Definition of Switch Geometry

Track Design Handbook NR/L2/TRK/2049

Sheet 10 of 202

Network Rail

Revision 3 Date: June 2008

A.2.1: CEN56E1 Vertical S&C - Standard Circular Curve Turnouts - Leads & Radii

Speeds shown may need alteration in respect of curved and canted main lines.

NOTES

1. Gauge is 1432 mm.

2. All dimensions are in millimetres.

3. Lead lengths are given from the toes of

switches to noses of common crossings.

4. * indicates a natural lead, i.e. the radii of

the switch and turnout are equal.

5. The length of straight in a CV STR 10 is

2217 mm measured along the main line.

6. The length of straight in a DV STR 13 is 6077 mm measured along the main line.

7. Maximum Turnout Speeds: [A] Turnout radius continued beyond IP. [B] Straight beyond IP (figures only given where

maximum speed is different to the curved beyond IP case).

Switch Crossing

1 in ~

Lead L2.

Nose to toe

Planing

radius

Switch

radius

Turnout

radius

Toe to heel

L1

Heel

H

Max turnout

speed [A] mph.

See note 7

Max turnout

speed [B] mph.

See note 7

AV 6 17 437 196 750 141 052 97 599 7317 279 15

6.5 18 040 196 750 141 052 117 821 7317 279 15

7 18 617 196 750 141 052 141 052* 7317 279 20

7.5 19 170 196 750 141 052 167 780 7317 279 20

8 19 700 196 750 141 052 198 620 7317 279 20

9.25 20 934 196 750 141 052 299 450 7317 279 20

BV 7 20 315 230 725 184 012 133 185 8737 289 20

7.5 20 901 230 725 184 012 157 024 8737 289 20

8 21 465 230 725 184 012 184 012* 8737 289 20

9.25 22 785 230 725 184 012 268 573 8737 289 20

10 23 520 230 725 184 012 344 544 8737 289 20

10.75 24 218 230 725 184 012 416 918 8737 289 20

CV 8 23 787 287 251 245 767 169 051 11 920 373 20

9.25 25 025 287 251 245 767 245 767* 11 920 373 25

10 25 716 287 251 245 767 305 201 11 920 373 25

STR 10 25 117 287 251 245 767 245 767/Str. 11 920 373 25

10.75 26 371 287 251 245 767 378 263 11 920 373 25

13 28 152 287 251 245 767 737 191 11 920 373 25

DV 9.25 27 642 367 038 331 687 230 112 12 440 298 25

10 28 513 367 038 331 687 277 328 12 440 298 25

10.75 29 346 367 038 331 687 331 687* 12 440 298 30 25

13 31 644 367 038 331 687 551 575 12 440 298 30

STR 13 29 940 367 038 331 687 331 687/Str. 12 440 298 25

15 33 464 367 038 331 687 858 076 12 440 298 30

EV 13 38 451 739 696 645 116 454 448 17 257 303 35 30

15 40 697 739 696 645 116 645 116* 17 257 303 40 35

16 41 752 739 696 645 116 762 010 17 257 303 40 35

18.5 44 211 739 696 645 116 1 139 974 17 257 303 40

21 46 444 739 696 645 116 1 700 938 17 257 303 40

FV 16 47 252 1 137 067 980 920 689 242 20 807 293 45 35

18.5 50 112 1 137 067 980 920 980 920* 20 807 293 50 40

21 52 743 1 137 067 980 920 1 363 999 20 807 293 50 45

24 55 638 1 137 067 980 920 2 001 909 20 807 293 50

SGV 18.5 54 518 1 398 518 1 263 740 926 126 24 357 299 50 40

21 57 329 1 398 518 1 263 740 1 263 740* 24 357 299 60 40

24 60 441 1 398 518 1 263 740 1 795 616 24 357 299 60 50

28 64 202 1 398 518 1 263 740 2 827 066 24 357 299 50

GV 21 62 149 1 826 293 1 650 380 1 189 637 27 907 301 55 40

24 65 520 1 826 293 1 650 380 1 650 380* 27 907 301 70 45

