Professional Documents

Culture Documents

QHSE Monthly Report - Nov 2013

Uploaded by

Sakthivel MurthyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QHSE Monthly Report - Nov 2013

Uploaded by

Sakthivel MurthyCopyright:

Available Formats

OSS Quality Highlights November 2013: OSS Singapore

QHSE MONTHLY MANAGEMENT REPORT November13

1) Halliburton (Sing II) Functionally accepted two parts of AGS housing and delivered to Halliburton Sing 2 for CMM inspection with NCR. Currently waiting for the CMM result from Halliburton Sing 2. 2) Customer Audit: i) ii) iii) Schlumberger vendor audit was completed on 6 & 7th Nov 2013. No major findings were recorded. Some highlighted observations are not yet closed. We will reply to Schlumberger by mid December 2013. Halliburton Safety audit was completed on 11th Nov 2013. No major findings were recorded. Some highlighted observations are not yet closed. We will reply to Halliburton by mid December 2013. Weatherford will visit Singapore plant for an audit on 9 Dec 2013.

3) Vendor Audit We have gone through with GOTI to reply to Halliburton on the findings. The current team in GOTI is not well prepared to reply on any findings which are concerns. We have spoken to Din to beef up his team and more actions are to be carried out to ensure that they are competent to handle any audit. The CAPA was sent to Halliburton and waiting for Mr Ragos reply. 4) Internal Audit Course: Syawai, Zarni, Zeyar and Amin attended internal audit course from 11th to 12th Nov 2013.

Page 1 of 12

OSS OSS Kakinada:

QHSE MONTHLY MANAGEMENT REPORT November13

The surveillance audit findings of 2 minor non conformances (AARs) are responded to API and all are resolved. OSSK can continue to use the Monogram. We are now waiting to receive all the certificates. HSE Management System has been implemented in OSSK. Prashant and Selva will continue to maintain the QHSE Management System in OSSK. There will be an impending audit from Schlumberger in early Dec 13. OSS Mumbai: HSE Management System has been implemented in OSSI. Prashant and Satish will continue to maintain the QHSE Management System in OSSI. SVP Thailand: Gopal and Sakthi will be travelling to SVP Sattahip for the 2nd stage API audit from 5th Dec 2013 to 20th Dec 2013. The 2nd stage audit has been scheduled on the 18th to 19th Dec 2013. According to discussion, the next plan is to assist SVP Songkhla for the API certification and continue the support services to SVP. PTOSS Jakarta: Gopal and Syawai has completed the 2nd stage API audit PTOSS Jakarta from 29th Oct 13 to 31st Oct 13. There were 7 minor non-conformances (NCs) recorded by the API auditor. Erwin has prepared the CAPA for the AARs but need to be revised. Targeted date on 15 Dec 2013 to complete and reply to API. OLIO Labuan: Full training for Amin was completed and he has started to prepare the documentations for stage one API audit. HSE Management System has been implemented in Labuan. Amin will continue to maintain the QHSE Management System in Labuan. Michael will travel to Labuan from 9th to 13th Dec 2013 to perform internal audit on the QHSE Management System and verify readiness of API Audit planned for Jan 14.

Page 2 of 12

OSS OSSTJ:

QHSE MONTHLY MANAGEMENT REPORT November13

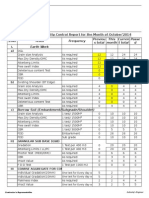

HSE Management System has been implemented in OSSTJ. Chao Yunfei and Yu Fuheng will continue to maintain the QHSE Management System in OSSTJ. Michael will travel to OSSTJ from 2th to 6th Dec 2013 to check on the preparation status of the Quality Management System and verify readiness of API Audit planned from 3rd to 5th Jan 2014. INSPECTION STATUS / NON-CONFORMANCE ITEMS Summary Month of November 2013 OSS NCRs : 08 7 NCR Use as it (23 parts) 1 NCR Scrap (1 Part)

