Professional Documents

Culture Documents

Flange Calculation Sheet..

Uploaded by

nguyenquoc1988Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange Calculation Sheet..

Uploaded by

nguyenquoc1988Copyright:

Available Formats

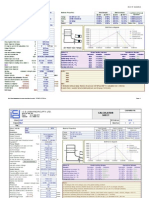

CNG TY C PHN DCH V C KH HNG HI - PTSC M&C - PHNG THIT K - T PIPELINE

PTSC MECHANICAL & CONSTRUCTION - ENGINEERING DEPARTMENT - PIPELINE TEAM

WELD NECK FLANGE RTJ 20"#1500 w.t. 17.5 mm: DESIGN IN ACCORDANCE WITH ASME VIII DIV.1 APP.2

Design: Worst Condition

Design pressure,P (MPa)

Design temperature (C)

Flange material

Corrosion allowance , c.a.(mm)

Bolt size (inch)

Bolt n

Bolt material

Bolt yield Sybolt (MPa)

Overlay thickness, w.o. (mm)

22.6726

70.00

ASTM A694 F65

1.00

3.00

16

ASTM A193 B7

655.00

0

GEOMETRY

Pipe OD (mm)

A (mm)

B (mm), including c.a.

R (mm)

C (mm)

t (mm)

D (mm)

G (mm)

g1 (mm)

hG (mm)

514.40

984.20

479.40

95.25

831.80

177.80

641.30

584.20

80.95

123.80

GasketRJ

w(mm)

b0=w/8=b(mm)

G(mm)

y(MPa)

m

31.75

3.96875

584.20

180

6.5

MOMENTCALCULATION

Operating

HD=.B.P/4(N)

4092480

HG=Wm1H(N)

2146887

HT=HHD(N)

1984861

Boltutilizationfactor=(Wm1/Ab)/Sy

Seating

HG=W(N)

9305451

Boltutilizationfactor=(W/Ab)/Sy

ALLOWABLE STRESSES (MPa)

Flange

Design temp Sfo

Atm . temp. Sfa

Bolting

151.43

151.43

Design temp Sb

Atm . temp. Sa

159

159

206200

Flange modulus of elasticity at design temp Eo (MPa)

206200

Flange modulus of elasticity at atm. temp Ea (MPa)

The following equation is used to determine the equivalent pressure due to the external

loads and hydrostatic pressure: P = 16.M/.G3+4.F/.G2+Pd

Design pressure,Pd (MPa)

Bending moment, M (N mm)

Axial Force, F (N)

h (mm)

139.35

go (mm)

17.50

Root bolt diameter (mm )

72.10

Number of bolts

16.00

g (mm)

673.10

r minimum (mm)

19.99

slope ()

24.48

E (mm)

76.20

L (mm)

17.50

16.00

225000000.00

248000.00

REQUIREDBOLTSAREA

Am=greaterof

51725

Wm2/SaorWm1/Sb(mm

Ab(mm2)

65325

W=(Am+Ab)Sa/2

9305451

Wm2=b..G.y(N)

Hp=2.b..G.m.P(N)

H=G..P/4(N)

Wm1=Hp+H(N)

1311106

2146887

6077340

8224227

hD=R+0.5*g1(mm)

hG=0.5*(CG)(mm)

hT=0.5*(R+g1+hG)(mm)

19.22%

135.725

123.8

150

MD=HD*hD(Nmm)

MG=HG*hG(Nmm)

MT=HT*hT(Nmm)

Mo(Nmm)

555451785

265784555

297729130

1118965470

hG=0.5*(CG)(mm)

21.75%

123.80

Mo'(Nmm)

1152014831

HUBANDSTRESSFORMULAFACTORS

K=A/B

T

Z

Y

U

Xg=g1/go

ho=SQR(B.go)

