Professional Documents

Culture Documents

Making The Violin Geometric Arching Shape - Kopia

Uploaded by

nostromo1979Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Making The Violin Geometric Arching Shape - Kopia

Uploaded by

nostromo1979Copyright:

Available Formats

1

Making the Violin Geometric Arching Shape and A Method of Thickness Graduating Plates

By Robert Zuger Mejerigatan 16 SE26734 Bjuv Sweden Email: zuger.robert@telia.com

INTRODUCTION

In an earlier report on The impact of arching on structural deflection the quality and consequences of specific arching when string load is applied are described. Read www.zuger.se under the header "design quality". In order to achieve this specific quality the practical work must be done very precisely. The basis for this work is the geometric structure of arching and the Partial Stabilizing Framework (PSF) that arise when the sound post is squeezed between the belly and back. This PSF basically has the shape of an octahedron. The corner lines of the octahedron are structural shape on the arch of the belly and back and named Straight Tangent Line (STL). These extended STLs make the perfect octahedron shape. This report describes how to accomplish and how to make the geometric arching with the use of templates known as the six. This report explains how to make these templates, which are the necessary tools we need to control the specific arching.

1. How to construct the cross sectional shapes

All perpendicular cross arcs along the length axis have a radius shape (convex shape). The scoop shape outside these arcs has a varying concave shape. Later on in this report there will be a description of how the scoop may look. In order to be able to construct any geometrical cross arcs we must know precisely the height along the length axis and the length of the chord line. The chord line is the distance between the abutments of the arc between the "base lines". First of all the base lines must be constructed to find the abutment locations of the cross arcs. How to construct the base line (Figure 1a) is explained at: www.zuger.se under the header structural design. The first arc to construct is the height (H) of the arc. Figure 1b shows how to construct this first arc. The distance between the base lines in the centre is the length of the chord line. The arc radiuses is a consequence of the size of the equilateral triangle. With the compass at the top of the equilateral triangle on the central axis, we can now draw the arc A to C. The height corresponds with the normal arc height we find on almost all violins. The height of the cross arc (H) is also the height of the length arc. We mark this by drawing a circle. This is shown on the figure 1b.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

Figure 1a. The final stage of the 2D geometric structure with the "base lines" (in red)

Figure 1b. Constructing the arc height (H) The next arc to construct is the length radius. We already know the length of this chord line, which is the length of the instrument. This is marked with the blue vertical lines on the length axis, Figure 1a. In order to be able to construct the radius of this arc we must follow the 3 steps as they are shown in Figure 2.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

STEP 1

STEP 2

STEP 3

Figure 2. Three steps for the construction of the arc radius. STEP 1 Now that we have constructed the height of the instrument arc, we can go on to construct the length arc A to C, Figure 3a. We draw a horizontal line with the length of the instrument A to C (Figure 3a). This is the length of the chord line of the length radius. This line must be divided into two equal parts. We use a compass and draw the radius R1 and R2 (Figure 2) and find the intersections at D and E. The size of the radius is not important as long as the points D and E are far enough from each other so that the drawn vertical axis becomes vertically precise. When we have the vertical axis we find the centre point of the circle and can mark the height of the arc (H). We get the size of the circle from the above description (Figure 1b). STEP 2 We now draw the line A to B, which also is a chord line. This line must be divided into two equal parts. We do this by drawing the radiuses R3 an R4 of equal size at the points A and B. Now we draw the line F to G and extend the line in order to intersect with the vertical axis, where we find the centre point for the radius. STEP 3 Now we can draw the radius connecting the points A to B to C and we have the shape of the length arc. Other perpendicular cross sections to construct - Templates 1, 3, 4, 5 and 6. In Figure 3a, locations are chosen at the widest bout shapes on the "base lines" at 3 and 6. Further on, find the intersection between the big broken circle and where the base line changes shape intersecting with the circles at 4 and 5. It is important to have exact information about the locations L1 to L5. Otherwise, we do not know where to check with the

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

templates while we shape the arc. L3 is at the centre of the instruments length. Figure 3b shows a 3D image of Figure 3a. We make circles so we can determine the height (H) of the cross arc at locations 3, 4, 5 and 6. The distance between the "base lines" is the chord length as it is on Figure 2, STEP 2, from A to C (see also Figure 3b). Following the procedure, STEPS 1 to 3 above give us the exact cross arc shape of the radiuses wherever we want them to be.

Figure 3a. The length arc shape with marked cross locations

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

Figure 3b, 3D. View of Figure 3a

2. What a template should look like

Now we have all the information needed to transform the constructed arc radiuses into suitable material that we can use to make the templates. The final shape of the template must look as in Figure 4. The templates red arc determines the radius of the wood. The template and the wood must both be measured on the same flat surface when we check the shaping result.