Details: 1 production non-conformance (068-13) is identified at production in-process inspection Customer: Halliburton Sing 2 Tool Description: 12.1875 HS NM SLEEVE STABILIZER NCR Description: As per Halliburton spec D00556974 Rev.A, maximum defect allowed 3 mm, existing defects size range from 3-6mm and also drawing SS.077204 Rev.C required Virgin Carbide on build up slopes area (8 places).Instead of that OSS placed 3/8 Virgin Carbide on build up slopes (8 places) which is oversize by 1/8. NCR Disposition: Use as it is (Given by customer) Rejected Qty: 2 pcs 1 production non-conformance (069-13) is identified at production in-process inspection Customer: Halliburton Sing 2 Tool Description: 8.405HS SPIRAL STABILIZER PM REPLACEMENT NCR Description: 1) As per Halliburton spec D00556974 Rev.A, maximum defect allowed 3 mm, existing defects size range from 4-6mm. 2) As per Halliburton drawing SS.077204 Rev.C required Virgin Carbide on build up slopes area (8 places).Instead of that OSS placed 3/8 Virgin Carbide on build up slopes (8 places) which is oversize by 1/8.

Page 3 of 12

OSS

QHSE MONTHLY MANAGEMENT REPORT November13 3) As per Halliburton drawing SS.077204 Rev. C the required pin connection counter bore ID (L23) is 3.125 (+0.010/-0.000), existing defects size is 3.146 for 1pc only (CP2340878). Use as it is (Given by customer) 2 pcs

NCR Disposition: Rejected Qty:

1 production non-conformance (070-13) is identified at production in-process inspection Customer: A. M. Castle & Co. Tool Description: ROUGHOUT MANDREL NCR Description: 1) Offset Undersized by 0.013on RH end and 0.017on LH end. 2) Run out over maximum tolerance by 0.008 3) Wall thickness over maximum tolerance by 0.0165 and under minimum tolerance by 0.004. NCR Disposition: Use as it is (Given by customer) Rejected Qty: 1 pc 1 production non-conformance (071-13) is identified at production in-process inspection Customer: Mersing Corporation (LL03146) Tool Description: 8 OD FLOAT SUB NCR Description: Bore ID was oversized by 3/4. NCR Disposition: Scrap - Return to Inventory for future order (Given by Production Manager) Rejected Qty: 1pc 1 production non-conformance (072-13) is identified at production in-process inspection Customer: Halliburton Sing 2 Tool Description: 5 3/4 Shorty Stabilizer Sleeve NCR Description: I.D. all oversized by 0.0025 to 0.004 from max tolerance. NCR Disposition: Use as it is (Given by customer) Rejected Qty: 8 pcs 1 production non-conformance (073-13) is identified at production in-process inspection Customer: Halliburton Sing 2 Tool Description: 12.1875 HS NM SLEEVE STABILIZER NCR Description: 1) As per Halliburton spec D00556974 Rev.A, maximum defect allowed 3 mm, existing defects size range from 4-6mm. 2) As per Halliburton drawing SS.077204 Rev.C required Virgin Carbide on build up slopes area (8 places).Instead of that OSS placed 3/8 Virgin Carbide on build up slopes (8 places) which is oversize by 1/8. NCR Disposition: Use as it is (Given by customer)

Page 4 of 12

OSS Rejected Qty: 6 pcs

QHSE MONTHLY MANAGEMENT REPORT November13

1 production non-conformance (074-13) is identified at production in-process inspection Customer: Halliburton Sing 2 Tool Description: 8.405HS SPIRAL STABILIZER PM REPLACEMENT NCR Description: 1) As per Halliburton spec D00556974 Rev.A, maximum defect allowed 3 mm, existing defects size range from 3-6mm. 2) As per Halliburton drawing SS.077204 Rev.C required Virgin Carbide on build up slopes area (8 places). Instead of that, OSS placed 3/8 Virgin Carbide on build up slopes (8 places) which is oversized by 1/8. NCR Disposition: Use as it is (Given by customer). Rejected Qty: 2 pcs 1 production non-conformance (075-13) is identified at production in-process inspection Customer: Halliburton Sing 2 Tool Description: 8.405HS SPIRAL STABILIZER PULSAR XOVER. NCR Description: 1) As per Halliburton drawing SS.077204 Rev. C required Virgin Carbide on build up slopes area (8 places). Instead of that, OSS placed 3/8 Virgin Carbide on build up slopes (8 places) which is oversized by 1/8. 2) As per Halliburton Spec No. D00556974 Rev. A, maximum defect allowed 3 mm, existing defects size range from 4-6mm. NCR Disposition: Use as it is (Given by Customer). Rejected Qty: 2 pcs Vendor NCRs :1

