Professional Documents

Culture Documents

MF5400 Manual 02-En

Uploaded by

Selmirije2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MF5400 Manual 02-En

Uploaded by

Selmirije2Copyright:

Available Formats

Splitting the tractor

02 - Splitting the tractor

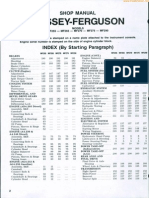

CONTENTS

2A10 - Splitting - Front frame / Perkins engine 2B11 - Splitting Perkins engine / GTA2020 2C11 - Splitting GBA20/GPA20 (cab fixed to centre housing) 2C13 - Splitting GBA20/GPA20 (cab fixed to gearbox)

Massey Ferguson 5400

CONTENTS - i

Splitting the tractor

CONTENTS - ii

Massey Ferguson 5400

Splitting - Front frame / Perkins engine

2A10 - Splitting - Front frame / Perkins engine

CONTENTS

A . General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 B . Disassembly and reassembly (6-cylinder Perkins engine) . . . . . . . . . . . . . . . . . . . . . 4 C . Disassembly and reassembly (4-cylinder Perkins engine) . . . . . . . . . . . . . . . . . . . . 10 D . Shimming the front frame (4-cylinder Perkins engine) . . . . . . . . . . . . . . . . . . . . . . 18

Massey Ferguson 5400 - Issue 5.a

2A10.1

Splitting - Front frame / Perkins engine

2A10.2

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

A . General

The front frame and the engine must be separated when each of the assemblies needs to be replaced, or when servicing is necessary on one of the mechanical elements located at the front of the engine. IMPORTANT: This section describes a general disassembly procedure. Before and during separation, check that all connections between the fixed assembly and mobile assembly have been disconnected.

Massey Ferguson 5400 - Issue 5.a

2A10.3

Splitting - Front frame / Perkins engine

B . Disassembly and reassembly (6-cylinder Perkins engine)

Preparation

1. Apply the hand brake. 2. Remove the side panels from each side of the engine and bonnet

Operations under the tractor

3. Remove the guard and the 4WD transmission shaft (if fitted).

MA-02-05084A

Operations on the right-hand side of the tractor

4. Disconnect the batteries. 5. Mark then disconnect: - the differential lock hose on the front axle, - the supply hose on the steering ram, - the lubrication hoses (running to and from the cooler) (Fig. 1). Remove the protective grille close to the radiator. Disconnect the air sleeve (1) (turbo outlet) from the cooling sleeve (Fig. 2).

Fig. 1

Operations on the left-hand side of the tractor

6. Mark and disconnect the supply hose on the steering ram. 7. Disconnect the air sleeve (2) (inlet on inlet manifold) from the cooling sleeve (Fig. 3). Fig. 2

Fig. 3

2A10.4

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Draining the cooling system

8. Unscrew the fin plug located on the left-hand side and front of the radiator. Drain the liquid into a clean container.

DANGER: If the engine is hot, gradually loosen the expansion tank plug before removing it in order to drive out the pressure from the system. 9. Disconnect the lower hose (1) and the hose (2) linking the expansion tank to the base of the radiator (Fig. 4).

Operations above the engine

10. Disconnect the upper hose (1) (Fig. 5).

Fig. 4

Operations at the front of the tractor

11. Remove the weights (if fitted). 12. Detach the air conditioning compressor, the condenser and the filter from their respective supports. Carefully remove them from the engine, without opening up the system (see chapter 12). 13. Mark and disconnect the electrical harnesses inside the grille. 14. Disconnect the air sleeves (3) and (4) on the air cooler located inside the grille (Fig. 6).

Fig. 5

Fig. 6

Massey Ferguson 5400 - Issue 5.a

2A10.5

Splitting - Front frame / Perkins engine

Preparing for disassembly

15. Cancel the oscillation, depending on assembly: - of the front axle beam (2WD) or - of the front axle (4WD), by inserting a suitable block on either side of the frame (1) as shown in Fig. 7. 16. Chock the rear wheels. 17. Install (Fig. 9): - a mobile stand under the front axle beam or front axle (depending on assembly); - a suitable sling at the front of the frame; - a fixed axle stand under the engine lower housing.

Disassembly

IMPORTANT: During separation, check that all connections (hoses, pipes and harnesses) are disconnected. 18. Remove the side screws (1) (Fig. 8). 19. With the help of an operator, loosen the screws (2)(3) (Fig. 8), simultaneously moving the front frame away from the engine.

MA-02-05085A

Fig. 7

DANGER: When disconnecting, use the sling to prevent the front frame assembly from tipping over.

2A10.6

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Fig. 8

Fig. 9

Massey Ferguson 5400 - Issue 5.a

2A10.7

Splitting - Front frame / Perkins engine

Reassembly

Screw specifications Screw M16 x 55 mm M16 x 60 mm M16 x 115 mm M20 x 190 mm M24 x 200 mm

20. Clean the mating faces of the engine and front frame. 21. Prior to reassembly check with a ruler that the supports (5) are aligned with the front face of the engine lower housing (Fig. 11). If not: - Adjust the support(s) until they are correctly aligned. - Tighten: - the screws (4) to a torque of 240 - 320 Nm (Loctite 270 or equivalent); - the screws (6) to a torque of 240 - 320 Nm. - Check correct alignment after tightening. 22. Screw a guide stud onto each rear face of the frame (Fig. 10). 23. With the help of an operator, connect the front frame to the engine. Take out the guide studs. 24. Fit and tighten the opposed screws (Fig. 13) in the following order: - screws (2) to a torque of 480 - 640 Nm; - screws (3) to a torque of 800 - 1040 Nm; - screws (1) to a torque of 240 - 320 Nm.

Fig. 10

Fig. 11

2A10.8

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Final steps

The final steps are not especially difficult. However, it will be necessary during reassembly to perform the tightening torques, adjustments and tests described below. Tightening torque As required, wheel screws or nuts (see chapter 6). Topping up of coolant, to the maximum level marked on the expansion tank (Fig. 12). Test: - the air conditioning system (if fitted - see chapter 12); - all mechanical, hydraulic and electrical functions relating to the operation. Check tightness: - of hydraulic unions, - of water hoses.

Fig. 12

Fig. 13

Massey Ferguson 5400 - Issue 5.a

2A10.9

Splitting - Front frame / Perkins engine

C . Disassembly and reassembly (4-cylinder Perkins engine)

NOTE: Two models of front frame are available for 5400 series tractors with 4-cylinder engines. Tractors with front frame without shimming front frame with shimming Power (hp) 65 to 95 105

Preparation

25. Apply the hand brake. 26. Take off the side panels, prefilter (105 hp engine), bonnet and central exhaust pipe (depending on option).

Operations underneath the tractor

27. Take off the guard, transmission shaft and differential lock supply pipe (4WD tractors).

Operations at the front of the tractor

28. Remove the front weights (if fitted). 29. Disconnect the batteries. If required, remove them from the grille compartment. Tractors with Perkins engines 65 to 95 hp Battery location In the grille compartment

Perkins engines 105 hp Behind the right-hand step. Sloping bonnet Behind the right-hand step.

Location of batteries 30. Detach the air conditioning compressor, the condenser and the filter from their respective supports (if fitted). Place the assembly beside the tractor without disconnecting the pipes and hoses (see chapter 12).

2A10.10

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Operations inside the grille

31. Mark then disconnect: - electrical harnesses, - air sleeves (3) and (4) on the cooler (105 hp Perkins engine, Fig. 27).

Operations on the right-hand side of the tractor

32. Mark and disconnect the supply hose on the steering ram. 33. Mark and disconnect the lubrication hoses running to and from the cooler (105 hp Perkins engine, Fig. 15). 34. Remove the protective grille close to the radiator. 35. Disconnect the air sleeve (1) (turbo outlet) from the cooling sleeve (105 hp Perkins engine, Fig. 16).

