Professional Documents

Culture Documents

Lecture 1

Uploaded by

urabiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 1

Uploaded by

urabiCopyright:

Available Formats

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM 420

Temporary Structures

Temporary

Structures

Formwork For

Concrete

CM

CM 420

420 Temporary Structures

CM 420 : Temporary Structures

The first part of CM 420 will deal with the materials,

methods and techniques associated with temporary

structures utilized in various construction operations,

such as:

concrete formwork construction

scaffolding

falsework/shoring

cofferdams

underpinning

diaphram/slurry walls

earth-retaining structures

construction dewatering.

A major emphasis will be placed on concrete formwork

construction covering detailed design analysis of both

vertical and horizontal timber formwork systems.

CM

CM 420

420 Temporary Structures

CM 420 - Temporary Structures

There will be two midterm exams and three quizzes.

Quizzed will be given throughout the quarter, sometimes

unannounced.

The first exam will be given on Tuesday February 1st and the

second one on Thursday, March 8th.

Grading System:

The course final grade will be calculated based on

the following weights:

25% for homework assignments

15% for three quizzes

30% for each midterm exam.

All exams will be closed book.

Professor Kamran M. Nemati

Winter Quarter 2007 1

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

CM 420 - Temporary Structures

Recommended Textbooks:

Hurd, M. K., Formwork for

Concrete. 6th edition, American

Concrete Institute, Detroit, Michigan,

1995.

Ratay, Robert T., Handbook of

Temporary Structures in

Construction. 2nd edition, McGraw

Hill, New York, 1996.

4

CM

CM 420

420 Temporary Structures

CM 420 - Temporary Structures

Class Web Site is located at:

http://courses.washington.edu/cm420/

CM

CM 420

420 Temporary Structures

Formwork for Concrete

Formwork development has paralleled the

growth of concrete construction

throughout the 20th century.

The increasing acceptance of concrete as

a major construction material presents

the form builder a new range of problems

in the development of appropriate

sheathing materials and maintenance of

rigid tolerances.

Professor Kamran M. Nemati

Winter Quarter 2007 2

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Formwork for Concrete

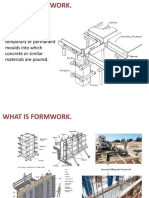

Formwork is a classic temporary

structure in the sense that:

it is erected quickly

highly loaded for a few hours

during the concrete placement

and within a few days

disassembled for future use.

Also classic in their temporary

nature are the connections, braces,

tie anchorages, and adjustment

devices which forms need.

7

CM

CM 420

420 Temporary Structures

Formwork for Concrete

The term "Temporary Structures" may not fully

imply the temporary, since some forms, tie

hardware, and accessories are used hundreds

of times, which necessitates high durability and

maintainability characteristics and design that

maximizes productivity.

Unlike conventional structures, the formwork

disassembly characteristics are severely

restricted by concrete bond, rigidity, and

shrinkage, which not only restricts access to the

formwork structure but causes residual loads

that have to be released to allow stripping from

the concrete which initiates disassembly.

8

CM

CM 420

420 Temporary Structures

Formwork for Concrete

Lumber was once the predominant form

material, but developments in the use of

plywood, metal, plastics, and other materials,

together with the increasing use of specialized

accessories have changed the picture.

Formwork was formerly built in place, used

once, and wrecked.

Because of high labor costs in the U.S., the

trend today is toward increasing prefabrication,

assembly in large units, erection by mechanical

means such as “flying” forms into place by

crane, and continuing reuse of the forms.

9

Professor Kamran M. Nemati

Winter Quarter 2007 3

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Formwork for Concrete

In 1908 the use of wood versus steel formwork was

debated at the ACI convention. Also, the advantages

of modular panel forming with its own connecting

hardware, and good for extensive reuse were realized.

By 1910 steel forms for paving were being produced

commercially and used in the field.

A 1909 construction

scene shows the

first application of

steel forms for

street paving.

10

CM

CM 420

420 Temporary Structures

Formwork for Concrete

Today modular panel forming is the norm.

11

CM

CM 420

420 Temporary Structures

Objectives of Form Building

Forms mold the concrete to desired size

and shape and control its position and

alignment.

But formwork is more than a mold; it is a

temporary structure that supports:

its own weight +

the freshly placed concrete +

construction live loads (including materials,

equipment, and personnel).

12

Professor Kamran M. Nemati

Winter Quarter 2007 4

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Objectives of Form Building

Basic objectives in form building are three

fold:

Quality - In terms of strength, rigidity,

position, and dimensions of the forms

Safety - for both the workers and the

concrete structure

Economy - the least cost consistent with

quality and safety requirements

Cooperation and coordination between

engineer / architect and the contractor are

necessary to achieve these goals.