1 Vendor non-conformance (CP001-13) is identified at incoming inspection Vendor: CLEFTON PRECISION PTE LTD Tool Description: Ring Gauges NCR Description: ID Oversized. NCR Disposition: 2 pcs as reworked by Vendor & 1 pc as Scrap (machining cost was reduced for 1 pc). Rejected Qty: 3 pcs Customer Complaints (Quality Escapes) : 0

Page 5 of 12

OSS Summary to date (2013) Vendor NCRs to date (2013) NCR Issued to date (2013) Customer complaints to date (2013) KPI Quality Escapes to date (2013) PCR & COC: PCR & COC Reviewed: 500 nos PCR & COC on Time: 475 nos KPI Achieved : 16 : 75 to production : 14

QHSE MONTHLY MANAGEMENT REPORT November13

: To minimize Quality Escapes Max. 3 Nos allowed. : 14

: To achieve 92% of the Quality documents to be completed within 2 DAYS from the date of Job completion. : 95% of the documents are completed on time.

Raw Material Inspection: Total items inspected: 51 nos Total items inspected within 3 days: 51 nos Total items inspected above 3 days: 0 KPI Achieved : To achieve 90% of the Raw Material Inspection to be completed within 3 DAYS from request. : 100% of the raw material inspections are completed on time.

Internal Audit & Continual Improvement: KPI : To complete at least ONE Cycle of Internal audit in the year 2013.

Page 6 of 12

OSS Achieved workshops. QHSE MANPOWER MOVEMENT & OVERTIME: : Not yet.

QHSE MONTHLY MANAGEMENT REPORT November13

Note : Internal Audit Program has scheduled to carry out in Dec 2013 due to hectic schedule in providing support to the satellite

The Quality Inspectors, Document Controller and Engineers worked for 1651.38 Hours (Effective hours) in total which includes 330.75 hours (paid overtime) and 58 hours (no pay overtime). 5 Man days taken for Annual Leave for Nov 2013 4 Man days taken for MC for Nov 2013 6 Man days taken for NS for Nov 2013 6 Man days taken for Internal Audit Course for Nov 2013 Total 2 Man days taken for overseas assignment for Nov 2013

Page 7 of 12

OSS

QHSE MONTHLY MANAGEMENT REPORT November13

Report for the month / year of: November 2013 MAN-HOURS Total no of workers: Number of MAN-HOURS worked (inclusive overtime, Sunday & Public Holiday) Accumulated MAN-HOURS worked since beginning of year (inclusive overtime, Sunday & PH) SAFETY / OCCUPATIONAL INJURIES Number of FATALITIES in the month: Number of Accident in the month: 0 1 89 20024 191503

Page 8 of 12

OSS

QHSE MONTHLY MANAGEMENT REPORT November13

Description of Accident Name of person involved: Chen Guo Ping (Lathe Machinist) Date/Time: 11 Nov 2013 at 14.55 pm. How did it happen: 1. Chen Guo Ping had completed the threading works of a 8 (NM) Drill Collar (22 L) at the first CNC Lathe Threading machine (200021-CL) and wanted to withdraw the Drill Collar out from the chuck and place it on the Pipe Rack. 2. He stood within the Pipe Rack area and had hooked the Drill Collar with the 2 legged metal chains linked to the Overhead Crane. 3. His right hand was controlling the Control Pendant to lift the Drill Collar. 4. As the Drill Collar was lifted up in suspension, it was not balanced and tends to sway out in a clockwise direction. 5. Guo Ping tried to bring it back by using his left hand. Unknowingly, he placed his left fingers between the metal chain and the Drill Collar in a blind spot. And in a split second, his left middle finger was pinched between the metal chain link and the Drill Collar. 6. Guo Ping lowered the overhead crane using the control pendant in his right hand to loosen and free his left middle finger. 7. When his left hand was freed, he removed his glove and he realized that the left middle finger tip was bleeding. There was a cut ~ inch near the finger tip. Corrective action: Give first aid treatment to him and then brought him to hospital for further treatment. Toolbox briefing to all Supervisors and Safety Officer to carry out more supervision, observe unsafe acts and to stop workers whenever necessary to educate them. Appoint someone for Lifting Supervisor course. This person will assist to oversee the Lifting operations. Number of LOST TIME INJURIES (LTI) in the month: Number of MEDICAL TREATMENT CASES (MTC) for the injured person in the month: Number of RESTRICTED WORK CASES (RWC) in the month: 1 1 0

