Professional Documents

Culture Documents

6MT (Diag) Manual Trans & Diff (Diag)

Uploaded by

Jasmin PartingtonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6MT (Diag) Manual Trans & Diff (Diag)

Uploaded by

Jasmin PartingtonCopyright:

Available Formats

MANUAL TRANSMISSION

AND DIFFERENTIAL

(DIAGNOSTICS)

6MT(diag)-2

Basic Diagnostic Procedure

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

Step Check Yes No

1 START INSPECTIONS.

1) Use the Check List for Interview to confirm

the condition of the problem from the user.

<Ref. to 6MT(diag)-3, Check List for Interview.>

2) Before performing diagnosis, inspect parts

related to the DCCD.

General inspection <Ref. to 6MT(diag)-4,

INSPECTION, General Description.>

Disconnection of harness connector

Visual check for harness connector damage

Oil leaks

Items related DCCD are OK? Go to step 2. Repair the defec-

tive items.

2 READ DTC.

Read the DTC. <Ref. to 6MT(diag)-10, Subaru

Select Monitor.>

NOTE:

For the DTC, refer to the List of Diagnostic

Trouble Code (DTC). <Ref. to 6MT(diag)-20,

List of Diagnostic Trouble Code (DTC).>

If the communication function of Subaru Se-

lect Monitor cannot be executed normally,

check the communication circuit. <Ref. to

6MT(diag)-10, Subaru Select Monitor.>

Is it possible to call out the

DTC?

Go to step 3.

NOTE:

Record all DTC.

Inspect based on

the Diagnostics

with Phenome-

non. <Ref. to

6MT(diag)-37,

Diagnostics with

Phenomenon.>

3 PERFORM DIAGNOSIS.

1) Inspect and repair all DTC using the Diag-

nostic Procedure with Diagnostic Trouble Code

(DTC). <Ref. to 6MT(diag)-21, Diagnostic Pro-

cedure with Diagnostic Trouble Code (DTC).>

NOTE:

Refer to List of Diagnostic Trouble Code

(DTC) for DTC. <Ref. to 6MT(diag)-20, List of

Diagnostic Trouble Code (DTC).>

2) Start the engine.

3) Read the DTC using the Select Monitor.

<Ref. to 6MT(diag)-10, Subaru Select Monitor.>

Is DTC displayed? Record all DTC

using the Diag-

nostic Procedure

with Diagnostic

Trouble Code

(DTC) for the

inspection. <Ref.

to 6MT(diag)-21,

Diagnostic Proce-

dure with Diagnos-

tic Trouble Code

(DTC).> Repeat

execute diagnosis

until DTC no longer

appears.

Inspect based on

the Diagnostics

with Phenome-

non. <Ref. to

6MT(diag)-37,

Diagnostics with

Phenomenon.>

6MT(diag)-3

Check List for Interview

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Check the following items when a problem has occurred.

NOTE:

Use copies of this page for interviewing customers.

Customers name

Date of purchase

Date of repair

Transmission model Transmission V.I.N.

Odometer distance km or miles

Frequency Continuous Intermittent ( times a day)

Weather Fine Cloudy Rainy Snowy

Others

( )

Place Highland Suburbs Inner city Uphill Rough road

Others

( )

Outside air temperature Hot Warm Cool Cold

Vehicle speed km/h (MPH)

DCCD manual mode display Flashing Other than flashing

Driving condition Not affected

When decelerating

At starting

When accelerating

While turning

( RH/ LH)

When cruising

Symptoms No change to AUTO or MANUAL

No change of front and rear torque distribution

No change to differential free

No change to differential lock

Tight corner braking condition is occurred in AUTO or MANUAL mode with differential

free

Noise or vibration

Others

( )

6MT(diag)-4

General Description

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

3. General Description

A: CAUTION

The airbag system wiring harness is routed near

the DCCD control module.

CAUTION:

Airbag system wiring harnesses and connec-

tors are yellow. Do not use an electric test

equipment to check these circuits.

Be careful not to damage the airbag system

wiring harness when performing diagnostics or

repair of the DCCD control module.

When measuring the voltage and resistance

of each control module or each sensor, use a ta-

pered pin with a diameter of less than 0.64 mm

(0.025 in) in order to avoid poor contact. Also,

do not insert the pin more than 5 mm (0.2 in) into

the part.

B: INSPECTION

1. POWER SUPPLY

1) Measure the battery voltage and specific gravity

of the electrolyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

2) Check the fuse condition.

3) Check the connecting condition of harness and

harness connector.

C: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

1B021XU0 SUBARU SELECT

MONITOR III KIT

Used for trouble shooting the electrical system

TOOL NAME REMARKS

Circuit tester Used for measuring resistance, voltage and current.

Oscilloscope Used for measuring the sensor.

ST1B021XU0

6MT(diag)-5

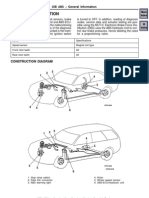

Electrical Component Location

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

(1) Engine control module (ECM) (6) C.DIFF +/ switch (12) Stop light switch

(2) VDC control module & hydraulic

control unit (VDCCM&H/U)

(7) Center differential (13) Rear differential oil temperature

switch

(8) Mode change switch

(3) DCCD control module (9) DCCD relay (14) Data link connector

(4) Throttle position sensor (10) DCCD manual mode display (15) Neutral position switch

(5) Yaw rate & lateral G sensor (11) Parking brake switch (16) Steering angle sensor

MT-01756

(1)

(3)

(4)

(5)

(6)

(2)

(7)

(8)

(9)

(15)

(13)

(10)

(11)

(12)

(14)

(16)

6MT(diag)-6

Electrical Component Location

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

EN-00156

(1)

MT-01719

(2)

(3)

MT-01720 MT-01721

(4)

MT-01722

(5)

(11)

SI-DRIVE

Sport

S

AUTO

MANU

C.DIFF

+

-

SportSharp

S#

PUSH

Intelligent

I

MT-01693

(6)

(8)

MT-01455

(7)

ODO

MT-01692

(10)

(12)

MT-01724 MT-01725

(13)

6MT(diag)-7

Electrical Component Location

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

MT-01755

(14)

MT-01234

(15)

MT-01426

(16)

MT-01752

(9)

6MT(diag)-8

Drivers Control Center Differential (DCCD) Control Module I/O Signal

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

5. Drivers Control Center Differential (DCCD) Control Module I/O

Signal

A: ELECTRICAL SPECIFICATION

MT-01684

B380

8 9 10

24 23 25

11 12 13 14 15

26 27 28

16

17 18 19 20 21 30 31 32

6 7

22

1 2 3 4 5

29

TO

6MT(diag)-9

Drivers Control Center Differential (DCCD) Control Module I/O Signal

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

B: WIRING DIAGRAM

Refer to WIRING DIAGRAM. <Ref. to WI-54,

Drivers Control Center Differential Control Sys-

tem.>

Check with ignition switch ON.

Contents

Measured terminal

(Connector & Terminal No.)

Measuring condition Voltage (V) Resistance ()

Positive terminal Ground terminal

DCCD output (B380) No. 2 (B380) No. 17

When differential is locked

(when DCCD manual

mode display is lock)

5.5 8.0

1.2 2.5

When differential is free

(When the parking brake

is pulled)

Less than 0.5

DCCD power supply

(B380) No. 3

Chassis ground Ignition switch ON 10 13

(B380) No. 4

Backup power supply (B380) No. 5 Chassis ground 10 13

Ignition power supply (B380) No. 6 Chassis ground Ignition switch ON 10 13

DCCD relay (B380) No. 10 Chassis ground Ignition switch ON Less than 1.0

Mode change switch (B380) No. 11 Chassis ground

When the switch is not

pressed

8.0 or more

When the switch is

pressed

Less than 1

Rear differential oil

temperature switch

(B380) No. 12 Chassis ground

When the rear differential

switch is ON

0.4 or more

When the rear differential

switch is OFF

Less than 8.0

CAN communication signal (+) (B380) No. 15 Chassis ground Ignition switch ON Pulse signal

CAN communication signal () (B380) No. 31 Chassis ground Ignition switch ON Pulse signal

Data link signal

(Subaru Select Monitor)

(B380) No. 16 Chassis ground

System ground circuit

(B380) No. 18 Chassis ground

0 Less than 1.0

(B380) No. 19 Chassis ground

(B380) No. 20 Chassis ground

(B380) No. 21 Chassis ground

System ground circuit (B380) No. 32 Chassis ground 0 Less than 1.0

Up switch (B380) No. 27 Chassis ground

When the switch is not

pressed/is pressed

8.0/1.0

Down switch (B380) No. 13 Chassis ground

When the switch is not

pressed/is pressed

8.0/1.0

6MT(diag)-10

Subaru Select Monitor

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

6. Subaru Select Monitor

A: OPERATION

1. READ DIAGNOSTIC TROUBLE CODE

(DTC)

1) Prepare the Subaru Select Monitor kit.

