Professional Documents

Culture Documents

Hank Tank

Uploaded by

Stefan ZahariaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hank Tank

Uploaded by

Stefan ZahariaCopyright:

Available Formats

UPDATED - January 10, 2012 My first hank drum was completed in February 2007 HI Pre note: I'm liking

this thing a lot more now that a hang drum sold on E-bay for nearly $10,000 !! You could have well over 300 of these propane tank hank drums for that price! A few words about my propane (LP) tank HANK-DRUM ("hank drum" -- Hang + Tank) PS: Much thanks to "Cheapbastid" on the Hang forum for coming up with the name "hank drum") I invented this instrument because of a love for the sound, music and idea of the hang drum created by two dedicated artists at PANArt company in Bern, Switzerland. In lieu of not being able to procure such a hang drum from Switzerland, I'm having a WHOLE lot of improvisational fun playing away on this simple tank drum. As humble as the idea is, it plays very much like the real thing & has a somewhat similar and quite pleasing sound. It is very responsive, requiring only a light, one-fingered tap to start it singing nicely. >>>>>>>>>>>>>>>>>>>>>>>>> PLEASE NOTE: Pantheon Steel, maker of beautiful steel drums (aka "steel pans") is now making and selling their version of the Hang - called "Halo" A truly beautiful instrument every bit as capable and pleasing as the Swiss Hang. Please contact them at pantheonsteel.com I recommend the Halo highly!! >>>>>>>>>>>>>>>>>>>>>>>>> >>>>>>>>>>>>>>>>>>>>>>>>> PLEASE NOTE: if you like the idea of my hank drum but don't want to make one yourself. I am far too busy to make them commercially (aside from my intense dislike of "production work") A number of other folks are making hank drums in various forms. The one I am most familiar with, the one I obtained is called a "Zen Tambour" and I am liking it very much (see YouTube video at http://www.youtube.com/watch?v=E1KzKI1YiDc). Please see http://exoticvessels.com/zentambour/ for much more info on this fascinating instrument. Unlike my "rough-and-ready" propane tank conversions, The Zen Tambour is drop-dead beautiful to look at as well as play. Along with the Pantheon Halo, this Zen Tambour is a prized possession. >>>>>>>>>>>>>>>>>>>>>>>>> NOTE: Many people have built hank drums from my plans here but of those I've heard played (youtube and otherwise), a lot of them are quite out-of-tune!! I am at a loss as to why this is!! If you can tune a guitar, you can properly tune this Drum. Please do not get impatient and settle for bad tuning -for one thing, I am proud of my hank drum invention and it gives it a bad name for people to be hearing (sometimes) WAY off tuning on the things! Take the extra time to tune it right -- it truly is NOT hard. Another LATER NOTE: Nice to see a lot of home-made hank drums popping up on YouTube.

I do notice that quite a few folks are not hitting the tongues "properly". It makes a LOT (repeat LOT) of difference in the tone/sound/volume WHERE on the tongues you hit. Try to hit the higher notes about a third of the way up from the base of the tongues instead of near the tip - EXPERIMENT. Lower notes aren't so fussy. Also, a far better tone is obtained if you hit very quickly - not allowing your finger to rest on the tongue even for an instant -- tap it as if you were testing a stove burner to see if it's hot. Also, I still see people not using the highly recommended bungee cords to mellow out the tone. These may seem like small points, but they're not.

CLICK HERE to see a short YouTube video of me playing this instrument CLICK HERE to see a second video of me and this instrument

PS: The tiny, tinny speakers in most laptops do a very poor job of representing the real sound of this instrument. Desk-tops do a far better job.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> There is NO doubt that you can build this hank drum if:

a- You b- You c- You don't) d- You e- You f- You g- You As you

know how to use an electric drill know how to use a pipe wrench know how to use a saber-saw (only a few mins practice needed if you know how to use a pair of Vise-Grips know how to use a file can tune a guitar can get a friend to help you with a-f above can see, basic stuff!