Figure 4. The final shape of a template 3. How to use the template Figure 5 shows how to use the template checking the progressing work.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

Figure 5. Checking the shape of the cross section It becomes possible to check if the shape of the wood is correct by moving the template sideways closing the gap at the precise locations of L1 to L6. To check on the left side, the template must be turned around. When we come close to the final shape we must check whether the shape is consistently circular. We do this by rotating the template on the surface, Figure 6. For this, we do not need the supporting table.

Figure 6. Checking the radius shape by rotating the template 4. Finding Straight Tangent Lines (STL) When we make our arching very precisely with the help of the templates, the STLs will arise on the arching surface. Figure 7 shows the location where we must look for the existence of the STLs. The STLs demarcate very precisely convex shape from concave shape. These STLs are based on geometric data. For exhaustively information read the report under the header "design quality" at www.zuger.se. The existence of the STLs can be checked with a simple device such as a ruler with a sharp edge, Figure 8. When we have found the direction of the STLs, we mark the lines on the arching, even if they are not completely perfect. Some light may come through under the ruler. With a compass we

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

check that the distances L1 and L2 are equal and also the STL length from E to A and B and from E to C and D so that mirror image shape is present. If there is any difference we must adjust the direction so that the locations become perfectly symmetrical on both side of the length axis. The STL shape becomes perfect when there is no gap under the ruler; this means that the line is tangent on the surface. Most certainly we must make small adjustments on the arching to achieve this perfect circumstance.

Figure 7. STLs located on the arching However, the STLs direction may be perfect, but the slope may differ. For this reason we must make another check. The extending STL must intersect at the rib level (the underside of the plate) in order to make a perfect octahedron, Figure 11. At that stage the STLs also make a perfect truncated pyramid, as seen in Figure 10. The device to use to check the correct slope is shown in Figure 8. It is constructed from a plastic caliper with a ruler blade glued on one side. On the other side there is a fixed mark where the ruler blade has its extension.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

Figure 8. The simple device made from a plastic caliper Figure 9 shows how to use and check that the extending STL is at the level of the rib.

Figure 9. Checking the presence of the STL and the slope

On the model shown in Figure 10, we see how the pyramid shape arises making an internal framework on the arching.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

Figure 10. STL shape bringing about pyramid shape. Figure 11 shows the extending octahedron. STLs on the belly and the back that build a perfect

Figure 11. The octahedron, the PSF.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

10

5. The shape of the scoop

The location on the convex arch shape may vary where the scoop starts (concave shape). This means that there is a point where the convex arc changes into a concave scoop shape. Figure 12 shows that different outlines fit on the geometric arc shape by controlling the width of the scoop. However, the transition level from convex to concave scope does not necessarily have to happen at the level of an isoline all the way around the instrument. Especially at the wider instrument shape the cross arc radiuses may extend to an individual lower level where the scope shape may start. This is illustrated in Figure 13. These conditions, accepting a different extend convex arc and concave scope make it possible to design a different instrument outline. The possible circumstances are shown on Figures 12 and 13.

Figure 12, different scope width a specific altitude on the convex arc.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

11

Figure 13, extended cross arcs diverge at the transition level.

6. Another arching quality

Figure 14, shows halve of the upper part the belly arching while the lower part shows halve the back visualized with isolines. Equal cross sections arise. In Figure 14, two pars are shown on the belly and back with equal numbers. Their numbers are 1 to 4 and on the back and 5 to 8 are on the belly. The reason that they have equal numbers due to the fact that they have equal cross sectional arc shapes. These circumstances also arise when we make the arching with the help of the constructed templates. The numbers of such possible cross sections are unlimited and are predictable due to the geometric arching construction. We must look at these cross sections as very small structural members, each with their individual arc shape and thickness. When the strung instrument compresses on the end blocks the structural members start to deflect equally on both the upper bout and lower bout. The only criterion to allow the equal deflection to happen is to graduate the thicknesses of the structural members to resultant in equal resistance. This ultimately is done on the strung instrument in the white.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

12

Figure 14, Special structural quality on the belly and back arching. Two very special qualities come about on the convex arching: 1. The Partial Stabilizing Framework (PSF), Figures 7, 10 and 11. 2. The equal cross sectional shape in the upper and lower bouts, Figure 14.

7. The shape of the outline

Figure 15, shows how the outline of the instrument is related to the 2D geometric structure. Observe the black triangles where the curvature of the outline is located. These triangles have equal size and have a specific location in the 2D geometric layout. Observe that the baseline is slightly outside the outer contour of the instrument and is not part of the outline.

