Professional Documents

Culture Documents

0913 Vertical Shaft Brick Kiln VSBK 01

Uploaded by

Joshua JordanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0913 Vertical Shaft Brick Kiln VSBK 01

Uploaded by

Joshua JordanCopyright:

Available Formats

Vertical Shaft Brick Kiln (VSBK)

An effective South-South Technology Transfer for climate change mitigation in the Clay Brick sector Paper for the 16th IUAPPA World Clean Air Congress

Authors:

Luca De Giovanetti (luca.degiovanetti@sa-vsbk.org) , John Volsteedt (john.volsteedt@sa-vsbk.org) Swisscontact South Africa (SA-VSBK), 107 Nicolson Street, Pretoria, South Africa

Abstract

The Vertical Shaft Brick Kiln (VSBK) is an energy efficient and less polluting technology for the firing of clay brick. Internationally constantly improved with the support of the Swiss Agency for Development and Cooperation (SDC), it has reached a higher level of efficiency in South Africa during the South-South technology transfer. The VSBK contributes positively to climate change mitigation due to an average 50% reduction in coal consumption and therefore CO2 emissions compared to clamp kiln, the traditional South African firing technology. Due to the vertical structure and efficient combustion the emission of other gases and particles is also drastically reduced. Emissions are now easily measured and are below the new South African air quality standards. The technology brings various economic and social benefits to the employers and workers, and is a good example of a clean and sustainable development contributing to South Africas international climate change targets.

About SA-VSBK

The SA-VSBK is a South-South Technology Transfer project implemented in South Africa by Swisscontact (Swiss Foundation for Technical Co-operation) in collaboration with SKAT (Swiss Resource Centre and Consultancies for Development). The project is funded by the Swiss Agency for Development and Cooperations (SDC) and part of their Global Climate Change Mitigation Programme, which in South Africa focuses on energy efficiency in the building sector. The primary objective of the project is to introduce and disseminate the VSBK brick firing technology as a viable and sustainable alternative firing technology for the clay brick industry, with many positive impacts from the economic, environmental and social point of view. The project is facilitating the transfer of the technology to the South African brick

entrepreneurs, generally small and middle size family businesses enterprise. The technology offers economic, environmental and social benefits to the clay brick manufacturers and therefore to the South African Air Quality. The project partners come from both the public and private sector, with a focus on creating a suitable business environment as well as knowledge download at various levels ensuring a successful transfer and take-up of the technology.

Figure 1: packing of fired clay bricks from the VSBK

South-South Technology Transfer

This project is an example of a successful South-South Technology transfer, where the technology and knowledge has been transferred directly from Asia (mainly India and Nepal) to South Africa. External intervention from the North has been limited and serves primarily as facilitator of this transfer. The technology transfer entails various activities, including: 1) organization of workshops to discuss and adapt the technology to the local needs and conditions; 2) exchange of experts to discuss the changes, supervise the construction, and for local capacity building: to transfer and anchor the knowledge in the country to a wide range of service providers; 3) monitor the performance and support in the operation; 4) redesign and adapt the technology according to the lessons learned.

Figure 2: Operation of a Clamp Kiln in South Africa

Now, faced with new environmental regulations, increasing coal costs and shrinking profits, South African brick entrepreneurs are actively looking for cleaner and more energy-efficient firing methods. The introduction of Vertical Shaft Brick Kiln (VSBK) technology aims to provide a cleaner and more equitable solution in reducing energy consumption and diminishing gas and particulate emissions during the firing process.

What is VSBK?

The Vertical Shaft Brick Kiln (VSBK) technology is an energy-efficient updraft kiln comprising of a vertical shaft from which bricks are loaded at the top and removed at ground level in a continuous process. An unloading tunnel runs through the centre of each kiln allowing for access to both sides of the shaft.

