Professional Documents

Culture Documents

Battery

Uploaded by

michaelliu1234560 ratings0% found this document useful (0 votes)

106 views0 pagesThe electrolyte is harmful to skin and eyes. Remove all rings, watches and other items with metal parts before working on the battery. Cells may be stored filled and charged for a period not exceeding 12 months. Storage of a filled battery at temperatures above +30degC (+86degF) can result in loss of capacity.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe electrolyte is harmful to skin and eyes. Remove all rings, watches and other items with metal parts before working on the battery. Cells may be stored filled and charged for a period not exceeding 12 months. Storage of a filled battery at temperatures above +30degC (+86degF) can result in loss of capacity.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

106 views0 pagesBattery

Uploaded by

michaelliu123456The electrolyte is harmful to skin and eyes. Remove all rings, watches and other items with metal parts before working on the battery. Cells may be stored filled and charged for a period not exceeding 12 months. Storage of a filled battery at temperatures above +30degC (+86degF) can result in loss of capacity.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

Important recommendations

I Never allow an exposed flame or

spark near the batteries, particularly

while charging.

I Never smoke while performing any

operation on the battery.

I For protection, wear rubber gloves,

long sleeves, and appropriate splash

goggles or face shield.

I The electrolyte is harmful to skin and

eyes. In the event of contact with

skin or eyes, wash immediately with

plenty of water. If eyes are affected,

flush with water, and obtain

immediate medical attention.

I Remove all rings, watches and other

items with metal parts before

working on the battery.

I Use insulated tools.

I Avoid static electricity and take

measures for protection against

electric shocks.

I Discharge any possible static

electricity from clothing

and/or tools by touching an

earth-connected part "ground"

before working on the battery.

1. Receiving the shipment

Unpack the cells immediately upon

arrival. Do not overturn the package.

Transport seals are located under the

cover of the vent plug.

I If the cells are shipped filled and

charged, the cells are ready for

asssembly. Remove the plastic

transport seals only before use.

I If the cells are shipped empty and

discharged, do not remove the plastic

transport seals until ready to fill the

cells.

The cells must never be charged with

the transport seals in place as this can

cause permanent damage.

2. Storage

Store the battery indoors in a dry, clean,

cool location (0C to +30C / +32F to

+86F) and well ventilated space on open

shelves.

Do not store in direct sunlight or expose

to excessive heat.

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

I Cells filled and charged

If cells are stored filled, they must be

fully charged prior to storage.

Cells may be stored filled and charged

for a period not exceeding 12 months

from date of dispatch from factory.

Storage of a filled battery at temperatures

above +30C (+86F) can result in loss of

capacity. This can be as much 5% per

10C (18F) above +30C (+86F) per year.

I Cells empty and discharged

Saft recommends to store cells empty

and discharged. This ensures compliance

with IEC 60623 section 4.9 (storage).

Cells can be stored like this for many

years.

I When deliveries are made in cardboard

boxes, store without opening the boxes.

I When deliveries are made in plywood

boxes, open the boxes before the

storage. The lid and the packing material

on top of the cells must be removed.

3. Electrolyte / cell oil

I Cells delivered filled and charged:

Check the level of electrolyte. It should

not be more than 20 mm below the

maximum level mark (upper). If this is

not the case, adjust the level with distilled

or deionized water. Cells delivered filled

have already cell oil in place.

In case of spillage of electrolyte during

the transport, the cells have to be

topped-up with E22 electrolyte. Fill the

cells about 20 mm above the minimum

level mark (lower) with electrolyte. Wait

4 hours and adjust if necessary before

commissioning.

I Cells delivered empty and discharged:

If the electrolyte is supplied dry, prepare it

according to its separate instructions sheet.

The electrolyte to be used is E22. Remove

the transport seals just before filling.

Fill the cells about 20 mm above the

minimum level mark (lower) with electrolyte.

Wait 4 to 24 hours and adjust if

necessary before commissioning.

It is recommended to add the cell oil

after the commissioning charge, with the

syringe, according to the quantity

indicated in the Tables A or B.

4. Installation

4.1. Location

Install the battery in a dry and clean

room. Avoid direct sunlight and heat.

The battery will give the best performance

and maximum service life when the

ambient temperature is between +10C

to +30C (+50F to +86F).

4.2. Ventilation

During the last part of charging, the

battery is emitting gases (oxygen and

hydrogen mixture). At normal float-

charge the gas evolution is very small

but some ventilation is necessary.

Note that special regulations for

ventilation may be valid in your area

depending on the application.

4.3. Mounting

Verify that cells are correctly

interconnected with the appropriate

polarity. The battery connection to load

should be with nickel plated cable lugs.