Fig. 14

Fig. 15

Fig. 16

Massey Ferguson 5400 - Issue 5.a

2A10.11

Splitting - Front frame / Perkins engine

Operations on the left-hand side of the tractor

36. Mark and disconnect the supply hose on the steering ram. 37. Remove the protective grille close to the radiator.

Draining the cooling system

38. Unscrew the fin plug located on the left-hand side and front of the radiator, to drain the system.

DANGER: If the engine is hot, gradually loosen the expansion tank plug before removing it in order to drive out the pressure from the system. 39. Disconnect the lower hose (1) and the hose (2) linking the expansion tank to the base of the radiator (Fig. 17).

Fig. 17

Operations above the engine

40. Disconnect the upper hose (1) (Fig. 18).

Fig. 18

2A10.12

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Page intentionally left blank

Massey Ferguson 5400 - Issue 5.a

2A10.13

Splitting - Front frame / Perkins engine

Preparing for disassembly

41. Cancel the oscillation, depending on assembly: - of the front axle beam (2WD) or - of the front axle (4WD), by inserting a suitable block on either side of the frame (1) as shown in Fig. 19. 42. Chock the rear wheels. 43. Install (Fig. 22): - a mobile stand under the front axle beam or front axle (depending on assembly); - a suitable sling at the front of the frame; - a fixed axle stand under the engine lower housing.

Disassembly

IMPORTANT: During separation, check that all connections (hoses, pipes and harnesses) are disconnected. Mark the position and location of shims (1) inserted between the engine lower housing and front frame (105 hp Perkins engine, Fig. 20). 44. Loosen and remove (Fig. 21): - For Perkins 65 to 95 hp engines: screws and bolts (2), (4) and (1); - for Perkins 105 hp engines: screws and bolts (2), (3), (4) and (1). With the help of an operator, gradually separate the front frame from the engine at the same time.

MA-02-05086A

Fig. 19

DANGER: When disconnecting, use the sling to prevent the front frame assembly from tipping over (Fig. 22).

Fig. 20

2A10.14

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Fig. 21

Fig. 22

Massey Ferguson 5400 - Issue 5.a

2A10.15

Splitting - Front frame / Perkins engine

Reassembly

INSTRUCTIONS: Use guide studs to assist reconnection of the front frame and engine. Specifications of the screws and nuts Front frame and Perkins 65 to 95 hp engine Screw M16 x 75 mm M16 x 85 mm M16 x 115 mm Nuts M16

Front frame and Perkins 105 hp engine Screw M16 x 85 mm M16 x 95 mm M16 x 105 mm M16 x 120 mm Nuts M16 Fig. 23

45. Clean the mating faces of the engine and front frame. 46. Screw two guide studs (1) to the front face of the engine (Fig. 23). 47. With the help of an operator, reconnect the front frame to the engine as follows: Front frame and Perkins 65 to 95 hp engine (Fig. 24) 48. Fit screws (2), (4) and bolts (1), simultaneously taking out the guide studs. 49. Tighten opposing screws and bolts to a torque of 240 - 320 Nm in the following order: (2) (4) (1). Front frame and Perkins 105 hp engine (Fig. 25) IMPORTANT: If it is necessary to shim the front frame, refer to D. 50. Fit screws (2), (3), (4) and bolts (1), simultaneously taking out the guide studs. 51. Tighten opposing screws and bolts to a torque of 240 - 320 Nm in the following order: (2) (3) (4) (1).

Fig. 24

Fig. 25

2A10.16

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Final steps

The final steps are not especially difficult. However, it will be necessary during reassembly to perform the tightening torques, adjustments and tests described below. Tightening torque As required, wheel screws or nuts (see chapter 6). Topping up of coolant, to the maximum level marked on the expansion tank (Fig. 26). Test: - the air conditioning system (if fitted - see chapter 12); - all mechanical, hydraulic and electrical functions relating to the operation. Check tightness: - of hydraulic unions, - of water hoses.

Fig. 26

Massey Ferguson 5400 - Issue 5.a

2A10.17

Splitting - Front frame / Perkins engine

D . Shimming the front frame (4-cylinder Perkins engine)

When the front frame is fitted to the Perkins 4-cylinder 105 Hp engine, the face of the engine/lower housing is not in contact with the face of the front frame. It is therefore advised to fill this space with shims (1) (Fig. 27) whose thickness will be measured and set afterwards. IMPORTANT: Shimming should only be carried out if the front frame and/or engine have been replaced. 52. With the help of an operator, connect the front frame to the engine.

Preparing for shimming (Fig. 28)

53. Fit only screws (4) and bolts (1), simultaneously taking out the guide studs. 54. Tighten opposing screws and bolts to a torque of 240 - 320 Nm in the following order: (4) (1).

Fig. 27

Fig. 28

2A10.18

Massey Ferguson 5400 - Issue 5.a

Splitting - Front frame / Perkins engine

Shimming

IMPORTANT: To avoid applying undue loads to the mating faces during shimming, avoid adjusting the safety stands placed under the engine and front axle during disassembly. 55. Using two stacked shims (1), each at least 2.30 mm thick (Fig. 29), measure the gap between the faces of the engine/lower housing and front frame. Determine the thickness of shims to be fitted by increasing, as required, the thickness of each shim until they fit tightly in the gap. NOTE: Shimming is carried out using shims between 2.30 and 2.60 mm thick. Inserting shims between the front frame and the engine 56. Slightly loosen the screws (4) and bolts (1) (Fig. 30). 57. Turn the shims (1) so that end "E" faces downwards. Insert them between the front frame and the engine/lower housing (Fig. 29). 58. Fit screws (2) and (3) (Fig. 30). 59. Tighten bolts and all screws of the front frame to a torque of 240 - 320 Nm in opposition and in the following order: (2) (3) (4) (1) (Fig. 30). 60. Release the safety stands. Fig. 29

Fig. 30

Massey Ferguson 5400 - Issue 5.a

2A10.19

Splitting Perkins engine / GTA2020

2B11 - Splitting Perkins engine / GTA2020

CONTENTS

A . General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 B . Disassembly and reassembly (Perkins 4-cylinder engine) . . . . . . . . . . . . . . . . . . . . . 4 C . Replacing the input shaft seal (tractors with dry clutch). . . . . . . . . . . . . . . . . . . . . 14 D . Disassembly and reassembly (6-cylinder Perkins engine) . . . . . . . . . . . . . . . . . . . . 16 E . Service tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Massey Ferguson 5400 - Issue 5.a

2B11.1

Splitting Perkins engine / GTA2020

2B11.2

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

A . General

Tractors in the 5400 series fitted with the GBA20 gearbox are fitted with a : - with a 4-cylinder Perkins engine - with a 6-cylinder Perkins engine Gearbox with Power Shuttle The tractor should be disconnected between the engine and the gearbox with Power Shuttle when access is necessary to carry out servicing on the main following elements: Engine interface - vibration damper - engine flywheel - engine adapter plate Gearbox interface - spacer and seal - internal hydraulic pipes, - Power Shuttle, - Speedshift Gearbox with mechanical reverse shuttle (dry clutch) The tractor should be disconnected between the engine and the gearbox with dry clutch when access is necessary to carry out servicing on the main following elements: Engine interface - diaphragm mechanism or friction disc, - engine flywheel - engine adapter plate Gearbox interface - spacer, - input shaft seal - internal hydraulic pipes and slave device assembly, - Speedshift, - mechanical reverse shuttle. IMPORTANT: - This section describes a general disassembly procedure. Before and during separation, check that all connections between the fixed assembly and mobile assembly have been disconnected. - The cab remains attached to the centre housing.

Massey Ferguson 5400 - Issue 5.a

2B11.3

Splitting Perkins engine / GTA2020

B . Disassembly and reassembly (Perkins 4-cylinder engine)

Preparation

1. Apply the hand brake. 2. Remove: - the side panels either side of the engine, - the prefilter (Perkins 105 hp engine), - the central exhaust pipe (depending on option), - the bonnet.

