Professional Documents

Culture Documents

Res 3

Uploaded by

neonapcanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Res 3

Uploaded by

neonapcanCopyright:

Available Formats

Wind Power and Wind Power Plant

Captured Wind Power (Mechanical Power)

Wind turbines cannot convert whole wind kinetic energy into mechanical energy.

Therefore if difference between input and output wind kinetic energy is calculated, the mechanical energy is found which is converted by blades.

1 2 vi2 vo Pk m 2

vi vi

Rzgar kanal k

Rzgar kanal girii

Pk : Mechanical power which is captured by blades

Input Wind Speed : Output Wind Speed : Wind speed in the blades plane ( ) =

+ 2 1 2

vk

vo vo

vk

Rotor Alan, A

If these insert into Pk, the formula turns into; = . . A . 3 .

Herein : efficiency of turbine.

Captured Wind Power (Mechanical Power)

Cp, Efficiency of Turbine

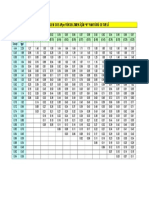

0,7 0,6 0,5 0,4 Cp 0,3 0,2 0,1 0 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

Blade efficiency decreases, because of turbulence effect when rotor spins so fast, or else because of missing wind increase when rotor spins so slow. Top Speed Ratio (TSR) is used as a function when blade efficiency is computed. =

=o/

ekil : Changing in Cp with

RRotor

. = = Rotor Diameter [m]

As it can be seen from here maximum efficiency of turbine is %59,26. This is known as Betz limit. German physicist Albert Betz is inventor of this limit.

= 2 Mechanical (Blade) Angular Speed [rad/s] Wind Speed[m/s] Linear Speed of Blades [m/s] Spinning Frequency[1/s, Hz]

Captured Wind Power (Mechanical Power)

cp

30

EXAMPLE: When wind speed is 15 m/s , rotor radius is 10m and duration of full turn is 1 second for a blade, compute the TSR.

KHO

Figure: Change in Cp and TSR for a Wind Turbine

Curves can be so different for several rotor and blade types.

Generally as an experiential expression, optimum TSR for

maximum power is, max = Herein is the number of blades.

4

NOTE: , mechanical angular velocity can be written as a function of rotor speed: 2 = 60 Note: = , = min() = 60 [ ] Herein, rpm

Captured Wind Power (Mechanical Power)

EXAMPLE: A wind turbine with 3 blades, has a rotor diameter as 30m and produces 250kW at 12m/s wind speed ;

a) When TSR=4.0 , compute the n . (rpm) b) What is the tip speed of rotor blades ? (m/s).

c) If generator needs 1500 rpm, compute the gear box ratio to synchronize rotor speed to generator speed.

d) Compute the efficiency for wind turbine.

SOLUTION:

Captured Wind Power (Mechanical Power)

EXAMPLE: A horizontal-axis wind turbine's rotor diameter is 30m, reaches its highest efficiency. According to this, calculate the turbine speed at related wind speed ?

SOLUTION:

EXAMPLE :Nominal gc 1.5 MW olan 2 kanatl ve yatay eksenli bir rzgr enerji santralnn genel sistem verimi %30 olarak llmtr. Rzgr trbini nominal gcne standart hava artlar altnda ve 12 m/s rzgr hznda ulamaktadr. Buna gre trbinin rotor ap ka metredir?

SOLUTION :

Torque and Power in Wind Turbines

Kanatlar YK/EBEKE TARAFI

Some of wind turbines are connected to grid directly and some of them are connected via gear box. = [ ]

= / =

Herein, torque occurs at the shaft which is connected to rotor.

Pg

Pt=Pm

Pw

Tt=Tm

r

Kanatlar

Pg

Pm Pt

YK/EBEKE TARAFI

Pw

Tt

Dili Kutusu

Tm

= 3 /2 This formula gives torsional stress when T torque is implemented to a cylindrical mass of which radius is r .

Torque and Power in Wind Turbines

EXAMPLE: A wind turbine of which nominal power is 0.9 MW and efficiency is %34, reaches his nominal power at 11 m/s (wind speed) when its rpm is 20. Horizontal-axis wind turbine shaft is designed to withstand a torsional stress as 35000 kN/m2, so; a.) Compute TSR values under standard atmospheric conditions. b.) When generator efficiency is %95 and gear box efficiency is %80, calculate the torque which occurs at turbine shaft. In this case, compute the cross-section of shaft. SOLUTION:

System Efficiency of Wind Turbines

Pw TRBN Cp Pt MEKANK LETM Pm GENERATR Pg

ELEKTRKSEL LETM

Pe

Table. Efficiencies of Some Wind Turbine Part

= = = = = = =

WES COMPONENTS Blade Gear Box Generator Transmission

EFFICIENCY Small Scale System Big Scale System 20%-40% 70%-80% 65%-85% 90%-98% 40%-50% 80%-95% 85%-95% 90%-98%

STATISTICAL ANALYSIS OF WIND DATA AND ENERGY PREDICTION OF WIND ENERGY

Average Wind Power : o Wind turbines are exposed to different wind speeds so wind power is generated, thats why average wind power is needed. o Average wind power can not be computed writing = in , because of there is a cubic relationship between wind speed and power. 1 1 3 = = 3 2 2 o As it can be seen, average of (v3) is needed, instead of speed.