Introduction

South Africa is a very energy and coal intensive economy. The country is the 13th larger emitter of CO2 in the world and has per capita emissions of 8.9 tCO2. This is mainly due to their highly coal based economy. The South African government has during the climate conference COP17 in Durban last year committed to reduce emissions by 34% by 2020 compared to business as usual. Energy efficient technologies provide the mechanisms to reduce Greenhouse Gas emissions in South Africa. This is particularly important for the clay brickmaking sector, a modern-state-of-the-art industry as far as mining and green (unfired) brick production is concerned. However when it comes to firing, many brickmakers still make use of the clamp kiln process, a traditional firing methodology, which although has been improved upon over time, remains relatively energy inefficient and commensurate with Greenhouse Gas emissions.

Figure 3: Structure of VSBK by Langkloof Brick, Jeffreys Bay, Eastern Cape, South Africa.

Internal body fuel is mixed into the bricks with a measured amount of external coal spread evenly between the layers of stacked bricks to control the firing temperature. The position of the fire in each shaft in relation to the updraft is determined by the rate the bricks are removed and loaded into the shaft. This reuses the rising heat, making it very fuel-

efficient. The firing shaft is very well insulated on all four sides, so that heat loss is minimised. Once the kiln reaches the specified temperature, the heat from the coal ignites the internal coal of the bricks so that very little heat is lost through exhaust gases or the kiln itself. These exhaust gasses are used for the gradual preheating of the unfired bricks on top, thus reducing energy consumption and CO emissions by up to 50% compared to the more commonly used clamp kilns.

The firing process is completed within a 24hour period, a considerably short firing cycle, which tolerates very few mistakes. It is essential to have the appropriate knowledge in order to ensure efficient operation of the VSBK and, thereby, the successful production of bricks that are consistent in quality.

The Origins of VSBK Technology

The VSBK technology evolved in rural China. The original version of a Chinese Vertical Shaft Brick Kiln was adapted from the traditional updraft intermittent kiln in the early 1970s. In 1985 the Chinese government commissioned the Energy Research Institute to improve its energy efficiencies and by 2000, between 50 000 and 60 000 units were in operation throughout the country. Through the support of SDC, the technology has since been enhanced and re-pioneered in Nepal, Pakistan, Afghanistan, India and Vietnam. In September 2011, South Africas very first SA-VSBK pilot plant was inaugurated at Langkloof Bricks, in Jeffreys Bay, in the Eastern Cape.

Figure 4: VSBK operational design

Benefits of the VSBK technology

The VSBK technology covers all three pillars of sustainable development and provides the following benefits:

How Does the VSBK Work?

The VSBK works on the basis of a counter current principle. When the lid is closed, the shaft and exhaust becomes an integral chimney system. The firing process of preheat, firing (vitrification) and cooling takes place within the shaft, as the bricks move down the shaft. Energy efficiency is derived through the verticality of the shaft and structural thermal efficiency.

Environmental Benefits

Each kiln will contribute to reduce by 600t per year the CO2 emissions, which with a 50% of clamp kiln conversion to this cleaner clay brick technology as VSBK by 2020, it is estimated to achieve half a million tons CO2 reduction per year.

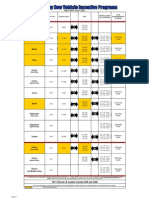

Table 1: Comparison of average energy required for firing for the main firing technologies in South Africa.

Production Mechanism Tunnel kiln Transverse Arch kiln Clamp kiln VSBK Worldwide SA-VSBK (Langkloof Bricks)

Firing Energy Required (per Kg of fired brick) 1.65 2.1 MJ/Kg 2.0 4.0 MJ/Kg 1.7 4.2 MJ/Kg 0.84 1.1 MJ/Kg 0.85 MJ/Kg and still improving!

All gases and particles as PM10, NOx, SOx, VOC, etc. are considerably reduced and easily measurable as a single point source. This with considerable benefits both for the labours and for the overall air quality. (PM10 were 2 measured at an average of 9.1 g/m ) **latest more updated emission results awaiting finalization**

Environmental Impact Assessment (EIA) requirements and process taking longer than expected and discouraging these changes.