Recommended torques for terminal bolts

are:

M 6 = 11 1.1 N.m (97.4 9.8 lbf.in)

M 8 = 20 2 N.m (177.0 17.7 lbf.in)

M10 = 30 3 N.m (265.0 26.6 lbf.in)

The connectors and terminals should be

corrosion-protected by coating with a

thin layer of anti-corrosion oil.

Remove the transport seals and close

the vent plugs.

5. Commissioning

Verify that the transport seals are

removed, the vents are closed and the

ventilation is adequate during this

operation.

A good commissioning is important.

Charge at constant current is preferable.

If the current limit is lower than indicated

in the Tables A or B, charge for a

proportionnaly longer time.

October 2009

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

For cells delivered filled by the factory:

- Cell oil is already in place.

- Check the electrolyte level and adjust

it to the maximum level mark (upper)

by adding distilled or deionized water.

For cells filled on location:

- Add the cell oil with the syringe,

according to the quantity indicated in

the Tables A or B.

- Check the electrolyte level and adjust

it the maximum level mark (upper)

by adding: electrolyte.

The battery is ready for use.

For capacity test purposes, the battery

has to be charged in accordance with

IEC 60623 section 4.

6. Charging in service

I Continuous parallel operation, with

occasional battery discharge.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

For two level charge:

float level

= 1.42 0.01 V/cell for L cells

= 1.40 0.01 V/cell for M and H cells

high level

= 1.47 - 1.70 V/cell for L cells

= 1.45 - 1.70 V/cell for M and H cells.

A high voltage will increase the speed

and efficiency of the recharging.

For single level charge:

float level: 1.43 - 1.50 V/cell.

I Buffer operation, where the load

exceeds the charger rating.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

1.50 - 1.60 V/cell.

7. Periodic Maintenance

I Keep the battery clean using only

water. Do not use a wire brush or

solvents of any kind. Vent plugs can be

rinsed in clean water if necessary.

I Check the electrolyte level. Never let

the level fall below the minimum level

mark (lower). Use only distilled or

deionized water to top-up.

Experience will tell the time interval

between topping-up.

Note: Once the battery has been filled

with the correct electrolyte either at

the battery factory or during the

battery commissioning, there is no

need to check the electrolyte density

periodically. Interpretation of density

measurements is difficult and could be

misleading.

I Check the charging voltage. If a battery

is parallel connected, it is important

that the recommended charging

voltage remains unchanged.

The charging voltage should be checked

and recorded at least once yearly.

If a cell float voltage is found below

1.35 V, high-rate charge is

recommended to apply to the cell

concerned.

I Check every two years that all

connectors are tight. The connectors

and terminal bolts should be corrosion-

protected by coating with a thin layer

of anti-corrosion oil.

I High water consumption is usually

caused by high improper voltage

setting of the charger.

8. Changing electrolyte

In most stationary battery applications,

the electrolyte will retain its effectiveness

for the life of the battery. However, under

special battery operating conditions, if the

electrolyte is found to be carbonated, the

battery performance can be restored by

replacing the electrolyte.

The electrolyte type to be used for

replacement in these cells is: E13.

Refer to "Electrolyte Instructions".

9. Environment

To protect the environment all used

batteries must be recycled.

Contact your local Saft representative

for further information.

I For cells filled and charged by the

factory and stored less than

6 months:

Constant current charge:

Charge for 10 h at 0.2 C

5

A

recommended (see Tables A or B).

Note: At the end of the charge, the

cell voltage may reach the level of

1.85 V per cell, thus the charger shall

be able to supply such voltage.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery into

two parts to be charged individually.

Constant voltage charge:

Charge for 24 h at 1.65 V/cell,

current limited to 0.2 C

5

A or charge

for 48 h at 1.55 V/cell, current

limited to 0.2 C

5

A (see Tables A or B).

I For cells filled on location or for filled

cells which have been stored more

than 6 months:

Constant current charge:

a) Charge for 10 h at 0.2 C

5

A

recommended (see Tables A or B)

b) Discharge at 0.2 C

5

A to 1.0 V/cell

c) Charge for 10 h at 0.2 C

5

A

recommended (see Tables A or B).

Note: At the end of the charge, the cell

voltage may reach the level of 1.85 V

per cell, thus the charger shall be able

to supply such voltage.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery into

two parts to be charged individually.

Constant voltage charge:

a) Charge for 30 h at 1.65 V/cell with

current limited to 0.2 C

5

A

(see Tables A or B)

b) Discharge at 0.2 C

5

A to 1.0 V/cell

c) Charge for 30 h at 1.65 V/cell

with current limited to 0.2 C

5

A

or charge for 48 h at 1.55 V/cell

current limited to 0.2 C

5

A

(see Tables A or B)

I Cell oil & electrolyte after

commissioning: wait for 4 hours after

commissioning.