( ) ( 3 )

3

STATISTICAL ANALYSIS OF WIND DATA AND ENERGY PREDICTION OF WIND ENERGY

Montly Wind Histogram: Mean Value : When mean value of blowing wind in a region, total covered distance by wind is divided by total time. = For example, assume measurements of a region are like that ;

Time(s) 20 30 30 20 Wind Speed(m/s) No Wind 6 12 15

20 0 +30 6 +30 12 +20 15 20+30+30+20 840 = = 8.4 [/] 100

We can calculate this in a different way ; =

20 100

30 100

12

30 100 20 100

6 15

= 8.4 /

STATISTICAL ANALYSIS OF WIND DATA AND ENERGY PREDICTION OF WIND ENERGY

In the perspective of probability; Probability of No wind case is 0,2 Probability of Wind Speed being 6 m/s is 0,3 Probability of Wind Speed being 12 m/s is 0,3 Probability of Wind Speed being 15 m/s is 0,2 In this case, mean value can be written in terms of probability. =

[

We can write the expression which is stated above, in a general form; [ ] = = ( )

P( = )]

If we write average of (v3)

3

3 = = [ 3 [ P( = )] [ 3

STATISTICAL ANALYSIS OF WIND DATA AND ENERGY PREDICTION OF WIND ENERGY

EXAMPLE: Compute the mean wind speed and power (w/m2) using data table which is given below . Calculate wind power for and 3 , when standard air density is 1.225 kg/m3 and compare the results.

V (m/s) Hour/year V (m/s) Hour/year 0 24 13 240 1 276 14 170 2 527 15 114 3 729 16 76 4 869 17 46 5 941 18 28 6 946 19 16 7 896 20 9 8 805 21 5 9 690 22 3 10 565 23 1 11 444 24 1 12 335 25 0

SOLUTION:

STATISTICAL ANALYSIS OF WIND DATA AND ENERGY PREDICTION OF WIND ENERGY

Wind Speed (m/s), vi 0 1 2 3 . 25 TOTAL Time Ratio in a (h/year) Year 24 276 527 729 . 0 8760 0,0027 0,0315 0,0602 0,0832 . 0 Vi x (Ratio (vi)3 X (Ratio in a Year) in a Year) 0 0,0315 0,120 0,250 . 0 =7 0 0,0315 0,48 2,25 . 0 3 =653.2 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter S1 (Celestial Timekeeping and Navigation)Document28 pagesChapter S1 (Celestial Timekeeping and Navigation)Марко Д. Станковић0% (1)

- Derivative IntegralsDocument1 pageDerivative IntegralsDerek_Chandler_214No ratings yet

- Siemens Selectivity-Tables - 06 - 2017 - en - 201706280824366428Document115 pagesSiemens Selectivity-Tables - 06 - 2017 - en - 201706280824366428neonapcanNo ratings yet

- Acti 9 Smartlink SI D - A9MEM1522Document2 pagesActi 9 Smartlink SI D - A9MEM1522neonapcanNo ratings yet

- FRECON Solar Pump Solution 2016 en V1 0.1Document23 pagesFRECON Solar Pump Solution 2016 en V1 0.1neonapcanNo ratings yet

- CHAPTER 9 Room Ventilation SystemsDocument6 pagesCHAPTER 9 Room Ventilation SystemsJuan IntriagoNo ratings yet

- Asfora EPH5600121Document2 pagesAsfora EPH5600121neonapcanNo ratings yet

- EP C TT1 1 TT 275 05.04.07en 01Document2 pagesEP C TT1 1 TT 275 05.04.07en 01neonapcanNo ratings yet

- 0cde89544caa549 EkDocument1 page0cde89544caa549 EkneonapcanNo ratings yet

- Transformer Impedance Tutorial PDFDocument1 pageTransformer Impedance Tutorial PDFJoe TeddyNo ratings yet

- Topic1 MechatronicsIntroductionDocument16 pagesTopic1 MechatronicsIntroductionneonapcanNo ratings yet

- Diversity FactorDocument3 pagesDiversity FactorgafscottNo ratings yet

- Matlab DersleriDocument61 pagesMatlab DersleriyureklikNo ratings yet

- Renewable Energy Systems: Prof. Dr. Muğdeşem TANRIÖVENDocument9 pagesRenewable Energy Systems: Prof. Dr. Muğdeşem TANRIÖVENneonapcanNo ratings yet

