Professional Documents

Culture Documents

Beun Et Al 2002 - Aerobic Granulation PDF

Uploaded by

Constanza ArriagadaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beun Et Al 2002 - Aerobic Granulation PDF

Uploaded by

Constanza ArriagadaCopyright:

Available Formats

Water Research 36 (2002) 702712

Aerobic granulation in a sequencing batch airlift reactor

J.J. Beun, M.C.M. van Loosdrecht*, J.J. Heijnen

Kluyverlaboratory for Biotechnology, Delft University of Technology, Julianalaan 67, 2628 BC Delft, The Netherlands Received 27 July 2000; received in revised form 15 March 2001; accepted 23 April 2001

Abstract Aerobic granular sludge was cultivated in an intensely mixed sequencing batch airlift reactor (SBAR). A COD loading of 2.5 kg Acetate-COD/(m3 d) was applied. Granules developed in the reactor within one week after inoculation with suspended activated sludge from a conventional wastewater treatment plant. Selection of the dense granules from the biomass mixture occurs because of the dierences in settling velocities between granules (fast settling biomass), and laments and ocs (slow settling biomass). At steady state the granules had an average diameter of 2.5 mm, a biomass density of 60 g VSS/l of granules, and a settling rate of >10 m/h. The biomass consisted of both heterotrophic and nitrifying bacteria. The reactor was operated over a long period during which the granular sludge proved to remain stable. The performance of the intermittently fed SBAR was compared to that of the continuously fed biolm airlift suspension reactor (BASR). The most importance dierence was that the density of the granules in the SBAR was much higher than the density of the biolms in the BASR. It is discussed that this could be due to the fact that the SBAR is intermittently fed, while the BASR is continuously fed. r 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Aerobic granules; Sequencing batch reactor; Airlift reactor; Biolms

1. Introduction Most wastewater treatment systems have some disadvantages such as a high surplus biomass production, low exibility with respect to uctuating loading rates, a large area requirement for reactors and clariers and a relatively low volumetric conversion capacity (0.52 kg COD/(m3 d) for activated sludge or conventional biolm systems). For anaerobic processes much more ecient reactors have been developed (40 kg COD/ (m3 d) for an UASB (upow anaerobic sludge blanket) reactor [1]). In these reactors the biomass grows as well settling granules, which allows the accumulation of high amounts of active biomass in the reactor. Moreover clariers are not needed because sludge separation is integrated in the UASB reactor itself.

*Corresponding author. Tel.: +31-15-2781618; fax: + 31-152782355. E-mail address: mark.vanloosdrecht@tnw.tudelft.nl (M.C.M. van Loosdrecht).

Despite the widespread use of UASB processes, the mechanism of biomass granulation is still subject of discussion. Our basic assumption is that, because of substrate diusion limitations, bacteria prefer growing in suspension over growing in a oc, which has again preference over growth in a biolm or granule. Growing in suspension is the most favorable form because in a oc, and even more in a biolm or granule, the bacteria experience diusion limitations for all kind of components involved. Growing as a oc, a biolm, or a granule only occurs when the bacteria are otherwise washed out [2]. We consider granular growth as a special case of biolm growth. Granulation in low turbulent systems by acidifying bacteria, nitrifying bacteria [3] and denitrifying bacteria [4] has been observed. Granulation by aerobic heterotrophs has been observed in high turbulent systems [2,5]. It has been hypothesized that the structure of biolms is the net result of biomass growth and detachment processes [6]. Growth of the biomass is mainly inuenced by the substrate loading rate and the growth yield. Detachment in these highly turbulent

0043-1354/02/$ - see front matter r 2002 Elsevier Science Ltd. All rights reserved. PII: S 0 0 4 3 - 1 3 5 4 ( 0 1 ) 0 0 2 5 0 - 0

J.J. Beun et al. / Water Research 36 (2002) 702712

703

Nomenclature a BASR COD d HRT IA MWX n reactor surface specic area of granules (m2 granule surface area/m3 reactor) biolm airlift suspension reactor chemical oxygen demand average granule diameter (mm) hydraulic retention time image analysis molecular weight of biomass=25 g/Cmol total number of granules in the reactor ()

SBAR SRT Vr Vx VSS X

sequencing batch airlift reactor sludge retention time working volume reactor (l) total volume of granules in the reactor (l) volatile suspended solids biomass