13

CM

CM 420

420 Temporary Structures

Objectives of Form Building

Economy is a major concern since formwork

costs constitutes up to 60 percent of the total

cost of concrete work in a project.

Form w ork Form w ork

Labor m aterial

Cost cost

Concrete,

rebar,

footings,

placem ent

In designing and building formwork, the

contractor should aim for maximum economy

without sacrificing quality or safety.

14

CM

CM 420

420 Temporary Structures

How Formwork Affects Concrete Quality

Size, shape, and alignment of slabs, beams,

and other concrete structural elements depend

on accurate construction of the forms.

The forms must be:

Sufficiently rigid under the construction loads to

maintain the designed shape of the concrete,

Stable and strong enough to maintain large

members in alignment, and

Substantially constructed to withstand handling and

reuse without losing their dimensional integrity.

The formwork must remain in place until the

concrete is strong enough to carry its own

weight, or the finished structure may be

damaged.

15

Professor Kamran M. Nemati

Winter Quarter 2007 5

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Causes of Formwork Failure

Formwork failures are the cause of many accidents and

failures that occur during concrete construction which

usually happen when fresh concrete is being placed.

Generally some unexpected event causes one member

to fail, then others become overloaded or misaligned

and the entire formwork structure collapses.

Formwork collapse

causes injuries, loss

of life, property

damage, and

construction delays

16

CM

CM 420

420 Temporary Structures

Causes of Formwork Failure

The main causes of formwork failure are:

1 - Improper stripping and shore removal

2 - Inadequate bracing

3 - Vibration

4 - Unstable soil under mudsills*, shoring

not plumb

5 - Inadequate control of concrete

placement

6 - Lack of attention to formwork details.

*Mudsill: A plank, frame, or small footing on the ground used as a base for a

shore or post in formwork.

17

CM

CM 420

420 Temporary Structures

Causes of Failure

Improper Stripping and Shore Removal

Premature stripping of forms, premature removal of

shores, and careless practices in re-shoring can

produce catastrophic results.

Case study:

Too early shore removal at Bailey's

Crossroads in Virginia (1972):

26-stories + apartment building

Forms were supported by floors 7-days

old or older

Failure occurred on the 24th floor, where

it was shored to the 5-day-old 23rd floor.

The overloaded 23rd floor failed in shear

around one or more columns,

triggering a collapse that carried through

the entire height of the building.

18

Professor Kamran M. Nemati

Winter Quarter 2007 6

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Causes of Failure

Inadequate Bracing

The more frequent causes of formwork failure,

however, are other effects that induce lateral

force components or induce displacement of

supporting members.

Inadequate cross bracing and horizontal

bracing of shores is one of the factors most

frequently involved in formwork accidents.

Investigations prove that many accidents

causing thousands of dollars of damage could

have been prevented only if a few hundred

dollars had been spent on diagonal bracing for

the formwork support.

19

CM

CM 420

420 Temporary Structures

Causes of Failure

Inadequate Bracing− Use of Diagonal Bracing

High shoring with heavy load at the top is

vulnerable to eccentric or lateral loading.

Diagonal bracing improves the stability of such

a structure, as do guys or struts to solid ground

or competed structures.

20

CM

CM 420

420 Temporary Structures

Causes of Failure

Inadequate Bracing

The main exhibition floor of the New York Coliseum

collapsed when concrete was being placed.

Forms for the floor slab were supported on two

tiers of shores.

Case study:

New York Coliseum

Formwork collapse,

where rapid

delivery of

concrete

introduced lateral

forces at the top of

high shoring.

21

Professor Kamran M. Nemati

Winter Quarter 2007 7

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Causes of Failure

Inadequate Bracing− Use of Diagonal Bracing

Case study: New York Coliseum

Increased diagonal bracing was added to all

remaining shoring, following partial collapse of

formwork.

22

CM

CM 420

420 Temporary Structures

Causes of Failure

Inadequate Bracing− Use of Diagonal Bracing

When a failure occurs at one part, inadequate

bracing may permit the collapse to extend to a

large portion of the structure and multiply the

damage.

Suppose a worker accidentally rams or

wheelbarrow into some vertical shores and

dislodges a couple of them. This may set up a

chain of reaction that brings down the entire floor.

One major objective of bracing is to prevent such

a minor accident or failure from becoming a

disaster.