28 69 628 1 826 293 1 650 380 2 484 540 27 907 301 70 55

32.365 73 676 1 826 293 1 650 380 3 835 055 27 907 301 55

HV 28 85 208 3 000 716 3 000 716 2 110 303 38 843 292 75 50

32.365 90 211 3 000 716 3 000 716 3 000 716* 38 843 292 90 55

Planing

curve

Switch

curve

L1

Heel Offset H

T

o

e

L2

I

P

N

o

s

e

16N

G

a

u

g

e

Turnout curve

T

r

a

c

k

D

e

s

i

g

n

H

a

n

d

b

o

o

k

N

R

/

L

2

/

T

R

K

/

2

0

4

9

S

h

e

e

t

1

1

o

f

2

0

2

N

e

t

w

o

r

k

R

a

i

l

R

e

v

i

s

i

o

n

1

D

a

t

e

:

J

u

n

e

2

0

0

8

A

.

2

.

2

:

C

E

N

5

6

E

1

V

e

r

t

i

c

a

l

S

&

C

C

i

r

c

u

l

a

r

C

u

r

v

e

T

u

r

n

o

u

t

s

-

S

e

t

t

i

n

g

O

u

t

O

f

f

s

e

t

s

Switch Crossin

g 1 in ~

Lead L2

Toe -

Nose

Offsets at 2500 intervals from the crossing nose

2500 5000 7500 10 000 12 500 15 000 17 500 20 000 22 500 25 000 27 500 30 000 32 500 35 000 37 500 40 000 42 500 45 000 47 500 50 000

AV 6 17 437 1059 736 479 286

6.5 18 040 1086 779 526 326

7 18 617 1110 817 569 366

7.5 19 170 1131 851 609 405

8 19 700 1149 882 646 443

9.25 20 934 1186 946 726 528 351

BV 7 20 315 1111 822 581 387

7.5 20 901 1132 856 621 426

8 21 465 1150 886 657 463 302

9.25 22 785 1187 950 737 547 381

10 23 520 1206 982 778 592 425

10.75 24 218 1222 1010 814 633 467 316

CV 8 23 787 1151 892 671 486

9.25 25 025 1188 955 746 564 407

10 25 715 1207 986 786 606 447

STR 10 25 117 1198 963 754 570 413

10.75 26 371 1222 1013 821 645 486

13 28 152 1259 1079 907 743 588 442

DV 9.25 27 642 1189 958 754 578 428 307

NOTES

1. All dimensions are in millimetres.

2. Gauge is 1432 mm.

3. Lead lengths are given from toes of switches to noses of common

crossings.

10 28 513 1207 990 795 622 472 345

10.75 29 346 1223 1017 831 663 514 384

13 31 644 1260 1084 919 765 623 492 373

STR 13 29 940 1255 1063 873 701 548 413 298

15 33 464 1284 1128 978 836 702 575 455 342

EV 13 38 451 1261 1088 929 784 652 535 431 341

15 40 697 1285 1132 989 855 731 617 512 417 332

16 41 752 1295 1150 1013 885 765 653 549 454 366

18.5 44 211 1315 1187 1065 949 837 732 632 537 448 364

21 46 444 1330 1216 1106 999 896 797 701 609 521 436 355

FV 16 47 252 1295 1152 1017 892 775 668 570 481 401 330

18.5 50 112 1315 1189 1069 955 848 747 653 565 483 408 339

21 52 743 1331 1218 1110 1006 907 812 722 637 556 480 409 342

24 55 638 1345 1245 1148 1054 964 876 792 711 633 558 486 417 351

SGV 18.5 54 518 1315 1190 1070 958 853 754 662 576 498 426 361 303

21 57 329 1331 1218 1111 1009 911 819 731 648 571 498 430 368 310

24 60 441 1345 1248 1150 1057 968 882 800 722 647 575 507 442 381 323

28 64 202 1359 1273 1189 1107 1027 950 874 801 730 662 595 531 469 409 351

GV 21 62 152 1331 1219 1112 1011 915 824 738 658 583 513 449 389 335

24 65 523 1345 1246 1151 1059 972 888 807 731 659 590 525 464 406 353 303

28 69 632 1360 1274 1190 1109 1031 955 881 811 742 676 613 552 494 438 385 334

32.365 73 680 1371 1296 1223 1151 1080 1012 945 879 816 754 693 634 577 522 468 415 365 316