Page 9 of 12

OSS

QHSE MONTHLY MANAGEMENT REPORT November13

Number of FIRST AID CASES (FAC) in the month: Number of NEAR MISS INCIDENTS REPORTED in the month: Number of INCIDENT REPORT submitted to MOM in the month: Number of SAFETY FINDING in this month

4

1 0 1 13

Jan Feb Mar Apr May Jun July Aug

2 2

11

0 0

0 0

00

Sep Oct Nov

Accumulated SAFETY FINDINGS in year 2013 HEALTH Number of OCCUPATIONAL ILLNESS CASES (cases of illness caused by work) in the month: 0

Page 10 of 12

OSS

QHSE MONTHLY MANAGEMENT REPORT November13

Number of MAN-DAYS LOST DUE TO OCCUPATIONAL ILLNESS in the month: ENVIRONMENT Number of FUEL, CHEMICAL or OIL SPILLS reported in the month: TRAINING/ORIENTATION Number of workplace safety policy TALK conducted in the month: Number of NEW EMPLOYEE SAFETY ORIENTATION conducted in the month: Number of 3RD PARTY/CONTRACTORS/VISITORS SAFETY ORIENTATION conducted in the month: Number of SAFETY TRAINING conducted for the month: Number of tool box talks conducted in the month: Others

1.

3 3 3 3 20

Accident free days record. As at 30th Nov 2013, the total number of accident free days is 19 Accident Free days. One reportable accident occurred on 11 Nov 2013 involving Chen Guo Ping Lathe Machinist.

2.

Safety Training/ Orientation Safety Orientation given to Contractor/Visitors: a) Multicrane ADC Pte Ltd - Sai , Themuchok, Ruang Rit, Shi Guang Zheng b) Saltire Energy Pte Ltd Hardi and Ema. c) Iszunaidi Inspector (GOTI) Safety Orientation given to following new OSS employees: a) Qin Jian- Machinist b) Yap Oi Kee Technical Engineer

Page 11 of 12

OSS c) Cao Wei Machinist Safety Training

a) Iszunaidi - Inspector from GOTI Risk Assessment on LPI, MPI and QC Inspection. b) Raju Maintenance Asst Supervisor SWP Lock Out Tag Out c) Production Machinists & workers Requirements and selection of Personal Protection Equipment 3.

QHSE MONTHLY MANAGEMENT REPORT November13

Fire Drill Exercise A Fire Drill was conducted on the 28 Nov 2013 at 11.00am. The timing was 4mins 12sec. Though the timing was longer than the previous one - 3mins 20sec, it was still considered a success as the drill was executed smoothly without any incident. Moreover, for this drill, which day and what time to activate the alarm was not notified to everyone.

4.