23

CM

CM 420

420 Temporary Structures

Causes of Failure

Vibration

Forms sometimes collapse when their

supporting shores or jacks are displaced by

vibration caused by:

passing traffic

movement of workers and equipment on

the formwork

the effect of vibrating concrete to

consolidate it.

Diagonal bracing can help prevent failure

due to vibration.

24

Professor Kamran M. Nemati

Winter Quarter 2007 8

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Causes of Failure

Unstable Soil under Mudsills, Shoring not Plumb

Formwork should be safe if it is adequately braced

and constructed so all loads are carried to solid

ground through vertical members.

Shores must be set plumb and the ground must be

able to carry the load without settling.

Shores and mudsills must not rest on frozen

ground; moisture and heat from the concreting

operations, or changing air temperatures, may

thaw the soil and allow settlement that overloads

or shifts the formwork.

Site drainage must be adequate to prevent a

washout of soil supporting the mudsills.

25

CM

CM 420

420 Temporary Structures

Causes of Failure

Inadequate Control of Concrete Placement

The temperature and rate of vertical placement of

concrete are factors influencing the development of

lateral pressures that act on the forms.

If temperature drops during construction operations,

rate of concreting often has to be slowed down to

prevent a build up of lateral pressure overloading the

forms. If this is not done, formwork failure may result.

Failure to regulate properly the rate

Fresh

and order of placing concrete on Concrete

horizontal surfaces or curved roofs H

γ

may produce unbalanced loadings

and consequent failures of formwork.

26

CM

CM 420

420 Temporary Structures

Causes of Failure

Lack of Attention to Formwork Details

Even when the basic formwork design is soundly

conceived, small differences in assembly details may

cause local weakness or overstress loading to form

failure.

This may be as simple as insufficient nailing, or failure

to tighten the locking devices on metal shoring.

Other details that may cause failure are:

Inadequate provisions to prevent rotation of beam forms

where slabs frame into them on the side.

Inadequate anchorage against uplift for sloping form faces.

Lack of bracing or tying of corners, bulkheads, or other

places where unequal pressure is found.

27

Professor Kamran M. Nemati

Winter Quarter 2007 9

CM

CM 420

420 Temporary Structures

Formwork for Concrete

CM

CM 420

420 Temporary Structures

Planning for Safety

OSHA (Occupational Safety and Health

Administration) regulations, American Concrete

Institute (ACI) recommendations, and local code

requirements for formwork should be followed:

Supervision and Inspection

Platform and Access for Workers

Control of Concreting Practices

Improving Soil Bearing and Bracing

Shoring and Re-shoring

Relationship of Architect, Engineer and Contractor

Maintaining and Coordinating Tolerances

Preparing a Formwork Specification

28

Professor Kamran M. Nemati

Winter Quarter 2007 10

You might also like

- Temporary StructureDocument27 pagesTemporary StructureNguyễn Thanh CườngNo ratings yet

- Cep Lecture5 FormworkDocument69 pagesCep Lecture5 FormworkKrm ChariNo ratings yet

- Formwork For Concrete - 7Th Edition4Document5 pagesFormwork For Concrete - 7Th Edition4prasad perka100% (1)

- Formwork 11Document77 pagesFormwork 11Anish OhriNo ratings yet

- 2concrete FormworkDocument38 pages2concrete FormworkNaveed DilberNo ratings yet

- Lecture2 FormworksDocument34 pagesLecture2 Formworkssamrawit aysheshimNo ratings yet

- Speedy Construction with Forms and MaterialsDocument23 pagesSpeedy Construction with Forms and MaterialsAr Jitendra KumarNo ratings yet

- Asha Chuhan DSR MICRO-PROJECTDocument18 pagesAsha Chuhan DSR MICRO-PROJECTAsha ChuhanNo ratings yet

- Mivan TechnologyDocument24 pagesMivan TechnologyArjun MNo ratings yet

- Form Work DR VSR Lec 1Document72 pagesForm Work DR VSR Lec 1mithunbmNo ratings yet

- ARCH402 Nora Ahmd 21902492Document16 pagesARCH402 Nora Ahmd 2190249221902492No ratings yet

- RCSDD - PPT Editing FormatDocument276 pagesRCSDD - PPT Editing Formatashok KumarNo ratings yet

- Presentation On ShutteringDocument29 pagesPresentation On ShutteringMukul KumarNo ratings yet

- Group 8 Lesson 11 PresentationDocument30 pagesGroup 8 Lesson 11 PresentationAaron PinedaNo ratings yet

- Construction Engineering Assignment 1Document3 pagesConstruction Engineering Assignment 1Usama EjazNo ratings yet