Operations under the tractor

3. Take off the guard, 4WD transmission shaft and differential lock supply pipe.

Operations at the front of the tractor

4. Remove the front weights (if fitted). 5. Disconnect the batteries. Tractors with Perkins engine up to 95 hp Battery location In the grille compartment

Perkins engines 105 hp Behind the right-hand step. Sloping bonnet Behind the right-hand step. Fig. 1

Location of batteries (Fig. 1)

2B11.4

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Operations on the right-hand side of the tractor

6. Take off the front right-hand mudguard. 7. If necessary, remove the vertical exhaust assembly (including support) (Fig. 2). 8. Mark then disconnect: - the hose on the steering ram or on the spool valve (Orbitrol), depending on the tractor type - the lubrication hoses running to and from the cooler (105 hp Perkins engine, Fig. 3).

Operations on the left-hand side of the tractor

9. Take off the front left-hand mudguard. 10. Mark then disconnect: - the hose on the steering ram or on the spool valve (Orbitrol), depending on the tractor type; - the fuel feed and return hoses on the engine, immediately blocking the ports. 11. Disconnect the cables connected to the positive terminal of the starter (Fig. 4).

MA-02-05093A

Fig. 2

Fig. 3

Fig. 4

Massey Ferguson 5400 - Issue 5.a

2B11.5

Splitting Perkins engine / GTA2020

Operations under the cab

CAUTION: If the engine is still hot, allow it to cool. NOTE: To work on the heating hoses, it is not necessary to drain the engine block cooling system. 12. Mark and pinch out each heating hose using a clamp fitted with protective jaws (Fig. 5). Disconnect them, immediately blocking the ports.

Operations on the engine

13. Disconnect the negative cables on the block at the rear left-hand side of the engine (Fig. 6). 14. Detach the air conditioning compressor, the condenser and the filter from their respective supports (if fitted). Carefully move them from the engine, without disconnecting the pipes and hoses (see chapter 12).

MA-02-05094A

Fig. 5

Operations at the front of the cab

15. Disconnect the connectors (2) and the ground terminals (1) on the left-hand side of the cab bulkhead (Fig. 7).

MA-02-05095A

Fig. 6

Fig. 7

2B11.6

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Preparing for disassembly

16. Cancel the oscillation: - of the front axle beam (2WD) or - of the front axle (4WD), by inserting a suitable wooden block on either side of the frame (1) as shown in Fig. 8. Chock the rear wheels. Install (Fig. 9): - a fixed axle stand at the front of the gearbox - a mobile axle stand at the rear of the engine - a mobile axle stand under the front frame. If necessary, separate the cab from the front right and left-hand supports (see chapter 12). Gently lift the front of the cab using two straps fitted to the side handles.

MA-02-05096A

17. 18.

19. 20.

Fig. 8

DANGER: Make the area around the cab safe by temporarily placing a wooden chock between each front support and the right and left-hand cab attachments.

MA-02-05090A

Fig. 9

Massey Ferguson 5400 - Issue 5.a

2B11.7

Splitting Perkins engine / GTA2020

Disassembly

IMPORTANT: During separation, check that all connections (hoses, pipes and harnesses) are disconnected. 21. Remove the screws attaching the engine to the gearbox (Fig. 14 depending on assembly). Mark their length and position. NOTE: The tractor may be fitted with one or two fuel tanks (depending on option): - Assembly 1: a single fuel tank on the left-hand side of the tractor - Assembly 2: a fuel tank on each side of the tractor. In this configuration, remove the right-hand fuel tank from the gearbox if it blocks access to the screws and nuts. Screw specifications Screw M16 x 50 mm M16 x 60 mm M16 x 80 mm M22 x 80 mm 22. Assisted by an operator, separate the assemblies (Fig. 9).

2B11.8

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Engine/GBA20 transmission with Power Shuttle connection

Fig. 10

Massey Ferguson 5400 - Issue 5.a

2B11.9

Splitting Perkins engine / GTA2020

Engine/GBA20 transmission with mechanical reverse shuttle connection

MA-02-05097A

Fig. 11

2B11.10

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Reassembly

23. Clean the mating faces of the engine and the gearbox spacer. 24. Check that the dowels (1) are present on the engine (Fig. 12). 25. Depending on the tractor type, carry out the following operations. Tractors with Power Shuttle (Fig. 13) Lightly smear the splines of the input shaft (1) with AS767 graphite grease or equivalent. Tractors with dry clutch (Fig. 13) Replace the seal (2) on the input shaft (1) (see C). Lightly smear the splines of the input shaft (1) and PTO shaft (3) with AS767 graphite grease or equivalent. 26. Screw two diametrically opposed guide studs onto the engine adaptor plate or onto the gearbox spacer.

MA-02-05098A

Fig. 12

1 3

MA-02-05099A

Fig. 13

Massey Ferguson 5400 - Issue 5.a

2B11.11

Splitting Perkins engine / GTA2020

27. Connect the engine to the gearbox spacer. IMPORTANT: If necessary, remove the starter and turn the engine flywheel ring gear using a suitable tool. This will ease the engagement of the splines of the vibration damper or friction disc (depending on assembly) with those of the input shaft. If there is resistance, do not force it; find the cause of the problem. 28. Once the elements are joined, remove the guide studs. 29. Lightly smear the thread of each screw (1) and (2) with Loctite 270 or equivalent. Position them according to the marks made during disassembly. Tighten (Fig. 14): - screws (1) to a torque of 240 - 320 Nm; - screws (2) to a torque of 630 - 840 Nm.

Fig. 14

Final steps

The final steps are not especially difficult. However, it will be necessary during reassembly to perform the tightening torques, adjustments and tests described below. Tightening torque As required, front cab screws (see chapter 12). Topping up of coolant, to the maximum level marked on the expansion tank (Fig. 14). Test: - the air conditioning system (if fitted - see chapter 12); - all mechanical, hydraulic and electrical functions relating to the operation. Checking tightness of hydraulic unions.

2B11.12

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Fig. 15

Massey Ferguson 5400 - Issue 5.a

2B11.13

Splitting Perkins engine / GTA2020

C . Replacing the input shaft seal (tractors with dry clutch)

4 1

Preliminary steps

30. Disconnect the tractor between the engine and the gearbox (see chapter 2).

Preparing for seal (2) replacement (Fig. 16)

31. Take the PTO shaft (3) out of the input shaft (1). Remove the snap ring (4) and the splined washer (5). 32. Take the worn seal (2) out of the input shaft (1) without using a sharp or pointed tool. 33. Clean the components. 34. Check there are no scratches: - in the seating of the seal (2) on the input shaft (1), - on the PTO shaft (3) at the seating of the lip of the seal (2).

3 5

2

MA-02-05100A

1

Fig. 16

2B11.14

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Replacing the seal (2) (Fig. 16)

35. Turn the PTO shaft (3) as required. Slide it into the input shaft (1). 36. Cover the PTO shaft splines with a flexible protection. 37. Smear the internal cavity of the seal (2) with miscible grease. 38. Position the seal (2) on the PTO shaft (3) so that its lip, when operating, is in contact with the transmission oil. Remove the flexible protection. Fit the seal (2) into the input shaft (1) using tool 3376803M1 (see E). IMPORTANT: Ensure that there are no seal fragments after fitting. 39. Slide the splined washer (5) onto the PTO shaft (3), turning its chamfer C towards the operator. 40. Fit a new snap ring (4) on the PTO shaft (3), opening it as little as possible. Check that it is positioned correctly at the bottom of the groove.

Final step

41. Reconnect the tractor between the engine and the gearbox (see chapter 2).

Massey Ferguson 5400 - Issue 5.a

2B11.15

Splitting Perkins engine / GTA2020

D . Disassembly and reassembly (6-cylinder Perkins engine)

Preparation

1. Apply the hand brake. 2. Remove: - the side panels either side of the engine, - the prefilter, - the bonnet.

Operations under the tractor

3. Take off the guard, 4WD transmission shaft and differential lock supply pipe.

Operations at the front of the tractor

4. Remove the front weights (if fitted).

Operations on the right-hand side of the tractor

5. Disconnect the batteries. 6. Remove the vertical exhaust assembly (including support Fig. 1). 7. Mark then disconnect: - the cables (positive and negative) on the starter - the supply hose on the steering ram, - the lubrication hoses (running to and from the cooler) (Fig. 2).