Greek symbols d penetration depth (mm) r biomass density (g VSS/l granules)

systems is mainly inuenced by shear forces [6]. It has been shown experimentally that a good balance between substrate loading and shear can result in smooth and strong biolms [7,8]. Slow growing bacteria with a low growth yield are more easily forced to grow as granules than fast growing aerobic heterotrophic bacteria. All these results were obtained in continuous fed systems. For many applications a discontinuous operated system is advantageous. Aerobic granular sludge can be cultured in a well mixed, aerated sequencing batch reactor (SBR) [911]. In these cases granular sludge with an SVIo50 ml/g were obtained. Dangcong et al. [12] also report the occurence of granular sludge in their system, although the SVI indicated in their paper of 100 ml/g seems to point to occulated sludge. In a SBR, wastewater is treated aerobically in successive cycles of a few hours. At the end of every cycle, settling of the biomass takes place before the euent is withdrawn, to keep the biomass in the reactor. Fast settling granular sludge greatly benets the SBR operation. Selection of the granules from a biomass mixture in a SBR can be easily based on the dierence in settling velocity between the granules (fast settling biomass) and the laments and ocs (slow settling biomass). The settling time is here chosen such that only particles with a settling velocity larger than 10 m/h are eectively retained in the reactor. The rest of the biomass does not settle fast enough and will be taken out with the euent. The aim of this research was to further develop a SBR process with granular sludge growth. The results are compared with biolm growth in airlift reactors.

diameter of 4 cm, and was positioned at a distance of 1.25 cm from the bottom of the down-comer. The reactor was operated as a sequencing batch reactor and was therefore called a Sequencing Batch Airlift Reactor (SBAR). The HRT was 5.6 hours and the substrate load was 2.5 kg COD/(m3 d). Air was introduced by a ne bubble aerator at the bottom of the reactor at a supercial air velocity of 80 m/h (4.4 Nl/ min). The air-ow rate was controlled by a mass-ow controller (mfc). The temperature of the reactor was maintained at 201C using a water jacket and a thermostat bath, the pH was maintained at 7.070.2 using 1 M NaOH and 1 M HCl. The reactor was well mixed and highly turbulent with a liquid circulation time of about 6 s. The reactor was operated in successive cycles of 3 h each. One cycle consisted of 2 min inuent addition, 170 min aeration, 3 min settling, and 5 min euent withdrawal. Euent was withdrawn at 50 cm from the bottom of the reactor. The settling time was chosen such that only particles with a settling velocity larger than 10 m/h were eectively retained in the reactor. Activated sludge from a conventional nutrient (N and P) removing wastewater treatment plant was used as inoculum. Dissolved oxygen (DO), pH and o-gas CO2 were monitored continuously. Dry weight of the reactor

2. Materials and methods 2.1. Reactor set-up and operation The airlift reactor had a working volume of 3.0 l (Fig. 1). The internal diameter of the down-comer was 6.25 cm. The riser was 90 cm in height, had an internal

Fig. 1. Schematic representation of the SBAR.

704

J.J. Beun et al. / Water Research 36 (2002) 702712

content (dw), ash content of the biomass, total organic carbon (TOC) in the euent, biomass bedvolume and biomass density (r) were measured almost daily. The morphology of the granules was measured regularly using Image Analysis (IA). Acetate, NH+ 4 , NO2 , and NO3 were measured occasionally during one cycle to determine the cyclic proles of these compounds. The reactor was operated over 140 days. At day 42 a few milligrams of nitrifying sludge was added to the reactor to accelerate the accumulation of nitriers in the reactor. Nitrication and denitrication processes were studied during operation of the reactor. These results will be discussed in a future paper. In order to evaluate optimization of the denitrication process in the reactor, from day 66 to day 71 the DO in the reactor was decreased to a constant level of 50% air saturation by mixing the air ow into the reactor with N2 gas. The total gas ow rate in the reactor was kept constant at 80 m/h. On all the other days the DO of the reactor was not regulated. 2.2. Media The composition of the concentrated media were as follows; Medium A: NaAc 97.7 mM, MgSO4 7H2O 3.7 mM. Medium B: K2HPO4 20 mM, KH2PO4 10 mM, KCl 4.8 mM, NH4Cl 30 mM, trace element solution according to Vishniac and Santer 10 ml/l [13]. In each cycle 150 ml of medium A, 150 ml of medium B and 1300 ml tap water were added to the reactor. This resulted in an inuent acetate concentration of 18.3 Cmmol/l, corresponding with a COD loading rate of 2.5 kg COD/(m3 d). The inuent NH+ 4 -N concentration was 2.8 mmol/l, or 39.4 mg NH+ 4 -N/l. 2.3. Analytical procedures The DO concentration in the reactor was measured online with a DO-electrode as a percentage of air saturation. The CO2 content of the o-gas was measured online with an infrared CO2 analyzer. The dry weight was determined by drying a sample for at least 24 h at 1051C. Ash content was determined according to Dutch standard method NEN6621 [14]. The biomass concentration of the euent was obtained by measuring the total TOC concentration of the euent and the TOC concentration of a ltered (0.45 mm lters) euent sample, and subtracting these two TOC values. The bedvolume of the settled biomass granules in the reactor was determined by reading the height of the biomass bed directly from a scale on the reactor column at the end of the settling period. The elemental composition (CHNS) of the biomass was determined by ash combustion in a partial oxygen atmosphere at 10201C using a Carlo Erba EA1108 elemental analyzer. The oxygen content of the biomass was obtained by subtracting the percentages of