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

SBLE 7.5 1.5 0.08 0.24 10 M 6

SBLE 15 3.0 0.11 0.35 10 M 6

SBLE 22 4.4 0.17 0.53 15 M 6

SBLE 30 6.0 0.15 0.46 15 M 6

SBLE 40 8.0 0.29 0.90 30 M 6

SBLE 47 9.4 0.19 0.59 20 M 6

SBLE 62 12 0.23 0.70 30 M 6

SBLE 75 15 0.32 1.0 25 M 8

SBLE 95 19 0.39 1.2 25 M 8

SBLE 110 22 0.39 1.2 30 M 10

SBLE 140 28 0.49 1.5 30 M 10

SBLE 185 37 0.65 2.0 40 M 10

SBLE 230 46 0.74 2.3 50 M 10

SBLE 275 55 0.94 2.9 60 M 10

SBLE 325 65 1.13 3.5 35 2 x M 10

SBLE 375 75 1.29 4.0 40 2 x M 10

SBLE 415 83 1.39 4.3 45 2 x M 10

SBLE 460 92 1.49 4.6 50 2 x M 10

SBLE 510 102 1.68 5.2 55 2 x M 10

SBLE 550 110 1.88 5.8 60 2 x M 10

SBLE 600 120 2.04 6.3 43 3 x M 10

SBLE 650 130 2.14 6.6 47 3 x M 10

SBLE 700 140 2.23 6.9 50 3 x M 10

SBLE 750 150 2.43 7.5 53 3 x M 10

SBLE 830 166 2.81 8.7 60 3 x M 10

SBLE 925 185 2.98 9.2 50 4 x M 10

SBLE 1020 204 3.36 10.4 55 4 x M 10

SBLE 1100 220 3.75 11.6 60 4 x M 10

SBLE 1200 240 3.91 12.1 52 5 x M 10

SBLE 1300 260 4.30 13.3 56 5 x M 10

SBLE 1400 280 4.69 14.5 60 5 x M 10

SBLE 1500 300 5.05 15.6 55 6 x M 10

SBLE 1600 320 5.44 16.8 58 6 x M 10

SBLE 1660 332 5.63 17.4 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

* Value for initial filling (E22).

The cell type shows the rated capacity in ampere hours (Ah).