2) Prepare the personal computer which has been

installed the Subaru Select Monitor.

3) Connect the USB cable between SDI (Subaru

Diagnosis Interface) and USB port on the personal

computer (dedicated port for the Subaru Select

Monitor).

NOTE:

The port for Subaru Select Monitor is the USB port

used for installing the Subaru Select Monitor.

4) Connect the diagnosis cable to SDI.

5) Connect the SDI to data link connector located in

the lower portion of the instrument panel (on the

drivers side).

CAUTION:

Do not connect the scan tools other than the

Subaru Select Monitor.

6) Start a PC.

7) Turn the ignition switch to ON.

8) Run the PC application help for Subaru Select

Monitor.

9) On the Main Menu display screen, select

{Each System Check}.

10) On the System Selection Menu display

screen, select {Transmission Control System}.

11) After the {Center Differential Control} is dis-

played, select [OK].

12) On the Transmission Diagnosis, select {Di-

agnostic Code(s) Display}.

13) On the Diagnostic Code(s) Display, select

{Temporary Diagnostic Code(s)} or {Memorized Di-

agnostic Code(s)}.

2. READ CURRENT DATA

1) On the Main Menu display screen, select

{Each System Check}.

2) On the System Selection Menu display

screen, select {Transmission Control System}.

3) After the {Center Differential Control} is dis-

played, select [OK].

4) Select {Current Data Display & Save} in the

Transmission Diagnosis screen.

5) On the Current Data Display & Save, select

{Normal sampling}.

6) Using the scroll key, scroll the display screen up

or down until the desired data is shown.

EN-05692

EN-06148

6MT(diag)-11

Subaru Select Monitor

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

A list of the support data is shown in the following table.

*1: Displayed by the number

0 in the manual mode

1 in AUTO[] / 2 in AUTO / 3 in AUTO[+]

*2: Displayed by the number

0 in AUTO mode

1 (Free), 2, 3, 4, 5, 6 (LOCK) in manual mode

NOTE:

For details concerning the operation procedure, refer to the PC Application Help for Subaru Select Monitor.

3. CLEAR MEMORY MODE

1) Place the change lever in neutral.

2) On the Main Menu display screen, select

{Each System Check}.

3) On the System Selection Menu display

screen, select {Transmission Control System}.

4) After the {Center Differential Control} is dis-

played, select [OK].

5) On the Transmission Diagnosis display

screen, select {Clear Memory}.

6) When the Done. Turn ignition switch OFF is

displayed, select [OK].

7) Turn the Subaru Select Monitor and ignition

switch to OFF. To turn the ignition switch to ON

again, wait for 10 seconds or more.

NOTE:

To clear the previous DTC, use {Clear Memory}.

For details concerning the operation procedure,

refer to the PC Application Help for Subaru Select

Monitor.

Contents Display Unit of measure

Center differential actual current C-Diff. Real Current A

Center differential indicated current C-Diff. Indicate Current A

Front vehicle speed sensor (RH) FR Wheel Speed km/h or MPH

Front vehicle speed sensor (LH) FL Wheel Speed km/h or MPH

Rear vehicle speed sensor (RH) RR Wheel Speed km/h or MPH

Rear vehicle speed sensor (LH) RL Wheel Speed km/h or MPH

Yaw rate & lateral G sensor Lateral G m/s

2

Yaw rate & lateral G sensor Yaw Rate deg/s

Steering angle Steering Angle Sensor deg

Engine speed signal Engine Speed rpm

Stop light switch signal Stop Light Switch ON or OFF

Rear differential oil temperature switch signal RR Diff. Oil Temp SW ON or OFF

Down shift signal Down Switch ON or OFF

Up shift signal Up Switch ON or OFF

AUTO selection mode DCCD Mode *1

Manual mode torque distribution DCCD Torque Allocation *2

Battery voltage Battery Voltage V

Accelerator position Accel. Opening Angle %

Parking switch Parking Position Switch ON or OFF

Center differential relay Center Diff. Relay ON or OFF

Mode change switch AUTO/MANUAL Mode Switch ON or OFF

Neutral signal Neutral Position Switch Neutral or other than neutral

6MT(diag)-12

Read Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

7. Read Diagnostic Trouble

Code (DTC)

A: OPERATION

Refer to Subaru Select Monitor for information on

how to display a DTC. <Ref. to 6MT(diag)-10, Sub-

aru Select Monitor.>

For details concerning DTCs, refer to List of Diag-

nostic Trouble Code (DTC). <Ref. to 6MT(diag)-

20, List of Diagnostic Trouble Code (DTC).>

6MT(diag)-13

Clear Memory Mode

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

8. Clear Memory Mode

A: OPERATION

Refer to Subaru Select Monitor for information

about how to clear a DTC. <Ref. to 6MT(diag)-11,

CLEAR MEMORY MODE, OPERATION, Subaru

Select Monitor.>

6MT(diag)-14

Drivers Control Center Differential (DCCD) Manual Mode Display

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

9. Drivers Control Center Differential (DCCD) Manual Mode Display

A: OPERATION

When there is a problem with a part or module, DCCD manual mode display blinks. (DCCD manual mode

display blinks even in AUTO mode condition.) Until the problem is detected and the ignition switch is turned

OFF, the blinking continues. The faulty parts can be recognized by reading the DTC through the Subaru Se-

lect Monitor.

DCCD manual mode display is as shown in the figure.

(A) If faulty (blinks at 1 Hz cycle) (E) 5 (I) 1 (FREE)

(B) If normal (F) 4 (J) No display (AUTO mode)

(C) Manual mode display (G) 3

(D) 6 (LOCK) (H) 2

MT-01775

(E) (D)

(A)

(B)

(C)

LOCK

(F)

(G) (H) (I) (J)

LOCK

6MT(diag)-15

Drivers Control Center Differential (DCCD) Manual Mode Display

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

B: INSPECTION

DIAGNOSIS:

DCCD manual mode display is open or shorted.

TROUBLE SYMPTOM:

DCCD manual mode display does not illuminate in manual mode.

WIRING DIAGRAM:

MT-01685

2

2

7

2

6

i10

i84 B280 B:

A

1

A

9

B

3

B

9

DCCD CM

B380

i10

8 7 6 5 4 3 2 1

2223 21 20 19 16 15 14 13 12 11 10 9

3435 33 32

17

30

18

31 29 28 27 26 25 24

i84 A:

B280 B:

1

8

2

FB-36

F/B FUSE NO. 5

(IG)

5 4 6

8 7

2 1

9

3

10

20 21

11 12 13 14 15

22 23 24 25

16 17

18 26 19

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

A:

I/F

LCD

DCCD INDICATOR

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

TO POWER SUPPLY CIRCUIT

MICRO COMPUTER

CAN TRANSCEIVER

& RECEIVER

COMBINATION

METER

BODY INTEGRATED

UNIT

6MT(diag)-16

Drivers Control Center Differential (DCCD) Manual Mode Display

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

Step Check Yes No

1 CHECK THE BODY INTEGRATED UNIT.

Read the DTC of body integrated unit using

Subaru Select Monitor.

Is DTC displayed? Perform the diag-

nosis according to

DTC.

Go to step 2.

2 CHECK COMBINATION METER.

Perform the self-diagnosis of combination

meter. <Ref. to IDI-13, Combination Meter.>

Is the self-diagnosis of combi-

nation meter OK?

Go to step 3. Repair it according

to combination

meter diagnostics.

3 CHECK IGNITION POWER SUPPLY CIRCUIT

OF DCCD CONTROL MODULE.

1) Connect the Subaru Select Monitor to the

vehicle.

2) Turn the ignition switch to ON.

3) Read the data of Battery Voltage using the

Subaru Select Monitor.

Is the voltage 11 V or more? Go to step 4. Repair the open

circuit of harness

between fuse (F/B

No. 12) and DCCD

control module, or

between fuse (F/B

No. 12) and bat-

tery.

4 CHECK DTC. Is DTC P1720 displayed? Perform the diag-

nosis according to

DTC.

Go to step 5.

5 CHECK MODE CHANGE SWITCH.

Read the data of AUTO/MANUAL Mode

Switch using the Subaru Select Monitor.

Does the display change to ON/

OFF according to the mode

change switch operation?

Go to step 6. Diagnose the

mode change

switch.

6 CHECK C.DIFF +/ SWITCH (UP/DOWN).

Read the data of Up Switch and Down

Switch using the Subaru Select Monitor.

Does the display change to ON/

OFF according to the C.DIFF

+/ switch operation?