HSE Management implementation at satellite workshops. a) OSS Mumbai & Kakinada, OSSTJ and OLIO Labuan HSE Policy Completed HSE Manual Completed HSE Procedures - Completed HSE Forms - Completed SWP - Completed HSE Records in progress. Risk Assessment, Training, Safety inspection, Registers of Lifting equipment, Chemicals (MSDS). Visits to all satellite will be arranged from Dec 2013. nd th OSSTJ 2 to 6 Dec 2013 th th Labuan 9 to 13 Dec 2013 th th OSSI Planned to travel from 15 to 20 Dec 2013

Page 12 of 12

You might also like

- First Aid in The Workplace PDFDocument21 pagesFirst Aid in The Workplace PDFLoredana IvanovNo ratings yet

- ESCL-SOP-013, Outsourcing Procedure - Doc Rev 01Document6 pagesESCL-SOP-013, Outsourcing Procedure - Doc Rev 01adiqualityconsult0% (2)

- Understanding Generator Set Ratings: Chad Dozier Market Development Manager Electric Power DivisionDocument7 pagesUnderstanding Generator Set Ratings: Chad Dozier Market Development Manager Electric Power DivisionSakthivel MurthyNo ratings yet

- Understanding Generator Set Ratings: Chad Dozier Market Development Manager Electric Power DivisionDocument7 pagesUnderstanding Generator Set Ratings: Chad Dozier Market Development Manager Electric Power DivisionSakthivel MurthyNo ratings yet

- API Assignment Q2Document2 pagesAPI Assignment Q2Salman Farooq50% (2)

- Job Analysis, Job Design and Quality of Work LifeDocument14 pagesJob Analysis, Job Design and Quality of Work Lifes1103294475% (8)

- Qhse PolicyDocument1 pageQhse PolicypremNo ratings yet

- Lessons Learned PDFDocument1 pageLessons Learned PDFYasir_Wafi_1101No ratings yet

- 5S: Workplace Organization and StandardizationDocument49 pages5S: Workplace Organization and StandardizationRoy Narap100% (1)

- QC TESTSDocument58 pagesQC TESTSAshok Kumar KollaNo ratings yet

- Alu-Tucp Vs NLRCDocument4 pagesAlu-Tucp Vs NLRCJboo Badique CaimoyNo ratings yet

- Toc-Ta Workpack Rev.1Document2 pagesToc-Ta Workpack Rev.1anjangandak293250% (2)

- Qhse Policy: Applicable Legislative, Regulatory and Customer-Based RequirementsDocument2 pagesQhse Policy: Applicable Legislative, Regulatory and Customer-Based RequirementsBenito TadeoNo ratings yet

- Employee Retention in HCLDocument44 pagesEmployee Retention in HCLananth46918974No ratings yet

- Gokpl Hse-Pro-004 Housekeepng Procedure: Genting Oil Kasuri Pte. LTDDocument10 pagesGokpl Hse-Pro-004 Housekeepng Procedure: Genting Oil Kasuri Pte. LTDMei LindaNo ratings yet

- Turkish Gas Pipeline extension to borderDocument1 pageTurkish Gas Pipeline extension to borderNizar KhalidNo ratings yet

- Bits CatalogDocument92 pagesBits CatalogzetboyNo ratings yet

- Standard Operating ProcedureDocument4 pagesStandard Operating ProcedureJAY BHAVSARNo ratings yet

- Inspection Record For Site WeldingDocument1 pageInspection Record For Site WeldingCinek_cin100% (1)

- Quality Control Assurance SystemsDocument9 pagesQuality Control Assurance SystemsSathi shNo ratings yet

- Material Management: Planning, Procurement, Storage, and Inventory ControlDocument84 pagesMaterial Management: Planning, Procurement, Storage, and Inventory ControlManya KrishnanNo ratings yet

- Cost Estimating in Construction CourseDocument46 pagesCost Estimating in Construction CourseNong Noc100% (1)

- Willis CNOOC HSE Management Practice-EnDocument54 pagesWillis CNOOC HSE Management Practice-EnTatak Bay Ahmed100% (1)

- VI-401466-PS-1 Example ISO 9001 Document Control ProcedureDocument7 pagesVI-401466-PS-1 Example ISO 9001 Document Control ProcedurevoyyNo ratings yet

- Case AnalysisDocument6 pagesCase AnalysisVaishali RathiNo ratings yet

- 26 32 13.13 Emergency GeneratorDocument9 pages26 32 13.13 Emergency Generator-Deny D'hana-No ratings yet

- Company's 2022 QHSE Annual ReportDocument33 pagesCompany's 2022 QHSE Annual ReportCallif Al AmienNo ratings yet