2.05

1.16

1.62

2.86

3.14

4.63

91.59

Xh=h/ho

F

V

f

e=F/ho

L=(t*e+1)/T+t3/d

d=(U/V).ho.go

1.52

0.571

0.028

1.0

0.006230

3.60

3157783.755

Special Flange Calculation Guide - Li Minh Th

1 of 2

CNG TY C PHN DCH V C KH HNG HI - PTSC M&C - PHNG THIT K - T PIPELINE

PTSC MECHANICAL & CONSTRUCTION - ENGINEERING DEPARTMENT - PIPELINE TEAM

STRESSCALCULATIONS

AllowableStress(MPa)

(1,5.Sfo)

227.145

(Sfo)

151.43

(Sfo)

151.43

(Sfo)

151.43

OPERATING

Formula

Longitudinalhub

SH=fMo/L.g1.B

Radialflange

SR=(1.33t.e+1)Mo/L.t.B

Tangentialflange

ST=Y.Mo/t.BZ.SR

greaterof.5(SH+SR)

or.5(SH+ST)

ActualStress(MPa)

AllowableStress(MPa)

(1,5.Sfa)

227.145

(Sfa)

151.43

(Sfa)

151.43

(Sfa)

151.43

98.89

50.70

128.81

113.8

SEATING

Formula

ActualStress(MPa)

Longitudinalhub

SH=fMo'/L.g1.B

101.81

Radialflange

SR=(1.33t.e+1)Mo'/L.t.B

52.20

Tangentialflange

ST=Y.Mo'/t.BZ.SR

132.61

greaterof.5(SH+SR)

or.5(SH+ST)

117.21

UTILIZATIONFACTOR

Formula

Longitudinalhub

SH=fMo/L.g1.B

Radialflange

SR=(1.33t.e+1)Mo/L.t.B

Tangentialflange

ST=Y.Mo/t.BZ.SR

greaterof.5(SH+SR)

or.5(SH+ST)

OPERATING

ActualStress(MPa)

UF

98.89

44%

50.70

33%

128.81

85%

113.8

75%

Formula

Longitudinalhub

SH=fMo'/L.g1.B

Radialflange

SR=(1.33t.e+1)Mo'/L.t.B

Tangentialflange

ST=Y.Mo'/t.BZ.SR

greaterof.5(SH+SR)

or.5(SH+ST)

SEATING

ActualStress(MPa)

UF

101.81

45%

52.20

34%

132.61

88%

117.21

77%

FLANGERIGIDITY

Formula

Rigidity

J=52.14VMo/L.Eo.go.KI.ho

KI=

OPERATING

RigidityJ

0.26

0.3

Criterion

<=1

Formula

Rigidity

J=52.14VMo'/L.Ea.go.KI.ho

Special Flange Calculation Guide - Li Minh Th

SEATING

RigidityJ

0.27

Criterion

<=1

2 of 2

You might also like

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Flange Analysis ASME Section VIII Div 1 Appendices 2 S 2004Document1 pageFlange Analysis ASME Section VIII Div 1 Appendices 2 S 2004Lava SatNo ratings yet

- Blind Flange Thickness CalculationDocument3 pagesBlind Flange Thickness CalculationKannapiran Krishnamoorthy75% (4)

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- Body Flange Bolt TorqueDocument1 pageBody Flange Bolt TorqueLcm Tnl100% (1)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Bolt TorqueDocument20 pagesBolt TorqueArjun Singh AroraNo ratings yet

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Flange CalculationDocument48 pagesFlange CalculationAndi SuntoroNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- ASME Code Calculations For Companion FlangesDocument9 pagesASME Code Calculations For Companion FlangesKamlesh DalavadiNo ratings yet

- TEST RING For AES HEDocument6 pagesTEST RING For AES HEAdrian StoicescuNo ratings yet

- Bolt torque calculation for sealing flangesDocument6 pagesBolt torque calculation for sealing flangessouren1975No ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Calculating bolt torque for sealing a 30Document4 pagesCalculating bolt torque for sealing a 30souren1975No ratings yet