Future steps

To overcome these remaining barriers and challenges, SDC has decided to support an additional four years of the project which will still be implemented by Swisscontact. The project will be constructed with a specific market-develop focus and look at a wider facilitation of improving the energy efficiency of the overall clay brick sector in South Africa. Intervention in the market areas will be: 1) Supply of low carbon bricks with the further support of the VSBK technology but also of facilitation of other energy efficient practices; 2) Enabling the business and political Environment by facilitating the access to carbon and green financing products and enabling a better and easier access to information for informed political decision; 3) Increasing the Demand of low carbon bricks in the market across the clay brick users value chain.

Economic benefits

With an energy consumption of 0.85 MJ/kg fired brick (compared to an average of 2.3 MJ/kg for clamp kiln) there is a coal saving of on average 50% reducing the embodied energy of the final brick and building. Breakage in production are below 2% compared to the average of 15% allowing more final saleable product with the same inputs.

Social Benefits

The VSBK helps to retain jobs and requiring more skilled people it provide opportunity for skills development. Improved health and safety on the working place with allow to a better working condition for the employees.

Challenges and barrier

Even if technology transfer has been successful and competences have been transferred to and anchored in South African local service providers and are ready to be multiplied, a wider uptake of the technology hasnt taken place yet. The main reason is that other challenges and barriers beside the technology still remain present. These challenges and barriers are: 1) Access to Finance to obtain preferential green credit lines to support the investment costs; 2) conservative mind set, cultural habit and traditional practice of business and operation; 3) lack of knowledge of detailed single operation practices and costs; 4) adverse investment climate due to national and international financial situation; 5)

Figure 5: Langkloof Bricks VSBK

"We believe the VSBK technology will fundamentally shift the way many clay brick manufacturers think about production in the future, from an economic, social and environmental perspective. - Nico Blake, Langkloof Bricks

You might also like

- Kara MohammedDocument185 pagesKara MohammedJoshua JordanNo ratings yet

- Operational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionDocument6 pagesOperational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionJoshua JordanNo ratings yet

- 12 DR SPGhosh CMADocument55 pages12 DR SPGhosh CMAJoshua JordanNo ratings yet

- Aib 030Document2 pagesAib 030Joshua JordanNo ratings yet

- Strategic Implications of Customer BehaviourDocument5 pagesStrategic Implications of Customer BehaviourJoshua JordanNo ratings yet

- International Standard: I So/Fdi SDocument22 pagesInternational Standard: I So/Fdi SJoshua JordanNo ratings yet

- New Method To Measure The Fill Level of The Ball Mill I - Theoretical Analysis and DEM SimulationDocument8 pagesNew Method To Measure The Fill Level of The Ball Mill I - Theoretical Analysis and DEM SimulationJoshua JordanNo ratings yet

- BallMill OperatingManualDocument25 pagesBallMill OperatingManualJoshua JordanNo ratings yet

- Nano MaterialsDocument356 pagesNano Materialsitsmeou11No ratings yet

- Coating Formation On Refractory Brick: Rcïary Cement KilnDocument7 pagesCoating Formation On Refractory Brick: Rcïary Cement KilnJoshua JordanNo ratings yet

- CHM 3609 - Inorganic Chemistry: X y Z XDocument3 pagesCHM 3609 - Inorganic Chemistry: X y Z XJoshua JordanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Council Requested Budget Adjustment AdditionsDocument58 pagesCouncil Requested Budget Adjustment AdditionsDarren KrauseNo ratings yet

- Sustainable Finance Final Report enDocument100 pagesSustainable Finance Final Report enmanopp16No ratings yet

- Wipo Pub Gii 2021Document226 pagesWipo Pub Gii 2021AK Aru ShettyNo ratings yet

- CrescimentoVerde EN PortugalDocument182 pagesCrescimentoVerde EN PortugalJose Elias VargasNo ratings yet