C, H, N, S and ash from 100%. The biomass density (r in g biomass 1 of granules) was determined with dextran blue [15,16] according to the method described in Appendix A. The acetate concentration of ltered samples from the reactor was measured by gas chromatography, and the NH+ 4 , NO3 , and NO2 concentrations of ltered samples were measured spectrophotometrically at 630 nm with an auto analyzer (Skalar 5010). Changes in morphology of the granules were followed by image analysis (IA) [17]. From a representative sample of granules the following parameters were measured:

*

d =average diameter measured as surface and volume based average; shape factor=capriciousness of the particle surface (0=line, 1=circle); aspect ratio=roundness of the particle (0=line, 1=circle).

For, each measurement, 500 granules were analyzed. Particle size distribution curves were made using the measured diameters. Photographs of the granules were taken to follow and show the progress of granulation. 2.4. Calculation procedures The sludge retention time (SRT) of the granular sludge was calculated from the biomass concentration in the reactor (dry weight) and the biomass concentration in the euent (there was no separate no excess sludge removal). The elemental biomass composition was taken as CH1.8O0.5N0.2. The total volume of granules present in the reactor Vx was calculated as follows: Vx Vr dw l r 1

with Vr as the working volume of the reactor (l), dw the dry weight of the reactor content (g VSS/l), and r as the biomass density (g VSS/l of granules). The total number of granules (n) present in the reactor was calculated as follows: Vx n4 1 2 3 p d 3 2 10 2

in which d is the surface average diameter of the granules (mm). The reactor specic surface area of the granules (a) was calculated as follows: a

3 2 4p1 2 d 10 n Vr 10 3

m2 =m3 :

J.J. Beun et al. / Water Research 36 (2002) 702712

705

The penetration depths of oxygen and of acetate were calculated according to s 6CL D ; d film qmax Cx 4

3.2. Observation of granulation during the start-up period (day 17) The observations during the start-up period (7 days) of the SBAR are given in Table 1. On day 1 the reactor was inoculated with 1 l of activated sludge (totally 9 gSS) from the return sludge ow of a conventional nutrient removal wastewater treatment plant (see Fig. 7). A settling period of 5 min was applied during the rst 6 days after inoculation to prevent wash out of all the biomass. On day 7 the settling period was decreased to 4 min, and on day 12 to its nal length of 3 min for the next 140 days. In the second cycle after inoculation of the reactor a clear feast period was already observed. On day 1 the feast period was about 100 min, and this decreased to about 60 min on day 3. From day 3 to day 4 the feast period increased again due to wash out of a large amount of the biomass. The wall of the reactor became completely covered with attached biomass in these rst 4 days. On day 6 the biomass grown on the wall of the reactor was removed from the reactor. In the liquid some very small granules were already visible (see also Fig. 7). These small granules quickly increased in diameter. As soon as this granulation process started, biomass growth on the wall diminished. The walls of the reactor needed to be cleaned every two months only, during the remainder of the operation period of 140 days. Within 7 days after inoculation granules were clearly observed in the reactor. The biomass concentration in the reactor started to increase and consequently the length of the feast period decreased again. Biomass granules, laments and ocs were present as a mixture in the reactor. Selection of the biomass granules from the mixture occurred during the settling period (Fig. 3). The settling time was chosen such that only particles with a settling velocity larger than 10 m/h were eectively retained in the reactor. The rapid transition from occulated to granular sludge shows that the chosen strategy was successful.

in which d is the penetration depth (m), CL is the concentration of oxygen or acetate in the liquid (mol/ m3), D is the diusion coecient (=7.2 106 m2/h), qmax is the maximal conversion rate of oxygen or acetate film ((C)mol/(Cmol h)), and CX is the biomass concentration in the biolm (=r=MwX (Cmol/m3)) [2].

3. Results 3.1. General observations The reactor was operated in successive cycles of 3 h each. In general, all acetate was consumed within a few minutes. When acetate was depleted, endogenous respiration occurred. The period when acetate was present is referred to as feast period. The remainder of the cycle is named famine period. The transition from feast to famine period was directly observed from a sharp increase in the dissolved oxygen (DO) concentration in the reactor. During the feast period the DO in the reactor was low (75% air saturation) due to oxygen consumption for acetate uptake and conversion. When all acetate was consumed, the DO immediately increased to almost 100% air saturation. Typical concentration proles during a cycle when the reactor was operating under stable conditions are shown in Fig. 2. Nitrication and denitrication occurred in the SBAR. This will be discussed in a future paper [18]. In general the conversions observed in this granular sludge reactor compare well to previous observations in a conventional activated sludge laboratory SBR [19,20].