Go to step 7. Check the C.DIFF

+/ switch.

7 CHECK INDICATION OF DCCD MANUAL

MODE DISPLAY.

Press the mode change switch to enter the

manual mode.

Does the DCCD manual mode

display illuminate?

Go to step 8. Check the poor

contact.

8 CHECK INDICATION OF DCCD MANUAL

MODE DISPLAY.

Read the data of DCCD Torque Allocation

using the Subaru Select Monitor.

Does the DCCD manual mode

display change according to the

C.DIFF +/ switch operation.

Go to step 9. Check the poor

contact.

9 CHECK OTHER DTC. Is there any other DTC dis-

played?

Perform the diag-

nosis according to

DTC.

DCCD manual

mode display is

OK.

6MT(diag)-17

Diagnostic Procedure for Subaru Select Monitor Communication

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

10.Diagnostic Procedure for Subaru Select Monitor Communication

A: COMMUNICATION FOR INITIALIZING IMPOSSIBLE

DIAGNOSIS:

Defective harness connector

TROUBLE SYMPTOM:

Subaru Select Monitor communication failure

WIRING DIAGRAM:

Step Check Yes No

1 CHECK SUBARU SELECT MONITOR POW-

ER SUPPLY CIRCUIT.

Measure the voltage between data link connec-

tor and chassis ground.

Battery & Terminal

(B40) No. 16 (+) Chassis ground ():

Is the voltage 10 V or more? Go to step 2. Repair the harness

connector between

the battery and

data link connec-

tor, and poor con-

tact of the

connector.

MT-01769

B40

B380 DCCD CM

B40

E

SBF-6

1

4

1

3

16

7

E

No. 13

2

8

2

9

3

0

3

1

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

E

B134 : A

ECM

C

6

B21

E2

A

5

3

6

B21

1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17 18 19 20 21 22

23 24 25 26 27 28 29 30 31 32 33

34 35

42 43

36 37 38 39

48 49 50 51 52 53 54

40 41

44 45 46 47

B136 : C

5

4

8

IG RELAY 2

MAIN SBF

B310

7

C: B136

16 10 11 12 13 14 15

25 24

30

9 8 7

17 18 19 20

28

21 22 23

29 32 31

1 2 3 4 5 6

27 26

33 34 35

A: B134

8

5 6

10 11 12 13 14 15

7 2 1 3 4

16

30

19 20 22

28 29

9 17

18 25 21 23 24

32 31

26 27

33 34

4 5 6 7 8 9

26 27 28 29 30

2 3 1

31 32 33 34 35 36

10 11 14 15 16 17 18 19

37 38 39 40

12 13

41 42 43 44 45 46

20 21

23 24 22 25

B310

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

E

1

7

1

SBF-8

No. 4

N

o

.

1

2

IGNITION

SWITCH

BATTERY

DATA LINK

CONNECTOR

VDC

CONTROL MODULE

6MT(diag)-18

Diagnostic Procedure for Subaru Select Monitor Communication

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

2 CHECK SUBARU SELECT MONITOR

GROUND CIRCUIT.

Measure the resistance of harness between

data link connector and chassis ground.

Battery & Terminal

(B40) No. 4 Chassis ground:

(B40) No. 5 Chassis ground:

Is resistance less than 1 ? Go to step 3. Repair the open

circuit of harness

between data link

connector and

ground terminal,

and poor contact of

connector.

3 CHECK COMMUNICATION OF SUBARU SE-

LECT MONITOR.

1) Turn the ignition switch to ON.

2) Check the communication with transmission

system.

Is the name of system dis-

played on Subaru Select Moni-

tor?

System is normal. Go to step 4.

4 CHECK COMMUNICATION OF SUBARU SE-

LECT MONITOR.

1) Turn the ignition switch to OFF.

2) Disconnect the DCCD control module con-

nector.

3) Turn the ignition switch to ON.

4) Check the communication with engine sys-

tem.

Is the name of system dis-

played on Subaru Select Moni-

tor?

Go to step 6. Go to step 5.

5 CHECK COMMUNICATION OF SUBARU SE-

LECT MONITOR.

1) Turn the ignition switch to OFF.

2) Connect the DCCD control module connec-

tor.

3) Disconnect the connector from ECM.

4) Turn the ignition switch to ON.

5) Check the communication with transmission

system.

Is the name of system dis-

played on Subaru Select Moni-

tor?

Inspect the ECM. Go to step 6.

6 CHECK HARNESS CONNECTOR BETWEEN

EACH CONTROL MODULE AND DATA LINK

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the DCCD control module and

ECM connectors.

3) Measure the resistance between data link

connector and chassis ground.

Battery & Terminal

(B40) No. 7 Chassis ground:

Is the resistance 1 M or

more?

Go to step 7. Check harness

and connector

between each con-

trol module and

data link connec-

tor.

7 CHECK HARNESS CONNECTOR BETWEEN

EACH CONTROL MODULE AND DATA LINK

CONNECTOR.

1) Disconnect the all modules that communi-

cate with Subaru Select Monitor.

2) Turn the ignition switch to ON.

3) Measure the voltage between data link con-

nector and chassis ground.

Battery & Terminal

(B40) No. 7 (+) Chassis ground ():

Is the voltage 1 V or more? Check harness

and connector

between each con-

trol module and

data link connec-

tor.

Go to step 8.

8 CHECK HARNESS CONNECTOR BETWEEN

DCCD CONTROL MODULE AND DATA LINK

CONNECTOR.

Measure the resistance between DCCD control

module connector and data link connector.

Battery & Terminal

(B380) No. 1 (B40) No. 7:

Is resistance less than 1 ? Go to step 9. Check harness

and connector

between DCCD

control module and

data link connec-

tor.

Step Check Yes No

6MT(diag)-19

Diagnostic Procedure for Subaru Select Monitor Communication

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

9 CHECK INSTALLATION OF DCCD CON-

TROL MODULE.

Turn the ignition switch to OFF.

Is the DCCD control module

connector connected to DCCD

control module?

Go to step 10. Connect the

DCCD control

module connector

to DCCD control

module?

10 CHECK POOR CONTACT OF DCCD CON-

TROL MODULE CONNECTOR.

Is there poor contact in the con-

nector?

Repair the poor

contact.

Go to step 11.

11 CHECK POWER SUPPLY OF DCCD CON-

TROL MODULE.

1) Disconnect the connector from DCCD con-

trol module.

2) Turn the ignition switch to ON.

3) Measure the voltage between DCCD con-

trol module connector and chassis ground.

Battery & Terminal

(B380) No. 13 (+) Chassis ground ():

(B380) No. 14 (+) Chassis ground ():

Are the voltages 10 13 V? Go to step 15. Go to step 12.

12 CHECK POWER SUPPLY CIRCUIT OF FUSE

(F/B NO. 12).

1) Turn the ignition switch to OFF.

2) Remove the fuse (F/B No. 12).

Is the fuse (F/B No. 12) blown

out?

Replace the fuse

(F/B No. 12). If the

new fuse (F/B No.

12) has blown out

easily, repair the

short circuit of har-

ness between fuse

(F/B No. 12) and

DCCD control

module.

Go to step 13.

13 CHECK POWER SUPPLY CIRCUIT OF FUSE

(M/B NO. 12).

Remove the fuse (M/B No. 12).

Is the fuse (M/B No. 12) blown

out?

Replace the fuse

(M/B No. 12). If the

new fuse (M/B No.

12) has blown out

easily, repair the

short circuit of har-

ness between fuse

(M/B No. 12) and

DCCD control

module.

Go to step 14.

14 CHECK POWER SUPPLY CIRCUIT OF DCCD

CONTROL MODULE.

Measure the resistance between the battery (+)

terminal and fuse.

Battery & Terminal

Battery (+) M/B No. 12:

Battery (+) F/B No. 12:

Is resistance less than 1 ? Repair the open

circuit.

Go to step 15.

15 CHECK HARNESS CONNECTOR BETWEEN

DCCD CONTROL MODULE AND CHASSIS

GROUND.

1) Turn the ignition switch to OFF.

2) Measure the resistance between DCCD

control module and chassis ground.

Connector & terminal

(B380) No. 28 Chassis ground:

(B380) No. 29 Chassis ground:

(B380) No. 30 Chassis ground:

(B380) No. 31 Chassis ground:

Is resistance less than 1 ? Check the poor

contact.

Repair the short

circuit or poor con-

tact of harness

between DCCD

control module and

transmission con-

nector.

Step Check Yes No

6MT(diag)-20

List of Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

11.List of Diagnostic Trouble Code (DTC)

A: LIST

1. SUBARU SELECT MONITOR DISPLAY

DTC Item Content of diagnosis Reference target

P1521 Brake Switch Circuit Range

Stop light switch circuit is open

or shorted.