- QHSE PolicyDocument1 pageQHSE PolicyPauloCuatoNo ratings yet

- Problems in AppraisalDocument3 pagesProblems in AppraisalnafesaNo ratings yet

- Work Immersion (Quarter 3, Week 1 and 2) Learning Activity Sheet Work Ethics and Safety in The WorkplaceDocument6 pagesWork Immersion (Quarter 3, Week 1 and 2) Learning Activity Sheet Work Ethics and Safety in The Workplacemarissa casareno almueteNo ratings yet

- Acceptance Sampling: Prepared by Anthony Lizza Penn State UniversityDocument29 pagesAcceptance Sampling: Prepared by Anthony Lizza Penn State UniversityMayurdhvajsinh JadejaNo ratings yet

- Quality, Management Plan - TemplateDocument9 pagesQuality, Management Plan - TemplateEsther AtereNo ratings yet

- 1-1 Corrective, Preventive, PredictiveDocument26 pages1-1 Corrective, Preventive, PredictiveAngie Barrera100% (1)

- Qhse Loss Prevention TeamDocument5 pagesQhse Loss Prevention TeamherikNo ratings yet

- Supply ChainDocument24 pagesSupply ChainAkhmadRifaniNo ratings yet

- Maintenance ConceptsDocument42 pagesMaintenance Conceptschala nigussieNo ratings yet

- Types of EmployeesDocument9 pagesTypes of EmployeesGerry Malgapo100% (1)

- Managing Boston Office ReorganizationDocument7 pagesManaging Boston Office ReorganizationKshitij SinghNo ratings yet

- Neo-Classical TheoryDocument17 pagesNeo-Classical TheoryDeep Agrawal100% (1)

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Copy of 2012 Manpower Timesheet December 16-30-1Document3 pagesCopy of 2012 Manpower Timesheet December 16-30-1Michelle Umali-EgiptoNo ratings yet

- Basics of Customer ServiceDocument13 pagesBasics of Customer ServicerautrajeshvNo ratings yet

- Audit Report: Procedure Title: Document Control Auditor: Audit No: Procedure Ref No: Auditee: DateDocument3 pagesAudit Report: Procedure Title: Document Control Auditor: Audit No: Procedure Ref No: Auditee: DateUmmy Faaza RosmiatiNo ratings yet

- QHSE Document ControllerDocument2 pagesQHSE Document ControllerMd asrar aliNo ratings yet

- Sales and Marketing Risks To Consider Yes No N/A Comments / Action RequiredDocument2 pagesSales and Marketing Risks To Consider Yes No N/A Comments / Action RequiredRob WillestoneNo ratings yet

- Vincotte International Middle EastDocument16 pagesVincotte International Middle Eastilkerkozturk100% (1)

- Monitoring The Quality of LogisticsDocument13 pagesMonitoring The Quality of LogisticsSantosh KumarNo ratings yet

- Neo Global English 2006Document53 pagesNeo Global English 2006charlessimoNo ratings yet

- Schlumberger Management System OverviewDocument20 pagesSchlumberger Management System OverviewsudharsanNo ratings yet

- Construction Personnel Management TechniquesDocument4 pagesConstruction Personnel Management Techniquessai kiranNo ratings yet

- Paper SolutionDocument6 pagesPaper Solutionamarpal07No ratings yet

- Challenges of Quality Assessment System (Qlassic) in Construction Industry in MalaysiaDocument23 pagesChallenges of Quality Assessment System (Qlassic) in Construction Industry in MalaysiaAsyraf HakeemNo ratings yet

- Sri Balaji Pharma Limited Quality PolicyDocument1 pageSri Balaji Pharma Limited Quality PolicyChilaNo ratings yet

- Foundations of Customer ServiceDocument12 pagesFoundations of Customer ServicemohammedNo ratings yet

- Production ManagementDocument18 pagesProduction ManagementMahesh TejaniNo ratings yet

- Carpenter Job Description SummaryDocument1 pageCarpenter Job Description SummaryΣπίθας ΣπιθαμήNo ratings yet