Table A: Standard range

SBM 11 2.2 0.10 0.30 15 M 6

SBM 15 3.0 0.11 0.33 15 M 6

SBM 22 4.4 0.15 0.46 15 M 6

SBM 30 6.0 0.15 0.46 15 M 6

SBM 43 8.6 0.31 0.95 20 M 6

SBM 56 11 0.36 1.1 20 M 6

SBM 65 13 0.32 1.0 25 M 8

SBM 84 17 0.39 1.2 25 M 8

SBM 112 22 0.45 1.4 30 M 8

SBM 138 28 0.55 1.7 40 M 10

SBM 161 32 0.61 1.9 40 M 10

SBM 184 37 0.78 2.4 50 M 10

SBM 208 42 0.94 2.9 60 M 10

SBM 231 46 0.94 2.9 60 M 10

SBM 277 55 1.13 3.5 40 2 x M 10

SBM 300 60 1.20 3.7 40 2 x M 10

SBM 323 65 1.26 3.9 40 2 x M 10

SBM 346 69 1.42 4.4 50 2 x M 10

SBM 369 74 1.55 4.8 50 2 x M 10

SBM 392 78 1.72 5.3 60 2 x M 10

SBM 415 83 1.88 5.8 60 2 x M 10

SBM 438 88 1.88 5.8 60 2 x M 10

SBM 461 92 1.84 5.7 60 2 x M 10

SBM 505 101 2.10 6.5 50 3 x M 10

SBM 555 111 2.33 7.2 50 3 x M 10

SBM 625 125 2.82 8.7 60 3 x M 10

SBM 690 138 2.78 8.6 60 3 x M 10

SBM 740 148 3.11 9.6 50 4 x M 10

SBM 830 166 3.79 11.7 60 4 x M 10

SBM 920 184 3.82 11.8 60 4 x M 10

SBM 965 193 3.69 11.4 40 6 x M 10

SBM 1040 208 4.72 14.6 60 5 x M 10

SBM 1150 230 4.66 14.4 60 5 x M 10

SBM 1220 244 5.50 17.0 60 6 x M 10

SBM 1390 278 5.60 17.3 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

SBH 8.3 1.7 0.12 0.36 10 M 6

SBH 12 2.4 0.14 0.44 15 M 6

SBH 16 3.2 0.16 0.48 15 M 6

SBH 19 3.8 0.25 0.77 15 M 6

SBH 29 5.8 0.31 0.95 20 M 6

SBH 39 7.8 0.36 1.1 25 M 8

SBH 49 9.8 0.42 1.3 30 M 8

SBH 59 12 0.49 1.5 30 M 10

SBH 69 14 0.58 1.8 40 M 10

SBH 79 16 0.58 1.8 40 M 10

SBH 88 18 0.74 2.3 50 M 10

SBH 98 20 0.71 2.2 50 M 10

SBH 118 24 0.87 2.7 60 M 10

SBH 137 28 1.20 3.7 40 2 x M 10

SBH 157 31 1.20 3.7 40 2 x M 10

SBH 177 35 1.46 4.5 50 2 x M 10

SBH 196 39 1.42 4.4 50 2 x M 10

SBH 236 47 1.84 5.7 60 2 x M 10

SBH 265 53 2.20 6.8 50 3 x M 10

SBH 294 59 2.10 6.5 50 3 x M 10

SBH 353 71 2.78 8.6 60 3 x M 10

SBH 393 79 2.82 8.7 50 4 x M 10

SBH 471 94 3.69 11.4 60 4 x M 10

SBH 491 98 3.53 10.9 50 5 x M 10

SBH 590 118 4.63 14.3 60 5 x M 10

SBH 640 128 4.21 13.0 50 5 x M 10

SBH 705 141 5.31 16.4 60 5 x M 10

SBH 765 153 5.24 16.2 60 5 x M 10

SBH 865 173 5.92 18.3 57 6 x M 10

SBH 920 184 6.28 19.4 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

Saft

Industrial Battery Group

12, rue Sadi Carnot

93170 Bagnolet - France

Tel: +33 1 49 93 19 18

Fax: +33 1 49 93 19 64

www.saftbatteries.com

Doc N 21124-2-1009

Data in this document is subject to change without

notice and becomes contractual only after written

confirmation.

Socit anonyme au capital de 31 944 000

RCS Bobigny B 383 703 873

Pragma - Printed in France - 3k

* Value for initial filling (E22).

The cell type shows the rated capacity in ampere hours (Ah).