<Ref. to 6MT(diag)-21, DTC P1521 BRAKE

SWITCH CIRCUIT RANGE, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P1720 DCCD CAN System Circuit

CAN communication circuit is

open or shorted.

<Ref. to 6MT(diag)-22, DTC P1720 DCCD CAN

SYSTEM CIRCUIT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P1767 DCCD Steering Angle Sensor

Open, short or communication

failure of the steering angle

sensor circuit

<Ref. to 6MT(diag)-23, DTC P1767 DCCD

STEERING ANGLE SENSOR, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P1769

Yaw Rate & Lateral G Sensor

Malfunction

Yaw rate & lateral G sensor

malfunction

<Ref. to 6MT(diag)-25, DTC P1769 YAW RATE &

LATERAL G SENSOR MALFUNCTION, Diag-

nostic Procedure with Diagnostic Trouble Code

(DTC).>

P1875 Circuit of Center Diff.

Open or short in the drivers

control center differential circuit

<Ref. to 6MT(diag)-27, DTC P1875 CIRCUIT OF

CENTER DIFF., Diagnostic Procedure with Diag-

nostic Trouble Code (DTC).>

6MT(diag)-21

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

12.Diagnostic Procedure with Diagnostic Trouble Code (DTC)

A: DTC P1521 BRAKE SWITCH CIRCUIT RANGE

DIAGNOSIS:

Stop light switch circuit is open or shorted.

TROUBLE SYMPTOM:

ABS does not operate.

WIRING DIAGRAM:

MT-01764

2 1 3 4

8 9 7 6 5

B65

B65

B159

B310

3

0

B

1

5

1

2

F

9

B225

1

2

7

.

5

A

B225

FB-3

F/B FUSE NO. 8

(B)

2 1

4 3

4 5 6 7 8 9

26 27 28 29 30

2 3 1

31 32 33 34 35 36

10 11 14 15 16 17 18 19

37 38 39 40

12 13

41 42 43 44 45 46

20 21

23 24 22 25

B310

B99

1 2 3 4 5

6 7 8 9 10 11 12

R168 B:

13

14

15 16

17

27

24

25

26

20

21

22

23

29

30

31 28 32 35

33

34

37

38

39 36 40

8

9

10

11 12

1 2

5

3 4

7

6

19

18

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20

R168 B:

F:

B159 F:

R3

B99

7

TO POWER SUPPLY

CIRCUIT

STOP LIGHT

SWITCH

FUSE &

RELAY BOX (F/B)

FUSE

(RELAY BLOCK)

VDC

CONTROL MODULE

6MT(diag)-22

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

B: DTC P1720 DCCD CAN SYSTEM CIRCUIT

NOTE:

For the diagnostic procedure, refer to DTC U1216. <Ref. to LAN(diag)-55, DTC U1216 HIGH-SPEED CAN

(DCCD) DATA ERROR, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

Step Check Yes No

1 CHECK DTC. Does the DTC related to stop

light SW appear in the VDC

diagnostics test mode?

Perform the diag-

nosis according to

DTC.

Go to step 2.

2 CHECK IGNITION POWER SUPPLY CIRCUIT

OF DCCD CONTROL MODULE.

1) Connect the Subaru Select Monitor to the

vehicle.

2) Turn the ignition switch to ON.

3) Read the data of Battery Voltage using the

Subaru Select Monitor.

Is the voltage 11 V or more? Go to step 3. Repair the open

circuit of harness

between fuse (F/B

No. 12) and DCCD

control module, or

between fuse (F/B

No. 12) and bat-

tery.

3 CHECK DTC. Is DTC P1720 displayed? Perform the diag-

nosis according to

DTC.

Go to step 4.

4 CHECK DCCD CONTROL MODULE.

1) Turn the ignition switch to ON.

2) Read the data of Stop Light Switch using

the Subaru Select Monitor.

Does the brake SW change to

ON/OFF according to the

depressing/releasing opera-

tion of brake?

Go to step 5. Check the poor

contact.

5 CHECK OTHER DTC. Is a DTC other than DTC P1521

displayed?

Perform the diag-

nosis according to

DTC.

The stop light

switch is currently

normal.

6MT(diag)-23

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

C: DTC P1767 DCCD STEERING ANGLE SENSOR

DIAGNOSIS:

Open, short or communication failure of the steering angle sensor circuit

TROUBLE SYMPTOM:

A tight corner braking symptom occurs.

WIRING DIAGRAM:

MT-01765

B310

B380 DCCD CM

12

B231

2

1

8

10

35

B231

1 2 3 4

4 5 6 7 8 9

26 27 28 29 30

2 3 1

31 32 33 34 35 36

10 11 14 15 16 17 18 19

37 38 39 40

12 13

41 42 43 44 45 46

20 21

23 24 22 25

B310 B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

3

STEERING ANGLE SENSOR

TO YAW RATE &

LATERAL G SENSOR

VDC

CONTROL

MODULE

6MT(diag)-24

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

Step Check Yes No

1 CHECK DTC. Does the DTC related to steer-

ing angle sensor appear in the

VDC diagnostics test mode?

Perform the diag-

nosis according to

DTC.

Go to step 2.

2 CHECK IGNITION POWER SUPPLY CIRCUIT

OF DCCD CONTROL MODULE.

1) Connect the Subaru Select Monitor to the

vehicle.

2) Turn the ignition switch to ON.

3) Read the data of Battery Voltage using the

Subaru Select Monitor.

Is the voltage 11 V or more? Go to step 3. Repair the open

circuit of harness

between fuse (F/B

No. 12) and DCCD

control module, or

between fuse (F/B

No. 12) and bat-

tery.

3 CHECK DTC. Is DTC P1720 displayed? Perform the diag-

nosis according to

DTC.

Go to step 4.

4 CHECK DCCD CONTROL MODULE.

1) Turn the ignition switch to ON.

2) Using the Subaru Select Monitor, read

Steering Angle Sensor data.

Does the Subaru Select Moni-

tor value change according to

the input from the steering to

the right and left?

Go to step 5. Go to step 6.

5 CHECK DTC.

1) Erase the memory.

2) Start the engine.

3) Read the DTC.

Is DTC P1767 displayed? Replace the steer-

ing angle sensor.

Go to step 6.

6 CHECK OTHER DTC. Is a DTC other than DTC P1767

displayed?

Perform the diag-

nosis according to

DTC.

The steering angle

sensor circuit is

currently operating

properly.

6MT(diag)-25

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

D: DTC P1769 YAW RATE & LATERAL G SENSOR MALFUNCTION

DIAGNOSIS:

Malfunction information transmitted from the yaw rate & lateral G sensor

TROUBLE SYMPTOM:

A tendency to understeer occurs during high speed cornering.

WIRING DIAGRAM:

MT-01691

B280 B:

1 2 3 4 5 6

7 8 9 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26

B380

B280 B:

B310

B230

B230

1

2

3

4

B231

1 2 3 4

4 5 6 7 8 9

26 27 28 29 30

2 3 1

31 32 33 34 35 36

10 11 14 15 16 17 18 19

37 38 39 40

12 13

41 42 43 44 45 46

20 21

23 24 22 25

B310

DCCD CM

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

FB-36

F/B FUSE NO. 5

(IG)

i10

2

2

6

2

7

LCD

DCCD INDICATOR

I/F

A

9

A

1

i84 A:

B

3

B

9

2 3

12

B231

A: i84

1 2 3 4 5 6 7 8

9 10 11 12 14 15 16 17 18 19 20 21 22 23

24 25 26 27 28 29 30 31 32 33 34 35

13

i10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

2

1

8

1

0

3

5

B136

ECM

C35

C27

C:

TO POWER SUPPLY

CIRCUIT

COMBINATION

METER

MICRO COMPUTER

CAN TRANSCEIVER & RECEIVER

POWER SUPPLY

CIRCUIT

BODY INTEGRATED UNIT

VDC

CONTROL MODULE

STEERING

ANGLE SENSOR

YAW RATE &

LATERAL G SENSOR

6MT(diag)-26

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

Step Check Yes No

1 CHECK DTC. Does the DTC related to lateral

G sensor or yaw rate sensor

appear in the VDC diagnostics

test mode?

Perform the diag-

nosis according to

DTC.

Go to step 2.

2 CHECK IGNITION POWER SUPPLY CIRCUIT

OF DCCD CONTROL MODULE.

1) Connect the Subaru Select Monitor to the

vehicle.

2) Turn the ignition switch to ON.

3) Read the data of Battery Voltage using the

Subaru Select Monitor.

Is the voltage 11 V or more? Go to step 3. Repair the open

circuit of harness

between fuse (F/B

No. 12) and DCCD

control module, or

between fuse (F/B

No. 12) and bat-

tery.