Fig. 2. Typical concentration proles during a steady state cycle of the SBAR (day 64). (a): () acetate; (E) ammonium; (m) NOx. (b): (bold line) DO; (normal line) CO2 production rate.

706

J.J. Beun et al. / Water Research 36 (2002) 702712

Table 1 Observations during start-up of the SBAR Day number 1 Action Inoculation with fresh activated sludge Settling period 5 min Settling period 5 min Settling period 5 min Settling period 5 min Settling period 5 min Removal of wall growth from the reactor Settling period 5 min Observation After 1 cycle operation, feast period is visible in the DO pattern (100 min)

2 3 4 5 6

Feast period decreases (60 min) Biomass is being washed out, feast period increases (100 min) Signicant biomass growth on the wall

Settling period 4 min

In liquid very small granules present Feast period increases due to very low biomass concentration after biomass removal from wall Granules become bigger, feast period decreases (70 min)

Fig. 3. Selection of well settling, dense granules in the SBAR.

3.3. Development of the granules from day 6 onwards The development of the granules in the reactor was followed by sampling and image analysis for about 140 days. The biomass concentration in the reactor increased to about 10 g VSS/l at day 65 (Fig. 4). Thereafter the biomass concentration decreased to about 7 g VSS/l around day 80. This decrease was likely caused by the fact that biomass granules partly broke up due to the decreased DO (50%) which was applied between day 66 and 71. The smaller biomass particles subsequently washed out. The biomass concentration in the euent uctuated around 250 mg VSS/l until day 40. Hereafter the euent biomass concentration decreased to about 75 mg VSS/l during the rest of the time (Fig. 4). This low biomass production was associated to a low sludge loading and consequently high sludge age of 50 days (Fig. 5). The surface average diameter of the granules increased to about 2.7 mm at day 30 and had a steady state value of 2.5 mm during the remainder of the experiment (Fig. 6). The aspect ratio and shape factor of the granules increased in the rst 10 days, and were both

stable for the rest of the time at a value of 0.70.8 (Fig. 6). This indicates that the granules were more or less spherical particles with a smooth surface. The density of the granules increased to 70 g VSS/l at day 80 (Fig. 6). Inoculation of the reactor with nitrifying biomass at day 42 did not notably inuence the density of the granules. After day 80 the density decreased to 40 g VSS/l within 7 days. This was associated to the deterioration of biomass granules due to the decreased DO applied from day 66 to day 71. After increasing the DO the density increased again to 60 g VSS/l at day 142. Photographs show the inoculum and the sludge on dierent days (Fig. 7). The inoculum consisted of suspended sludge and sludge ocs only. Small granules were already present after 6 days of operation. On day 37 the granules had a more or less steady state average diameter of about 2.5 mm (see also Fig. 6). Thereafter no signicant change of the granules occurred. The photograph of day 63 only shows some more laments on the surface of the granules. These disappeared again after a few days (Fig. 7). The inner structure of the granules was observed in more detail under the light microscope by cutting the granules in two with a razor blade. In general

J.J. Beun et al. / Water Research 36 (2002) 702712

707

Fig. 4. Total number of granules in the SBAR (K), biomass concentration in the SBAR (E) and in the euent of the SBAR (m) from day 6 until day 142.

Fig. 5. Sludge retention time (SRT) of the SBAR () and reactor specic surface area of the granules (m) from day 6 until day 142.

two layers could be observed in the granule: (1) the center of the granule, which was about 1.7 min in diameter, and (2) the outer layer with a thickness of about 0.4 mm. The outer layer had a rather dense structure. The center of the granule had a more uy and gelly structure and was more transparent compared to the outer layer of the granule. No big empty holes resulting from complete lysis of the interior biomass were observed in the center of the granule. The penetration depths were calculated according to Eq. (4) to be between 17 mm (in the feast period) and 20 mm (in the famine period) for oxygen, and between

115 mm (completely aerobic conversion) and 520 mm (completely anoxic conversion) for acetate. This corresponds with the thickness of 400 mm of the denser outer layer of the granules. Due to the penetration depth of acetate biomass growth mainly occurred in this outer layer. 3.4. Particle size distribution Particle size distribution in the SBAR was followed using image analysis. In Fig. 8 the distributions on day 6 and day 63 are shown. Day 6 is the rst day after

708

J.J. Beun et al. / Water Research 36 (2002) 702712

Fig. 6. Development of the average diameter of the granules in the SBAR (K), the aspect ratio (E), the shape factor (*), and the density r of the granules () from day 6 until day 142.