Figure 15, The outline of the instrument as it is related to the 2D geometric layout.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

13

Copy the outline of a good instrument on translucent paper. Figure 16 is a photo copy of a Stradivarius violin. It becomes possible to cover a major part of the outline by laying the paper upside down on the photocopy. To do this, the outline must rotate. Figure 16 shows that the outline in the red sectors of the upper and lower bouts cover each other perfectly. C to D covers E to F and C to D has equal shape from E to F1 It also becomes possible to do the same procedure for each one of the isolines. Four of them are shown on Figure 16, they come from the computer calculated isolines on top of the photo figure. A major part of the isolines in the green sector between A and B, cover each other very precisely. Each isolines must rotate separately covering its shape. The curvature diverges outside the sector A to B in the direction of the length axis. The curvature from C to A and from B to F are different. Studying the instrument's outline and the lowest isoline, it becomes obvious that they have a close relationship to each other. It is likely that the arching has a greater influence on the outline than the outline has on the arching.

Figure 16, Mirror image shape of the outline and the Isolines.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

14

8. Hollowing and graduating the plate thicknesses

When hollowing the inside we must also make STLs at the same location. Example A has parallel inside and outside STLs. The centre line remains straight when stretched. Example A, the centre line of the cross section shows correctly a straight line when the structure becomes stretched. Examples B1 and B2, explains what will happen with STLs that have the wrong thickness shape on the inside when the structure becomes stretched by tension. Example B1 has the correct outside STL but the curved inside shape is wrong, causing the centre line of the structure not to be straight. Example B2 shows what happens with B1 when this shape becomes stretched. There will arise a deformation that will change the cross-sectional shape. There will arise compression on the outside and tension on the inside to make a straight center line.

Figure 17. Shows different conditions that may arise on STLs After much of the hollowing has been done, we must carve out the inside STLs. Figure 18 shows how this is done. We must mark the STL position on the inside exactly where the STL is on the arch outside location. With a scraper we make a ditch at the location of the inside STL. With a ruler, we check carefully that we also have a perfect straight inside STL shape.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

15

Figure 18. The STL ditch On the belly the inside and outside STLs are always almost parallel like the A shape in Figure 17. On the back the thickness from the centre decreases. The cross section thus looks like Figure 19 with a centre line in the middle ofan isosceles trapezoid shape.

Figure 19. Decreasing thickness on Back STLs still has a straight centre line. When all four inside STLs have their main location and are close to the thickness we believe is correct, we mark the STLs. We make marks in order to measure the thickness at specific locations with a caliper checking that equal thickness is close to where the mirror image is located, Figure 20.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

16

Figure 20. Marked STLs with checkpoints for thickness control When we have the correct thicknesses on the STL checkpoints, the next step is graduating the arching thicknesses. We mark STL so we do not scrap on that location while scraping at others. Figure 21 shows the belly from the inside. The areas are sectorized. In the length axis, we find the columns as they are described in the report on structural deflection on: www.zuger.se. There are two columns - one on the left and one on the right. The lateral arching shape on the left and right side of the columns are marked bout.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

17

Figure 21. Hollowing the sectors and columns Hollowing the Belly Inside The process starts with graduating the thickness on the columns. Observe that the length and arc shapes of the columns are almost equal. From the sound post location to the cross section in front of the upper F-hole eyes we have a flat shape on the outside along the length axis. On a normal-sized violin the columns have a length of about 159-160 mm and an equal arc shape. The length of the flat shape is about 35-40 mm. The compression force on the end blocks acts unequally on the columns because the neck applies an extra momentum that brings about extra compressing stress. The deflection of the column, buckling by compression from string load, can be regulated by graduating the thicknesses. In this buckling process the lateral arching shape is also involved. The lateral "bout" areas are not expected to have equal wood quality on both sides of the column. There will always be some slight differences. Graduating the thicknesses of the upper and lower bout areas must be approached differently in order to have equal stress and deformation. This is no easy task and experience is needed to find understanding of how to handle this problem. This will be explained in another paper. Hollowing the back inside Hollowing the back principally is done in the same way as the belly. However, we must observe the different function of the back in relation to the belly. While the belly has two compressed columns, the back is brought into a state of bending. The deformation may look the same but the action of bending and buckling comes from different force actions. For this reason, the momentum that brings about the bending force requires more resistance where the reaction is given the partial stabilizing framework (the STLs and the sound post). The framework acts differently on the back than on the belly. Slightly reducing the thickness from the centre to the end blocks makes it possible for the bending force to become equal all the way. Lateral arching increases in the direction of the end blocks and becomes part of the bending process on the length axis. Understanding this influence is important.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