Table B: Non standard range

SBL 7.5 1.5 0.08 0.24 10 M 6

SBL 16 3.2 0.11 0.35 10 M 6

SBL 30 6.0 0.15 0.46 15 M 6

SBL 37 7.4 0.22 0.69 15 M 6

SBL 45 9.0 0.19 0.59 20 M 6

SBL 48 9.6 0.28 0.86 15 M 6

SBL 59 12 0.23 0.7 30 M 6

SBL 70 14 0.32 1.0 25 M 8

SBL 90 18 0.39 1.2 25 M 8

SBL 102 21 0.39 1.2 30 M 10

SBL 131 27 0.49 1.5 30 M 10

SBL 135 27 0.55 1.7 40 M 10

SBL 167 34 0.65 2.0 50 M 10

SBL 173 35 0.65 2.0 40 M 10

SBL 199 40 0.78 2.4 60 M 10

SBL 214 43 0.74 2.3 50 M 10

SBL 237 48 0.97 3.0 40 2 x M 10

SBL 256 52 0.94 2.9 60 M 10

SBL 269 54 1.13 3.5 40 2 x M 10

SBL 301 61 1.20 3.7 50 2 x M 10

SBL 304 61 1.13 3.5 40 2 x M 10

SBL 334 67 1.26 3.9 50 2 x M 10

SBL 346 70 1.26 3.9 40 2 x M 10

SBL 366 74 1.42 4.4 60 2 x M 10

SBL 387 78 1.36 4.2 50 2 x M 10

SBL 398 80 1.55 4.8 60 2 x M 10

SBL 429 86 1.49 4.6 50 2 x M 10

SBL 470 94 1.68 5.2 60 2 x M 10

SBL 500 100 1.91 5.9 50 3 x M 10

SBL 510 102 1.88 5.8 60 2 x M 10

SBL 595 119 2.33 7.2 60 3 x M 10

SBL 600 120 2.14 6.6 47 3 x M 10

SBL 645 129 2.23 6.9 50 3 x M 10

SBL 665 133 2.56 7.9 50 4 x M 10

SBL 770 154 2.78 8.6 60 3 x M 10

SBL 795 159 3.11 9.6 60 4 x M 10

SBL 835 167 3.11 9.6 50 5 x M 10

SBL 860 172 2.98 9.2 50 4 x M 10

SBL 995 199 3.88 12.0 60 5 x M 10

SBL 1020 204 3.72 11.5 60 4 x M 10

SBL 1070 214 3.72 11.5 50 5 x M 10

SBL 1280 256 4.66 14.4 60 5 x M 10

SBL 1450 290 5.31 16.4 57 6 x M 10

SBL 1540 308 5.60 17.3 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

SBM 86 17 0.42 1.3 30 M 8

SBM 287 57 1.39 4.3 50 2 x M 10

SBM 359 72 1.62 5.0 60 2 x M 10

SBM 431 86 2.07 6.4 50 3 x M 10

SBM 540 108 2.43 7.5 60 3 x M 10

SBM 575 115 2.78 8.6 50 4 x M 10

SBM 720 144 3.24 10.0 60 4 x M 10

SBM 900 180 4.05 12.5 60 5 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

SBH 25 5.0 0.30 0.92 15 M 6

SBH 38 7.6 0.39 1.2 20 M 6

SBH 51 10 0.42 1.3 25 M 8

SBH 64 13 0.52 1.6 30 M 8

SBH 77 15 0.52 1.6 30 M 10

SBH 89 18 0.61 1.9 40 M 10

SBH 102 20 0.68 2.1 40 M 10

SBH 115 23 0.91 2.8 50 M 10

SBH 128 26 0.84 2.6 50 M 10

SBH 141 28 1.07 3.3 60 M 10

SBH 153 31 1.04 3.2 60 M 10

SBH 179 36 1.23 3.8 40 2 x M 10

SBH 204 41 1.36 4.2 40 2 x M 10

SBH 230 46 1.81 5.6 50 2 x M 10

SBH 256 51 1.68 5.2 50 2 x M10

SBH 281 56 2.14 6.6 60 2 x M 10

SBH 307 61 2.10 6.5 60 2 x M 10

SBH 345 69 2.72 8.4 50 3 x M 10

SBH 383 77 2.52 7.8 50 3 x M 10

SBH 422 84 3.17 9.8 60 3 x M 10

SBH 460 92 3.14 9.7 60 3 x M 10

SBH 510 102 3.37 10.4 50 4 x M 10

SBH 560 112 4.24 13.1 60 4 x M 10

SBH 615 123 4.21 13.0 60 4 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

You might also like

- Bioethanol From CornDocument13 pagesBioethanol From Cornpricett100% (1)

- Unit H/617/1143 Financial and Management Accounting Techniques For Managers Level 4 15 CreditsDocument8 pagesUnit H/617/1143 Financial and Management Accounting Techniques For Managers Level 4 15 Creditsshamshad alamNo ratings yet

- Cima F3 DumpsDocument6 pagesCima F3 DumpsOlivia Merchant67% (3)

- Chapter 01Document5 pagesChapter 01Alima Toon Noor Ridita 1612638630No ratings yet

- F6 SMART Notes FA20 Till March-2022 byDocument44 pagesF6 SMART Notes FA20 Till March-2022 byAshfaq Ul Haq OniNo ratings yet

- Valid F2 CIMA Braindumps - F2 Dumps PDF Exam Questions CimaDumpsDocument9 pagesValid F2 CIMA Braindumps - F2 Dumps PDF Exam Questions CimaDumpsCarly MartinNo ratings yet

- 2003 December (Answer)Document22 pages2003 December (Answer)Luke WanNo ratings yet

- (PDF) CIMA P3 Practice PDF - Prep Academia - Academia - EduDocument1 page(PDF) CIMA P3 Practice PDF - Prep Academia - Academia - EduChampyNo ratings yet

- Introduction to Bookkeeping and Accounting PrinciplesDocument20 pagesIntroduction to Bookkeeping and Accounting PrinciplesTrịnh Thanh Mai0% (1)

- Accy 517 Syllabus (Fall 2015)Document6 pagesAccy 517 Syllabus (Fall 2015)VerguishoNo ratings yet

- CST Design Studio - WorkflowDocument102 pagesCST Design Studio - WorkflowHeber Bustos100% (7)

- Free Space Optical Communication PDFDocument233 pagesFree Space Optical Communication PDFIgor Novid100% (1)

- OPzS Installation & Operating InstructionsDocument3 pagesOPzS Installation & Operating InstructionskommuNo ratings yet

- Ni-Cd battery installation guideDocument2 pagesNi-Cd battery installation guidePrem SagarNo ratings yet

- P3 September 2012 AnswersDocument11 pagesP3 September 2012 AnswersJaved AhmedNo ratings yet

- P3 - Performance StrategyDocument17 pagesP3 - Performance StrategyWaqas BadshahNo ratings yet

- CIMA F3 (P3) Risk and Control Strategy SyllabusDocument7 pagesCIMA F3 (P3) Risk and Control Strategy SyllabushmbogirriNo ratings yet

- CIMA Business Mathematics Fundamentals Past Papers PDFDocument107 pagesCIMA Business Mathematics Fundamentals Past Papers PDFSiphoKhosaNo ratings yet