Fig. 7. Photographs of the sludge in the SBAR on dierent days after inoculation (bar=1 mm).

inoculation of the reactor that granules were visible (Table 1 and Fig. 7). Most of the granules were smaller than 0.5 mm in diameter on this day (Fig. 8). The particle size distribution curve of day 63 is representative for the steady state situation of the SBAR. It is a normal distribution curve with some more small granules of about 0.5 mm. The median value of the granule diameter was around 3 mm, the average granule diameter was around 2.5 mm. The particle size distribution curves on many dierent days showed that the system is able to recover very fast after disturbances. On day 15, an unexpected, momentary increase of the pH to 9 caused

disruption of particles. The distribution curve of this day showed that there were mainly small granules of around 0.5 mm present. On day 16 the distribution curve was already similar to the one on day 14. 4. Discussion 4.1. The SBAR It was demonstrated that aerobic granular sludge could be cultivated on dened medium, and kept in stable operation in the SBAR for months.

J.J. Beun et al. / Water Research 36 (2002) 702712

709

Fig. 8. Particle size distribution in the SBAR at day 6 (start of granulation) and day 63 (steady state).

The SBAR was easily started-up with suspended activated sludge from a normal wastewater treatment plant. Granules developed in the reactor within 1 week after inoculation. It is not fully clear how these granules in the very beginning were formed. One possibility is that they originate from the biolm grown on the wall of the reactor, although during cleaning that biolm was removed completely from the reactor. Due to the high liquid circulation velocity small pieces could be broken from the biolm. These pieces could be starting material for formation of granules. Another possibility is some fast settling ocs/material from the inoculum. We did not observe the typical fungal intermediate phase as observed previously [11]. In that case there was no inoculum used at all. Subsequent development of new granules could occur out of broken pieces from these initial granules [5]. Selection of the granules from the biomass mixture in the reactor occurred by utilizing the dierence in settling velocity between the granules (fast settling biomass) and the laments and ocs (slow settling biomass). The settling time was chosen such that only particles with a settling velocity larger than 10 m/h were eectively retained in the reactor. Slow settling biomass was taken out with the euent, the euent port was just above the settled sludge layer. All biomass above this point, after 3 min settling, was removed from the system. After 1 month of operation a pseudo steady state granule diameter was reached. The granules had a stable diameter of 2.5 mm for the remainder of the operation period. The biomass concentration in the reactor still increased after 1 month of operation. The density of the granules and/or the number of granules in the reactor increased with increasing biomass content. The granules in the reactor had a smooth surface, and reached a high density of about 60 g VSS/l of granules. The granules were able to deal with disturbances (e.g. momentary increase of pH) and uctuations (decreased DO).

After disturbances, the granules usually partly broke up, and subsequently recovered very fast. 4.2. The SBAR compared with the biolm airlift suspension reactor The formation of aerobic biomass granules has been reported previously in a continuously fed turbulent system, the biolm airlift suspension reactor (BASR) [5,17]. In the BASR granules developed from biolm fragments that originated from broken up biolm particles. In principle granules are biolms without a carrier. Evaluating the dierence in granule formation in both reactors (Table 2) makes it possible to discuss the mechanisms involved. In the BASR data were gathered for heterotrophic biolms, autotrophic biolms, and a combination of heterotrophic and autotrophic biolms. Until now, the SBAR was operated mainly as a COD removal reactor. In later stages of the experiment both heterotrophic and autotrophic biomass were present in the SBAR. Optimization for N-removal and further enrichment of autotrophic biomass was not carried out yet. Comparing the granules and biolms formed in the SBAR and the BASR, the most striking dierence is the density of the biomass in the biolm that is much higher in the SBAR than in the BASR. The reason for this large dierence is probably the way the reactors are fed i.e. continuously for the BASR and intermittently for the SBAR. Almost all other operational factors (such as volume loading rate and DO) were similar. When there is substrate present in the SBAR (i.e. the feast period), the granules get penetrated with acetate over a depth of 500 mm because the acetate concentration in the liquid is high due to pulse feeding. In the continuously fed BASR, the acetate concentration in the liquid is always very low (o0.1 Cmmol/l). Acetate can therefore not penetrate completely into the biolm (o20 mm), and the cells deeper in the biolm will be deprived of acetate. In the SBAR the cells in the

710

J.J. Beun et al. / Water Research 36 (2002) 702712

Table 2 Comparison of the SBAR with the BASR SBAR (Heterotrophic and autotrophic biomass) Acetate load (kg COD/(m3 d)) Supercial gas ow rate (m/h) HRT (h) Average specic biomass Formation rate (d1) Dry weight (g VSS/l) d (mm) r (g VSS/l granules) n a (m2/m3)

a

BASR (Heterotrophic and autotrophic biomass) [16] 1 80 0.67 0.054 7.3 1.41 (dc 0:26)a 20 1.8 105 390

BASR (Heterotrophic biomass) [16] 4.6 80 0.67 0.020.16 1.2 0.56 (dc 0:26)a 20 1.4 106 470

BASR (Autotrophic biomass) [5] F 80 1 0.0015 25 0.75 (dc 0:26)a 60 4 106 2300

2.5 80 5.6 0.0008 8 2.5 60 5 104 375

dc diameter carrier.

center of the granules can therefore take up acetate and grow (using either oxygen or nitrate as electron acceptor). Growth of the cells in the center of the granules leads to an increasing biomass density of the granules. Modeling studies [21] also showed that more substrate limited biolms (i.e. in continuously fed systems like the BASR) develop a surface with lamentous structures with a high porosity and a low density. For conversion of acetate, an electron acceptor (O2 or NO 3 ) is needed. In both the SBAR as the BASR O2 will not penetrate completely into the biolm. For the BASR the O2 penetration depth is around 80 mm, i.e. larger then the acetate penetration depth. The O2 penetration depth in the SBAR is in the feast period around 20 mm, i.e. smaller then the acetate penetration depth. At decreased DO as applied for 1 week in the SBAR, O2 penetration will be even less. The cells below this penetration depth can use NO 3 as electron acceptor. When this is not available, lysis of the cells in the center of the biolm will occur. The biolm will get a less dense structure and nally break up into pieces. This was observed when applying a DO of 50% in the reactor between day 66 and day 71. The density of the biolms can also be inuenced by the specic growth rate of the biomass. A lower specic growth rate leads to more dense biolms [22]. The average specic growth rate of the biomass in the SBAR was much lower than in the BASR (higher penetration depth of substrate, i.e. lower eective sludge loading). This might also have contributed in a higher density in the SBAR. For the biolm structure the inuence of shear forces has to be taken into account as well. The balance between biomass growth and shear determines the nal structure of the granules [6]. The dierence in shear forces between the SBAR and BASR is not clear. The

supercial gas ow rate in both reactors was similar. The BASR contains basalt as a carrier material. It has been demonstrated that for non-growing biolms in an airlift reactor the detachment forces increased with increasing bare carrier concentration [23,22] showed that in growing systems the detachment rate is higher when more bare carriers are present. These observations can easily be understood, since a higher concentration of particles leads to a higher collision frequency and thus higher detachment forces. Considering the total number of particles in the reactor (Table 2) the detachment should in principle be highest in the BASR, since the total number of particles was a factor 10 higher than in the SBAR. Summarizing it can be said that the specic biomass growth rate in the SBAR was lower than in the BASR, leading to a denser biolm. The detachment forces in the SBAR were probably lower than in the BASR, leading to a less dense biolm. The balance between these two factors is obviously more favorable in the SBAR than in the BASR, since the density of the biomass in the SBAR was much higher than in the BASR.

5. Conclusions In a sequencing batch airlift reactor, aerobic granular sludge could easily be cultivated, and maintained under stable operation for months. Granules developed in the reactor within 1 week after inoculation with suspended activated sludge. The dierence in settling velocity between the granules (fast settling biomass) and the laments and ocs (slow settling biomass) is seen as the dominant factor to obtain granular sludge. The density of the granules in the SBAR was much higher than the density of comparable biolms in the BASR. This dierence is probably due to the fact that

J.J. Beun et al. / Water Research 36 (2002) 702712

711

the SBAR is intermittently operated, while the BASR is continuously fed with substrate. Feeding substrate as a pulse results in penetration of acetate over a depth of 500 mm into the granules. In the BASR acetate penetration is less than 20 mm. Acetate will not reach the cells deeper and no growth will occur there. For practical application, the SBAR should have a high H/D ratio (column height/column diameter) to improve selection of granules by the dierence in settling velocity. The additional advantage is that a high H/D ratio and the absence of an external settler result in a reactor with a small footprint. The good settling characteristics of the biomass allow, in a SBR process, a short standstill time for settling, allowing a more ecient use of reactor volume.

[4]

[5]

[6]

[7]

Appendix A A.1. Granules density determination by dextran blue A known amount of a dextran blue solution (1 g/l) is added to a representative sample (and known amount) of the reactor, in a volume ratio of about 1 : 1. The mixture is gently mixed, and subsequently the granules are allowed to settle. A known amount of the liquid above the settled granules is removed and a sample is taken from it (fraction 1). A known amount of demineralized water is added to the granules. The mixture is mixed gently. The granules are allowed to settle. A known amount of the liquid above the settled granules is removed and a sample is taken from it (fraction 2). This last step is repeated until four fractions are obtained. The four fractions and the original dextran blue solution are analyzed by a spectrophotometer at 620 nm. Subsequently, the volume of the biomass in the reactor sample could be calculated, since dextran blue only binds to the water and not to the biomass. Measuring also the dry weight of the reactor sample allows calculation of the density of the granules (g biomass/1 of granules).

[8]

[9]

[10]

[11]

[12]

[13] [14] [15]

[16]

[17]

References

[1] Lettinga G, Hulsho Pol LW, Zeeman G. Biological wastewater treatment anaerobic treatment (in Dutch). Department of Environmental Technology, Wageningen Agricultural University. Wageningen, The Netherlands, 1993. [2] Tijhuis L, Van Loosdrecht MCM, Heijnen JJ. Formation and growth of heterotrophic aerobic biolms on small suspended particles in airlift reactors. Biotechnology & Bioengineering 1994;44:595608. [3] De Beer D, Heuvel JC, Van den Ottengraf SPP. Microelectrode measurements of the activity distribution in [18]

[19]

[20]

nitrifying bacterial aggregates. Applied and Environmental Microbiology 1993;59(2):5739. Van der Hoek JP. Granulation of denitrifying sludge. In: Lettinga G, Zehnder AJB, Grotenhuis JTC, Hulsho Pol LW, editors. Granular Aerobic Sludge. Pudoc: Wageningen, The Netherlands, 1988. p. 20310. Van Benthum WAJ, Garrido-Fernandez JM, Tijhuis L, Van Loosdrecht MCM, Heijnen JJ. Formation and detachment of biolms and granules in a nitrifying biolm airlift suspension reactor. Biotechnology Progress 1996;12(6):76472. Van Loosdrecht MCM, Eikelboom D, Gjaltema A, Mulder A, Tijhuis L, Heijnen JJ. Biolm structures. Water Science Technology 1995;32:3543. Tijhuis L, Hijman B, Van Loosdrecht MCM, Heijnen JJ. Inuence of detachment, substrate loading and reactor scale on the formation of biolms in airlift reactors. Applied Microbiology and Biotechnology 1995;45:717. Kwok WK, Picioreanu C, Ong SL, Van Loosdrecht MCM, Ng WJ, Heijnen JJ. Inuence of biomass production and detachment forces on biolm structures in a biolm airlift suspension reactor. Biotechnology & Bioengineering 1998;58(4):4007. Morgenroth E, Sherden T, Van Loosdrecht MCM, Heijnen JJ. Aerobic granular sludge in a sequencing batch reactor. Water Research 1997;31(12):31914. Heijnen JJ, Van Loosdrecht MCM. Werkwijze voor het verkrijgen van korrelvormige groei van een micro-organisme in een reactor. European patent 1998. Beun JJ, Hendriks A, Van Loosdrecht MCM, Morgenroth E, Wilderer PA, Heijnen JJ. Aerobic granulation in a sequencing batch reactor. Water Research 1999;33(10): 228390. Dangcong P, Bernet N, Delgenes J-P, Moletta R. Aerobic granular sludge-a case report. Water Research 1999;33:8903. Vishniac W, Santer M. The Thiobacilli. Bacteriological Reviews 1975;21:195213. NNI NEN 6621, Bepaling van de asrest, Nederlands Normalisatie Instituut, Delft, 1982. Jimenez B, Noyola A, Capdeville B. Selected dyes for residence time distribution evaluation in bioreactors. Biotechnology Techniques 1988;2(2):7782. Jimenez B, Noyola A, Capdeville B, Roustan M, Faup G. Dextran blue colorant as a reliable tracer in submerged lters. Water Research 1988;22(10):12537. Tijhuis L, Van Benthum WAJ, Van Loosdrecht MCM, Heijnen JJ. Solids retention time in spherical biolms in a biolm airlift suspension reactor. Biotechnology & Bioengineering 1994;44(8):86779. Beun JJ, Van Loosdrecht MCM, Heijnen JJ. (submitted) N-removal in a granular sludge sequencing batch airlift reactor. Biotechnology & Bioengineering, submitted for publication. Beun JJ, Paletta F, Van Loosdrecht MCM, Heijnen JJ. Stoichiometry and kinetics of poly-b-hydroxybutyrate metabolism in aerobic, slow growing, activated sludge cultures. Biotechnology & Bioengineering 2000;67(4): 37989. Beun JJ, Verhoef EV, Van Loosdrecht MCM, Heijnen JJ. Stoichiometry and kinetics of poly-b-hydroxybutyrate

712

J.J. Beun et al. / Water Research 36 (2002) 702712 formation of biolms in a biolm airlift suspension reactor. IAWQ/IWA Conference on Biolm systems. New York, 1999. [23] Gjaltema A, Tijhuis L, Van Loosdrecht MCM, Heijnen JJ. Detachment of biomass from suspended non-growing spherical biolms in airlift reactors. Biotechnology & Bioengineering 1995;45:25869.

metabolism under denitrifying conditions in activated sludge cultures. Biotechnology & Bioengineering 2000;68(5):496507. [21] Picioreanu C, Van Loosdrecht MCM, Heijnen JJ. Eect of diusive and convective substrate transport on biolm structure formation: a two-dimensional modeling study. Biotechnology & Bioengineering 2000; 69. [22] Villasenor JC, Van Loosdrecht MCM, Picioreanu C, Heijnen JJ. Inuence of dierent substrates on the