- DSR MicroprojectDocument15 pagesDSR Microprojectshobhitsahu7208No ratings yet

- FormworkDocument11 pagesFormworkcoolczoneNo ratings yet

- Formwork System: - Meor Muhammad Azrin 01DSB10F1012 - Ruzaini Azri 01DSB10F1002 - Nur Sya'Ira 01DSB10FDocument23 pagesFormwork System: - Meor Muhammad Azrin 01DSB10F1012 - Ruzaini Azri 01DSB10F1002 - Nur Sya'Ira 01DSB10Fmeor_azrinNo ratings yet

- Framed StructuresDocument26 pagesFramed StructuresSamit ThakurNo ratings yet

- Construction Systems - CCANZ CH 15 - Formwork PDFDocument14 pagesConstruction Systems - CCANZ CH 15 - Formwork PDFracing.phreakNo ratings yet

- Technical University of Kenya Formwork GuideDocument8 pagesTechnical University of Kenya Formwork GuideTeddy MatiekaNo ratings yet

- What is Formwork? Understanding its Importance and UsageDocument21 pagesWhat is Formwork? Understanding its Importance and UsageMohamad HaniffNo ratings yet

- Plastic Formwork Advantages in ConstructionDocument12 pagesPlastic Formwork Advantages in ConstructionNarlyn TevesNo ratings yet

- Prefabricated Structures IntroductionDocument36 pagesPrefabricated Structures IntroductionMamthasenaNo ratings yet

- Final Exam August 16, 2014Document9 pagesFinal Exam August 16, 2014mulkeab11No ratings yet

- Formwork Is An Ancillary ConstructionDocument25 pagesFormwork Is An Ancillary ConstructionSarinNo ratings yet

- Bridge Inspection and Maintenance: DR Mohd Haziman B Wan IbrahimDocument60 pagesBridge Inspection and Maintenance: DR Mohd Haziman B Wan Ibrahimziming liNo ratings yet

- L.D College of Engineering: A Report On Construction Site VisitDocument15 pagesL.D College of Engineering: A Report On Construction Site VisitNeel TurkhiyaNo ratings yet

- Formwork: Requirements of A Good FormworkDocument34 pagesFormwork: Requirements of A Good Formworkweston chege100% (1)

- SRIVIDYA COLLEGE ENGINEERING TECHNOLOGY QUESTION BANK ROOF TRUSSESDocument8 pagesSRIVIDYA COLLEGE ENGINEERING TECHNOLOGY QUESTION BANK ROOF TRUSSESAravindNo ratings yet

- Fatima Michael College RC Design Course MaterialDocument127 pagesFatima Michael College RC Design Course MaterialAyush GargNo ratings yet

- CHAPTER 3 Formwork Part 1Document39 pagesCHAPTER 3 Formwork Part 1nasNo ratings yet

- Appendix 1 - Formwork BasicsDocument12 pagesAppendix 1 - Formwork Basicschandra BandaraNo ratings yet

- Chapter 4 - Construction Method in Reinforced ConcreteDocument27 pagesChapter 4 - Construction Method in Reinforced Concretepritti_naa100% (1)

- Durocrete Mix Design Manual GuideDocument65 pagesDurocrete Mix Design Manual Guideengsam777No ratings yet

- Concret Mix Design (M10 To M100)Document65 pagesConcret Mix Design (M10 To M100)Rajesh Kollipara93% (14)

- Construction Technology II Lesson 9Document88 pagesConstruction Technology II Lesson 9sydney augustNo ratings yet

- Fundamentals of Post-Tensioned Concrete Design For BuildingsDocument49 pagesFundamentals of Post-Tensioned Concrete Design For Buildingssalaverria0% (1)

- NotesDocument31 pagesNotesErika Nell LachicaNo ratings yet

- ADVANCED CONCRETE TECHNOLOGIES ASSIGNMENTDocument14 pagesADVANCED CONCRETE TECHNOLOGIES ASSIGNMENTkavya.dasthariNo ratings yet

- Construction Systems - CCANZ CH 15 - FormworkDocument14 pagesConstruction Systems - CCANZ CH 15 - FormworkGopal SudhirNo ratings yet

- Basic Concepts of ConcreteDocument19 pagesBasic Concepts of ConcreteSathish SelvaNo ratings yet

- Concrete TechnologyDocument88 pagesConcrete TechnologysalahNo ratings yet

- Ce1302 Design of RC ElementsDocument22 pagesCe1302 Design of RC Elementsjs kalyana rama100% (1)