3 CHECK DTC. Is DTC P1720 displayed? Perform the diag-

nosis according to

DTC.

Go to step 4.

4 CHECK DCCD CONTROL MODULE.

1) Drive the vehicle on a flat road.

2) Stop the vehicle with the front wheels in a

straight forward direction.

3) Read the data of Yaw Rate and Lateral G

using the Subaru Select Monitor.

Does the yaw rate and lateral G

value change according to the

vehicle behavior? When the

vehicle stops, is the yaw rate

value within 4 4 deg/s, and

also is the lateral G value within

1.5 1.5 m/s

2

?

Go to step 5. Go to step 6.

5 CHECK DTC.

1) Erase the memory.

2) Start the engine.

3) Read the DTC.

Is DTC P1769 displayed? Replace the yaw

rate & lateral G

sensor.

Go to step 6.

6 CHECK OTHER DTC. Is a DTC other than DTC P1769

displayed?

Perform the diag-

nosis according to

DTC.

Yaw rate & lateral

G sensors are cur-

rently normal.

6MT(diag)-27

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

E: DTC P1875 CIRCUIT OF CENTER DIFF.

DIAGNOSIS:

Center differential output signal circuit is open or shorted.

TROUBLE SYMPTOM:

Center differential does not operate.

The lock ratio of the center differential does not change, or malfunction occurs.

A tight corner braking symptom occurs.

An oversteer tendency will become apparent.

A tendency to understeer occurs during high speed cornering.

WIRING DIAGRAM:

MT-01796

B380

B128

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

DCCD CM

1

3

1

4

1

5

3

2

4 1

T9

T16

T17

B220

2

8

2

7

2

5

2

6

2 1

7

1

1

1

2

B220

13

14

15 16

17

27

24

25

26

20

21

22

23

29

30

31 28 32 35

33

34

37

38

39 36 40

8

9

10

11 12

1 2

5

3 4

7

6

19

18

B128

1 3

4 5 6

2

T16

1 2

MB-26

M/B FUSE NO. 12

(B)

FB-38

F/B FUSE NO. 12

(IG)

DCCD

RELAY

TO POWER SUPPLY CIRCUIT

CENTER

DIFFERENTIAL

6MT(diag)-28

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

Step Check Yes No

1 CHECK HARNESS BETWEEN DCCD CON-

TROL MODULE AND TRANSMISSION HAR-

NESS.

1) Turn the ignition switch to OFF.

2) Disconnect the DCCD control module har-

ness connector.

3) Disconnect the transmission harness con-

nector and the bulk harness connector.

4) Measure resistance of the harness between

DCCD control module harness connector and

the transmission harness connector.

Connector & terminal

(B380) No. 15 (B128) No. 1:

(B380) No. 32 (B128) No. 4:

Is resistance less than 1 ? Go to step 2. Repair the bulk

harness open cir-

cuit between

DCCD control

module and trans-

mission harness.

2 CHECK HARNESS BETWEEN DCCD CON-

TROL MODULE AND TRANSMISSION HAR-

NESS.

Measure the resistance between DCCD control

module harness connector and chassis ground.

Connector & terminal

(B380) No. 15 Chassis ground:

(B380) No. 32 Chassis ground:

Is the resistance 1 M or

more?

Go to step 3. Repair the bulk

harness short cir-

cuit between

DCCD control

module and trans-

mission harness.

3 CHECK CENTER DIFFERENTIAL.

Measure the resistance between transmission

harness connector terminals.

Connector & terminal

(T9) No. 1 No. 4:

Is the resistance between 1.2

and 2.5 ?

Go to step 4. Replace the center

differential.

4 CHECK OUTPUT SIGNAL OF DCCD CON-

TROL MODULE.

1) Connect all harness connectors.

2) Turn the ignition switch to ON.

3) Release the parking brake.

4) Press the mode change switch to enter the

manual mode.

5) Press the C.DIFF +/ switch to enter the

lock position.

6) Measure the voltage between DCCD con-

trol module harness connectors.

Connector & terminal

(B380) No. 15 (+) No. 32 ():

Is the voltage 5.5 8.0 V? Go to step 5. Go to step 6.

5 CHECK OUTPUT SIGNAL OF DCCD CON-

TROL MODULE.

1) Move the C.DIFF +/ switch from the differ-

ential lock position to the differential free posi-

tion.

2) Read the voltage between DCCD control

module harness connectors.

Connector & terminal

(B380) No. 15 (+) No. 32 ():

Does the voltage drop in stages

according to the DCCD manual

mode display?

Circuit is currently

operating properly.

Go to step 6.

6MT(diag)-29

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

6 CHECK FUSE (NO. 12).

Remove the fuse (M/B No. 12).

Is the fuse (M/B No. 12) blown

out?

Replace the fuse

(M/B No. 12). If the

new fuse (M/B No.

12) has blown out

easily, check for

the short circuit to

chassis ground of

harness between

fuse (M/B No. 12)

and DCCD control

module, or

between fuse (M/B

No. 12) and relay.

Go to step 7.

7 CHECK POWER SUPPLY CIRCUIT OF DCCD

RELAY.

1) Install the fuse.

2) Turn the ignition switch to OFF.

3) Disconnect the DCCD relay harness con-

nector.

4) Measure the voltage between DCCD relay

harness connector and chassis ground.

Connector & terminal

(B220) No. 25 (+) Chassis ground ():

Is the voltage 10 V or more? Go to step 8. Repair the open or

short circuit

between fuse (M/B

No. 12), DCCD

relay, and battery.

8 CHECK IGNITION POWER SUPPLY CIRCUIT

OF DCCD RELAY.

1) Turn the ignition switch to ON.

2) Measure the voltage between DCCD relay

and chassis ground.

Connector & terminal

(B220) No. 27 (+) Chassis ground ():

Is the voltage 10 V or more? Go to step 9. Repair the open

circuit between

fuse (F/B No. 12),

DCCD relay, and

battery.

9 CHECK HARNESS BETWEEN DCCD CON-

TROL MODULE AND DCCD RELAY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from DCCD con-

trol module.

3) Measure resistance of the harness between

DCCD control module connector and DCCD

relay connector.

Connector & terminal

(B380) No. 7 (B220) No. 28:

(B380) No. 13 (B220) No. 26:

(B380) No. 14 (B220) No. 26:

Is resistance less than 1 ? Go to step 10. Repair the open

circuit of harness

between DCCD

control module

connector and

DCCD relay con-

nector.

10 CHECK HARNESS BETWEEN DCCD CON-

TROL MODULE AND DCCD RELAY.

Measure the resistance of harness between

DCCD control module connector and chassis

ground.

Connector & terminal

(B380) No. 7 Chassis ground:

(B380) No. 13 Chassis ground:

(B380) No. 14 Chassis ground:

Is the resistance 1 M or

more?

Go to step 11. Repair the short

circuit of harness

between DCCD

control module

connector and

DCCD relay con-

nector.

11 CHECK DCCD RELAY.

Measure the resistance between DCCD relay

terminals.

Terminals

No. 25 No. 26:

Is the resistance 1 M or

more?

Go to step 12. Replace the DCCD

relay.

Step Check Yes No

6MT(diag)-30

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

12 CHECK DCCD RELAY.

Connect the battery positive lead to terminal

No. 27 and the negative lead to terminal No. 28,

then measure the resistance between DCCD

relay terminals.

Terminals

No. 25 No. 26:

Is resistance less than 1 ? Go to step 13. Replace the DCCD

relay.

13 CHECK DCCD CONTROL MODULE RELAY

DRIVE CIRCUIT.

1) Connect all the connectors.

2) Turn the ignition switch to ON.

3) Measure the voltage between DCCD con-

trol module and chassis ground.

Connector & terminal

(B380) No. 7 (+) Chassis ground ():

Is the voltage less than 1 V? Go to step 14. Go to step 17.

14 CHECK IGNITION POWER SUPPLY CIRCUIT

OF DCCD CONTROL MODULE.

Measure the voltage between DCCD control

module and chassis ground.

Connector & terminal

(B380) No. 13 (+) Chassis ground ():

(B380) No. 14 (+) Chassis ground ():

Is the voltage 8 V or more? Go to step 15. Go to step 17.

15 CHECK CENTER DIFFERENTIAL.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to the

data link connector.

3) Turn the ignition switch to ON.

4) Turn on the Subaru Select Monitor.

5) Press the mode change switch to enter the

manual mode.

6) Release the parking brake.

7) Press the C.DIFF +/ switch to enter the

lock position.

8) In the Subaru Select Monitor, read C-Diff.

Indicate Current and C-Diff. Real Current

data.