MA-02-05087A

Fig. 1

Operations on the left-hand side of the tractor

8. Mark and disconnect the supply hose on the steering ram. 9. Mark and disconnect the fuel feed and return hoses on the engine, immediately blocking the ports.

MA-02-05088A

Fig. 2

2B11.16

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Operations under the cab

10. Mark, pinch out and disconnect each heating hose, immediately blocking the ports.

Operations on the engine

11. If necessary, disconnect the connector (3) of the main wiring harness (Fig. 3). 12. Detach the air conditioning compressor, the condenser and the filter from their respective supports (if fitted). Carefully remove them from the engine, without opening up the system (see chapter 12).

3 1

Operations at the front of the cab

13. Disconnect the connectors (2) and the ground terminals (1) on the left-hand side of the cab bulkhead (Fig. 3).

MA-02-05040B

Fig. 3

Preparing for disassembly

14. Cancel the oscillation, depending on assembly: - of the front axle beam (2WD) or - of the front axle (4WD), by inserting a suitable block on either side of the frame (1) as shown in Fig. 4. 15. Chock the rear wheels.

MA-02-05089A

Fig. 4

Massey Ferguson 5400 - Issue 5.a

2B11.17

Splitting Perkins engine / GTA2020

16. Install (Fig. 5): - a fixed axle stand at the front of the gearbox - a mobile axle stand at the rear of the engine - a mobile axle stand under the front frame. 17. If necessary, separate the cab from the front right and left-hand supports (see chapter 12). 18. Gently lift the front of the cab using two straps fitted to the side handles.

Disassembly

IMPORTANT: During separation, check that all connections (hoses, pipes and harnesses) are disconnected. 19. Remove the screws and nuts attaching the engine to the gearbox (Fig. 6 or Fig. 7 depending on assembly). Mark their length and position. NOTE: The tractor may be fitted with one or two fuel tanks (depending on option): - Assembly 1: a single fuel tank on the left-hand side of the tractor - Assembly 2: a fuel tank on each side of the tractor. In this configuration, remove the right-hand fuel tank from the gearbox if it blocks access to the screws and nuts. Specifications of the screws, studs and nuts Screw M16 x 60 mm M16 x 115 mm M16 x 185 mm M22 x 160 mm Studs Nuts

DANGER: Make the area around the cab safe by temporarily placing a wooden chock between each front support and the right and left-hand cab attachments.

M12 x 185 mm M12 M22 x 160 mm M22

20. Assisted by an operator, separate the assemblies (Fig. 5).

MA-02-05090A

Fig. 5

Massey Ferguson 5400 - Issue 5.a

2B11.18

Splitting Perkins engine / GTA2020

Engine/GBA20 transmission with Power Shuttle connection

Fig. 6

Massey Ferguson 5400 - Issue 5.a

2B11.19

Splitting Perkins engine / GTA2020

Engine/GBA20 transmission with mechanical reverse shuttle (dry clutch) connection

1 1 1 2 3 1 1 2 3

MA-02-05102A

Fig. 7

2B11.20

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

Reassembly

21. Clean the mating faces of the engine and the gearbox spacer. 22. Check: - the presence of dowels (1) on the engine (Fig. 8) - the tightness of the upper stud (M12) on the engine adapter plate (Loctite 270), - the tightness of the lower studs (M22) on the gearbox spacer (Loctite 270). 23. Depending on the tractor type, carry out the following operations. Tractors with Power Shuttle (Fig. 9) Lightly smear the splines of the input shaft (1) with AS767 graphite grease or equivalent. Tractors with dry clutch (Fig. 9) Replace the seal (2) on the input shaft (1) (see C). Lightly smear the splines of the input shaft (1) and PTO shaft (3) with AS767 graphite grease or equivalent. 24. If necessary, screw two extra diametrically opposed guide studs into the gearbox.

MA-02-05091A

Fig. 8

1

MA-02-05092A

3

Fig. 9

Massey Ferguson 5400 - Issue 5.a

2B11.21

Splitting Perkins engine / GTA2020

Fig. 10

2B11.22

Massey Ferguson 5400 - Issue 5.a

Splitting Perkins engine / GTA2020

25. Connect the engine to the gearbox spacer. IMPORTANT: If necessary, remove the starter and turn the engine flywheel ring gear using a suitable tool. This will ease the engagement of the splines of the vibration damper or friction disc (depending on assembly) with those of the input shaft. If there is resistance, do not force it; find the cause of the problem. 26. Once the elements are joined, remove the guide studs (if fitted). 27. Lightly smear the thread of the each screw and nut with Loctite 270 or equivalent. Position them according to the marks made during disassembly. Tighten (Fig. 10): - screws (1) to a torque of 240 - 320 Nm; - screws (2) to a torque of 240 - 320 Nm; - screws (3) to a torque of 630 - 840 Nm. - nuts (4) to a torque of 100 - 130 Nm; - nuts (5) to a torque of 630 - 840 Nm.

Final steps

The final steps are not especially difficult. However, it will be necessary during reassembly to perform the tightening torques, adjustments and tests described below. Tightening torque As required: - Front cab screws (see chapter 12) - Screws (2) of connector (3) on main wiring harness from 2.82 to 3.15 Nm (Fig. 3 and Fig. 11). Topping up of coolant, to the maximum level marked on the expansion tank (Fig. 12). Test: - the air conditioning system (if fitted - see chapter 12); - all mechanical, hydraulic and electrical functions relating to the operation. Checking tightness of hydraulic unions.

Fig. 11 Fig. 12

Massey Ferguson 5400 - Issue 5.a

2B11.23

Splitting Perkins engine / GTA2020

E . Service tool

Tool available in the AGCO network

3376803M1: Fitting drift for input shaft seal (tractors with dry clutch) (Fig. 13)

MA-02-05101A

Fig. 13

2B11.24

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

2C11 - Splitting GBA20/GPA20 (cab fixed to centre housing)

CONTENTS

A . General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 B . Disassembly and reassembly with the cab fixed to the centre housing . . . . . . . . . 4

Massey Ferguson 5400 - Issue 5.a

2C11.1

Splitting GBA20/GPA20 (cab fixed to centre housing)

2C11.2

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

A . General

Disconnecting the tractor with the cab fixed to the centre housing allows access: - to the gearbox output shaft, - to the creeper or super creeper unit and selection mechanism (depending on option), - to the PTO clutch, - to the hand brake mechanism. IMPORTANT: This section describes a general disassembly procedure. Before and during separation, check that all connections between the fixed assembly and mobile assembly have been disconnected.

Massey Ferguson 5400 - Issue 5.a

2C11.3

Splitting GBA20/GPA20 (cab fixed to centre housing)

B . Disassembly and reassembly with the cab fixed to the centre housing

Preparation

1. Apply the hand brake. 2. Remove: - the side panels either side of the engine, - the prefilter, - the central exhaust pipe (depending on option), - the bonnet (if necessary). 3. Remove the steps. 4. Disconnect the batteries. Tractors with Perkins engines 65 to 95 hp Battery location In the grille compartment

Perkins engines 105 hp Behind the right-hand step. Sloping bonnet Behind the right-hand step.

Location of batteries (Fig. 1)

Fig. 1

2C11.4

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

Operations underneath the tractor

5. Take off the guard, 4WD transmission shaft and differential lock supply pipe. 6. Drain the oil from the gearbox and centre housing. 7. Remove the lubrication pipe (1) of the Power Shuttle (if fitted) located between the centre housing and gearbox (Fig. 2).

Operations on the right-hand side of the tractor

8. Remove the batteries and their support located behind the right-hand step. 9. Mark then disconnect: - the hose on the steering ram or spool valve (Orbitrol), - the main pipe (17 bar) to the selector cover plate, - the front differential lock hose on the right-hand hydraulic cover plate - the return hoses on the selector cover plate - the gear cable and rod on the selector cover plate, - the creeper or super creeper gear cable (depending on option).