- BPP P3 Step 6 AnswersDocument29 pagesBPP P3 Step 6 AnswersRavi Pall100% (1)

- Acca P6 QuestionDocument8 pagesAcca P6 QuestionChuaJieLingNo ratings yet

- Tutorial Letter 501/0/2021: Information StrategyDocument26 pagesTutorial Letter 501/0/2021: Information StrategyItumeleng KekanaNo ratings yet

- E3 - Enterprise StrategyDocument24 pagesE3 - Enterprise StrategyAfiqah MohamadNo ratings yet

- F3 Revision SummariesDocument45 pagesF3 Revision SummariesShahid AliNo ratings yet

- Get More Past Papers FromDocument110 pagesGet More Past Papers FromRehman Muzaffar100% (1)

- VIVA Answers (Mock-2)Document12 pagesVIVA Answers (Mock-2)isuri abeykoon100% (1)

- CIMA P3 Notes - Performance Strategy - Chapter 8Document6 pagesCIMA P3 Notes - Performance Strategy - Chapter 8Mark Horance Hawking100% (1)

- VIVA Questions (Mock-1)Document11 pagesVIVA Questions (Mock-1)isuri abeykoonNo ratings yet

- E3 - Mock Exam Pack PDFDocument154 pagesE3 - Mock Exam Pack PDFMuhammadUmarNazirChishtiNo ratings yet

- Learn deferred tax and accounting for timing differencesDocument10 pagesLearn deferred tax and accounting for timing differencesteddy matendawafaNo ratings yet

- Smart Notes Acca f6 2015 (35 Pages)Document38 pagesSmart Notes Acca f6 2015 (35 Pages)SrabonBarua100% (2)

- ACCA F1 2012 NotesDocument19 pagesACCA F1 2012 NotesThe ExP GroupNo ratings yet

- Cima p3 Nov201Document28 pagesCima p3 Nov201Rony BanikNo ratings yet

- Ipcc Tax Practice Manual PDFDocument651 pagesIpcc Tax Practice Manual PDFshakshi gupta100% (1)

- Premium Version With AnswerDocument87 pagesPremium Version With Answermuhammad bilalNo ratings yet

- Consuming Passions: Sue BrearDocument2 pagesConsuming Passions: Sue Brearobert07No ratings yet

- Fac 1601 Financial AccountingDocument39 pagesFac 1601 Financial AccountingDeanNo ratings yet

- 8524Document7 pages8524KhurramRiaz100% (1)

- SMA QuizDocument76 pagesSMA QuizQuỳnh ChâuNo ratings yet

- E3 Enterprise Strategy (2010 Syllabus) A Guide For StudentsDocument5 pagesE3 Enterprise Strategy (2010 Syllabus) A Guide For StudentsQamarUlHaq100% (1)

- Acca 2.4 Revision Question BankDocument6 pagesAcca 2.4 Revision Question BankJoy Nelson-Graham50% (2)

- CIMA Operational Case Study Mock Exam 3 Marici Power: UnseenDocument14 pagesCIMA Operational Case Study Mock Exam 3 Marici Power: UnseenForappForappNo ratings yet

- CIMA F2 Text Supplement Construction PDFDocument18 pagesCIMA F2 Text Supplement Construction PDFSiang MingNo ratings yet

- Sa Apr09 PogueDocument7 pagesSa Apr09 PogueDanish IqbalNo ratings yet

- Professional: $245 Academic: $135 Student: $39 Two-Year Student: $78Document5 pagesProfessional: $245 Academic: $135 Student: $39 Two-Year Student: $78anwarNo ratings yet

- Results: Ba2: Chapter 1 - Knowledge Check: The Context of Management AccountingDocument163 pagesResults: Ba2: Chapter 1 - Knowledge Check: The Context of Management AccountingBảo Lê GiaNo ratings yet

- 001 2011 4 eDocument180 pages001 2011 4 eNozipho MpofuNo ratings yet

- 1 Procurement Best Practice Guideline Procurement Planning enDocument13 pages1 Procurement Best Practice Guideline Procurement Planning enYani IriawadiNo ratings yet

- Jun 2006 - Qns Mod ADocument11 pagesJun 2006 - Qns Mod AHubbak Khan100% (2)

- E3 Cima Workbook Q & A PDFDocument100 pagesE3 Cima Workbook Q & A PDFJerome ChettyNo ratings yet

- The Business Landscape For MSMEs and Large Enterprises in Zambia - ZBS July 2010Document78 pagesThe Business Landscape For MSMEs and Large Enterprises in Zambia - ZBS July 2010Chola MukangaNo ratings yet