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 pagesBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Bolt Torque As Per ASME PCC-1 - MDocument31 pagesBolt Torque As Per ASME PCC-1 - Mmechengg01100% (2)

- Material translations table provides standards equivalentsDocument12 pagesMaterial translations table provides standards equivalentsbalajiNo ratings yet

- Flange Leakage Check SheetDocument1 pageFlange Leakage Check SheetEhtisham AndrAbiNo ratings yet

- Bolt Torque Appendix-ODocument1 pageBolt Torque Appendix-OSachin5586100% (1)

- #REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionDocument31 pages#REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionSivi NallamothuNo ratings yet

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533No ratings yet

- Minimum Distance Between Two Circumferential PipeDocument7 pagesMinimum Distance Between Two Circumferential PipeAbdulrahmanNo ratings yet

- Bolt Stress and Torque Values for Standard FlangesDocument1 pageBolt Stress and Torque Values for Standard FlangesMaung SheinNo ratings yet

- 9-Flanges & Design of Non-Standard Flange PDFDocument35 pages9-Flanges & Design of Non-Standard Flange PDFUday Gokhale75% (4)

- Assembly Bolt Stress As Per Asme Pcc-1 2013Document12 pagesAssembly Bolt Stress As Per Asme Pcc-1 2013Anonymous RytT6uvX1No ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- Bolt Torque CalculatorDocument9 pagesBolt Torque Calculatoraauppal100% (3)

- Blind flange design calculationDocument4 pagesBlind flange design calculationmukesh100% (2)

- HotTap Tie-In Analysis Caesar IIDocument24 pagesHotTap Tie-In Analysis Caesar IIvarshneydushyantNo ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- BOLT TORQUE CALCULATION pcc1Document4 pagesBOLT TORQUE CALCULATION pcc1Abhay UpadhyayNo ratings yet

- FlangeCalc AS1210 v1.5Document28 pagesFlangeCalc AS1210 v1.5Ben100% (1)

- Line Calculation & Sizing (HYSYS) - PPT Professional Development Course-Bangladesh - 2015.10.05Document18 pagesLine Calculation & Sizing (HYSYS) - PPT Professional Development Course-Bangladesh - 2015.10.05AriefNo ratings yet

- ETABS 2016 beam design analysisDocument1 pageETABS 2016 beam design analysisSham TajasNo ratings yet

- Tube Mill Work Order Mill No.: 2: REV.: MohdDocument1 pageTube Mill Work Order Mill No.: 2: REV.: Mohdkrishnasharma_me5542No ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Product Range DN 32+: Standard or CustomizedDocument2 pagesProduct Range DN 32+: Standard or CustomizedViale ElvioNo ratings yet

- Branch Reinforcement Calculation DetailsDocument17 pagesBranch Reinforcement Calculation DetailsVikash Tiwari100% (3)

- AAP S6 High Pressure Fittings E2 SDocument23 pagesAAP S6 High Pressure Fittings E2 SJusthyTaquiri0% (1)

- Boq For RSP Ccas PipingDocument3 pagesBoq For RSP Ccas Pipingkoushikdey_2011No ratings yet

- ASME VIII-1 Calculations for Sample Pressure VesselDocument21 pagesASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- Webemja PDFDocument1 pageWebemja PDFpunitg_2No ratings yet

- PT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsDocument1 pagePT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsAndri Mutiar0% (1)

- Retiring Wall Thickness Calculation For PipeDocument4 pagesRetiring Wall Thickness Calculation For PipeFares JawadNo ratings yet

- Mechanical PropertiesDocument4 pagesMechanical PropertiesSh KittanehNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Sham TajasNo ratings yet

- Declaration of Performance for MTH AnchorsDocument3 pagesDeclaration of Performance for MTH AnchorsFerencz ZsoltNo ratings yet

- Orifice Plate CalculationDocument10 pagesOrifice Plate CalculationkswaghmareNo ratings yet