1

MA-02-05103A

Fig. 2

Massey Ferguson 5400 - Issue 5.a

2C11.5

Splitting GBA20/GPA20 (cab fixed to centre housing)

10. On tractors fitted with a creeper or super creeper unit (Fig. 3), carry out the following operations. - Remove the rod (3) (if necessary). - Remove the screw (2). - Pull the pin (1) outwards in order to free the "D" finger of the final drive fork. 11. Mark and disconnect the electrical connectors on: - the right and left-hand hydraulic cover plates, - the selector cover plate; - the Speedshift solenoid valve, - Power Shuttle proportional solenoid valves (if fitted).

Operations on the left-hand side of the tractor

12. Mark then disconnect: - the hose on the steering ram or spool valve (Orbitrol), - the harness of the fuel gauge on the fuel tank - the fuel feed and return hoses on the engine, immediately blocking the ports, - the vent hose on the fuel tank. 13. Drain the tank (if necessary). Remove it. 14. Disconnect the transmission lubrication supply line (pipes and hoses) located to the front and left of the gearbox.

MA-02-05104A

Fig. 3

2C11.6

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

Operations under the cab

15. Mark and pinch out each heating hose using a clamp fitted with protective jaws (Fig. 4). Disconnect them, immediately blocking the ports.

Operations on the engine

16. Disconnect: - the connector of the main engine harness, - the throttle control cable on the injection pump (4-cylinder Perkins engine only). 17. Detach the air conditioning compressor, the condenser and the filter from their respective supports. Carefully remove them from the engine, without opening up the system (see chapter 12).

MA-02-05094A

Fig. 4

Preparing for disassembly

18. Cancel the oscillation, depending on assembly: - of the front axle beam (2WD) or - of the front axle (4WD), by inserting a suitable wooden block on either side of the frame (1) as shown in Fig. 5. 19. Chock the rear wheels.

MA-02-05089A

Fig. 5

Massey Ferguson 5400 - Issue 5.a

2C11.7

Splitting GBA20/GPA20 (cab fixed to centre housing)

20. Install (Fig. 6): - a fixed axle stand at the front of the centre housing, - a fixed axle stand at the rear of the hitch hook, - a mobile axle stand at the rear of the gearbox. 21. If necessary, separate the cab from the front right and left-hand supports (see chapter 12). 22. Gently lift the front of the cab using two straps fitted to the side handles.

Disassembly

IMPORTANT: During separation, check that all connections (hoses, pipes and harnesses) are disconnected. 23. Remove the screws (1) and nuts (2) fixing the gearbox to the centre housing (Fig. 7). Mark their length and position. Specifications of the screws and nuts Screws (1) Nuts (2) M14

DANGER: Make the area around the cab safe by temporarily placing a wooden chock between each front support and the right and left-hand cab attachments.

M14 x 45 mm M14 x 60 mm M14 x 70 mm

24. Remove the wooden chocks inserted during step 22. 25. Assisted by an operator, separate the assemblies (Fig. 6). 26. Hold the cab still using suitable axle stands positioned under the right and left-hand supports (Fig. 6).

Fig. 6

2C11.8

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

MA-02-05105A

Fig. 7

Massey Ferguson 5400 - Issue 5.a

2C11.9

Splitting GBA20/GPA20 (cab fixed to centre housing)

Reassembly

27. Clean the mating faces of the gearbox and the centre housing. On the centre housing 28. Check the presence of dowels (4) (Fig. 8). NOTE: The dowels are force fitted. 29. Position the spring (1) in the PTO clutch (Fig. 9). 30. Smear the mating face of the centre housing with Loctite 5206 or equivalent, avoiding the Hare and Tortoise ports. 31. Replace the "O" rings (2) (Fig. 9). 32. If necessary, screw two diametrically opposed guide studs onto the centre housing.

MA-02-05109A

Fig. 8

5206

MA-02-05106A

Fig. 9

2C11.10

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

On the gearbox 33. Check that the PTO shaft is present and positioned correctly. 34. Depending on the option, carry out the following actions. Gearbox without creeper or super creeper unit (Fig. 10) Check the correct assembly of the connecting shaft (1) fitted with the sleeves (2) and double pins (3). Gearbox with creeper unit (Fig. 11) Check: - the correct assembly of the connecting shaft (1) fitted with the sleeve (2) and double pin (3), - that the control mechanism (fork and coupler) is operating correctly in each position. Push the fork (4) towards the front of the gearbox in direct drive position. NOTE: The output shaft of the gearbox with creeper unit supports the connecting shaft (1) via the needle roller bearing (5).

Fig. 10

Fig. 11

Massey Ferguson 5400 - Issue 5.a

2C11.11

Splitting GBA20/GPA20 (cab fixed to centre housing)

Gearbox with super creeper unit (Fig. 12) Check: - the presence of the connecting shaft (1) fitted with the sleeve (2) and double pin (3), - that the control mechanism (fork and coupler) is operating correctly in each position. Push the fork (4) towards the front of the gearbox in super creeper position. NOTE: The output shaft of the gearbox with super creeper unit supports the connecting shaft (1) via the needle roller bearing (5).

3 5

MA-02-05107A

Fig. 12

2C11.12

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to centre housing)

On the centre housing (Fig. 13) 35. Pull the pin (1) outwards. Turn finger D towards the front of the centre housing (version with creeper or super creeper unit). 36. Attach the gearbox to the centre housing. IMPORTANT: If there is resistance when moving the elements (gearbox, centre housing) together, do not force them; find the cause of the problem. 37. Once the elements are joined, remove the guide studs (if fitted). 38. Fit the screws (1) and nuts (2) (Fig. 7) according to the marks made during disassembly. Tighten the screws and nuts to a torque of 155 - 195 Nm. 39. Engage finger D in the fork of the creeper or super creeper unit (if fitted). 40. Fit a new seal on the screw (2) (Fig. 13). Lightly smear the thread of the screw (2) with Loctite 242 or equivalent. Tighten the screw moderately. 41. Refit the rod (3) (if fitted).

242

MA-02-05108A

Fig. 13

Massey Ferguson 5400 - Issue 5.a

2C11.13

Splitting GBA20/GPA20 (cab fixed to centre housing)

Final steps

The final steps are not especially difficult. However, it will be necessary during reassembly to perform the tightening torques, adjustments and tests described below. Tightening torque: - Front cab screws (see chapter 12) - Rear wheel screws or nuts (see chapter 6). Top up: - Transmission oil in the housings (check using the gauge located at the rear of the centre housing) - Coolant, to the maximum level marked on the expansion tank. Adjustment: - of the creeper or super creeper gear cable (if fitted), - of the control rod and cable of the four basic gears, - of the throttle control cable on the injection pump (4-cylinder engine only). Test: - the air conditioning system (if fitted - see chapter 12); - the mechanical reverse shuttle or Power Shuttle (depending on option), - the four basic gears, - the Hare and Tortoise ranges - the Speedshift, - the creeper or super creeper unit (depending on option). Check tightness: - the mating faces; - Hydraulic unions

2C11.14

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

2C13 - Splitting GBA20/GPA20 (cab fixed to gearbox)

CONTENTS

A . General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 B . Disassembly and reassembly with the cab fixed to the gearbox . . . . . . . . . . . . . . . 4

Massey Ferguson 5400 - Issue 5.a

2C13.1

Splitting GBA20/GPA20 (cab fixed to gearbox)

2C13.2

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

A . General

Disconnecting the tractor with the cab fixed to the gearbox is quite similar to disconnecting with the cab fixed to the centre housing. However, all disassembly operations close to the centre housing required to make the rear axle mobile must also be included. Disconnecting the tractor in this way allows replacement: - of the rear axle crownwheel and pinion - of the centre housing. IMPORTANT: This section describes a general disassembly procedure. Before and during separation, check that all connections between the fixed assembly and mobile assembly have been disconnected.

Massey Ferguson 5400 - Issue 5.a

2C13.3

Splitting GBA20/GPA20 (cab fixed to gearbox)

B . Disassembly and reassembly with the cab fixed to the gearbox

Preparation

1. Apply the hand brake. 2. Remove: - the side panels either side of the engine, - the prefilter, - the central exhaust pipe (depending on option), - the bonnet (if necessary). 3. Remove the steps. 4. Disconnect the batteries. Tractors with Perkins engines 65 to 95 hp Battery location In the grille compartment

Perkins engines 105 hp Behind the right-hand step. Sloping bonnet Behind the right-hand step.