- AC2091 Financial Reporting: Session 4Document40 pagesAC2091 Financial Reporting: Session 4NadiaIssabellaNo ratings yet

- E3 - Enterprise StrategyDocument28 pagesE3 - Enterprise StrategyJaved AhmedNo ratings yet

- ACCA P2 Mock Exam QuestionsDocument10 pagesACCA P2 Mock Exam QuestionsGeo DonNo ratings yet

- TOPCIMA Analysis Hanging by A ThreadDocument9 pagesTOPCIMA Analysis Hanging by A ThreadGeorge KauteNo ratings yet

- Audit and Assurance: AnswersDocument20 pagesAudit and Assurance: AnswersLauren McMahonNo ratings yet

- Cima C01 Samplequestions Mar2013Document28 pagesCima C01 Samplequestions Mar2013Abhiroop Roy100% (1)

- Alcad Batt SpecDocument2 pagesAlcad Batt SpecIsaac VoonNo ratings yet

- ALCAD HC+P - I&O InstructionDocument2 pagesALCAD HC+P - I&O InstructionsiavoshsaifNo ratings yet

- Deep Cycle MaintenanceDocument8 pagesDeep Cycle MaintenanceJony M. TemnikarNo ratings yet

- E Installation of BatteryDocument16 pagesE Installation of BatteryPrashant KadamNo ratings yet

- Lead Acid Batteries Installation and MaintenanceDocument6 pagesLead Acid Batteries Installation and MaintenanceUsman AliNo ratings yet

- Charging Method and EquipmentDocument16 pagesCharging Method and EquipmentlrpatraNo ratings yet

- Qualmega Ni-Cd Battery Installation GuideDocument2 pagesQualmega Ni-Cd Battery Installation GuideKelvin LiewNo ratings yet

- Product Guide: Single Port MagjackDocument4 pagesProduct Guide: Single Port Magjackmichaelliu123456No ratings yet

- Surge Resistant 461 Series Telelink FuseDocument4 pagesSurge Resistant 461 Series Telelink Fusemichaelliu123456No ratings yet

- STW5NA90Document6 pagesSTW5NA90michaelliu123456No ratings yet

- 18Mb Pipelined Qdr™Ii Sram Burst of 2 Advance Information IDT71P72204 IDT71P72104 IDT71P72804 IDT71P72604Document22 pages18Mb Pipelined Qdr™Ii Sram Burst of 2 Advance Information IDT71P72204 IDT71P72104 IDT71P72804 IDT71P72604michaelliu123456No ratings yet

- AV02-0488EN DS ATF-54143 08jun2012Document16 pagesAV02-0488EN DS ATF-54143 08jun2012patopickNo ratings yet

- Shanghai Sunrise Electronics Co., LTD.: Ss22A Thru Ss26ADocument1 pageShanghai Sunrise Electronics Co., LTD.: Ss22A Thru Ss26Amichaelliu123456No ratings yet

- NtcthermDocument38 pagesNtcthermmichaelliu123456No ratings yet

- RF2125 High Power Linear Amplifier IC DatasheetDocument6 pagesRF2125 High Power Linear Amplifier IC Datasheetmichaelliu123456No ratings yet

- SDRAMDocument86 pagesSDRAMmichaelliu123456No ratings yet

- MosfetDocument16 pagesMosfetmichaelliu123456No ratings yet

- MosfetDocument16 pagesMosfetmichaelliu123456No ratings yet

- STW5NA90Document6 pagesSTW5NA90michaelliu123456No ratings yet

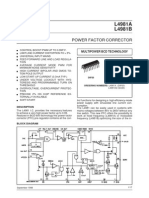

- L4981ADocument17 pagesL4981AMcu CdiiNo ratings yet

- LM 339Document11 pagesLM 339Adi PamungkasNo ratings yet

- L4981ADocument17 pagesL4981AMcu CdiiNo ratings yet

- LM 339Document11 pagesLM 339Adi PamungkasNo ratings yet

- SMR40Document4 pagesSMR40michaelliu123456No ratings yet

- 74LCX16245 Low Voltage 16-Bit Bidirectional Transceiver With 5V Tolerant Inputs and OutputsDocument9 pages74LCX16245 Low Voltage 16-Bit Bidirectional Transceiver With 5V Tolerant Inputs and Outputsmichaelliu123456No ratings yet

- ANTRICE S.A. POWER SUPPLY RACKDocument3 pagesANTRICE S.A. POWER SUPPLY RACKmichaelliu123456No ratings yet