- Plate CalculationDocument7 pagesPlate CalculationminhthanhmosNo ratings yet

- Production Work Order for Spiral Steel PipeDocument1 pageProduction Work Order for Spiral Steel PipeAditya Dwi SaputraNo ratings yet

- Company Name: Job InformationDocument7 pagesCompany Name: Job InformationAlvin LeongNo ratings yet

- DIN 17100 TablasDocument2 pagesDIN 17100 Tablasanonimarium100% (3)

- 20 Reefer Container Ij ContainerDocument32 pages20 Reefer Container Ij ContainerElvisor Visor100% (1)

- ThicknessDocument2 pagesThicknessmohmecirdiNo ratings yet

- Company Name: Job InformationDocument6 pagesCompany Name: Job InformationAlvin LeongNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage TankDocument4 pagesSVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tanknguyenquoc1988100% (1)

- Diaphram Plunger Injection PumpDocument8 pagesDiaphram Plunger Injection PumpengrtahirNo ratings yet

- Diesel Sigma S 10w API CDSFDocument1 pageDiesel Sigma S 10w API CDSFnguyenquoc1988No ratings yet

- MAXROY Series A, B & D DatasheetDocument4 pagesMAXROY Series A, B & D Datasheetnguyenquoc1988No ratings yet

- Appendix 5 - TC - Process 1Document2 pagesAppendix 5 - TC - Process 1nguyenquoc1988No ratings yet

- Vendor Data Review Responsibility Matrix (09jan12)Document9 pagesVendor Data Review Responsibility Matrix (09jan12)nguyenquoc1988No ratings yet

- STV SW Project Level Gauge DatasheetDocument4 pagesSTV SW Project Level Gauge Datasheetnguyenquoc1988No ratings yet

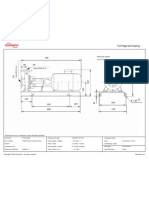

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- Piping System Safety ChecklistDocument1 pagePiping System Safety Checklistnguyenquoc1988No ratings yet

- Centrifugal PumpDocument2 pagesCentrifugal Pumpnguyenquoc1988No ratings yet

- g06 013 Heavy Maintenance Components List ADocument2 pagesg06 013 Heavy Maintenance Components List Anguyenquoc1988No ratings yet

- Mechanical Packages - Project ComparisonDocument10 pagesMechanical Packages - Project Comparisonnguyenquoc1988No ratings yet

- How To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be CloudDocument2 pagesHow To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be Cloudnguyenquoc1988No ratings yet

- Polyurethane Insulation Coating Specification for STV South West Project PipelinesDocument42 pagesPolyurethane Insulation Coating Specification for STV South West Project Pipelinesnguyenquoc1988100% (1)

- List of HVAC SpecificationsDocument46 pagesList of HVAC Specificationsnguyenquoc1988100% (1)

- HST A TS M DS 0031 - Rev F01 Datasheet For MTG Housing LouversDocument1 pageHST A TS M DS 0031 - Rev F01 Datasheet For MTG Housing Louversnguyenquoc1988No ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- PumpDocument1 pagePumpnguyenquoc1988No ratings yet

- PumpDocument10 pagesPumpnguyenquoc1988No ratings yet

- HST A TS M TR 0020 - Rev F01 TR For Microturbine Generator HousingDocument24 pagesHST A TS M TR 0020 - Rev F01 TR For Microturbine Generator Housingnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- Mechanical COG of EquipmentDocument1 pageMechanical COG of Equipmentnguyenquoc1988No ratings yet

- Seismic LoadDocument37 pagesSeismic Loadnguyenquoc1988No ratings yet

- 1.1 General Background: Seminar Report 2021Document20 pages1.1 General Background: Seminar Report 2021Classic PrintersNo ratings yet

- 491-80044934 A4-P 1.0 enDocument49 pages491-80044934 A4-P 1.0 enAtiq Ur RehmanNo ratings yet