Location of batteries (Fig. 1)

Fig. 1

2C13.4

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

Operations underneath the tractor

5. Take off the guard, 4WD transmission shaft and differential lock supply pipe. 6. Drain the oil from the gearbox and centre housing. 7. Remove the lubrication pipe (1) of the Power Shuttle (if fitted) located between the centre housing and gearbox (Fig. 2).

Operations on the right-hand side of the tractor

8. Remove the batteries and their support located behind the right-hand step. 9. Mark then disconnect: - the main pipe (17 bar) to the selector cover plate, - the front differential lock hose on the right-hand hydraulic cover plate - the return hoses on the selector cover plate - the gear cable and rod on the selector cover plate (if necessary) - the creeper or super creeper gear cable (depending on option).

1

MA-02-05103A

Fig. 2

Massey Ferguson 5400 - Issue 5.a

2C13.5

Splitting GBA20/GPA20 (cab fixed to gearbox)

10. On tractors fitted with a creeper or super creeper unit (Fig. 3), carry out the following operations. - Remove the rod (3) (if necessary). - Remove the screw (2). - Pull the pin (1) outwards in order to free the "D" finger of the final drive fork. 11. Mark and disconnect the electrical connectors on: - the right and left-hand hydraulic cover plates, - the selector cover plate; - the Speedshift solenoid valve, - Power Shuttle proportional solenoid valves (if fitted).

Operations on the left-hand side of the tractor

12. Mark then disconnect: - the harness of the fuel gauge on the fuel tank - the fuel feed and return hoses on the engine, immediately blocking the ports, - the vent hose on the fuel tank. 13. Drain the tank (if necessary). Remove it. 14. Disconnect the transmission lubrication supply line (pipes and hoses) located to the front and left of the gearbox.

MA-02-05104A

Fig. 3

2C13.6

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

Operations under the cab

15. Mark then disconnect: - the right and left-hand brake hoses, - the control hose of the trailer brake valve (if fitted), immediately blocking the ports, - the hand brake cable, - the speed sensor connectors (power take-off and forward speed).

Operations at the rear of the tractor

16. Mark and disconnect the control cables: - of the auxiliary spool valves, - of the PTO (all versions). 17. Mark and disconnect the connectors: - of the linkage valve - of the PTO - of the draft sensor (top link).

MA-02-05089A

Fig. 4

Preparing for disassembly

18. Cancel the oscillation, depending on assembly: - of the front axle beam (2WD) or - of the front axle (4WD), by inserting a suitable wooden block on either side of the frame (1) as shown in Fig. 4. 19. Chock the front wheels.

Massey Ferguson 5400 - Issue 5.a

2C13.7

Splitting GBA20/GPA20 (cab fixed to gearbox)

20. Install (Fig. 5): - a fixed axle stand at the rear of the gearbox, - a mobile axle stand at the front of the rear axle, - a mobile axle stand at the rear of the hitch hook. 21. Separate the cab from the right and left-hand rear supports (see chapter 12). 22. Gently lift the cab rear using two straps fitted to the hooks on the rear lower pillars.

Disassembly

IMPORTANT: During separation, check that all connections (hoses, pipes and harnesses) are disconnected. 23. Remove the screws (1) and nuts (2) fixing the gearbox to the centre housing (Fig. 6). Mark their length and position. Specifications of the screws and nuts Screws (1) Nuts (2) M14

DANGER: Make the area around the cab safe by temporarily inserting a wooden chock between each rear support and the right and left-hand cab attachments.

M14 x 45 mm M14 x 60 mm M14 x 70 mm

24. Remove the wooden chocks inserted during step 22. 25. Assisted by an operator, separate the assemblies (Fig. 5). 26. Hold the cab still using suitable axle stands positioned under the right and left-hand supports (Fig. 5).

Fig. 5

2C13.8

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

MA-02-05105A

Fig. 6

Massey Ferguson 5400 - Issue 5.a

2C13.9

Splitting GBA20/GPA20 (cab fixed to gearbox)

Reassembly

27. Clean the mating faces of the gearbox and the centre housing. On the centre housing 28. Check the presence of dowels (4) (Fig. 7). NOTE: The dowels are force fitted. 29. Position the spring (1) in the PTO clutch (Fig. 8). 30. Smear the mating face of the centre housing with Loctite 5206 or equivalent, avoiding the Hare and Tortoise ports. 31. Replace the "O" rings (2) (Fig. 8). 32. If necessary, screw two diametrically opposed guide studs onto the centre housing.

MA-02-05109A

Fig. 7

5206

MA-02-05106A

Fig. 8

2C13.10

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

On the gearbox 33. Check that the PTO shaft is present and positioned correctly. 34. Depending on the option, carry out the following actions. Gearbox without creeper or super creeper unit (Fig. 9) Check the correct assembly of the connecting shaft (1) fitted with the sleeves (2) and double pins (3). Gearbox with creeper unit (Fig. 10) Check: - the correct assembly of the connecting shaft (1) fitted with the sleeve (2) and double pin (3), - that the control mechanism (fork and coupler) is operating correctly in each position. Push the fork (4) towards the front of the gearbox in direct drive position. NOTE: The output shaft of the gearbox with creeper unit supports the connecting shaft (1) via the needle roller bearing (5).

Fig. 9

Fig. 10

Massey Ferguson 5400 - Issue 5.a

2C13.11

Splitting GBA20/GPA20 (cab fixed to gearbox)

Gearbox with super creeper unit (Fig. 11) Check: - the presence of the connecting shaft (1) fitted with the sleeve (2) and double pin (3), - that the control mechanism (fork and coupler) is operating correctly in each position. Push the fork (4) towards the front of the gearbox in super creeper position. NOTE: The output shaft of the gearbox with super creeper unit supports the connecting shaft (1) via the needle roller bearing (5).

3 5

MA-02-05107A

Fig. 11

2C13.12

Massey Ferguson 5400 - Issue 5.a

Splitting GBA20/GPA20 (cab fixed to gearbox)

On the centre housing (Fig. 12) 35. Pull the pin (1) outwards. Turn finger D towards the front of the centre housing (version with creeper or super creeper unit). 36. Attach the gearbox to the centre housing. IMPORTANT: If there is resistance when moving the elements (gearbox, centre housing) together, do not force them; find the cause of the problem. 37. Once the elements are joined, remove the guide studs (if fitted). 38. Fit the screws (1) and nuts (2) (Fig. 6) according to the marks made during disassembly. Tighten the screws and nuts to a torque of 155 - 195 Nm. 39. Engage finger D in the fork of the creeper or super creeper unit (if fitted). 40. Fit a new seal on the screw (2) (Fig. 12). Lightly smear the thread of the screw (2) with Loctite 242 or equivalent. Tighten the screw moderately. 41. Refit the rod (3) (if fitted).

242

MA-02-05108A

Fig. 12

Massey Ferguson 5400 - Issue 5.a

2C13.13

Splitting GBA20/GPA20 (cab fixed to gearbox)

Final steps

The final steps are not especially difficult. However, it will be necessary during reassembly to perform the tightening torques, adjustments and tests described below. Tightening torque: - Front cab screws (see chapter 12) - Rear cab screws (see chapter 12) - Rear wheel screws or nuts (see chapter 6). Top up: - Transmission oil in the housings (check using the gauge located at the rear of the centre housing) - Coolant, to the maximum level marked on the expansion tank. Adjustment: - of the creeper or super creeper gear cable (if fitted), - of the control rod and cable of the four basic gears. Test: - the air conditioning system (if fitted - see chapter 12); - the mechanical reverse shuttle or Power Shuttle (depending on option), - the four basic gears, - the Hare and Tortoise ranges - the Speedshift, - the creeper or super creeper unit (depending on option). Check tightness: - the mating faces; - Hydraulic unions

2C13.14

Massey Ferguson 5400 - Issue 5.a

You might also like

- MF5400 Manual 04-EnDocument30 pagesMF5400 Manual 04-EnSelmirije2No ratings yet

- MF5400 Manual 08-EnDocument194 pagesMF5400 Manual 08-EnSelmirije2100% (3)