18

Figure 18 shows how the STL shapes on the inside are made, a ditch, before any other thickness graduation will be done . This process making the ditches may start when the overall thickness is about 5mm to 6mm. When the inside STL are at their correct location, we mark the STLs as shown on Figure 20. Using this working method makes it possible to check whether the thicknesses are equal at mirror image location. This will be important when the sector shape thickness is graduated the areas are minimized. Figures 22 and 23 show the scraping directions in the sectors. We see that the column shape thickness may be decreased. Thinning the column reduces the stiffness. The lateral arching may participate in the buckling of the column allowing the bouts to bulge. The arrows point out the favorable direction of scraping when the STL thicknesses and the column thicknesses have been established. Scraping this way in a downhill direction becomes precise in controlling the sector thicknesses between the inside STL and the column. Its easy to check and compare thicknesses between mirror image locations in the sectors of the bouts. In the Cbout sector we find some convex inside shape, close the corner blocks.. Here we must be precise because it is easy to reduce the thickness too much in this area.

Figure 22 The scraping process for the belly after STLs and column graduation

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

19

Figure 23. The scraping process for the back after STLs and column graduation At the end of this working process with free plates, we may find that our thickness graduations of the columns, the STLs and the sector shapes do not have the quality we expected. The combination of these factors might bring forth an arching structure that is too stiff. The flexibility must be improved. It is always possible to improve the flexibility by adjusting the thickness graduation of the columns, the STLs and the sector areas. Sector areas may be enlarged into the column areas, as shown in Figures 23 and 24. By doing so we will reduce the buckling resistance of the columns.

9. Incorrect arching deformation arise with incorrect STL location.

Figure 24 illustrate two incorrect STL locations for the C end point on the rib the C1 and C2 locations. ABCD is an isosceles trapezoid the base of a perfect pyramid. On the lower bout side we find equal long corner lines (A to E and B to E). We also observe equal triangle shape AFE and BFE. F and G are the lower and upper block locations. When these triangles that also have an equal arching shape become compressed by the application of the string load, deflection may (must) become equal. This can only happen when wood quality conditions are equal and have equal thickness graduation. Now we look at the upper bout triangles. The circumstances are the same on the triangles EDG and ECG. When the direction of the corner line STL thus EC instead end at C1 or C2 the STL is shorter or longer, which means that the length and slope diverge. The shape and size of the triangles EC1G or EC2G no longer are equal to EDG. In addition, the arch structure becomes different. When string load is applied at G the triangles with their arching shapes will not be stressed equally. Deflection and stresses will be different and affect the complete arching structure. Consider also the explanation given related to Figure 14

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

20

The conditions are out of our control and expectation. The reacting structure, the STLs, being part of the Partial Stabilizing Framework (PSF), also affects the stress and deformation in the C-bout shapes AED and BEC1 or BEC2 differently and finally also affects the deflection on the arching related to the triangles AFE and BFE. The reason why these circumstances are shown is to give an understanding of the importance of the mirror image shape along the centre line. Incorrect conditions described above become obstacles arriving for an optimal functional static and dynamic state. Correct structural conditions eliminate these barriers.

Figure 24. Different STL lengths affect stress conditions in the sector shapes During the first year of the strung instrument with faults described above will try to find a new stress state. Such state can only arise when deflection takes place on the arching. While this process is going on the stress on the compressed sound post changes. Normally it becomes less. A new longer sound post is needed to finally bring about stress conditions that, to some extent, are equal on all four STLs locations.

10. Checking free plate frequency vibrations with the Chladni method developed by Carleen Hutchins

In the early 1960s, Carleen Hutchins introduced a method graduating free plates with help of a sweep generator [2] based on Chladni modes (patterns) on stringed instrument plates. My own experience using the method tells me that it becomes possible to achieve equal frequency result (vibrating modes on free plates) by graduating the thicknesses differently. The Hutchins Method does not take into account any stress or structural deflection that will arise on the strung instrument with string load. These conditions will have a great impact on the dynamic and acoustic results. Carleen Hutchins never explained the importance of the function of arching.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

21

CH describes her opinion about arching and what she believes violin-makers understand with the following lines [3] : The experienced maker simply needs to look and eye-ball the shape of his arches, for he knows how to change the arches relative to the grain of the wood and various other subtleties that cannot be got from any sort of measurement technique. The result of the eye-balled arch shape is not known and it becomes impossible to give any technical explanation of its function in the strung instrument. The following pictures show the results of the vibration mode 5 after the thickness graduation with the method described above. For extensive information about Hutchins Method, see [4]. Figures 25, 26 and 27 show the vibration responses of a viola belly, the mode 5 shape. What we see on these figures are the nodal lines where no vibrations occur. On one side the structure move upward and on the other side the structure move downward. Figure 26 shows the normal shape of mode 5 at the frequency that we can hear when we knock on the plate holding it at the nodal line with our thumb and forefinger. Figure 25 shows the shape at approximately one octave lower and Figure 27 shows the frequency approximately one octave higher. Such circumstances, having three mode 5s, have not been shown in any report earlier.