- Res 1Document18 pagesRes 1neonapcanNo ratings yet

- ReadmeDocument2 pagesReadmeKenichi EitaquNo ratings yet

- Res 2Document17 pagesRes 2neonapcanNo ratings yet

- TRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateDocument4 pagesTRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateCarlo OlivarNo ratings yet

- Altos Easystore Users ManualDocument169 pagesAltos Easystore Users ManualSebNo ratings yet

- Schermer 1984Document25 pagesSchermer 1984Pedro VeraNo ratings yet

- How To Make An Effective PowerPoint PresentationDocument12 pagesHow To Make An Effective PowerPoint PresentationZach Hansen100% (1)

- Note Hand-Soldering eDocument8 pagesNote Hand-Soldering emicpreampNo ratings yet

- Reflective Memo 1-PracticumDocument5 pagesReflective Memo 1-Practicumapi-400515862No ratings yet

- Different Principles Tools and Techniques in Creating A BusinessDocument5 pagesDifferent Principles Tools and Techniques in Creating A BusinessLuna LedezmaNo ratings yet

- Work Permits New Guideline Amendments 2021 23.11.2021Document7 pagesWork Permits New Guideline Amendments 2021 23.11.2021Sabrina BrathwaiteNo ratings yet

- Alufix Slab Formwork Tim PDFDocument18 pagesAlufix Slab Formwork Tim PDFMae FalcunitinNo ratings yet

- Chalcedony Value, Price, and Jewelry Information - International Gem SocietyDocument8 pagesChalcedony Value, Price, and Jewelry Information - International Gem Societyasset68No ratings yet

- Performance Evaluation of The KVM Hypervisor Running On Arm-Based Single-Board ComputersDocument18 pagesPerformance Evaluation of The KVM Hypervisor Running On Arm-Based Single-Board ComputersAIRCC - IJCNCNo ratings yet

- 16-ELS-Final-Module 16-08082020Document18 pages16-ELS-Final-Module 16-08082020jeseca cincoNo ratings yet

- Credit CardDocument6 pagesCredit CardJ Boy LipayonNo ratings yet

- Manual TV Hyundai HYLED3239iNTMDocument40 pagesManual TV Hyundai HYLED3239iNTMReinaldo TorresNo ratings yet

- Certificate of Attendance: Yosapat NashulahDocument2 pagesCertificate of Attendance: Yosapat NashulahStrata WebNo ratings yet

- Weekly Lesson Plan: Pry 3 (8years) Third Term Week 1Document12 pagesWeekly Lesson Plan: Pry 3 (8years) Third Term Week 1Kunbi Santos-ArinzeNo ratings yet

- HC+ Shoring System ScaffoldDocument31 pagesHC+ Shoring System ScaffoldShafiqNo ratings yet

- State Farm Claims: PO Box 52250 Phoenix AZ 85072-2250Document2 pagesState Farm Claims: PO Box 52250 Phoenix AZ 85072-2250georgia ann polley-yatesNo ratings yet

- IGCSE 0408 Unseen Poem QuestionsDocument5 pagesIGCSE 0408 Unseen Poem QuestionsMenon HariNo ratings yet

- Ziarek - The Force of ArtDocument233 pagesZiarek - The Force of ArtVero MenaNo ratings yet

- 4D Beijing (Muslim) CHINA MATTA Fair PackageDocument1 page4D Beijing (Muslim) CHINA MATTA Fair PackageSedunia TravelNo ratings yet

- Previous Papers GPSC Veterinary Officer AHI Advt. No. 33 2016 17 Date of Preliminary Test 08 01 2017 Subject Concerned Subject Que 101 To 300 Provisional Key PDFDocument18 pagesPrevious Papers GPSC Veterinary Officer AHI Advt. No. 33 2016 17 Date of Preliminary Test 08 01 2017 Subject Concerned Subject Que 101 To 300 Provisional Key PDFDrRameem Bloch100% (1)

- BBAG MPR and STR LISTSDocument25 pagesBBAG MPR and STR LISTShimanshu ranjanNo ratings yet

- Lecture 1 Electrolyte ImbalanceDocument15 pagesLecture 1 Electrolyte ImbalanceSajib Chandra RoyNo ratings yet

- IELTS Material Writing 1Document112 pagesIELTS Material Writing 1Lê hoàng anhNo ratings yet

- Newcastle University Dissertation FormatDocument6 pagesNewcastle University Dissertation FormatWriteMyEnglishPaperForMeSterlingHeights100% (1)

- Financial Management of Public Sector Unit (PSU) - NotesDocument23 pagesFinancial Management of Public Sector Unit (PSU) - Notesbiz19100% (1)

- PMDG 737NGX Tutorial 2 PDFDocument148 pagesPMDG 737NGX Tutorial 2 PDFMatt HenryNo ratings yet

- دور أخلاقيات الأعمال في تحسين أداء المنظماتDocument14 pagesدور أخلاقيات الأعمال في تحسين أداء المنظماتChaima LaifaNo ratings yet