- Master Mf6400 WSM 02 enDocument214 pagesMaster Mf6400 WSM 02 enSelmirije2No ratings yet

- Master Mf8600 WSM 03 enDocument160 pagesMaster Mf8600 WSM 03 enSelmirije2100% (1)

- MF5400 Manual 05-EnDocument462 pagesMF5400 Manual 05-EnSelmirije2100% (2)

- Master Mf6400 WSM 07 enDocument334 pagesMaster Mf6400 WSM 07 enNelson Conselho100% (1)

- Power take-off overviewDocument312 pagesPower take-off overviewosteanu100% (2)

- Champion 120-135-150Document812 pagesChampion 120-135-150Николай Петков100% (1)

- MF5400 Manual 01-EnDocument58 pagesMF5400 Manual 01-EnSelmirije2No ratings yet

- MF8200 Series SM 019640Document1,964 pagesMF8200 Series SM 019640Dalibor Sopina Duc67% (3)

- MF5400 Workshop Manual 03-EngineDocument42 pagesMF5400 Workshop Manual 03-EngineFerran Alfonso100% (2)

- Master Mf8600 WSM 01 enDocument324 pagesMaster Mf8600 WSM 01 enSelmirije289% (9)

- 0299 250 2 Sys El en 144Document254 pages0299 250 2 Sys El en 144api-1948325050% (2)

- MF6400 WSM 03 en PDFDocument58 pagesMF6400 WSM 03 en PDFosteanuNo ratings yet

- Master Mf6400 WSM 07 enDocument334 pagesMaster Mf6400 WSM 07 enSelmirije2100% (1)

- Repair Instructions Favorit 500Document4 pagesRepair Instructions Favorit 500Jaring VisserNo ratings yet

- Mas 6110Document468 pagesMas 6110Yurii ChinovNo ratings yet

- Agrotron 118Document840 pagesAgrotron 118Sabadsag DariusNo ratings yet

- Valtra Fault CodesDocument4 pagesValtra Fault Codeshelio100% (1)

- Master Mf6400 WSM 03 enDocument58 pagesMaster Mf6400 WSM 03 enSelmirije2100% (2)

- Master Mf8600 WSM 02 enDocument366 pagesMaster Mf8600 WSM 02 enSelmirije2100% (3)

- Master Mf6400 WSM 01 enDocument72 pagesMaster Mf6400 WSM 01 enSelmirije2100% (1)

- 9658 9658 9658 Massey Ferguson Tractor MF 6475 6480 6485 6490 6495 6499 6497 6470 6465 6460 6455 6445 Workshop Shop Service Repair Manual PDFDocument1 page9658 9658 9658 Massey Ferguson Tractor MF 6475 6480 6485 6490 6495 6499 6497 6470 6465 6460 6455 6445 Workshop Shop Service Repair Manual PDFGustavo Canelas Vargas100% (1)

- инструкция по эксплуатации 9540-9680WTSDocument492 pagesинструкция по эксплуатации 9540-9680WTSshapochka_vNo ratings yet

- 15814842-Fendt Xylon Favorit Series Tractors Transmission Repair PDF PDFDocument410 pages15814842-Fendt Xylon Favorit Series Tractors Transmission Repair PDF PDFteodorescu_dan_575% (4)

- MF 6400 Gearbox GuideDocument644 pagesMF 6400 Gearbox Guideosteanu100% (6)

- Fendt 800 Vario ManualDocument19 pagesFendt 800 Vario Manualgraig27No ratings yet

- Explorer90 105enDocument339 pagesExplorer90 105enBogdan Constantin100% (1)

- McCormick MC135 Power6 Tractor Operator Manual PDFDocument15 pagesMcCormick MC135 Power6 Tractor Operator Manual PDFfjjsjekdmme0% (1)

- 0298 199 0 SV en 300Document56 pages0298 199 0 SV en 300andis_a100% (1)

- SM New Holland T5030 T5040 T5050 T5060 TractorDocument10 pagesSM New Holland T5030 T5040 T5050 T5060 Tractorاحمد الشبراوى الشبراوى100% (1)

- 6000 - 6010 - 6020 - Series John Deere 6920 Parts Catalog PDFDocument374 pages6000 - 6010 - 6020 - Series John Deere 6920 Parts Catalog PDFАлексей Миронов100% (3)

- OIB Dyna-4&6 7614 To 7618 Maintenance 4373743Document179 pagesOIB Dyna-4&6 7614 To 7618 Maintenance 4373743Huu Cuong Nguyen100% (1)

- Newholland FeilkoderDocument19 pagesNewholland Feilkoderaliosha2k89% (9)

- The Medium-Horsepower Series From Massey Ferguson: Pure Performance and PowerDocument36 pagesThe Medium-Horsepower Series From Massey Ferguson: Pure Performance and PowerKos Basil100% (1)

- 4 300 Series Tractor Workshop ManualDocument51 pages4 300 Series Tractor Workshop ManualBertho Quisoccala Llampi0% (2)

- Sm-Deutz Fahr Agrotron k90 k100 k110 k120 Profiline TractorDocument777 pagesSm-Deutz Fahr Agrotron k90 k100 k110 k120 Profiline TractorPiotr Grzela100% (2)

- John Deere 8530 Service Manual PDFDocument502 pagesJohn Deere 8530 Service Manual PDFDanilo mendesNo ratings yet

- Servisno Uputstvo Za Massey Ferguson Traktore Serije 6100-6190Document815 pagesServisno Uputstvo Za Massey Ferguson Traktore Serije 6100-6190lazakiraj86% (28)

- Technical Manual Tractors 6820, 6920 and 6920S RepairDocument21 pagesTechnical Manual Tractors 6820, 6920 and 6920S RepairQuer Quer0% (2)

- Fastrac 3170Document21 pagesFastrac 3170Patka1130% (1)

- XTX - TTX PDFDocument338 pagesXTX - TTX PDFAndrei Mihai50% (2)

- Linked PDFDocument369 pagesLinked PDFSaeid Sharifi100% (1)

- 210 PumaDocument392 pages210 Pumamatey100% (3)

- Katalog 920 PDFDocument707 pagesKatalog 920 PDFbubulelaman100% (4)

- MF 6400Document17 pagesMF 6400milancebre0% (1)

- CASE IH MAXXUM 120 Multicontroller TRACTOR Service Repair Manual PDFDocument120 pagesCASE IH MAXXUM 120 Multicontroller TRACTOR Service Repair Manual PDFjfjksekdmeik67% (3)

- MF8925 ManualDocument670 pagesMF8925 ManualGedas Pocius83% (6)

- AtlesDocument26 pagesAtlesAnonymous CdUZMZJq73No ratings yet

- Alpine 3676095M1GBDocument444 pagesAlpine 3676095M1GBDario Mamani Castillo100% (1)

- t6010 PDFDocument412 pagest6010 PDFPapy PlusNo ratings yet

- Master Mf6400 Wsm 02 EnDocument214 pagesMaster Mf6400 Wsm 02 Enhms2024kftNo ratings yet

- Massey Ferguson Mf5400 Workshop Manual 02 Splitting The TractorDocument7 pagesMassey Ferguson Mf5400 Workshop Manual 02 Splitting The Tractoriva100% (51)

- Engine, Torque Converter and TransmissionDocument10 pagesEngine, Torque Converter and Transmissionalonso100% (1)

- SECTION 2001 Separating and Removing The EngineDocument24 pagesSECTION 2001 Separating and Removing The Enginelungu mihaiNo ratings yet

- Camshaft TimingDocument8 pagesCamshaft TimingHarol Ariel Sanchez MezaNo ratings yet

- Engine Removal Guide for 1/4-Ton 4x4 TrucksDocument76 pagesEngine Removal Guide for 1/4-Ton 4x4 Trucksgwa4940% (1)

- Camshaft Timing: Testing and AdjustingDocument8 pagesCamshaft Timing: Testing and AdjustingsxturboNo ratings yet