Figure 25. Half mode 5 frequency of a viola belly, 156 Hz

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

22

Figure 26. The normal mode 5 frequency of a viola belly, 307 Hz

Figure 27. The double mode 5 frequency of a viola belly, 661 Hz. Static stress and vibration conditions become related to the bowl structures that arise in the upper and lower bout arching. The bowl arching shapes have concave shape on the inside in all directions and convex shapes on the outside.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

23

On free back plates vibration patterns becomes active in the bowl areas, Figure 28 and 29.

Figure 28

Figure 29

What we see on the lower bout area of these back plates are mode 5 (ring shaped mode) shapes that arise at approximately one octave higher than the normal "mode 5" frequency. The reason why the upper bout area does not have this ring mode shape depends on the anisotropic relationship in bending stiffness in length and the cross direction. The plate in the upper bout has smaller width, which does not allow the free plate bowl to vibrate making a ring. On the strung instrument, the deflection of the upper bout creates the bulging ring shape demarcated by the STLs and instrument outline. We observe this deflection shape on the holographic picture of the back plate of an instrument when the fine tuner increases the string tension, Figure 30.

Figure 30. The deflection of the back

Figure 31. The bowl areas with border shapes

Figure 30 shows outward bulging on the bout shapes of the back. The bowls, Figure 31, are demarcated by the STLs and have a triangular shape in front of the end blocks. Figure 30 shows that the bulging, in relation to the length axis, has almost equal deflecting shape on the left and right side of the lower bout in relation to the length axis. The bulging in the upper bout bowl is different on the left and right side which depend on an incorrect thickness graduation. Observe the shape and function of the STLs that brings about the Partial Stabilizing Framework (PSF) and demarcates the bowl shape.

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

24

References [1] Robert Zuger; The Impact of Arching Shape on Structural Deflection, http://zuger.se/design%20quality.html [2] Carleen Hutchins; Scientific American October 1981, The Acoustics of violin plates. [3] Carleen Hutchins; Sound generation in Winds strings Computers, page 136., ISBN 9185428-13-3 [4] Ghladni patterns for violin plates, The University of South Wales, Sydney, Australia, http://www.phys.unsw.edu.au/jw/chladni.html

Article Copyright 2012 Robert

Zuger. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed

You might also like

- Artikel 1986 09 Stradivari Gibson PDF PDFDocument7 pagesArtikel 1986 09 Stradivari Gibson PDF PDFCarlos AlbertoNo ratings yet

- Antonio Stradivari 1694 'Maria Ex Muir Mackenzie'Document7 pagesAntonio Stradivari 1694 'Maria Ex Muir Mackenzie'Antonio Miletti100% (1)

- The 'Betts' Stradivari 1704: A MasterpieceDocument7 pagesThe 'Betts' Stradivari 1704: A MasterpieceParacelso CelsoNo ratings yet

- 066-069 Trade SecretsDocument3 pages066-069 Trade Secretsblancofrank545100% (3)

- Pplleeaassee Ttaakkee Ttiim Mee Ttoo Rreeaadd Tthhiiss Wwaarrnniinngg!!Document8 pagesPplleeaassee Ttaakkee Ttiim Mee Ttoo Rreeaadd Tthhiiss Wwaarrnniinngg!!nhandutiNo ratings yet

- Plate Tuning PDFDocument132 pagesPlate Tuning PDFConsuelo FroehnerNo ratings yet

- Working Methods Guarneri Del GesùDocument10 pagesWorking Methods Guarneri Del GesùhorozimbuNo ratings yet

- Recreating Classical Violin VarnishDocument15 pagesRecreating Classical Violin VarnishMassimiliano Giacalone100% (1)

- Edge WorkDocument16 pagesEdge Worknostromo1979100% (1)

- Controlling Arch ShapeDocument9 pagesControlling Arch Shapenostromo1979100% (1)

- Del Gesu Table of MeasurementsDocument1 pageDel Gesu Table of MeasurementsCarl100% (1)

- Gasparo Da SaloDocument31 pagesGasparo Da SaloFrancesco Maria MazzoliniNo ratings yet

- A Viol RestorationDocument31 pagesA Viol RestorationFrancesco Maria MazzoliniNo ratings yet

- Violin Construction PDFDocument43 pagesViolin Construction PDFNóra RajcsányiNo ratings yet

- K The Sound HolesDocument7 pagesK The Sound HolesTeggy GatiaNo ratings yet

- Achieving Tonal Repeatability in Violins Through Plate Flexural StiffnessDocument9 pagesAchieving Tonal Repeatability in Violins Through Plate Flexural Stiffnessblancofrank545100% (1)

- Shaping Violin or Viola CornersDocument19 pagesShaping Violin or Viola CornersJairo Duarte100% (2)

- Strad Tap TonesDocument5 pagesStrad Tap TonesAlfstrad100% (2)

- Area Tuning The ViolinDocument10 pagesArea Tuning The ViolinRotar Razvan100% (1)

- Creating a Scroll Using Geometric TemplatesDocument3 pagesCreating a Scroll Using Geometric TemplatesDeaferrantNo ratings yet

- Violin Making ProjectDocument7 pagesViolin Making ProjectEnrique Mata100% (7)

- Antonio Stradivari 1694 'Maria Ex Muir Mackenzie': Description AND Measurements: Roger HargraveDocument7 pagesAntonio Stradivari 1694 'Maria Ex Muir Mackenzie': Description AND Measurements: Roger HargraveCarlos AlbertoNo ratings yet

- Bok InstrumentDocument27 pagesBok InstrumentAmeli ChanNo ratings yet

- Violin Making Guide by Walter H. MaysonDocument68 pagesViolin Making Guide by Walter H. MaysonBeray Selen100% (1)

- Violin MakingDocument69 pagesViolin MakingJeffrey Grosser88% (8)

- How To Make A Violin 1900Document178 pagesHow To Make A Violin 1900als36violi100% (3)

- 58042859Document8 pages58042859Weibin Liu100% (2)

- A Dictionary of Violin MakersDocument116 pagesA Dictionary of Violin MakersFernando Coton Luthier100% (6)

- Violin Templates and The Form PDFDocument9 pagesViolin Templates and The Form PDFAndrés Medina100% (1)

- Artikel 1986 09 Stradivari Gibson PDFDocument7 pagesArtikel 1986 09 Stradivari Gibson PDFFábio Daniel HadadNo ratings yet

- Example Chapter The Makers of Central Italy DesideriDocument5 pagesExample Chapter The Makers of Central Italy DesideriGlaucio Freitas100% (1)

- Modernized Violin VarnishesDocument3 pagesModernized Violin VarnishesMartin AllegroNo ratings yet

- Two Violin Forms:: Commentary and AnalysesDocument17 pagesTwo Violin Forms:: Commentary and Analysesnostromo1979100% (1)

- PollensDocument13 pagesPollensAdam AcostaNo ratings yet

- Effect of wood removal on vibration frequencies of bridgesDocument5 pagesEffect of wood removal on vibration frequencies of bridgesCristian TorricoNo ratings yet

- Bow Rehair ProcessDocument2 pagesBow Rehair Processsalecello2113No ratings yet

- The Identification of Cremonese Violins Part 1Document8 pagesThe Identification of Cremonese Violins Part 1PHilNam100% (1)

- Treble Viol Plan by LaBarreDocument7 pagesTreble Viol Plan by LaBarrePaola BrancatoNo ratings yet

- A Note On Practical Bridge Tuning For The Violin Maker Carleen M. HutchinsDocument4 pagesA Note On Practical Bridge Tuning For The Violin Maker Carleen M. HutchinsNikolai BuerginNo ratings yet

- Martin Schleske explores empirical tools in violin makingDocument15 pagesMartin Schleske explores empirical tools in violin makingFábio Daniel HadadNo ratings yet

- Tables of Me Sure SP Be Ley CelloDocument1 pageTables of Me Sure SP Be Ley CelloPascal DupontNo ratings yet

- Violin Repair and RestorationDocument148 pagesViolin Repair and RestorationMichael Mayson100% (3)

- The Treble Viol - LaBarre - DissertationDocument93 pagesThe Treble Viol - LaBarre - DissertationThiago EndrigoNo ratings yet

- 8 - Ways of HearingDocument5 pages8 - Ways of Hearingnostromo1979100% (1)

- How To Make A Violin, J. Broadhouse, Rev. Ed.Document139 pagesHow To Make A Violin, J. Broadhouse, Rev. Ed.Beray Selen100% (10)

- Making Transparent Golden Varnish from a Historical RecipeDocument3 pagesMaking Transparent Golden Varnish from a Historical Recipemarcellomorrone100% (1)