Is the center differential indi-

cated current and the center

differential actual current both

approximately 3.6 4.0 A?

Go to step 16. Go to step 17.

16 CHECK CENTER DIFFERENTIAL.

1) Operate the C.DIFF +/ switch so that the

C-Diff. Indicate Current becomes 1.6A.

2) Read the data of the C-Diff. Real Current

data using the Subaru Select Monitor.

Is the center differential actual

current about the same as the

center differential indicated cur-

rent?

Go to step 18. Go to step 17.

17 CHECK POOR CONTACT IN HARNESS

CONNECTORS.

Is there poor contact in the har-

ness connector?

Repair the poor

contact.

Go to step 18.

18 CHECK DTC.

1) Erase the memory. <Ref. to 6MT(diag)-13,

Clear Memory Mode.>

2) Read the DTC using the Select Monitor.

<Ref. to 6MT(diag)-12, Read Diagnostic Trou-

ble Code (DTC).>

Is P1875 displayed? Check the poor

contact.

Go to step 19.

19 CHECK DTC. Are DTCs other than P1875

displayed?

Perform the diag-

nosis according to

DTC.

The center differ-

ential circuit is cur-

rently operating

properly.

Step Check Yes No

6MT(diag)-31

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

13.Diagnostic Procedure without Diagnostic Trouble Code (DTC)

A: CHECK REAR DIFFERENTIAL OIL TEMPERATURE SWITCH

DIAGNOSIS:

Input signal circuit of rear differential oil temperature switch is open or shorted.

TROUBLE SYMPTOM:

Center differential remains free

An oversteer tendency will become apparent.

Rear differential oil temperature warning light illuminates.

WIRING DIAGRAM:

MT-01838

R167

i102

R148

R159

B380

DCCD CM

4

0

5

B92 R5

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16

i10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

i102

B92

2 3 4 5 6 7 8 9

11 12 13 14 17 18 19 20

1

10 15 16

i10

12

8

E

COMBINATION

METER

REAR

DIFFERENTIAL

OIL TEMPERATURE

SWITCH

REF. TO GND

[GND-05]

6MT(diag)-32

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

Step Check Yes No

1 CHECK REAR DIFFERENTIAL OIL TEMPER-

ATURE SWITCH WARNING LIGHT CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the DCCD control module har-

ness connector.

3) Turn the ignition switch to ON.

4) Measure the voltage of the rear differential

oil temperature switch.

Connector & terminal

(B380) No. 5 (+) Chassis ground ():

Is the voltage less than 0.4 V? Go to step 6. Go to step 2.

2 CHECK HARNESS BETWEEN DCCD CON-

TROL MODULE AND COMBINATION

METER.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from the

combination meter.

3) Disconnect the connector from the rear dif-

ferential oil temperature switch.

4) Measure the resistance between combina-

tion meter and DCCD control module harness

connectors.

Connector & terminal

(B380) No. 5 (i10) No. 40:

Is resistance less than 1 ? Go to step 3. Repair the open

circuit between

DCCD control

module and the

combination meter.

3 CHECK HARNESS BETWEEN DCCD CON-

TROL MODULE AND REAR DIFFERENTIAL

OIL TEMPERATURE SWITCH.

Measure the resistance between DCCD control

module harness connector and rear differential

oil temperature switch harness connector.

Connector & terminal

(B380) No. 5 (R148) No. 1:

Is resistance less than 1 ? Go to step 4. Repair the open

circuit between

DCCD control

module and rear

differential oil tem-

perature switch.

4 CHECK REAR DIFFERENTIAL OIL TEMPER-

ATURE SWITCH GROUND CIRCUIT.

1) Disconnect the harness connector from the

bracket ground of the rear differential.

2) Measure the resistance between the rear

differential oil temperature switch ground har-

ness connector and chassis ground.

Connector & terminal

(R159) No. 1 Chassis ground:

Is the resistance1 M or more? Repair the open

circuit of the rear

differential oil tem-

perature ground

circuit, and contact

failure of the har-

ness connector.

Go to step 5.

5 CHECK REAR DIFFERENTIAL OIL TEMPER-

ATURE SWITCH.

Measure the resistance between the rear differ-

ential oil temperature switch and the rear differ-

ential oil temperature switch body.

Terminals

(R148) No. 1 Rear differential oil

temperature switch body:

Is resistance less than 1 ? Go to step 6. Replace the rear

differential oil tem-

perature switch.

6 CHECK REAR DIFFERENTIAL OIL TEMPER-

ATURE WARNING LIGHT.

1) Turn the ignition switch to ON.

2) Short the chassis ground and the combina-

tion meter harness connector.

Terminals

(i10) No. 40 (+) Chassis ground ():

Does the rear differential oil

temperature light turn OFF?

Check the poor

contact.

Check the combi-

nation meter.

6MT(diag)-33

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

B: CHECK PARKING BRAKE SWITCH

DIAGNOSIS:

Input signal circuit of parking brake switch is open or shorted.

TROUBLE SYMPTOM:

It does not show a differential free tendency even when the parking brake switch is applied.

Remains differential free even when the parking brake switch is released.

WIRING DIAGRAM:

MT-01767

B380 DCCD CM

2

B

9

B

3

1

8

B280 B: B281 C:

B281 C:

5 6 7

8

2 1

9

4 3

10

24 22 23 25

11 12 13 14 15

26 27 28

16 17 18 19

20 21

B99

R4

B99

R3

C

1

5

5

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

B280 B:

1 2 3 4 5 6

7 8 9 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26

1 2 3 4 5

6 7 8 9 10 11 12

BODY INTEGRATED UNIT

PARKING

BRAKE

SWITCH

6MT(diag)-34

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

Step Check Yes No

1 CHECK IGNITION CIRCUIT OF DCCD CON-

TROL MODULE.

1) Connect the Subaru Select Monitor to the

vehicle.

2) Turn the ignition switch to ON.

3) Read the data of Battery Voltage using the

Subaru Select Monitor.

Is the voltage 11 V or more? Go to step 2. Repair the open

circuit of harness

between fuse (F/B

No. 12) and DCCD

control module, or

between fuse (F/B

No. 12) and bat-

tery.

2 CHECK DTC. Is DTC P1720 displayed? Perform the diag-

nosis according to

DTC.

Go to step 3.

3 CHECK DCCD CONTROL MODULE.

1) Operate the parking brake lever.

2) Read the data of Parking Position Switch

using the Subaru Select Monitor.

Is the ON/OFF normally

detected?

The parking brake

switch circuit is

currently operating

properly.

Go to step 4.

4 CHECK THE BODY INTEGRATED UNIT.

1) Operate the parking brake lever.

2) Read the data of Parking Position Switch

using the Subaru Select Monitor.

Is the ON/OFF normally

detected?

Go to step 7. Go to step 5.

5 CHECK HARNESS BETWEEN BODY INTE-

GRATED UNIT AND PARKING BRAKE

SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from body inte-

grated unit.

3) Check for open circuit, short circuit to bat-

tery and short circuit to ground between the

body integrated unit connector and parking

brake switch connector.

Connector & terminal

(B281) No. 15 (R4) No. 1:

Is the harness normal? Go to step 6. Repair or replace

the harness.

6 CHECK PARKING BRAKE SWITCH.

Measure the resistance between parking brake

switch terminals.

Is the resistance less than 10

when the parking brake lever is

pulled?

Is the resistance 1 M or more

when the parking brake lever is

released?

Replace the body

integrated unit.

Replace the park-

ing brake switch.

7 CHECK DTC.

Check DTC of body integrated unit.

Is DTC related CAN displayed? Perform the diag-

nosis according to

DTC.

Check the poor

contact of DCCD

system.

6MT(diag)-35

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

C: CHECK DCCD MULTI SELECT SWITCH

DIAGNOSIS:

Input signal of DCCD multi select switch is open or shorted.

TROUBLE SYMPTOM:

Does not enter manual mode or AUTO mode when the mode change switch is pressed.

Mode does not change in AUTO mode.

Initial torque can not be changed in manual mode.

NOTE:

Other switch input can not be received if either mode change switch or C.DIFF +/ switch is stuck ON.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK CURRENT DATA.

1) Display the current data AUTO/MANUAL

Mode Switch of DCCD control module, using

Subaru Select Monitor.

2) Press the manual mode change switch.

Does the data change to OFF/

ON?

Go to step 2. Go to step 4.

2 CHECK CURRENT DATA.

1) Display the current data Up Switch of

DCCD control module, using Subaru Select

Monitor.

2) Push the multi select switch toward plus.

Does the data change to OFF/

ON?

Go to step 3. Go to step 5.

3 CHECK CURRENT DATA.

1) Display the current data Down Switch of

DCCD control module, using Subaru Select

Monitor.