- Module 1 - Concrete As Construction MaterialDocument24 pagesModule 1 - Concrete As Construction Materialabinash choudharyNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Concrete Structures: Repair, Rehabilitation and StrengtheningFrom EverandConcrete Structures: Repair, Rehabilitation and StrengtheningNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Rehabilitation of Concrete Structures with Fiber-Reinforced PolymerFrom EverandRehabilitation of Concrete Structures with Fiber-Reinforced PolymerNo ratings yet

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- SchneiderElectric 111711 PDFDocument17 pagesSchneiderElectric 111711 PDFShiva Naga KumarNo ratings yet

- Section-1 Es enDocument75 pagesSection-1 Es enSushmit SharmaNo ratings yet

- Action Verbs For ResumesDocument2 pagesAction Verbs For Resumesapi-2627751040% (1)

- Decision Support For Maintenance and Refurbishment Planning of Hydropower PlantsDocument10 pagesDecision Support For Maintenance and Refurbishment Planning of Hydropower PlantsSushmit SharmaNo ratings yet

- OT3 GIS For BeginnersDocument37 pagesOT3 GIS For Beginnersmakmohit6037No ratings yet

- What Is New in PMBOK Guide 6th EdDocument130 pagesWhat Is New in PMBOK Guide 6th EdMikiRoniWijaya94% (16)

- Labour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazetteDocument44 pagesLabour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazettenepalcaNo ratings yet

- PPA ProcedureDocument5 pagesPPA ProcedureSushmit SharmaNo ratings yet

- Electricity Act 2049-EnglishDocument14 pagesElectricity Act 2049-EnglishFariyad AnsariNo ratings yet

- Cement Grouted Rock Bolts PDFDocument28 pagesCement Grouted Rock Bolts PDFSushmit SharmaNo ratings yet

- Labour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazetteDocument44 pagesLabour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazettenepalcaNo ratings yet

- Decision Support For Maintenance and Refurbishment Planning of Hydropower PlantsDocument10 pagesDecision Support For Maintenance and Refurbishment Planning of Hydropower PlantsSushmit SharmaNo ratings yet

- EIA IEE Working Procedure 2073Document4 pagesEIA IEE Working Procedure 2073Sushmit SharmaNo ratings yet

- Hydropower Development Policy, 2049: 1. BackgroundDocument5 pagesHydropower Development Policy, 2049: 1. BackgroundRajpNo ratings yet

- Christie Burger Henk HattinghDocument28 pagesChristie Burger Henk HattinghSushmit SharmaNo ratings yet

- Asset Management Council 1205 TheAsset0602 PDFDocument48 pagesAsset Management Council 1205 TheAsset0602 PDFSushmit SharmaNo ratings yet

- A Holistic Approach To Asset Management in The NetherlandsDocument10 pagesA Holistic Approach To Asset Management in The NetherlandsSushmit SharmaNo ratings yet

- Crucial Role of Physical Modeling in Developing Intake ConfigurationDocument20 pagesCrucial Role of Physical Modeling in Developing Intake Configurationrelu100% (1)

- 02 Sanchez AM Overview PDFDocument20 pages02 Sanchez AM Overview PDFSushmit SharmaNo ratings yet

- Fostering Academic Cooperation and CollaborationDocument22 pagesFostering Academic Cooperation and CollaborationSushmit SharmaNo ratings yet

- Barreiro-Trigos Octavio PDFDocument72 pagesBarreiro-Trigos Octavio PDFSushmit SharmaNo ratings yet

- GIS Tutorial 1 Basic WorkbookDocument417 pagesGIS Tutorial 1 Basic WorkbookJuan95% (21)

- Good Governance in The Public SectorDocument54 pagesGood Governance in The Public Sectorhermione_crisNo ratings yet

- Supply Chain Management Fact SheetDocument4 pagesSupply Chain Management Fact SheetYong Yang YangNo ratings yet

- 05 Supplier Selection Process PDFDocument15 pages05 Supplier Selection Process PDFSushmit SharmaNo ratings yet

- HCF PDFDocument68 pagesHCF PDFSushmit SharmaNo ratings yet

- PMI ManagingSubcontracts March2010Document25 pagesPMI ManagingSubcontracts March2010Sushmit SharmaNo ratings yet

- Multilevel Project Governance Trends and OpportunitiesDocument18 pagesMultilevel Project Governance Trends and OpportunitiesSushmit SharmaNo ratings yet

- Case Template Nuremberg-Ingolstadt FinalDocument45 pagesCase Template Nuremberg-Ingolstadt FinalSushmit SharmaNo ratings yet

- PCI Parking BuildingDocument125 pagesPCI Parking BuildingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet