Professional Documents

Culture Documents

Raincheck Brochure

Uploaded by

Nandini SCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raincheck Brochure

Uploaded by

Nandini SCopyright:

Available Formats

Acoustic Damping for Metal Profile Ceilings

BB93 Solution HTM 08 01 Solution

Introduction

Benefits

Introduction Acoustic innovators, Sound Reduction Systems Ltd, in association with DEDPAN Technology, have developed the perfect acoustic damping material to reduce the noise generated by rain falling on metal profiled roofing systems. Rain falling on these types of roofs causes a nuisance in many different environments, ranging from commercial offices to industrial factory units. The problem has been highlighted in the BB93 design guide on acoustics within schools. Referring specifically to the issue mentioned above, the guidance of BB93 is to provide damping of the profiled cladding (e.g. using commercial damping materials). The problem of rain noise on profiled metal roofing systems is a well documented one, yet a test procedure to measure rain noise in the laboratory was only officially published in 2006. BS EN ISO 140-18 outlines a method of simulating rainfall under ideal conditions, using a water tank with a perforated base suspended above the test specimen, with a receiver room below. The application of Raincheck provides significant improvements to the overall roofing system under these test conditions. SRS Raincheck is the perfect solution to the issue of rain noise in commercial, industrial and educational environments. Should you require further details, or to discuss your particular application in greater detail, please feel free to contact our industry leading technical team on 01204 380074 or email info@soundreduction.co.uk A Raincheck demo is available to view on our You Tube Channel: www.youtube.com/soundreduction

BB93 Solution to rain noise in schools 08 01 Solution to rain noise in HTM healthcare buildings Improves learning and working conditions rain noise through all metal Reduces profile roofs

Manufactured in association with Technology

Supplied in self adhesive rolls and strips Extremely high performance for both New Build and Ideal Retro-fit installations Only 1mm thick

Tested to BS EN ISO 140-18

Installation

Installation

Prior to installation, it is essential that the surface to be treated with Raincheck is clean and dry. Raincheck is quickly and easily installed on the metal profiled sections. Simply remove a section of the backing paper and adhere the Raincheck strip to the metal profile. The lightweight, flexible material will easily mould to the contours of the roofing system. Work your way along the profile in small stages, removing small sections of the backing paper and compressing the rain check material to the profile as you go. Ensure that there are no air pockets in the material. If an air pocket develops, you can burst the pocket with a trimming knife and press the material back down. Moderate hand pressure should be fine to achieve a good bond, however, if a stronger bond is required, a hand roller can be used to ensure a more even application of pressure across the surface of the Raincheck. For the best results, SRS recommend that a surface area equivalent to 60% of the total roof size is treated with the Raincheck product, using an even distribution of the material across the space. PHYSICAL PROPERTIES: Colour: Green Weight: 1.90Kg/m Flexibility

2

Acoustic Performance:

Plots of Sound Intensity Level

BS EN ISO 140-18:2006 outlines a method of simulating rainfall under laboratory conditions using a water tank with a perforated base, suspended above a test specimen. Measurements are taken below the specimen within the receiving -12 room to assess the sound intensity level re 10 W/m2 (dB). The lower the sound intensity level within the receiver room, the greater the effect of the damping material. In the acoustic tests below, measurements of sound intensity for each type of rain condition were made directly in accordance with BS EN ISO 15186-1:1997 and BS EN ISO 140-18:2006. Test subject : (3.7m2) 5no 400 x 2102mm, 0.9mm gauge, 3.5kg/m2, ribbed aluminium standing seam roof with stucco emboss installed at a pitch of 7 below the water tank. Test Reference: WS219329

Heavy Rainfall - Simulated conditions for rainfall that occurs every 50 years

Moderate Rainfall - Simulated conditions of rainfall that occurs every 2 years

Adhesive Type: Acrylic P.S Flexible to 5oC

Structure Untreated Roof

Roof with 164mm Raincheck/40% roof coverage Roof with 246mm Raincheck/60% roof coverage

(bent around a 30mm mandrel):

Thickness: 1.0mm Maximum Temperature Tolerance: 190oC (short exposures) Flammability: Pass FMVSS 302

A-Weighted Sound Intensity Level LiA (dB) Heavy Rain Moderate Rain 70.6 54.1 66.0 49.4 64.3 48.1

The SRS Raincheck Challenge

1 Hold a tin can by the ring pull at the top and use a hard object, such as an item of metal cutlery or a metal pen to strike the can. You will clearly be able to hear the tinny sound of the can resonating in the room.

Remove the backing paper and apply the Raincheck strip around the middle of the can.

3 Striking the can with only a very small percentage of total surface area treated with Raincheck produces an extremely different effect. The damping effect of Raincheck dramatically reduces the vibration of the can, producing a very dull thud.

Sound Reduction Systems Ltd Adam St, Off Lever St, Bolton BL3 2AP Tel: +44 (0)1204 380074 Fax: +44 (0)1204 380957 E-mail: info@soundreduction.co.uk Web: www.soundreduction.co.uk

Site conditions and installation standards vary. SRS cannot take responsibility for the performance of any installed system of which SRS products are only a part, or that have been installed incorrectly. Prior to installation, it is necessary to identify and eliminate possible flanking paths that may compromise the acoustic performance of any SRS product.

You might also like

- Sound Attenuators LeafletDocument7 pagesSound Attenuators LeafletSundar Ramasamy0% (1)

- Rigidal Systems Standing Seam Roofing2 File000761Document12 pagesRigidal Systems Standing Seam Roofing2 File000761muradali01No ratings yet

- COM-BLD SSR24 Installation ManualDocument94 pagesCOM-BLD SSR24 Installation ManualAelfwine EinshpiedNo ratings yet

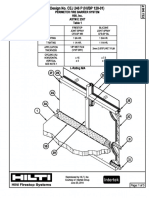

- Hilti Firestop DesignDocument3 pagesHilti Firestop DesignAristo OnanNo ratings yet

- Soundproofing Solutions-En 2019 02 PDFDocument182 pagesSoundproofing Solutions-En 2019 02 PDFTanase MariusNo ratings yet

- White Book C04 Partitions Section 3Document180 pagesWhite Book C04 Partitions Section 3Chris FindlayNo ratings yet

- Effectiveness of en 12354-6Document6 pagesEffectiveness of en 12354-6Neeskens D'melloNo ratings yet

- HSE-Acoustic & Fire DoorsDocument6 pagesHSE-Acoustic & Fire DoorsInterior ProjectsNo ratings yet

- Sound Insulation - NRCDocument372 pagesSound Insulation - NRCKhader Abu-daggaNo ratings yet

- INM 7.0 User's GuideDocument449 pagesINM 7.0 User's Guidepepeluis666No ratings yet

- ATSL Brochure (201310)Document30 pagesATSL Brochure (201310)dgtdejanNo ratings yet

- Bridal Buyer Nov Dic 2012Document84 pagesBridal Buyer Nov Dic 2012mohzgoNo ratings yet

- Fsi Window SystemsDocument144 pagesFsi Window SystemsFrederico FerreiraNo ratings yet

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Document2 pages55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNo ratings yet

- Louvres Bro enDocument84 pagesLouvres Bro entagiriNo ratings yet

- VEDAFEU Fire Barrier SystemsDocument32 pagesVEDAFEU Fire Barrier SystemsShyam AwalNo ratings yet

- Tetra Tech Sound Vibration Analysis 201704Document86 pagesTetra Tech Sound Vibration Analysis 201704OpgcNo ratings yet

- Silencer PRINTDocument2 pagesSilencer PRINTChandima WijesekeraNo ratings yet

- Stretch Ceiling SystemsDocument16 pagesStretch Ceiling SystemsDan CristeaNo ratings yet

- Acoustical Products For Interior Walls and Ceilings: Better Architecture Through Better AcousticsDocument8 pagesAcoustical Products For Interior Walls and Ceilings: Better Architecture Through Better AcousticsSham Salonga PascualNo ratings yet

- Acoustic Absorption Characterization and Prediction of Natural Coir FibersDocument11 pagesAcoustic Absorption Characterization and Prediction of Natural Coir FibersUty VictoriaNo ratings yet

- Sheet Steel Facts 16Document4 pagesSheet Steel Facts 16Giordano VieiraNo ratings yet

- 1 ISTIQ Acoustic DoorDocument6 pages1 ISTIQ Acoustic DoorjaladimudaNo ratings yet

- Academic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportDocument23 pagesAcademic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportNeeskens D'melloNo ratings yet

- Shure Headphone Brochure 2010Document6 pagesShure Headphone Brochure 2010Angelic__DemonNo ratings yet

- Advanced Integrity Testing For Roofing and Water ProofingDocument10 pagesAdvanced Integrity Testing For Roofing and Water ProofingHARSHALNo ratings yet

- Acoustic Catalog 0109Document63 pagesAcoustic Catalog 0109Socaciu VioricaNo ratings yet

- Acoustic Emission TestingDocument6 pagesAcoustic Emission TestingJaneswar PrabhakarNo ratings yet

- Acoustics lesson 3 overviewDocument43 pagesAcoustics lesson 3 overviewSyed Basith MNo ratings yet

- Articulation IndexDocument5 pagesArticulation IndexaniketkoliNo ratings yet

- As 1277-1983 Acoustics - Measurement Procedures For Ducted SilencersDocument8 pagesAs 1277-1983 Acoustics - Measurement Procedures For Ducted SilencersSAI Global - APACNo ratings yet

- Airborne Sound InsulationDocument118 pagesAirborne Sound InsulationJohn LinnonNo ratings yet

- Fire Stop Fischer - Comparacion Fischer - HiltiDocument10 pagesFire Stop Fischer - Comparacion Fischer - HiltiduraeduNo ratings yet

- Concealed HingesDocument86 pagesConcealed HingesTeth ConcioNo ratings yet

- BD Systems Brochure 2016 05Document164 pagesBD Systems Brochure 2016 05Rajat KatyalNo ratings yet

- BuildingMaterialsPropertiesPerformanceandApplications 1 PDFDocument422 pagesBuildingMaterialsPropertiesPerformanceandApplications 1 PDFminkhangNo ratings yet

- Acoustical Considerations For Hotels and Hostels As Per NBCDocument10 pagesAcoustical Considerations For Hotels and Hostels As Per NBCashNo ratings yet

- Optimal Design of Acoustic Metamaterial of MultiplDocument20 pagesOptimal Design of Acoustic Metamaterial of Multiplxavi alonsoNo ratings yet

- TGD Part EDocument88 pagesTGD Part EOlivia SaferNo ratings yet

- Airborne Sound Insulation CalculatorDocument2 pagesAirborne Sound Insulation CalculatorApril Dagli DiestroNo ratings yet

- 20160401b33d44-Scyon Axon Installation Manual May 2015 v2 FADocument8 pages20160401b33d44-Scyon Axon Installation Manual May 2015 v2 FAarhivojkanNo ratings yet

- Acoustic EnclosureDocument11 pagesAcoustic EnclosurempwasaNo ratings yet

- BS en 22553 1995Document59 pagesBS en 22553 1995sourav bohrayNo ratings yet

- ZNR-22 Zinsser Mold Killing PrimerDocument2 pagesZNR-22 Zinsser Mold Killing PrimerAjay PanchalNo ratings yet

- Pressed Steel Door: By: Ar. Amandeep KaurDocument12 pagesPressed Steel Door: By: Ar. Amandeep KaurTushar VarshneyNo ratings yet

- C008 - Quiet Revolution Noise Statement 20100803v1Document15 pagesC008 - Quiet Revolution Noise Statement 20100803v1Roland PetersNo ratings yet

- NoiseControl Brochure 30-29-121Document40 pagesNoiseControl Brochure 30-29-121fostbarrNo ratings yet

- 7-Arc 103Document204 pages7-Arc 103Igor VasiljevicNo ratings yet

- Kenneth Kaliski Slides 6.7.11Document21 pagesKenneth Kaliski Slides 6.7.11Northeast Wind Resource Center (NWRC)No ratings yet

- Aqua Silencer Report 2Document25 pagesAqua Silencer Report 2avikashNo ratings yet

- Nexygen Plus 41 User Manual Issue 10Document107 pagesNexygen Plus 41 User Manual Issue 10MARY CARMEN NAVARRETE GUILENNo ratings yet

- Product Specification: Leminar Air-Conditioning Industries LLCDocument8 pagesProduct Specification: Leminar Air-Conditioning Industries LLCMaher Al LobnanyNo ratings yet

- Chapter One 1.0 1.1 Background of StudyDocument19 pagesChapter One 1.0 1.1 Background of Studyblock boyNo ratings yet

- SUNPAL Architectural System-BrochureDocument20 pagesSUNPAL Architectural System-BrochureGirish Dhawan0% (1)

- Updated Silencers Bro PDFDocument20 pagesUpdated Silencers Bro PDFdimchienNo ratings yet

- Fire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsDocument8 pagesFire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsSamiYousifNo ratings yet

- More About NoiseDocument7 pagesMore About NoiseAbolfazl KhakiNo ratings yet

- Top 10 Noise Control Solutions 2015 EmailDocument12 pagesTop 10 Noise Control Solutions 2015 EmailRodrigo MottaNo ratings yet

- Types of Acoustic MaterialsDocument6 pagesTypes of Acoustic MaterialsAr Apurva SharmaNo ratings yet

- Chevening Scholarship: Everything You Need to KnowDocument3 pagesChevening Scholarship: Everything You Need to KnowNandini SNo ratings yet

- Colour Design and CreativityDocument10 pagesColour Design and CreativityBianca SamaleaNo ratings yet

- Scholarships For Master's Studies in The United KingdomDocument7 pagesScholarships For Master's Studies in The United KingdomNandini SNo ratings yet

- Final ThoughtDocument6 pagesFinal ThoughtHaroon HussainNo ratings yet

- The Influence of Color in Interior DesignDocument57 pagesThe Influence of Color in Interior DesignNandini S100% (1)

- THATCHING of ROOF WITH Fire Retardent TreatmentDocument8 pagesTHATCHING of ROOF WITH Fire Retardent TreatmentNandini SNo ratings yet

- GCI Factsheet Refrigerants PDFDocument4 pagesGCI Factsheet Refrigerants PDFNandini SNo ratings yet

- SDGs Booklet Web en PDFDocument24 pagesSDGs Booklet Web en PDFkasfurNo ratings yet

- GCI Factsheet RefrigerantsDocument208 pagesGCI Factsheet RefrigerantsNandini SNo ratings yet

- Design Concept Central Iay Final UPDocument217 pagesDesign Concept Central Iay Final UPNandini SNo ratings yet

- Internship Requirement at MHTDocument1 pageInternship Requirement at MHTNandini SNo ratings yet

- Sustainable Building Design: Muscoe Martin, AIADocument6 pagesSustainable Building Design: Muscoe Martin, AIANandini SNo ratings yet

- News Summary PMAYDocument3 pagesNews Summary PMAYNandini SNo ratings yet

- Archfacultydetails Integral UniversityDocument1 pageArchfacultydetails Integral UniversityNandini SNo ratings yet

- 2a.ganga Basin UPDocument4 pages2a.ganga Basin UPNandini SNo ratings yet

- Low Cost ConstructionDocument11 pagesLow Cost ConstructionSanjoli JainNo ratings yet

- Analyze Indeterminate Beams Using Force MethodDocument14 pagesAnalyze Indeterminate Beams Using Force Methodadnan_kasalo100% (1)

- Using Color Effectively: Terms To Learn Chapter ObjectivesDocument12 pagesUsing Color Effectively: Terms To Learn Chapter ObjectivesNandini SNo ratings yet

- Silicone Structural Glazing Manual: Project ReviewDocument1 pageSilicone Structural Glazing Manual: Project ReviewNandini SNo ratings yet

- MP Bhumi Vikas Adhiniyam 2012Document319 pagesMP Bhumi Vikas Adhiniyam 2012abhijeetsaboo100% (3)

- Structural Change Fundamentals and Growth An Overview RevisedDocument23 pagesStructural Change Fundamentals and Growth An Overview RevisedNandini SNo ratings yet

- Introduction To Sustainable DesignDocument28 pagesIntroduction To Sustainable DesignJMBcrapNo ratings yet

- India TalkDocument16 pagesIndia TalksilberksouzaNo ratings yet

- Urgp Benefits of Green InfrastructureDocument42 pagesUrgp Benefits of Green InfrastructureNandini SNo ratings yet

- 0304Document9 pages0304Nandini SNo ratings yet

- Tree Report For Web PrimeDocument32 pagesTree Report For Web PrimeNandini SNo ratings yet

- Water Supply Systems Volume IDocument153 pagesWater Supply Systems Volume Isofianina05No ratings yet

- Analysis of Indeterminate Structures by Force MethodDocument17 pagesAnalysis of Indeterminate Structures by Force Methodatish k100% (2)

- UDPFI Guidelines - Vol 1 - Executive SummaryDocument8 pagesUDPFI Guidelines - Vol 1 - Executive SummaryAbhinav VardhanNo ratings yet

- Table 1 GIDocument3 pagesTable 1 GINandini SNo ratings yet

- 2430 & TB2448 ComarisionDocument6 pages2430 & TB2448 ComarisionpiyushNo ratings yet

- Ethiopia WarehouseDocument5 pagesEthiopia WarehouseJohn TesfamariamNo ratings yet

- PP 1-SERIES METHACRYLATE ADHESIVE TECH DATADocument3 pagesPP 1-SERIES METHACRYLATE ADHESIVE TECH DATAJoanna SąsaraNo ratings yet

- 3 RPM and 6 RPMDocument4 pages3 RPM and 6 RPMAnonymous T32l1RNo ratings yet

- VAV Terminal Units: Type LVCDocument16 pagesVAV Terminal Units: Type LVCNikosNo ratings yet

- CER 127.2 Act. 10 Loss On Ignition Drying and Firing Shrinkage Tests PARTIALDocument8 pagesCER 127.2 Act. 10 Loss On Ignition Drying and Firing Shrinkage Tests PARTIALGrandeur Paglinawan IINo ratings yet

- Pipe Line CalculationDocument14 pagesPipe Line Calculationsamirbendre1No ratings yet

- Detention Tank 1 Construction Rev 1Document23 pagesDetention Tank 1 Construction Rev 1johnNo ratings yet

- Static Electricity Balloon ExperimentDocument2 pagesStatic Electricity Balloon ExperimentRosalyn RechsteinerNo ratings yet

- English PDFDocument170 pagesEnglish PDFTechgreed India100% (2)

- Laminar Flow in ChannelsDocument15 pagesLaminar Flow in ChannelsNeybilNo ratings yet

- Greystone F2811FL Fireplace User ManualDocument7 pagesGreystone F2811FL Fireplace User Manualb0beiiiNo ratings yet

- Design Variables That Affect Building ConstructionDocument5 pagesDesign Variables That Affect Building ConstructionK_O_Ennin100% (6)

- Solutions For Agricultural FilmsDocument12 pagesSolutions For Agricultural FilmsAlfredo Ch. LinoNo ratings yet

- Deliverable List & Price Terminal BBM DexDocument1 pageDeliverable List & Price Terminal BBM DexEvi Puspita SariNo ratings yet

- Plastic BendingDocument1 pagePlastic BendingmajmjudNo ratings yet

- Method Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.ADocument127 pagesMethod Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.AMinh HảiNo ratings yet

- Mech1442851738363 PDFDocument57 pagesMech1442851738363 PDFMonevNo ratings yet

- OMN Coating Resins WaterBased PS Americas PDFDocument2 pagesOMN Coating Resins WaterBased PS Americas PDFNatalia Rodriguez100% (1)

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoNo ratings yet

- A554-15 Standard Specification For Welded Stainless Steel Mechanical TubingDocument8 pagesA554-15 Standard Specification For Welded Stainless Steel Mechanical TubingChuthaNo ratings yet

- Cable Types and Sizes ChartDocument43 pagesCable Types and Sizes ChartMohamed MostafaNo ratings yet

- Catalog 3800 Quick Coupling ProductsDocument229 pagesCatalog 3800 Quick Coupling ProductsANKUSH PARMARNo ratings yet

- G+2 Villa First Floor Roof Structural DrawingDocument4 pagesG+2 Villa First Floor Roof Structural DrawingsmallhouseconstructionsNo ratings yet

- Technical Report Documentation PageDocument149 pagesTechnical Report Documentation PageANo ratings yet

- Intralox in Catalog PDFDocument346 pagesIntralox in Catalog PDFMohammad Bataineh67% (3)

- Flextures Hourglass PivotDocument2 pagesFlextures Hourglass PivotReyginald MarronNo ratings yet

- Valve RatesDocument34 pagesValve RatesDeepthy VasavanNo ratings yet

- 32 Samss 021Document41 pages32 Samss 021naruto256No ratings yet

- Rolling (Bulk Deformation Process)Document27 pagesRolling (Bulk Deformation Process)Kazal ArefinNo ratings yet