2) Push the multi select switch toward minus.

Does the data change to OFF/

ON?

The switch circuit

is normal.

Go to step 6.

MT-01768

B380

1 2 3 4

17 18 19 20

5 6 7 8

21 22 23 24

9 10 11 12

25 26 27 28

13 14 15 16

29 30 31 32

B98

2 3 4 5 6 7 8 9

11 12 13 14 17 18 19 20

1

10 15 16

REF. TO GND

[GND-05]

B380 DCCD CM

6

2

2

4

R33

R2

B98

139

1

3

1

45

1

R33

1

5

2 3 4

6 7 8 9 10

2

E

MULTI SELECT SWITCH

(DCCD)

A

U

T

O

/

M

A

N

U

A

L

(

)

(

)

6MT(diag)-36

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

4 CHECK MODE CHANGE SWITCH.

1) Disconnect the multi select switch connec-

tor.

2) Press the mode change switch.

3) Using the tester, measure the resistance

between terminals.

Connector & terminal

(R33) No. 1 No. 9:

Is resistance less than 1 ? Go to step 7. Replace the multi

select switch.

<Ref. to FU(STI)-

48, SI-DRIVE

(Subaru Intelligent

Drive) Selector.>

5 CHECK MULTI SELECT SWITCH.

1) Push the multi select switch toward plus.

2) Using the tester, measure the resistance

between terminals.

Connector & terminal

(R33) No. 2 No. 9:

Is resistance less than 1 ? Go to step 7. Replace the multi

select switch.

<Ref. to FU(STI)-

48, SI-DRIVE

(Subaru Intelligent

Drive) Selector.>

6 CHECK MULTI SELECT SWITCH.

1) Push the multi select switch toward plus.

2) Using the tester, measure the resistance

between terminals.

Connector & terminal

(R33) No. 3 No. 9:

Is resistance less than 1 ? Go to step 7. Replace the multi

select switch.

<Ref. to FU(STI)-

48, SI-DRIVE

(Subaru Intelligent

Drive) Selector.>

7 CHECK HARNESS.

Use a tester to measure the resistance between

the multi select switch harness connector and

chassis ground.

Connector & terminal

(R33) No. 9 Chassis ground:

Is resistance less than 1 ? Go to step 8. Repair or replace

the ground circuit.

8 CHECK HARNESS.

1) Disconnect the DCCD control module con-

nector.

2) Use a tester to measure the resistance

between the DCCD control module and the

multi select switch.

Connector & terminal

(R33) No. 1 (B380) No. 6:

(R33) No. 2 (B380) No. 22:

(R33) No. 3 (B380) No. 4:

Is resistance less than 1 ? Go to step 9. Repair or replace

the open circuit of

the harness.

9 CHECK HARNESS.

Using the tester, measure the resistance

between terminals.

Connector & terminal

(R33) No. 1 (R33) No. 2:

(R33) No. 1 (R33) No. 3:

(R33) No. 3 (R33) No. 2:

Is the resistance 1 M or

more?

Go to step 10. Repair or replace

the short circuit of

the harness.

10 CHECK HARNESS.

Using the tester, measure the resistance

between terminals.

Connector & terminal

(R33) No. 1 Chassis ground:

(R33) No. 2 Chassis ground:

(R33) No. 3 Chassis ground:

Is the resistance 1 M or

more?

Check the poor

contact.

Repair or replace

the short circuit of

the harness.

Step Check Yes No

6MT(diag)-37

Diagnostics with Phenomenon

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

14.Diagnostics with Phenomenon

A: INSPECTION

Symptom Problem parts

A tight corner braking symptom occurs. VDCCM&H/U

ABS wheel speed sensor

Yaw rate & lateral G sensor

Steering angle sensor

CAN communication signal

Center differential

C.DIFF +/ switch

Mode change switch

Tire/Wheel

DCCD control module

ECM

Body integrated unit

An oversteer tendency will become apparent. Throttle position sensor

ECM

C.DIFF +/ switch

Mode change switch

Tire/Wheel

DCCD control module

Center differential

DCCD relay

Rear differential oil temperature switch

Neutral position switch

Steering angle sensor

VDCCM

CAN communication signal

Body integrated unit

Yaw rate & lateral G sensor

A tendency to understeer occurs during high speed cornering. VDCCM&H/U

ABS wheel speed sensor

CAN communication signal

Throttle position sensor

Yaw rate & lateral G sensor

Center differential

ECM

Engine speed signal

Neutral position switch

Steering angle sensor

Body integrated unit

Torque characteristics of the center differential do not change. C.DIFF +/ switch

DCCD relay

Center differential

DCCD control module

DCCD indicator does not operate. (is not displayed) Combination meter

DCCD control module

DCCD indicator does not operate even when the C.DIFF +/

switch is operated. (Displayed but does not change. or display

blinks.)

C.DIFF +/ switch

Combination meter

DCCD control module

DCCD AUTO mode does not operate even when the C.DIFF

+/ switch is operated. (Displayed but does not change. )

Mode change switch

Combination meter

DCCD control module

Body integrated unit

CAN communication signal

6MT(diag)-38

Diagnostics with Phenomenon

MANUAL TRANSMISSION AND DIFFERENTIAL (DIAGNOSTICS)

DCCD AUTO mode display does not illuminate. Mode change switch

Combination meter

DCCD control module

Body integrated unit

CAN communication signal

Will not become differential free or remains differential free Parking brake switch

Center differential

Mode change switch

C.DIFF +/ switch

Rear differential

Tire/Wheel

DCCD relay

Rear differential oil temperature switch

DCCD control module

ECM

Body integrated unit

VDCCM

Yaw rate & lateral G sensor

CAN communication signal

ABS does not operate. VDCCM&H/U

CAN communication signal

Stop light switch

DCCD control module

ECM

Body integrated unit

Yaw rate & lateral G sensor

Will not lock the differential. Or the differential is continually

locked.

VDCCM&H/U

ABS wheel speed sensor

CAN communication signal

Center differential

C.DIFF +/ switch

Mode change switch

Tire/Wheel

DCCD control module

DCCD relay

ECM

Body integrated unit

Yaw rate & lateral G sensor

Symptom Problem parts

You might also like

- Immobilizer (Diag)Document24 pagesImmobilizer (Diag)Benjamin Sheffer100% (3)

- 1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionDocument12 pages1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionwilliamNo ratings yet

- PrecheDocument3 pagesPrechePrayogi Sr.No ratings yet

- Manual Transmission and Differential (Diagnostics)Document38 pagesManual Transmission and Differential (Diagnostics)GURBZHNo ratings yet

- Alarmes SmartcraftDocument52 pagesAlarmes SmartcraftEdgar PinheiroNo ratings yet

- Function and Integration: Sensors and Electromechanical ComponentsDocument27 pagesFunction and Integration: Sensors and Electromechanical ComponentsjesusNo ratings yet

- 320 DisplayDocument217 pages320 DisplayAlex Consuegra MedinaNo ratings yet

- HGM1770Document16 pagesHGM1770Thao Nguyen XuanNo ratings yet

- MSB 97e17 502 PDFDocument10 pagesMSB 97e17 502 PDFAutof FerreiraNo ratings yet

- 312A PumpDocument202 pages312A Pumpsamir kadriNo ratings yet

- 07 DiagnosticsDocument132 pages07 DiagnosticsJosué Soldera100% (2)

- Mase at 92B: Automatic Control PanelDocument13 pagesMase at 92B: Automatic Control Paneltzapore23No ratings yet

- CX-5 - DriveLine AxleDocument181 pagesCX-5 - DriveLine AxleJuan ManuelNo ratings yet

- 2008 CX 9 ServiceManualDocument2,589 pages2008 CX 9 ServiceManualJacob SolomonNo ratings yet

- DND9000Document97 pagesDND9000Michael MinehartNo ratings yet

- mazda-ABS LED DiagnosisDocument19 pagesmazda-ABS LED DiagnosisTudorMătrescu100% (3)

- Diagnostico Parte 1 MalibuDocument161 pagesDiagnostico Parte 1 MalibuHugo Armando Escamilla LozanoNo ratings yet

- DTC P0776 / P0777 DTC Detecting Condition and Trouble AreaDocument5 pagesDTC P0776 / P0777 DTC Detecting Condition and Trouble Areajorge luis guevara martinezNo ratings yet

- New Fault Codes ModelDocument156 pagesNew Fault Codes ModelIzz Bahar92% (13)

- 3408E Engine Emissions Retrofit Repower Tier II For 988F Series II and 988F Wheel Loader 8YG00001-UP (MACHINE) (SEBP4379 - 19) - DocumentationDocument59 pages3408E Engine Emissions Retrofit Repower Tier II For 988F Series II and 988F Wheel Loader 8YG00001-UP (MACHINE) (SEBP4379 - 19) - Documentationelias aguirreNo ratings yet