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Solar Water Heating SystemDocument1 pageSolar Water Heating SystemJiya RobertNo ratings yet

- TDS Brushbond India5Document2 pagesTDS Brushbond India5SK Emran AliNo ratings yet

- Econocast 30 SdsDocument4 pagesEconocast 30 SdsJosue MorenoNo ratings yet

- Msds Anhydrous HCLDocument9 pagesMsds Anhydrous HCLfebby diovanyNo ratings yet

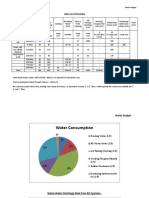

- Water consumption and waste analysisDocument6 pagesWater consumption and waste analysisNaveen MathurNo ratings yet

- TPW5 TRAINING MANUALDocument68 pagesTPW5 TRAINING MANUALClaudio Cocio JaimeNo ratings yet

- Chemical Waste Management GuidelinesDocument5 pagesChemical Waste Management GuidelinesSolomon SundayNo ratings yet

- LESSON PLAN Water ConservationDocument8 pagesLESSON PLAN Water ConservationkarlacamilledeleonNo ratings yet

- Sikagard - 619: Penetrating 2-Component Epoxy Resin SealerDocument2 pagesSikagard - 619: Penetrating 2-Component Epoxy Resin Sealerthe pilotNo ratings yet

- Project Quality Plan for General Construction WorksDocument19 pagesProject Quality Plan for General Construction WorksArc HindapNo ratings yet

- - Cô Vũ Mai Phương - Đề thi thử tốt nghiệp THPT 2023 - Cụm trường phía Nam - Hưng YênDocument5 pages- Cô Vũ Mai Phương - Đề thi thử tốt nghiệp THPT 2023 - Cụm trường phía Nam - Hưng YênPhuc LeNo ratings yet

- Bunding and Terracing-593Document16 pagesBunding and Terracing-593Fahlian_Johan__3611No ratings yet

- Wendland RetainingWallsDocument30 pagesWendland RetainingWallsMahn NguyenNo ratings yet

- Sewage Sludge Ash (SSA) PR CementDocument5 pagesSewage Sludge Ash (SSA) PR CementMAHESH A VNo ratings yet

- Axion Dishwashing Hand Lemon-Lime 5.30.07 - ColgateDocument3 pagesAxion Dishwashing Hand Lemon-Lime 5.30.07 - ColgateBLU LOGISTICS COLOMBIANo ratings yet

- Final Synopsys Lakhwar Dam PDFDocument11 pagesFinal Synopsys Lakhwar Dam PDFAkash BhartiNo ratings yet

- Water Pump Sizing CalculationsDocument24 pagesWater Pump Sizing CalculationsdheerajNo ratings yet

- Top-Notch Unit 3 VocabularyDocument3 pagesTop-Notch Unit 3 VocabularyDavid Hernandez RamirezNo ratings yet

- Slum Rehabilation Center@Document20 pagesSlum Rehabilation Center@Soumith SunnyNo ratings yet

- Bedzed Monitoring Report 2007Document39 pagesBedzed Monitoring Report 2007JCNo ratings yet

- Checklist For Technical Evaluation of Infrastructure ProjectsDocument2 pagesChecklist For Technical Evaluation of Infrastructure ProjectsEmman TyNo ratings yet

- Here are the answers to the pre-assessment questions:1. False2. C3. B 4. C5. A6. True7. E8. E9. True 10. F11. C12. C13. C14. True15. C16. E17. True18. True19. A20. True21. True22. True23. False24. BDocument28 pagesHere are the answers to the pre-assessment questions:1. False2. C3. B 4. C5. A6. True7. E8. E9. True 10. F11. C12. C13. C14. True15. C16. E17. True18. True19. A20. True21. True22. True23. False24. BNani Kumar100% (3)

- WetlandsDocument21 pagesWetlandsapi-345686634No ratings yet

- Solar Water DistllatorDocument3 pagesSolar Water DistllatorJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Internship Report HarangiDocument104 pagesInternship Report HarangiHarsha DharmapalNo ratings yet

- Hydronic Buffer Tank Install Manual 090811Document6 pagesHydronic Buffer Tank Install Manual 090811Andres CarrascoNo ratings yet

- Arpit PorwalDocument14 pagesArpit PorwalMalav PatelNo ratings yet

- Straub Manual Tehnic LQ E - 12Document64 pagesStraub Manual Tehnic LQ E - 12zenogredinaNo ratings yet

- SRAC Publication No. 454 Recirculating Aquaculture Tank Production Systems Aquaponics Integrating Fish and Plant Culture PDFDocument16 pagesSRAC Publication No. 454 Recirculating Aquaculture Tank Production Systems Aquaponics Integrating Fish and Plant Culture PDFJeferson MorenoNo ratings yet

- SSA PDC 8a&bDocument2 pagesSSA PDC 8a&bMageswary Kunalan100% (2)