- V E R Y IMPORTANT: USE ONLY NEW - NEVER-BEEN-FILLED - 20 pound propane tanks. Input keywords such as - propane tank explosion - into YouTube to see the reason why!! These new tanks cost $27 or so at Home Depot stores (I've been told that they're as low as $19 in big city discount outlets). Even if you hear and feel no liquid in a used tank, there may still be gas inside - which can be very explosive. Then too, valves have been known to jam and the newer type LP valves can more easily fool one into believing that a tank is empty. Heed this caution: use a NEW tank. - Remove the valve mechanism using a Plumber's pipe wrench. A 3 or 4 foot long "extender" is almost always needed to get the screw-threads to start turning (it's glued-in/sealed at the factory and can take some determined convincing to unscrew). One sure-fire trick is to very tightly clamp a 2' long hefty (1" D.or so) length of water-pipe vertically in a vise, then holding the tank on it's side, slip the handle-holes over the pipe. Now with the tank resting on the vise, use the pipe-wrench/extender. This method works largely becasue it keeps the tank stable -- keeps it from rolling around. LATER NOTE -- THIS REMOVING METHOD WORKS LIKE A CHARM - EVERY TIME EASILY. IF IT DOESN'T WORK FOR YOU, YOU'RE DOING SOMETHING WRONG! PLEASE READ THE ABOVE INSTRUCTIONS CAREFULLY. - The metal ring that is welded to the tank's bottom also has to be removed. It comes off quite easily with a sharp chisel. LATER NOTE (9/2/07): A far easier and quicker way to remove this ring is to clamp Vise-Grip pliers onto the ring, 1/4 inch from the ring/tank weld then worry it back & forth a few times til it breaks free. Repeat with the other 3 welds. I just de-ringed a tank this way in less than a minute. The welds usually break off flush with the tank, but if not simply file off any leftover bumps. This ring can be cut, re-formed and bolted onto the tank's carrying-handle ring (creating a complete circle) -- this makes an excellent base that keeps the tank from tipping over when set bottom-side up for playing. - To make the small slot that the saber-saw blade will fit into, I drill three fairly closed-spaced 1/16" holes - positioned about 1/4 inch from the end of one of each tongue's legs. I then carefully (wear goggles!!) "worry"

these holes into one long hole that will fit the saber-saw blade. Crude -but works fine. LATER NOTE (1-10-2012): a Dremel tool with 1-1/4" reinforced "cutoff wheel" works better for making these slots. I didn't have this setup until recently. - I use a regular off-the-shelf saber-saw to cut the tongues. The saw-blade has to be ground-down so the back-side is half as wide, in order to follow the curves of the tongues. WEAR SAFETY GOGGLES -- the less-wide blade can break all the easier with possibly disasterous results to eyes. I use hearing protection too --- look like a Martian! I prefer cheaper saber saws. They're lighter, easier to use and usually do NOT have this silly "noscrew" spring-loaded blade "quick" attachment (which I find works very poorly). I just bought a nice Black and Decker for $20. Also, small, cheap grinding wheels, that are used with a regular electric drill, work nicely to grind down the saw-blade. Home Depot and Walmart sell these wheels inexpensively. I must confess that this cutting of the curved portion of each tongue is by far the part of making a hank drum that I least like. Even having built wuite a few of these jobbies, I still break probably 4 or 5 saw-blades as well as a similar number of 1/16" drill bits! After a LOT of trial and error, the saw blade that seems to hold up best is Vermont American brand bimetal, fine tooth. Rounding these curves has ceased to be fun! - I always cut the tongue lengths a good 1/4 inch shorter than I think will produce the desired note. After saber-sawing, the tongues are fine-tuned using a bare hack-saw blade with the end wrapped in duct tape to keep from cutting my hand. GO VERY SLOWLY -- it's FAR easier to flatten a note than to sharpen it (to sharpen it, you have to run the saber-saw blade along the perimeter of the tongue, seeking to nibble away a fraction of metal & reduce the mass of the tongue - & thus raise the pitch --- this wearying process goes very slowly in comparison with how lightning-fast the tongues can be flattened). - The scale I used is D minor Pentatonic: (I fell in love with this scale after hearing a fellow in Pennsylvania's beautiful youtube uploads in this scale). (low to high) Low note ("ding") is D. Circle-notes are (running up the scale & alternating right-left-right-left etc) A, C, D, F, G, A, C . You can make this drum in any key/scale you'd like. Just use my template dimensions as a starting point. For example, if you'd like to include an E note, refer to my F note and just (carefully & slowly) lengthen each leg of the tongue until the E note is achieved.

- The fact that the Low D note is NOT in the center, but instead is located between the two highest notes, does not seem to be much of a liability. It IS however, the closest note to the center. I'd LIKE to have put it in the center, but after doing so on an experimental tank, it confounded the other notes considerably -- thus this "off-center" placement. I'm sure hang players would have little trouble playing this slightly off-center Low D "ding". - The saber-sawing process magnetizes the filings to a point where they're quite pesky! While sawing and tuning, I find that taking an old towel and forcefully whapping each tongue dislodges these filings nicely. Once all cut and tuned, I insert a garden hose under high pressure into the tank and let it run for about ten minutes while rotating and swishing around the tank. This gets rid of the metal filings. - Tuning the beast: I rough-tune each tongue by ear to just a bit higher-pitch than desired, then use a simple electronic tuner to fine tune each tongue to pitch. Here are a few tricks I have found to be quite useful in the process. I start with the low A tongue, silencing all the other tongues by sticking a pea-sized glob of Mortite brand window-caulking rope (actually very clay-like), available at any hardware store, across the top of the roundy end of each tongue (masking-tape works too). Thus silenced, the overtones and harmonics of these notes dont confound the electronic tuner. For reasons I don't understand, (stringed and wind music generation I DO understand -- but the best I can do with this musical-steel stuff is to take my best guess, then launch into a barrage of adjustments & experimentation until I find something that works to my liking. There are lots and lots of variables with musical-steel methinks!!) the two highest notes tune (& sound) noticeably better with NO Mortite silencing the other notes. For finetuning, lengthening of the tongues, I only use a hacksaw blade itself. An observation: Please take the time and care to tune this thing properly. Quite a few folks have built one of these hank drums & several have sent me sound samples while others have uploaded to YouTube. While many of these sound quite nice, in far too many cases, it's obvious that their tongues are not tuned properly -one or more note(s) being out of pitch! It's not that hard at all to get it right -CLOSELY follow my tuning instructions (do not "wing it"), go slow and you won't go wrong. - A bungee-cord or two (or even three) wrapped around the tank just down from the tongues really does do wonders in helping control any excessive tank ring as

well as undesirable overtones. I can't imagine playing one of these instruments with no bungees. LATER NOTE (8/23/07): Just discovered that black rubber bungees work FAR better than round, multi-color, cloth-covered ones -- must be due to more contact area. Here again, videos sent me and on YouTube show people playing these drums without bungees -- far too ringy & brash a sound! - Later note: I just had occasion to play this drum with the thing's base resting on concrete & was amazed to hear just how much the sound suffered - lower notes were muffled. I'd only played it on carpet, grass or in my lap previously. Must be that the sound conducts into the concrete & acts similarily to a mute on a fiddle. This problem was completely solved by taking a short length of discarded garden-hose, splitting it lengthwise & working it onto the base, securing it a few times with colored duct-tape. Also has the advantage of not scratching any surface that the drum rests on. Later note: An alternate method of expanding the above digitalized template to proper size is to use the old "grid-square" method. I have applied grid squares to the template -- each square on the template represents a quarter of an inch -- even though it obviously does not measure 1/4" on the computerized template. Carefully tape together several sheets of 1/4" graph paper taking care that where sheets overlaps, all lines line-up. Look carefully at a square on a tongue -- count where the corresponding square should be on the blank graph paper & carefully draw in the tongue line. It's not that critical so long as when it comes time to actually cut the metal, you leave each leg of the tongue amply long (at least a quarter inch) for fine-tuning. Crafters quilters, rug-weavers all use this simple "grid-square" method to expand small magazine designs to whatever size they wish. This instrument is not especially light -- an off-the shelf tank weighs 17 pounds (a pound or two less with the bottom ring and valve mechanism removed) but it does have a comfortable built-in carrying handle. In my case, the weight has not been an issue. I cart it around to all sorts of places quite easily. Think of a piano! A later note: a lot of people desiring to make a hank drum but living outside of the United States have reminded me that "20 pound propane tanks" are not available in their country! I have been trying to determine just what type of tanks ARE available overseas, with limited results. In any event, as evidenced by seeing very

successful hanks made using other types of tanks on YouTube, if you've got one of these other type of tanks, give it a try! You might consider not using my template, but instead using my tongue shape & dimensions applied to your tank BUT with the legs of each tongue initially cut MUCH shorter. See what pitch this shortened tongue produces & carefully adjust accordingly. PLEASE LET ME KNOW how this goes so I can include more detailed info in this article. Thanks If more "would-be-hang-drum-players-who-can't-obtain-a-PanArt-instrument" saw how easy this thing is to make, how good it sounds in person & how much GREAT fun it is to play, I think that they'd be more around. But please TUNE the contraption properly!! LATER NOTE (1-10-2012): After recently conducting a hank-drum (& other instrument) making workshop in Africa, where things like saber-saw blades were very hard to find, I (admittedly reluctantly) opted to use rectangular tongues instead of my usual "tongue-shaped", roundy tougues. Have to say that I noticed no (zero) difference in tone, volume or playability. I did notice that with three straight sides per tongue, the instruments were MUCH easier to build. So - hopefully I will soon add a rectangular-tongue template to this web-page. In the meantime, if you'd rather make the easier rectangular-tongued hank, I might suggest still using my roundytongued template above to get the general idea of width and length. Using same width, plan on the rectangular version being shorter than the roundy. Try locating the top of each the rectangular tongue 3/16" down on the tank from what the above template shows and then stopping your right and left cuts WELL before what is shown above. Then carefully work their lengths to pitch. PLEASE LET ME KNOW HOW THIS GOES. I have been so busy that since I got back from Africa, I have not had the chance to do this myself yet. I DO have a rectangular template for SENEGALESE tanks (see elsewhere on my webpage here) but their tanks are much thicker than US tanks & unsure how that template would work. Kindly share your thoughts and ideas with me please. Thanks dhavlena@gmail.com PS: I still like the LOOKS of roundy tongues better! Hard for an old fart to change! Another idea/observation -- I recently (2011) made a few hanks from wellwater air tanks.