- 980F WHEEL LOADER 3HK00001-UP (MACHINE) POWERED BY 3406 ENGINE (SEBP1999 - 01) - Systems & ComponentsDocument9 pages980F WHEEL LOADER 3HK00001-UP (MACHINE) POWERED BY 3406 ENGINE (SEBP1999 - 01) - Systems & ComponentsTransportation MaintananceNo ratings yet

- Pwee9410 L400 95 Chassis 27Document0 pagesPwee9410 L400 95 Chassis 27Selmirije2No ratings yet

- Master Mf6400 WSM 03 enDocument58 pagesMaster Mf6400 WSM 03 enSelmirije2100% (2)

- Front Axle, Steering and Related Components: Sparex Replacement Spare Parts For Ford/New Holland (65 - )Document39 pagesFront Axle, Steering and Related Components: Sparex Replacement Spare Parts For Ford/New Holland (65 - )Selmirije2100% (1)

- RT55H Parts Manual 053-118Document229 pagesRT55H Parts Manual 053-118Selmirije2No ratings yet

- Repair Manual Driven Front Axle Mt22/Mt23 Series: Marmon-Herrington All-Wheel DriveDocument54 pagesRepair Manual Driven Front Axle Mt22/Mt23 Series: Marmon-Herrington All-Wheel DrivelordgwyddionNo ratings yet

- Master Mf8600 WSM 02 enDocument366 pagesMaster Mf8600 WSM 02 enSelmirije2100% (3)

- MF5400 Workshop Manual 03-EngineDocument42 pagesMF5400 Workshop Manual 03-EngineFerran Alfonso100% (2)

- DriveshaftDocument1 pageDriveshaftSelmirije2No ratings yet

- MF5400 Manual 01-EnDocument58 pagesMF5400 Manual 01-EnSelmirije2No ratings yet

- Master Mf8600 WSM 01 enDocument324 pagesMaster Mf8600 WSM 01 enSelmirije289% (9)

- Master Mf6400 WSM 07 enDocument334 pagesMaster Mf6400 WSM 07 enSelmirije2100% (1)

- Carraro 711-19 Axle Workshop ManualDocument0 pagesCarraro 711-19 Axle Workshop ManualSelmirije2100% (1)

- DL6 DL8 DL10 DL12 Dynalift Parts ManualsDocument442 pagesDL6 DL8 DL10 DL12 Dynalift Parts ManualsSelmirije2100% (2)

- Carraro Drive Axle Main CatalogDocument15 pagesCarraro Drive Axle Main CatalogMichael BochoridisNo ratings yet

- February '96: 710-19 CARRARO AXLE Ref. 126139 For "J.I. CASE" Spare Parts ListDocument7 pagesFebruary '96: 710-19 CARRARO AXLE Ref. 126139 For "J.I. CASE" Spare Parts ListSelmirije2No ratings yet

- Master Mf6400 WSM 01 enDocument72 pagesMaster Mf6400 WSM 01 enSelmirije2100% (1)

- DFA1101GZ5AD6J 907 Operational Manual 200606 - EnglishDocument0 pagesDFA1101GZ5AD6J 907 Operational Manual 200606 - EnglishSelmirije2No ratings yet

- 20-David Brown EEDocument0 pages20-David Brown EESelmirije2No ratings yet

- 4 Wheel DriveDocument43 pages4 Wheel DriveSelmirije2No ratings yet

- MF 200-Series Workshop Sec WatDocument0 pagesMF 200-Series Workshop Sec WatSelmirije2No ratings yet

- Cat Pieces 230Document24 pagesCat Pieces 230Selmirije2No ratings yet

- John Deere Valve AdjustmentDocument13 pagesJohn Deere Valve AdjustmentautobritaiNo ratings yet

- Engine MX-310 MagnumDocument59 pagesEngine MX-310 Magnumkeingar100% (1)

- Leatherman Wave ManualDocument2 pagesLeatherman Wave ManualGuilherme ChiminelliNo ratings yet

- Essie Waste ManagementDocument2 pagesEssie Waste ManagementrupenderNo ratings yet

- Schneider BreakerDocument170 pagesSchneider BreakerJon Lopez50% (2)

- Hybrid Device BSHDocument21 pagesHybrid Device BSHBommineediLakshmanKumarNo ratings yet

- Marten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsDocument391 pagesMarten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsJed MansouriNo ratings yet

- Part 1Document82 pagesPart 1Jaydeep ZankatNo ratings yet

- Sitren PSR 100 0209 en 2000 IfDocument2 pagesSitren PSR 100 0209 en 2000 IfSuryasai RednamNo ratings yet

- High Rise Structural Systems: Presented byDocument35 pagesHigh Rise Structural Systems: Presented byvidi herdianaNo ratings yet

- Laboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD ProcessDocument8 pagesLaboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD Processpedro aguilarNo ratings yet

- The 16 Losses PDFDocument3 pagesThe 16 Losses PDFsenzo scholarNo ratings yet

- Chromium Plating of Press ToolsDocument6 pagesChromium Plating of Press Toolsrajamech46No ratings yet

- Porosity Specific Surface Area Practice GuideDocument91 pagesPorosity Specific Surface Area Practice Guidesilentpolter100% (2)

- Cleanliness and Beautification Action Plan S.Y. 2021-2022 Areas of Concern Objectives Strategies Persons Involve Time Frame Success IndicatorDocument4 pagesCleanliness and Beautification Action Plan S.Y. 2021-2022 Areas of Concern Objectives Strategies Persons Involve Time Frame Success IndicatorMARITES TUMOLVA100% (3)

- AASHTO M 320-10 Performance Graded Asphalt BinderDocument7 pagesAASHTO M 320-10 Performance Graded Asphalt BinderplavingalneemaNo ratings yet

- AMIAD Water Systems Arkal Spin Klin 7 X4" Galaxy User Guide: Installation and Operation InstructionsDocument23 pagesAMIAD Water Systems Arkal Spin Klin 7 X4" Galaxy User Guide: Installation and Operation InstructionsLuongNo ratings yet

- P 329E ContinuousCastingPlantsForCopperDocument24 pagesP 329E ContinuousCastingPlantsForCopperI SinhrooNo ratings yet

- Petroleum and Petroleum Products - Liquefied Petroleum Gas (LPG) - SpecificationDocument8 pagesPetroleum and Petroleum Products - Liquefied Petroleum Gas (LPG) - SpecificationJon GoeltomNo ratings yet

- Các loại đầu nối cho ống- fittings for high pressure PDFDocument45 pagesCác loại đầu nối cho ống- fittings for high pressure PDFKiên MaiNo ratings yet

- Smartdek Design ManualDocument48 pagesSmartdek Design ManualranddyNo ratings yet

- 18.5200 MUS KS01 Foam SeparatorDocument32 pages18.5200 MUS KS01 Foam SeparatorIndra KushwahaNo ratings yet

- Day 2 200 ItemsDocument25 pagesDay 2 200 ItemsRobert DelfinNo ratings yet

- Chapter 21 22 - Chemical Reactions Balancing Chemical EquationsDocument34 pagesChapter 21 22 - Chemical Reactions Balancing Chemical EquationsAlwielland BelloNo ratings yet

- South African Cotton Textile Pipeline Statistics 2016-2020Document16 pagesSouth African Cotton Textile Pipeline Statistics 2016-2020Siphumelele QithiNo ratings yet

- Parallel Session ICMIA Update 12 NovDocument4 pagesParallel Session ICMIA Update 12 NovnagatozzNo ratings yet

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDocument7 pagesAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilNo ratings yet

- Turboexpander Lubricant Problems.Document3 pagesTurboexpander Lubricant Problems.dr_kh_ahmedNo ratings yet

- Internal Epoxy Coating in Surface CondenserDocument14 pagesInternal Epoxy Coating in Surface CondenserChaudhari SanketNo ratings yet

- Sp168f PDFDocument10 pagesSp168f PDFAmbar SolangeNo ratings yet

- Forged Valve and Fittings For Sour ServiceDocument1 pageForged Valve and Fittings For Sour ServiceVijay AcharyaNo ratings yet

- Adsorption by BhanuDocument20 pagesAdsorption by BhanuHiren vaghaniNo ratings yet