- Violin PDFDocument44 pagesViolin PDFblancofrank545No ratings yet

- Stradivari Violin SpecsDocument2 pagesStradivari Violin SpecsZeus_11188% (25)

- Amati Antonio & Girolamo 134-358Document225 pagesAmati Antonio & Girolamo 134-358Max RakshaNo ratings yet

- Coloring Agents For Varnish: Colors - General OverviewDocument1 pageColoring Agents For Varnish: Colors - General Overviewnostromo1979No ratings yet

- Guadagnini 1776 MedidasDocument8 pagesGuadagnini 1776 MedidasGuadagnini Rolim86% (7)

- George Gemünder's Progress in Violin Making: With Interesting Facts Concerning the Art and Its Critics in GeneralFrom EverandGeorge Gemünder's Progress in Violin Making: With Interesting Facts Concerning the Art and Its Critics in GeneralNo ratings yet

- Violin-Making: A Historical and Practical GuideFrom EverandViolin-Making: A Historical and Practical GuideRating: 4.5 out of 5 stars4.5/5 (4)

- A Guide to Violin Varnish - A Selection of Classic Articles on the Development and Qualities of Different Violin Varnishes (Violin Series)From EverandA Guide to Violin Varnish - A Selection of Classic Articles on the Development and Qualities of Different Violin Varnishes (Violin Series)No ratings yet

- The Repairing & Restoration of Violins 'The Strad' Library, No. XII.From EverandThe Repairing & Restoration of Violins 'The Strad' Library, No. XII.No ratings yet

- Michael Darnton/VIOLIN MAKING/Understanding ToneDocument11 pagesMichael Darnton/VIOLIN MAKING/Understanding Tonenostromo1979No ratings yet

- Coloring Agents For Varnish: Colors - General OverviewDocument1 pageColoring Agents For Varnish: Colors - General Overviewnostromo1979No ratings yet

- Violin FarmDocument1 pageViolin Farmnostromo1979No ratings yet

- Refining Linseed OilDocument10 pagesRefining Linseed Oilnostromo1979No ratings yet

- Subject To ChangeDocument7 pagesSubject To Changenostromo1979100% (1)

- Sustainable Luthierie - A Pioneer's GuideDocument13 pagesSustainable Luthierie - A Pioneer's Guidenostromo1979100% (1)

- Two Violin Forms:: Commentary and AnalysesDocument17 pagesTwo Violin Forms:: Commentary and Analysesnostromo1979100% (1)

- Strad FF HolesDocument1 pageStrad FF Holesnostromo1979No ratings yet

- Microsoft Word For The Strad Part 1 8 SeptDocument10 pagesMicrosoft Word For The Strad Part 1 8 Septnostromo1979100% (1)

- Oil Varnish ReciipeDocument2 pagesOil Varnish Reciipenostromo1979No ratings yet

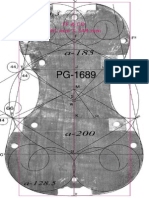

- PG Mould in PDFDocument1 pagePG Mould in PDFblancofrank545No ratings yet

- Muratov PGDocument1 pageMuratov PGnostromo1979100% (1)

- Microsoft Word For The Strad Part 1 8 SeptDocument10 pagesMicrosoft Word For The Strad Part 1 8 Septnostromo1979100% (1)

- Creating classical violin forms through edgework and purfling techniquesDocument4 pagesCreating classical violin forms through edgework and purfling techniquesCristian TorricoNo ratings yet

- Pernambuco and BowsDocument13 pagesPernambuco and Bowsnostromo1979100% (1)

- Wood For SoundDocument10 pagesWood For SoundJayMorgan100% (1)

- Bridge Tuning JanssonDocument5 pagesBridge Tuning Janssonnostromo1979No ratings yet

- Scroll Carving Techniques for LuthiersDocument17 pagesScroll Carving Techniques for LuthiersZeus_111100% (1)

- Echard in Situ EDX On VarnishDocument6 pagesEchard in Situ EDX On Varnishnostromo1979No ratings yet

- Michael Darnton/VIOLIN MAKING/Corner Blocks - : Derivation of The Stradivari Corner BlockDocument5 pagesMichael Darnton/VIOLIN MAKING/Corner Blocks - : Derivation of The Stradivari Corner Blocknostromo1979No ratings yet

- 8 - Ways of HearingDocument5 pages8 - Ways of Hearingnostromo1979100% (1)

- CH BridgeDocument4 pagesCH Bridgenostromo1979No ratings yet

- Measuring and tuning a violin bridge's resonance frequencyDocument8 pagesMeasuring and tuning a violin bridge's resonance frequencyOmid Sharifi100% (1)