HV 28 85 208 1360 1274 1 192 1112 1036 962 892 824 760 698 639 583 531 481 434 390 349 311

32.365 90 211 1371 1297 1224 1154 1086 1019 955 893 833 775 720 666 614 565 517 472 429 387 348 311

IP

Nose

16N

G

a

u

g

e

Heel length L1

10 000

7500

5000

2500

T

o

e

Lead length L2

Track Design Handbook NR/L2/TRK/2049

Sheet 12 of 202

Network Rail

Revision 9 Date: June 2008

A.2.3: NR60 Inclined S&C Standard Circular Curve Turnouts - Leads and

Radii

NOTES

1. These are natural turnouts (switch and turnout radii equal).

2. The heel position coincides with the start of the transition in the transitioned turnouts shown on sheet A.3.3,

and has no relevance to the position of the last fixed block/baseplate as defined in vertical S&C design.

3. All the above turnouts will use fixed, rather than swing nose, crossings.

4. All dimensions are in millimetres. Gauge is 1435mm.

5. Maximum Turnout Speeds: [A] Turnout radius continued beyond IP. [B] Straight beyond IP.

Switch

Designation

Crossing

Angle

1 in ~

Lead

(Toe to IP)

L2

Centreline

switch

radius

Centreline

turnout

radius

Heel length

L1

Heel Offset

H

Max turnout

speed [A] mph.

See note 5

Max turnout

speed [B] mph.

See note 5

NR60C 8.25 23 928 194 930 194 930 11 430 319.82 25

20

NR60D 9.5 27 554 258 475 258 475 11 584 246.74 30 25

NR60E 12.5 36 255 447 498 447 498 15 417 252.80 40 30

NR60F 15.75 45 681 710 450 710 450 20 441 280.58 50 35

NR60SG 20.25 58 732 1 174 417 1 174 417 28 435 329.49 65 40

NR60G 23.5 68 158 1 581 643 1 581 643 28 301 241.06 75 45

NR60H 31.25 90 634 2 796 873 2 796 873 37 648 241.30 100 55

L1

Heel Offset H

Mathematical

Toe

S

witch

curve

16N

IP

Nose

T

u

r

n

o

u

t

c

u

r

v

e

G

a

u

g

e

L2

Planing

curve

Track Design Handbook NR/L2/TRK/2049

Sheet 13 of 202

Network Rail

Revision 2 Date: June 2008

A.2.4: NR60 Inclined S&C Standard Circular Curve Turnouts - Leads and

Radii

NOTES

1. See Sheet J.1.1 for permitted usage.

2. The heel position coincides with the start of the transition in the transitioned turnouts shown in Sheet A.3.3,

and has no relevance to the position of the last fixed block/baseplate as defined in vertical S&C design.

3. All the above turnouts will use fixed, rather than swing nose, crossings.

4. All dimensions are in millimetres. Gauge is 1435mm.

5. Maximum Turnout Speeds: [A] Turnout radius continued beyond IP. [B] Straight beyond IP (figures only given

where maximum speed is different to the curved beyond IP case).

Switch

Designation

Crossing

Angle

1 in ~

Lead toe - IP

L2

Centreline

switch

radius

Centreline

turnout

radius

Heel length

L1

Heel Offset

H

Max turnout

speed [A] mph.

See note 5

Max turnout

speed [B] mph.

See note 5

NR60C 9.5 25 160 194 930 284 822 11 430 319.82 25

NR60D 8.25 26 004 258 475 185 562 11 584 246.74 25 20

11 29 264 258 475 372 559 11 584 246.74 30 25

12.5 30 829 258 475 526 343 11 584 246.74 30

NR60E 9.5 32 454 447 498 237 267 15 417 252.80 25

11 34 424 447 498 330 766 15 417 252.80 30 25

13.5 37 405 447 498 540 978 15 417 252.80 40 30

15.75 39 809 447 498 811 082 15 417 252.80 40 35

NR60F 12.5 41 818 710 450 410 903 20 440 280.58 35 30

13.5 43 061 710 450 490 648 20 440 280.58 40 30

17.25 47 304 710 450 895 159 20 440 280.58 50 35

NR60SG 17.25 55 540 1 174 417 788 326 28 435 329.49 50 35

21.5 59 974 1 174 417 1 375 580 28 435 329.49 65 45

23.5 61 862 1 174 417 1 762 047 28 435 329.49 60 50

NR60G 21.5 65 687 1 581 643 1 282 213 28 301 241.06 65 45

27 72 202 1 581 643 2 230 155 28 301 241.06 70 50

NR60H 33.5 93 289 2 796 873 3 312 779 37 648 241.30 100 60

L1

Heel Offset H

Mathematical

Toe

S

w

itch

curve

16N

IP

Nose

T

u

r

n

o

u

t

c

u

rv

e

G

a

u

g

e

L2

Planing

curve

T

r

a

c

k

D

e

s

i

g

n

H

a

n

d

b

o

o

k

N

R

/

L

2

/

T

R

K

/

2

0

4

9

S

h

e

e

t

1

4

o

f

2

0

2

N

e

t

w

o

r

k

R

a

i

l

R

e

v

i

s

i

o

n

2

D

a

t

e

:

F

e

b

r

u

a

r

y

2

0

0

7

A

.

3

.

1

:

C

E

N

5

6

E

1

V

e

r

t

i

c

a

l

S

&

C

S

t

a

n

d

a

r

d

T

r

a

n

s

i

t

i

o

n

e

d

T

u

r

n

o

u

t

s

a

n

d

C

r

o

s

s

o

v

e

r

s

-

L

e

a

d

s

a

n

d

R

a

d

i

i

NOTES

1. All dimensions are in millimetres.

2. Gauge is 1432 mm.

3. All angles are shown in centre-line measure.

4. Lead lengths are shown between the toes of switches and the noses of

common crossings.

5. Speeds shown may need alteration in respect of curved and canted main

lines.

6. # For details of the cant applied within a GV24/28 turnout see drawing RE/

PW/655.

7.

*

For details of the GV24/28 extended transition turnout (no cant) see

drawing RE/PW/781.

8. The HV32.365/45.75 turnout uses a swing nose crossing; the IP to nose

dimension being - 4118.

Switch Crossing 1 in ~ Lead lengths Switch

radius

Turnout

radius

Length of

transition

Length of

straight to

nose

Turnout

speed

(mph)

Natural Actual Toe to nose

L2

Nose to

nose across

a 1970

interval

Toe to toe

across a

1970 interval

AV 7 9.25 19 698 4589 43 984 141 052 141 052 9760 1188 20

BV 8 9.25 21 808 4589 48 204 184 012 184 012 6195 469 15

8 10 22 261 4975 49 497 184 012 184 012 9170 920 20

8 10.75 22 852 5360 51 065 184 012 184 012 11 730 1510 20

CV 9.25 10.75 25 448 5360 56 256 245 767 245 767 7366 584 20

9.25 13 27 007 6513 60 526 245 767 245 767 13 000 3271 25

DV 10.75 13 30 125 6513 66 762 331 687 331 687 10 630 964 25

10.75 15 31 713 7533 70 960 331 687 331 687 17 455 2534 30

EV 15 18.5 42 017 9315 93 349 645 116 645 116 16 255 1560 35

15 21 44 066 10 585 98 718 645 116 645 116 24 555 3605 40

FV 18.5 24 52 606 12 109 117 321 980 920 980 920 24 290 2787 50

21 28 56 331 14 138 126 801 980 920 1 364 999 30 000 5165 50

SGV 21 28 60 782 14 138 135 702 1 263 740 1 263 740 30 075 3787 60

GV 24 # 28 66 678 14 138 147 493 1 650 380 1 650 380 19 640 1538 60

24

*

28 67 135 14 040 148 310 1 650 380 1 650 380 36 200 - 7056 70

24 32.365 69 933 16 350 156 216 1 650 380 1 650 380 38 000 3559 70

HV 32.365 45.75 93 153 32 830 219 137 3 000 716 3 000 716 55 700 2730 90

L2

Planing

Radius

Switch

Radius

Turnout

Radius

Transition

S

tr

I.P. Natural Angle

16N

T

o

e

Nose of Actual Crossing

G

a

u

g

e

T

r

a

c

k

D

e

s

i

g

n

H

a

n

d

b

o

o

k

N

R

/

L

2

/

T

R

K

/

2

0

4

9

S

h

e

e

t

1

5

o

f

2

0

2

N

e

t

w

o

r

k

R

a

i

l

R

e

v

i

s

i

o

n

1

D

a

t

e

:

J

u

n

e

2

0

0

8

A

.

3

.

2

:

C

E

N

5

6

E

1

V

e

r

t

i

c

a

l

S

&

C

T

r

a

n

s

i

t

i

o

n

e

d

T

u

r

n

o

u

t

s

-

S

e

t

t

i

n

g

O

u

t

O

f

f

s

e

t

s

NOTES

1. All dimensions are in millimetres.

2. Gauge is 1432 mm.

3. Lead lengths are given from toes of switches to noses of common

crossings.

4. # denotes a GV 24/28 turnout to drawing RE/PW/655.

5. * denotes a GV 24/28 extended transition turnout to drawing RE/PW/781.

6. (T) = Theoretical values, (A) = Actual values of existing installations.

Switch Crossing 1 in Lead L2 Offsets at 2500 intervals from the crossing nose

Natural Actual Toe to

nose

2500 5000 7500 10 000 12 500 15 000 17 500 20 000 22 500 25 000 27 500 30 000 32 500 35 000 37 500 40 000 42 500 45 000 47 500 50 000 52 500

AV 7 9.25 19 698 1177 913 666 448

BV 8 9.25 21 808 1178 920 687 487

8 10 22 261 1198 954 725 521

8 10.75 22 852 1215 985 766 564 387

CV 9.25 10.75 25 447 1216 990 780 593 432

9.25 13 27 007 1255 1063 874 694 527 378

DV 10.75 13 30 125 1256 1066 884 713 558 423 306

10.75 15 31 713 1281 1115 951 793 642 503 377

EV 15 18.5 42 017 1313 1178 1046 917 793 675 566 466 376

15 21 44 066 1329 1210 1091 974 860 749 643 542 447 360 282

FV 18.5 24 52 606 1344 1240 1136 1034 933 836 741 650 564 483 408 339

21 28 56 331 1359 1269 1180 1091 1003 916 830 747 665 587 511 439 370 306

SGV 21 28 60 782 1359 1269 1180 1092 1004 918 834 752 673 597 524 455 391 331

GV 24 # 28 66 679 1359 1270 1181 1094 1008 925 844 766 692 621 554 492 432 377

24 28 67 135 1358 1270 1184 1099 1015 934 855 778 705 634 567 503 443 387 335

24 32.365 69 933 1371 1293 1216 1140 1064 988 914 842 771 702 635 570 508 449 393 341

HV (T) 32 365 45.75 93 153 1287 1233 1178 1124 1070 1016 963 910 858 807 756 706 658 610 564 519 476 434 393 354 317

HV (A) 32 365 45.75 93 153 1287 1233 1178 1124 1070 1016 963 911 859 808 757 708 660 613 567 522 479 438 398 359 323

IP Nose

16N

G

a

u

g

e

10 000

7500

5000

2500

T

o

e

Heel length L1

Lead length L2

Track Design Handbook NR/L2/TRK/2049

Sheet 16 of 202

Network Rail

Revision 9 Date: June 2008

A.3.3: NR60 Inclined S&C Standard Transitioned Turnouts & Crossovers -

Leads and Radii

Transitioned Turnouts

NOTES

1. All lengths are measured along the main line straight (right hand switch rail for a right hand turnout and the left

hand switch rail for a left hand turnout.)

2. All dimensions are in millimetres. Gauge is 1435mm.

L1 = Length of straight, T - C (see sheet A.1.4: NR60 Inclined S&C Switch Details).

L2 = Length of transition curve, C - B (see sheet A.1.4).

L3 = Length of switch radius, R (see sheet A.1.4).

L4 = Length of transition curve from radius R to straight through crossing.

L5 = Length of straight to common crossing intersection point, IP.

Transitioned crossovers, across 1970 six-foot (running edges)

NOTES

1. # NR60G 31.25 has a different heel position from standard (see sheets A.1.4. & A.2.3.) - 32 201.085 mm from

toe, offset 313.52 mm.