- HSE Leadership - DD LWD MWD PWDDocument3 pagesHSE Leadership - DD LWD MWD PWDAKOMOLAFE ABAYOMINo ratings yet

- RoadMap ISO9001Document5 pagesRoadMap ISO9001rivelino70No ratings yet

- Qa Imco Hse Ms QT 001 Hse Management SystemDocument21 pagesQa Imco Hse Ms QT 001 Hse Management SystemFrancis Enriquez TanNo ratings yet

- Competency Assessment FormDocument8 pagesCompetency Assessment FormJohn GavazziNo ratings yet

- Presentation On QFD and VOCDocument12 pagesPresentation On QFD and VOCvundavilliravindraNo ratings yet

- Cover LetterDocument2 pagesCover Letterajin gsencNo ratings yet

- Maintenance Management AnsDocument23 pagesMaintenance Management AnsTim NagaralNo ratings yet

- Oil and Gas AuditDocument7 pagesOil and Gas AuditShamsur Rahman Russell100% (1)

- Max Plant AceDocument8 pagesMax Plant AceNaviin AgrawalNo ratings yet

- JSA Format Internal ReactorDocument13 pagesJSA Format Internal Reactorsakthi venkatNo ratings yet

- HSECESDocument2 pagesHSECESKmt_AeNo ratings yet

- Strategy For Pipeline ProtectionsDocument12 pagesStrategy For Pipeline ProtectionsvktoNo ratings yet

- Operations Management Assignment PlanDocument1 pageOperations Management Assignment Plan杨光No ratings yet

- Logistics Services SindhuDocument86 pagesLogistics Services SindhubandichaituNo ratings yet

- PPL Internship Report Abdullah Haider AliDocument15 pagesPPL Internship Report Abdullah Haider AliAbdullah Haider AliNo ratings yet

- Guide To Opito Approval For Training ProvidersDocument31 pagesGuide To Opito Approval For Training ProvidersmashanghNo ratings yet

- Improve Customer Satisfaction SurveyDocument2 pagesImprove Customer Satisfaction Survey20UCC035 GOPINATH SNo ratings yet

- LBC Project HSE Plan EwekoroDocument55 pagesLBC Project HSE Plan EwekoroYemi Jonathan Olushola100% (1)

- Computer Integrated ManufacturingDocument6 pagesComputer Integrated ManufacturingRajesh Kumar Bayar0% (1)

- AAC Project DetailsDocument7 pagesAAC Project DetailsN Gangadhar Reddy100% (1)

- Faber Medi-Serve SDN BHD: Privatisation of Hospital Support Services Ministry of Health, MalaysiaDocument7 pagesFaber Medi-Serve SDN BHD: Privatisation of Hospital Support Services Ministry of Health, MalaysiaragunatharaoNo ratings yet

- Dahej Standby Jetty 2264Document9 pagesDahej Standby Jetty 2264Anonymous i3lI9MNo ratings yet

- DVB-T and DVB-T2 Comparison and Coverage: July 6, 2011Document30 pagesDVB-T and DVB-T2 Comparison and Coverage: July 6, 2011Sakthivel MurthyNo ratings yet

- Axis Inspection Quality ManualDocument33 pagesAxis Inspection Quality ManualSakthivel MurthyNo ratings yet

- JYTHRDFRDocument6 pagesJYTHRDFRSakthivel MurthyNo ratings yet

- Age of Empires 3 Patch InformationDocument7 pagesAge of Empires 3 Patch InformationAlika StanleyNo ratings yet

- ReadmeDocument12 pagesReadmeselo57No ratings yet

- N1509 01Document1 pageN1509 01Sakthivel MurthyNo ratings yet

- Contributed By: Darkmanx4LfDocument2 pagesContributed By: Darkmanx4LfSakthivel MurthyNo ratings yet

- OVIDocument38 pagesOVISakthivel MurthyNo ratings yet

- ReadmeDocument12 pagesReadmeselo57No ratings yet

- Contributed By: Darkmanx4LfDocument2 pagesContributed By: Darkmanx4LfSakthivel MurthyNo ratings yet

- Hammer Union - 1502: Pressure TransmitterDocument3 pagesHammer Union - 1502: Pressure TransmitterSakthivel MurthyNo ratings yet