- 築跡12 eBookDocument48 pages築跡12 eBookchungkiyanNo ratings yet

- Kuliah UmumDocument6 pagesKuliah UmumYosua ardianNo ratings yet

- SDSN Indicator ReportDocument16 pagesSDSN Indicator ReportZulfiyah SilmiNo ratings yet

- Hybrid VehiclesDocument14 pagesHybrid VehiclesCosmin Mihai KiritaNo ratings yet

- BP Energy Outlook 2023Document66 pagesBP Energy Outlook 2023Danna Lizeth Rueda ParedesNo ratings yet

- Energy Master AberdeenDocument58 pagesEnergy Master AberdeenrifqihazaziNo ratings yet

- Prius P Hev ManualDocument16 pagesPrius P Hev Manualrey1004No ratings yet

- Toyota of Palo Alto Finance Incentives Rebates 0% Financing Corolla CamryDocument1 pageToyota of Palo Alto Finance Incentives Rebates 0% Financing Corolla CamryToyota of Palo AltoNo ratings yet

- Trade and Environment Review 2009-2010Document230 pagesTrade and Environment Review 2009-2010Carlos PaniaguaNo ratings yet

- Tunisia Country Climate and Development ReportDocument96 pagesTunisia Country Climate and Development Reportwassim bouraouiNo ratings yet

- Report Component IDocument172 pagesReport Component IYashwanth Kumar PuducheriNo ratings yet

- South Asia and Climate Change: A Way Forward: November 2014Document41 pagesSouth Asia and Climate Change: A Way Forward: November 2014Swati AnandNo ratings yet

- HCSP-Presales-Smart PV (Commercial & Industrial) V1.0 Training MaterialDocument88 pagesHCSP-Presales-Smart PV (Commercial & Industrial) V1.0 Training Materialjesrcontreras1976No ratings yet

- OECD - Investing in Climate, Investing in Growth PDFDocument314 pagesOECD - Investing in Climate, Investing in Growth PDFCatalin CNo ratings yet

- A Project Report On " Carbon Emissions Trading in India": Department of Business and Industrial ManagementDocument73 pagesA Project Report On " Carbon Emissions Trading in India": Department of Business and Industrial ManagementSHUKLA YOGESHNo ratings yet

- CCUS Brochure - EN - FinalDocument32 pagesCCUS Brochure - EN - Finalshraddha admaneNo ratings yet

- Fang Et Al. (2023) Social Media and Energy Justice A Global EvidenceDocument12 pagesFang Et Al. (2023) Social Media and Energy Justice A Global EvidenceAubin DiffoNo ratings yet

- Green Finance For Green GrowthDocument24 pagesGreen Finance For Green GrowthSreejith BhattathiriNo ratings yet

- History of Hybrid Electric Vehicles 3Document24 pagesHistory of Hybrid Electric Vehicles 3ADITYA DAS 17BEE0267No ratings yet

- Sustainability: Aviation BriefingDocument16 pagesSustainability: Aviation BriefingHAGFAH FarnairNo ratings yet

- The Role of Rail Decarbonization FinalDocument111 pagesThe Role of Rail Decarbonization FinaljaddellelNo ratings yet

- Chaptercase 3: Consider This - .Document1 pageChaptercase 3: Consider This - .Mohammad Irfan Amin TanimNo ratings yet

- Generation Adequacy Final Report - For PublicationDocument141 pagesGeneration Adequacy Final Report - For PublicationMuhammad KuncoroNo ratings yet

- Chapter 5 UnescoDocument21 pagesChapter 5 UnescosydjjNo ratings yet

- Republic Act No 2641Document44 pagesRepublic Act No 2641Mark PascoNo ratings yet

- MEA Clean Energy Report EN 220726bDocument13 pagesMEA Clean Energy Report EN 220726bJibranNo ratings yet