Switch

designation

Crossing angle

1 in ~

L3 L4 L5 L

Turnout speed

mph

NR60C 11 9253 13 234 662 25 326 25

NR60D 13.5 9078 15 872 2345 29 800 30

NR60E 17.25 12 122 21 997 1492 38 906 40

NR60F 21.5 16 290 26 382 1939 48 761 50

NR60SG 27 23 100 31 618 2054 62 107 60

NR60G #31.25 26 010 38 550 1384 72 135 70

NR60G 33.5 22 110 39 555 5958 73 814 75

Switch

designation

Crossing angle

1 in ~

Turnout lead

length L

Lead across 1970

six-foot

Total crossover lead

length

Crossover speed

mph

NR60C 11 25 326 5808 56 460 25

NR60D 13.5 29 800 7159 66 760 30

NR60E 17.25 38 906 9179 86 991 40

NR60F 21.5 48 761 11 463 108 985 50

NR60SG 27 62 107 14 413 138 627 60

NR60G #31.25 72 135 16 692 160 961 70

NR60G 33.5 73 814 17 897 165 525 75

L

G

a

u

g

e

L1 L2 L3 L4 L5

T C B

R

A

IP

T

ransition Y

=

3

Y

=

1

2

IP

Straight

Mathematical

Toe

Origin of

Clothoidal Entry

Curve

T

r

a

c

k

D

e

s

i

g

n

H

a

n

d

b

o

o

k

N

R

/

L

2

/

T

R

K

/

2

0

4

9

S

h

e

e

t

1

7

o

f

2

0

2

N

e

t

w

o

r

k

R

a

i

l

R

e

v

i

s

i

o

n

1

D

a

t

e

:

J

u

n

e

2

0

0

8

A

.

4

.

1

:

C

E

N

5

6

E

1

V

e

r

t

i

c

a

l

S

&

C

L

e

a

d

s

a

n

d

R

a

d

i

i

A

c

r

o

s

s

S

t

a

n

d

a

r

d

(

1

9

7

0

)

T

r

a

c

k

I

n

t

e

r

v

a

l

NOTES

1. All dimensions are in millimetres.

2. Gauge is 1432 mm.

3. Leads are from nose to nose and are to the nearest 1 mm.

4. Radii are to the nearest 1 mm.

Xing 1 in 4 4.5 5 5.5 6 6.5 7 7.5 8 9.25 10 10.75 13 15 16 18.5 21 24 28 32.365 45.75

1 in

IP to

nose

64 72 80 88 96 104 112 120 128 148 160 172 208 240 256 296 336 384 448 518 - 4118

4 64 1811 89 815 51 641 39 057

4.5 72 1942 2088 123 436 70 213 52 632

5 80 2058 2217 2360 164 726 92 821 69 034

RADII 5.5 88 2161 2333 2488 2628 214 492 119 870 88 531

6 96 2437 2604 2756 2894 273 540 151 762 111 392 91 356

6.5 104 2709 2872 3021 3158 342 676 188 900 137 886 92 007

7 112 2978 3137 3285 3421 422 708 231 688 126 304 105 550

7.5 120 3245 3401 3547 3682 514 442 180 735 141 154 120 069

8 128 3344 3509 3664 3807 3942 279 396 195 072 157 061 112 312

9.25 148 3748 3923 4087 4241 4589 649 655 360 545 188 770 150 040 139 544 123 681

10 160 4059 4234 4400 4774 4975 811 961 266 672 195 528 178 109 153 101 140 002

10.75 172 4368 4545 4945 5160 5360 397 788 258 003 228 559 189 010 169 470 156 318

13 208 4912 5383 5640 5880 6513 736 845 539 182 361 420 296 323 258 440 232 625

15 240 5698 5988 6260 6985 7533 2 013 859 710 737 496 611 398 825 340 609 309 137 271 766

16 256 5835 6140 6427 7195 7779 8043 1 099 162 659 625 497 667 410 235 365 456 314 385

18.5 296

LEADS

6130 6469 6790 7657 8326 8630 9315 1 651 689 910 613 655 371 548 201 440 903

21 336 6738 7089 8046 8792 9133 9908 10 586 2 031 309 1 087 411 821 253 601 978