- L6561Document11 pagesL6561michaelliu123456No ratings yet

- Ammp 5618Document7 pagesAmmp 5618michaelliu123456No ratings yet

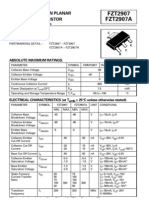

- FZT2907 Switching Transistor SpecsDocument2 pagesFZT2907 Switching Transistor Specsmichaelliu123456No ratings yet

- UC3825ADWDocument15 pagesUC3825ADWmichaelliu123456No ratings yet

- LM393 ComparatorDocument18 pagesLM393 Comparatormichaelliu123456No ratings yet

- New Product: Series Surface Mount T Z Transient Voltage SuppressorDocument3 pagesNew Product: Series Surface Mount T Z Transient Voltage Suppressormichaelliu123456No ratings yet

- Data SheetDocument23 pagesData Sheetmichaelliu123456No ratings yet

- LNB - 1208HB 1107HBNDocument1 pageLNB - 1208HB 1107HBNmichaelliu123456No ratings yet

- R1LV0408D Series: 4M SRAM (512-Kword × 8-Bit)Document14 pagesR1LV0408D Series: 4M SRAM (512-Kword × 8-Bit)michaelliu123456No ratings yet

- New Product: Series Surface Mount T Z Transient Voltage SuppressorDocument3 pagesNew Product: Series Surface Mount T Z Transient Voltage Suppressormichaelliu123456No ratings yet

- Manual E-Claw EngDocument18 pagesManual E-Claw Engshyampillai2007No ratings yet

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Document2 pagesElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262No ratings yet

- Electrical Power Transmission & DistributionDocument18 pagesElectrical Power Transmission & DistributionMd Saif KhanNo ratings yet

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaNo ratings yet

- Manual de TallerDocument252 pagesManual de TallerEdison RodriguezNo ratings yet

- ManualDocument14 pagesManualnas_hoNo ratings yet

- Magic Quadrant For Identity Governance and AdministrationDocument18 pagesMagic Quadrant For Identity Governance and AdministrationmilosvblNo ratings yet

- Physics (Jee Advanced)Document8 pagesPhysics (Jee Advanced)PranavMachingal100% (1)

- CCH Power CalculateDocument4 pagesCCH Power Calculateangga measNo ratings yet

- Ecdis-W: Warship Electronic Chart Display and Information SystemDocument2 pagesEcdis-W: Warship Electronic Chart Display and Information SystemEngr Muhammad SalmanNo ratings yet

- ZMD402AT-CT Technical DataDocument7 pagesZMD402AT-CT Technical DataCarlos SandersNo ratings yet

- System ConfigurationDocument13 pagesSystem ConfigurationEdlyn Estopa BuenoNo ratings yet

- TNK500P Taneko Industrial Generator (TNK JKT)Document2 pagesTNK500P Taneko Industrial Generator (TNK JKT)Rizki Heru HermawanNo ratings yet

- BV DoshiDocument29 pagesBV DoshiAnkit LuthraNo ratings yet

- AC 43-9-1 Amdt 0Document15 pagesAC 43-9-1 Amdt 0Harry NuryantoNo ratings yet

- PLSQL 6 1 PracticeDocument5 pagesPLSQL 6 1 PracticeHahaNo ratings yet

- Life 365 V 2 Users ManualDocument67 pagesLife 365 V 2 Users ManualAmanda VegaNo ratings yet

- Quality Criterion of Road Lighting Measurement and ExploringDocument96 pagesQuality Criterion of Road Lighting Measurement and ExploringNitin UpadhyayNo ratings yet

- Catalogo Recordplus General ElectricDocument12 pagesCatalogo Recordplus General ElectricDruen Delgado MirandaNo ratings yet

- Engineering Mechanics Tutorial Question BankDocument13 pagesEngineering Mechanics Tutorial Question Bankrajeev_kumar365No ratings yet

- Military Standard for Circular Connector Insert ArrangementsDocument59 pagesMilitary Standard for Circular Connector Insert ArrangementsVadim RiabovNo ratings yet

- BOnd Strength ASTM-F904-98Document1 pageBOnd Strength ASTM-F904-98akash.biradarNo ratings yet

- Tender Evaluation FormDocument1 pageTender Evaluation FormbkimaxNo ratings yet

- Silo Fluidizer: Keep Dry Bulk Materials MovingDocument2 pagesSilo Fluidizer: Keep Dry Bulk Materials MovingHùng Thanh NguyễnNo ratings yet

- f094 PDFDocument4 pagesf094 PDFAnshuman SinghNo ratings yet

- Cloud Radio Access Network Architecture Towards 5G NetworkDocument171 pagesCloud Radio Access Network Architecture Towards 5G NetworkwobblegobbleNo ratings yet

- Documentation For: Bank - MasterDocument6 pagesDocumentation For: Bank - MastervijucoolNo ratings yet