- Edge WorkDocument16 pagesEdge Worknostromo1979100% (1)

- Controlling Arch ShapeDocument9 pagesControlling Arch Shapenostromo1979100% (1)

- Bridge HillDocument29 pagesBridge Hillnostromo1979No ratings yet

- Comparison of Arching Profiles of Golden Age Cremonese Violins and Some Mathematically Generated CurvesDocument18 pagesComparison of Arching Profiles of Golden Age Cremonese Violins and Some Mathematically Generated Curvesnostromo1979No ratings yet

- Sound Holes MITDocument0 pagesSound Holes MITPhilip Gregory SouglesNo ratings yet

- Bridge Tuning JanssonDocument5 pagesBridge Tuning Janssonnostromo1979No ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakaRamli UsmanNo ratings yet

- Antiquity: Middle AgesDocument6 pagesAntiquity: Middle AgesPABLO DIAZNo ratings yet

- Imaging Approach in Acute Abdomen: DR - Parvathy S NairDocument44 pagesImaging Approach in Acute Abdomen: DR - Parvathy S Nairabidin9No ratings yet

- Active and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Document5 pagesActive and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Kamal deep singh SinghNo ratings yet

- WassiDocument12 pagesWassiwaseem0808No ratings yet

- Practice Like-Love - Hate and PronounsDocument3 pagesPractice Like-Love - Hate and PronounsangelinarojascnNo ratings yet

- Equipment, Preparation and TerminologyDocument4 pagesEquipment, Preparation and TerminologyHeidi SeversonNo ratings yet

- Reinvestment Allowance (RA) : SCH 7ADocument39 pagesReinvestment Allowance (RA) : SCH 7AchukanchukanchukanNo ratings yet

- IntroductionDocument34 pagesIntroductionmarranNo ratings yet

- Course Tutorial ASP - Net TrainingDocument67 pagesCourse Tutorial ASP - Net Traininglanka.rkNo ratings yet

- Micropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldDocument8 pagesMicropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldIJBSS,ISSN:2319-2968No ratings yet

- Miami Police File The O'Nell Case - Clemen Gina D. BDocument30 pagesMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceNo ratings yet

- Newcomers Guide To The Canadian Job MarketDocument47 pagesNewcomers Guide To The Canadian Job MarketSS NairNo ratings yet

- Failure Analysis Case Study PDFDocument2 pagesFailure Analysis Case Study PDFScott50% (2)

- The Singular Mind of Terry Tao - The New York TimesDocument13 pagesThe Singular Mind of Terry Tao - The New York TimesX FlaneurNo ratings yet

- Florence Walking Tour MapDocument14 pagesFlorence Walking Tour MapNguyễn Tấn QuangNo ratings yet

- IMM Indian Oil Case Group 3Document13 pagesIMM Indian Oil Case Group 3Soniya AgnihotriNo ratings yet

- C Exam13Document4 pagesC Exam13gauravsoni1991No ratings yet

- Finance at Iim Kashipur: Group 9Document8 pagesFinance at Iim Kashipur: Group 9Rajat SinghNo ratings yet

- CGV 18cs67 Lab ManualDocument45 pagesCGV 18cs67 Lab ManualNagamani DNo ratings yet

- Impact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisDocument5 pagesImpact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Put The Items From Exercise 1 in The Correct ColumnDocument8 pagesPut The Items From Exercise 1 in The Correct ColumnDylan Alejandro Guzman Gomez100% (1)

- Supplier GPO Q TM 0001 02 SPDCR TemplateDocument6 pagesSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoNo ratings yet

- BoQ East Park Apartment Buaran For ContractorDocument36 pagesBoQ East Park Apartment Buaran For ContractorDhiangga JauharyNo ratings yet

- SQL Server 2008 Failover ClusteringDocument176 pagesSQL Server 2008 Failover ClusteringbiplobusaNo ratings yet

- Roadmap For Digitalization in The MMO Industry - For SHARINGDocument77 pagesRoadmap For Digitalization in The MMO Industry - For SHARINGBjarte Haugland100% (1)

- Deluxe Force Gauge: Instruction ManualDocument12 pagesDeluxe Force Gauge: Instruction ManualThomas Ramirez CastilloNo ratings yet

- 14 15 XII Chem Organic ChaptDocument2 pages14 15 XII Chem Organic ChaptsubiNo ratings yet

- Username: Password:: 4193 Votes 9 Days OldDocument6 pagesUsername: Password:: 4193 Votes 9 Days OldΘώμηΜπουμπαρηNo ratings yet

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Document19 pagesHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeNo ratings yet