- Ac InstaDocument2 pagesAc InstaSakthivel MurthyNo ratings yet

- EulaDocument60 pagesEulaGleider TorresNo ratings yet

- Unions, Swivels, Treating Irons & Circulating Heads GuideDocument7 pagesUnions, Swivels, Treating Irons & Circulating Heads GuideSakthivel MurthyNo ratings yet

- Hammer Union - 1502: Pressure TransmitterDocument3 pagesHammer Union - 1502: Pressure TransmitterSakthivel MurthyNo ratings yet

- Thread Disk ReportDocument1 pageThread Disk ReportSakthivel MurthyNo ratings yet

- VISION TESTING AND STANDARDS FOR AIRCRAFT INSPECTORSDocument11 pagesVISION TESTING AND STANDARDS FOR AIRCRAFT INSPECTORSvrapciudorianNo ratings yet

- Lean ManufacturingDocument29 pagesLean ManufacturingltcmenishadNo ratings yet

- How to fill out a transmittal formDocument3 pagesHow to fill out a transmittal formSakthivel MurthyNo ratings yet

- Occupational Health and Safety - Enhancing Your Management SystemDocument31 pagesOccupational Health and Safety - Enhancing Your Management SystemSakthivel MurthyNo ratings yet

- Print Specification Details of Bajaj Discover 150 FDocument2 pagesPrint Specification Details of Bajaj Discover 150 FSakthivel MurthyNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationSakthivel MurthyNo ratings yet

- HR PoliciesDocument3 pagesHR PoliciesakashtrivedeNo ratings yet

- A Study of Performance Appraisal in Public SectoreDocument25 pagesA Study of Performance Appraisal in Public SectoreNeelampariNo ratings yet

- Motivation strategies at MicrosoftDocument5 pagesMotivation strategies at MicrosoftJay DixitNo ratings yet

- Case 4.6 A New Work EthicDocument3 pagesCase 4.6 A New Work EthicAbdul Rajak AR100% (1)

- Discussion 6Document1 pageDiscussion 6dreiNo ratings yet

- Mid Term Exam Semester 2Document36 pagesMid Term Exam Semester 2Cornelia PîrvulescuNo ratings yet

- Business CommunicationDocument13 pagesBusiness CommunicationMd Alimur Razee RealNo ratings yet

- Research in Personnel and Human Resources Management .VOL.25 978-0-7623-1327-3Document382 pagesResearch in Personnel and Human Resources Management .VOL.25 978-0-7623-1327-3Paul Fairlie100% (1)

- Relation Between 7 Major Losses of Equipment and Overall Equipment EfficiencyDocument2 pagesRelation Between 7 Major Losses of Equipment and Overall Equipment EfficiencySwapnil KhadeNo ratings yet

- Factors Contributing to Employee Turnover in Pharma CompaniesDocument11 pagesFactors Contributing to Employee Turnover in Pharma CompaniesUthra PandianNo ratings yet

- Communication and EthicsDocument18 pagesCommunication and EthicsJalees Ur Rehman100% (1)

- Hawthorne Experiments Reveal Social Factors Impact ProductivityDocument5 pagesHawthorne Experiments Reveal Social Factors Impact ProductivityIshank SinghNo ratings yet

- Employee Disciplinary FormDocument2 pagesEmployee Disciplinary FormAl Wildan BSDNo ratings yet

- KPO and BPO still governed by Labor CodeDocument1 pageKPO and BPO still governed by Labor CodeMatthew TurnerNo ratings yet

- 13th Month Pay Law and JurisprudenceDocument2 pages13th Month Pay Law and JurisprudenceJennylyn Biltz AlbanoNo ratings yet

- Why Performance Appraisal Is ImportantDocument6 pagesWhy Performance Appraisal Is ImportantMatin NickNo ratings yet

- SEIU Local 888 Spark, September 2012Document4 pagesSEIU Local 888 Spark, September 2012randwilsonNo ratings yet

- Primark's Organizational StructureDocument4 pagesPrimark's Organizational StructureNick TelsaNo ratings yet