- 2007 Civic Hybrid SystemDocument188 pages2007 Civic Hybrid SystemAngel Valladares67% (3)

- EcDocument11 pagesEcFrancesca Ackumbur0% (1)

- GR00003400C 23aDocument178 pagesGR00003400C 23aJe RelNo ratings yet

- Prueba y Ajust Sistema ElectronicoDocument52 pagesPrueba y Ajust Sistema ElectronicoIginio Malaver VargasNo ratings yet

- BrakeDocument263 pagesBrakeSatish DevisettiNo ratings yet

- P0138 DiagnosisDocument11 pagesP0138 DiagnosisWaqas HaiderNo ratings yet

- Troublesshooting Manual 3b6 PDFDocument50 pagesTroublesshooting Manual 3b6 PDFAugusto Oliveira86% (21)

- Testeoajuste320l PDFDocument222 pagesTesteoajuste320l PDFJimmyJavierTorresSalas100% (1)

- Cdr-4Mps / Cdr-8Mps Users Guide: CDR Series Revision Date: 07/12/06Document27 pagesCdr-4Mps / Cdr-8Mps Users Guide: CDR Series Revision Date: 07/12/06Vlad PkNo ratings yet

- Terra CanDocument530 pagesTerra CanEduardo FloresNo ratings yet

- Old Elec SpeedoDocument7 pagesOld Elec SpeedoDony AvaterNo ratings yet

- Wjcs-Ii Microcomputer System Technical Instructions: I. OverviewDocument12 pagesWjcs-Ii Microcomputer System Technical Instructions: I. OverviewQuangNo ratings yet

- Pin On Disk Tribometer ManualDocument53 pagesPin On Disk Tribometer Manualanhntran4850100% (1)

- Workshop Manual - Steering: 2013 - CX-5 On-Board DiagnosticsDocument112 pagesWorkshop Manual - Steering: 2013 - CX-5 On-Board DiagnosticsNuttapong Sukgan100% (1)

- Abs Highlander 3Document3 pagesAbs Highlander 3Cristian JaramilloNo ratings yet

- 2007 Honda CivicDocument5,048 pages2007 Honda CivicFabius Montanus84% (19)

- 2005 Honda Odyssey Auto TransDocument529 pages2005 Honda Odyssey Auto Transcnn9088% (8)

- Testing & Adjusting Cat - Dcs.sis - Controller PDFDocument179 pagesTesting & Adjusting Cat - Dcs.sis - Controller PDFmnlar100% (7)

- Tc-2060 Instruction Manual v0.09Document93 pagesTc-2060 Instruction Manual v0.09Herry SusiloNo ratings yet

- 07 - Tfaw3 We 0431Document266 pages07 - Tfaw3 We 0431jrrodrigueza2100% (2)

- CruiseControl Diagnostics2004 PDFDocument48 pagesCruiseControl Diagnostics2004 PDFDanno NNo ratings yet

- Curso DTCDocument82 pagesCurso DTCingenierognvNo ratings yet

- Topeak Panoram V10c ManualDocument2 pagesTopeak Panoram V10c ManualModina Vince CarbonNo ratings yet

- Instrument Panel PDFDocument54 pagesInstrument Panel PDFred eagle winsNo ratings yet

- General Information: Construction DiagramDocument27 pagesGeneral Information: Construction Diagram123Ginodem100% (1)

- TS Mounting InstructionDocument28 pagesTS Mounting InstructionLinweiXiaNo ratings yet

- Model: Service ManualDocument49 pagesModel: Service ManualJose Mosqueda CortesNo ratings yet

- Wind TrackerDocument6 pagesWind TrackercatrionakangNo ratings yet

- Tea Sensor de VelocidadeDocument6 pagesTea Sensor de VelocidadeValmaq Prestação Serviço LdaNo ratings yet

- Diagrama Electrico de Transmcion 160HDocument4 pagesDiagrama Electrico de Transmcion 160HJuan CarlosNo ratings yet

- Defecte Cutie AutomataDocument134 pagesDefecte Cutie AutomataGoranka Bulatovic Ilic100% (1)

- 01-69 Central Locking System OBDDocument55 pages01-69 Central Locking System OBDmink4uNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Industrial Machinery World Summary: Market Values & Financials by CountryFrom EverandIndustrial Machinery World Summary: Market Values & Financials by CountryNo ratings yet

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- ISTR 10-1 (PVC Roll-Up Ventilation Door Instruction Manual)Document32 pagesISTR 10-1 (PVC Roll-Up Ventilation Door Instruction Manual)JuniorNo ratings yet

- f430 Owners ManualDocument134 pagesf430 Owners ManualКонстантин Хороший100% (1)

- DFL1160 999系列 (KD5K) 使用手册 ENDocument115 pagesDFL1160 999系列 (KD5K) 使用手册 ENlocario1No ratings yet

- 2013 Ford Fiesta 1.6l Sohc Fluid CapacitiesDocument1 page2013 Ford Fiesta 1.6l Sohc Fluid CapacitiesRubenNo ratings yet

- ContinueDocument2 pagesContinueTaufik NurhidayatNo ratings yet

- BA Axor 940 09-17 en GBDocument280 pagesBA Axor 940 09-17 en GBAlvin RamarajuNo ratings yet

- Interruptores InteligentesDocument12 pagesInterruptores InteligentesedgarwalterNo ratings yet

- Manual de Servico XR400R 96-04Document276 pagesManual de Servico XR400R 96-04viniwiermann100% (1)

- Engine, Removing and Installing: Special Tools and EquipmentDocument20 pagesEngine, Removing and Installing: Special Tools and Equipmentifu62319No ratings yet

- Porsche 911 Brochure Full DetailsDocument88 pagesPorsche 911 Brochure Full DetailsKuldeep YadavNo ratings yet

- Peugeot 807Document234 pagesPeugeot 807Adam OlowNo ratings yet

- Cat Forklift Dpl40 Service Operation Maintenance ManualDocument28 pagesCat Forklift Dpl40 Service Operation Maintenance Manualxycedfsf100% (35)

- Operators Manual 5610 PDFDocument63 pagesOperators Manual 5610 PDFCarlos Alberto Rueda100% (1)

- Assembling and Testing Manual TransmissionDocument66 pagesAssembling and Testing Manual TransmissionTesda Ptc Malilipot100% (3)

- Blue Bird All American Owner Manual PDFDocument104 pagesBlue Bird All American Owner Manual PDFJörgen Mannberg67% (3)

- Background of Manual TransmissionDocument3 pagesBackground of Manual TransmissionAlgie PlondayaNo ratings yet

- Development of Two-Speed Dual-Clutch Transmission For Seamless Gear Shifting in EVsDocument9 pagesDevelopment of Two-Speed Dual-Clutch Transmission For Seamless Gear Shifting in EVsThiên ThanhNo ratings yet

- EatonDocument143 pagesEatonBrayandPach100% (1)

- Cordona GP Switch 2009 PDFDocument2 pagesCordona GP Switch 2009 PDFBagus Prasti RamdhaniNo ratings yet

- 2009-12-29 224215 01 Escape Steering Squeek TSB 06-23-03Document2 pages2009-12-29 224215 01 Escape Steering Squeek TSB 06-23-03Randy SmithNo ratings yet

- Euro III BH117L Service Manual 1st January 2006 PDFDocument329 pagesEuro III BH117L Service Manual 1st January 2006 PDFKhom JeknokNo ratings yet

- Silnik A490 XinchaiDocument40 pagesSilnik A490 XinchaiTomaszNo ratings yet

- STOPPING DISTANCE TEST PROCEDURE - Saej299v001Document4 pagesSTOPPING DISTANCE TEST PROCEDURE - Saej299v001wilian_coelho3309100% (1)

- Body Repair Manual PDFDocument170 pagesBody Repair Manual PDF2663bNo ratings yet

- (TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 501-600Document100 pages(TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 501-600LUIS HERNANDONo ratings yet

- CX New EngineDocument68 pagesCX New Enginehelp3r100% (1)

- 343R 345RX 343F 345FX 345FXT: Workshop ManualDocument63 pages343R 345RX 343F 345FX 345FXT: Workshop ManualandrasorNo ratings yet

- Mitsubishi Automatic Transmission 5a51 Service ManualDocument10 pagesMitsubishi Automatic Transmission 5a51 Service ManualKaitlyn100% (51)

- Design of An Automatic Gear-Shifter For BicycleDocument32 pagesDesign of An Automatic Gear-Shifter For BicycleJohn Rafael AtienzaNo ratings yet

- Still Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts Manualhannah100% (47)