- Enviro Processtanks® & Manholes®: Request Catalogue (/index - Php/Technical-Support-And-Catalogues)Document1 pageEnviro Processtanks® & Manholes®: Request Catalogue (/index - Php/Technical-Support-And-Catalogues)ssdprojects RexNo ratings yet

- Jurnal ItayoDocument5 pagesJurnal ItayoFlorence Brenda PoppyNo ratings yet

- Concrete Kerb Specification SheetDocument1 pageConcrete Kerb Specification Sheetyamanta_rajNo ratings yet

- SG653PB1 ADocument5 pagesSG653PB1 ADANILO MEDINA OSORIONo ratings yet

- Tricocat PDFDocument44 pagesTricocat PDFJuan PabloNo ratings yet

- Experiment # 6 Bernoulli's Theorem Demonstration Apparatus: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsDocument11 pagesExperiment # 6 Bernoulli's Theorem Demonstration Apparatus: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsAbdullah AlshihriNo ratings yet

- Wattle and DaubDocument6 pagesWattle and DaubdolphinNo ratings yet

- Technozen Quiz MaterialDocument35 pagesTechnozen Quiz MaterialKarthi100% (1)

- Bus Air Conditioner InstallationDocument26 pagesBus Air Conditioner InstallationMaría AlvarezNo ratings yet

- Aropol LP 67400Document2 pagesAropol LP 67400Ahmed ZamanNo ratings yet

- ADM Specs GRP Enclosures and KiosksDocument3 pagesADM Specs GRP Enclosures and KiosksMahiBoumNo ratings yet

- E21-G02 - 1 Identification of Circuit Conductor & Phase RelationDocument6 pagesE21-G02 - 1 Identification of Circuit Conductor & Phase RelationMuhammad IrfanNo ratings yet

- Project ReportDocument599 pagesProject ReportFarzad DehghanNo ratings yet

- MTC DetailsDocument2 pagesMTC DetailsHarisul IslamNo ratings yet

- Dedicated Outdoor Air SystemsDocument5 pagesDedicated Outdoor Air SystemseduardofemecNo ratings yet

- A Study of Manufacturing and Experimental Behaviour of Cellular Lightweight Concrete (CLC) BricksDocument8 pagesA Study of Manufacturing and Experimental Behaviour of Cellular Lightweight Concrete (CLC) BricksSankara RaoNo ratings yet

- AE342 LectureNotes W1Document11 pagesAE342 LectureNotes W1Mert YılmazNo ratings yet

- Mechanical Supervisor ResumeDocument4 pagesMechanical Supervisor ResumeAnwar Rahman100% (4)

- HOT DIPPED GALVANIZED Z PURLINS SUBMITTALDocument4 pagesHOT DIPPED GALVANIZED Z PURLINS SUBMITTALMariam MousaNo ratings yet

- Dokumen - Tips - Pompe de Caldura BuclaDocument96 pagesDokumen - Tips - Pompe de Caldura BuclaAnonymous oKTCFZNTmNo ratings yet

- Girder TrussDocument0 pagesGirder Truss74747474No ratings yet

- CONCASTDocument44 pagesCONCASTParthaNo ratings yet

- Heat and Thermodynamics: This Chapter CoversDocument10 pagesHeat and Thermodynamics: This Chapter CoversLaxankNo ratings yet

- Thomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıDocument375 pagesThomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıÖzlem Temel YalçınNo ratings yet

- BOQ For Bought Out Items (Condensate & Flash) PDFDocument1 pageBOQ For Bought Out Items (Condensate & Flash) PDFsppatilNo ratings yet

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDocument5 pagesGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VNo ratings yet

- RAM Foundation User ManualDocument122 pagesRAM Foundation User ManualJohn DoeNo ratings yet

- Acoustic Plaster and Spray BrochureDocument12 pagesAcoustic Plaster and Spray BrochureStil_AcousticsNo ratings yet