They worked fine but ringy overtones were an issue. Instead of the bungeebands, on a whim I stuffed half of an old t-shirt into the tank & it worked!! Mellowed it right out. Lemme know if you repeat this experiment.

CLICK HERE to see Jim Doble's neat-looking thick-metal, BIG-tank playground drums! Beautiful! Gotta try something that big with a hank!! Dennis Havlena - W8MI dhavlena@gmail.com Mackinac Straits, northern Michigan Originally posted July 3, 2007

You might also like

- And So This Is ChristmasDocument1 pageAnd So This Is ChristmasStefan ZahariaNo ratings yet

- HookDocument2 pagesHookStefan ZahariaNo ratings yet

- Evil Elvis VersuriDocument1 pageEvil Elvis VersuriStefan ZahariaNo ratings yet

- SacrificeDocument1 pageSacrificeStefan ZahariaNo ratings yet

- Uptown FunkDocument2 pagesUptown FunkStefan ZahariaNo ratings yet

- Dreadlock HollidayDocument9 pagesDreadlock HollidayStefan ZahariaNo ratings yet

- DON.t Leave VersuriDocument9 pagesDON.t Leave VersuriStefan ZahariaNo ratings yet

- The Long and Winding Road LyricsDocument1 pageThe Long and Winding Road LyricsStefan ZahariaNo ratings yet

- Swing The Mood Soca DanceDocument5 pagesSwing The Mood Soca DanceStefan ZahariaNo ratings yet

- Ver SuriDocument7 pagesVer SuriStefan ZahariaNo ratings yet

- Wicked Game Lyrics and MeaningDocument1 pageWicked Game Lyrics and MeaningkendrialbuquerqueNo ratings yet

- White Christma1Document1 pageWhite Christma1Stefan ZahariaNo ratings yet

- Achy Breacky HeartDocument11 pagesAchy Breacky HeartStefan ZahariaNo ratings yet

- Lonely This ChristmasDocument2 pagesLonely This ChristmasStefan ZahariaNo ratings yet

- Wildest MomentsDocument1 pageWildest MomentsStefan ZahariaNo ratings yet

- Achy Breacky HeartDocument11 pagesAchy Breacky HeartStefan ZahariaNo ratings yet

- Karma Chameleon - Boy GeorgeDocument2 pagesKarma Chameleon - Boy GeorgeStefan ZahariaNo ratings yet

- Dreadlock HollidayDocument9 pagesDreadlock HollidayStefan ZahariaNo ratings yet

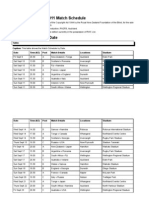

- Rugby World Cup 2011 Match ScheduleDocument13 pagesRugby World Cup 2011 Match Scheduledulmin96No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 175 Pages of SongsDocument175 pages175 Pages of SongsCynthia Clayton Rakich100% (1)

- Paganini - Carnival in Venice (Violin Solo and Piano) PDFDocument13 pagesPaganini - Carnival in Venice (Violin Solo and Piano) PDFDominik.acc.No ratings yet

- Partner Song ListDocument1 pagePartner Song ListKhaya PaladaNo ratings yet

- Maneskin Torna A Casa Spartito Piano Sheet MusicDocument5 pagesManeskin Torna A Casa Spartito Piano Sheet MusicVaiva LakstauskaiteNo ratings yet

- The Count of Monte Cristo Vocal ScoreDocument260 pagesThe Count of Monte Cristo Vocal ScoreSofi Forte89% (28)

- Ave Verum: Grave Rit A TempoDocument7 pagesAve Verum: Grave Rit A Tempoerica usherNo ratings yet

- Vem, agora é tempo de adorarDocument14 pagesVem, agora é tempo de adorarMisael Abrantes Dos ReisNo ratings yet

- Super Mario Bros Overworld PDFDocument1 pageSuper Mario Bros Overworld PDFDylan MinesNo ratings yet

- Joseph Beach A Lotta Love Rhetorical AnalysisDocument4 pagesJoseph Beach A Lotta Love Rhetorical Analysisapi-549237267No ratings yet

- Football Basketball ChaosDocument3 pagesFootball Basketball ChaosRobyn JonesNo ratings yet

- Coppelia Lake BRDocument41 pagesCoppelia Lake BRjoeNo ratings yet

- Simon Frith - Can Music ProgressDocument12 pagesSimon Frith - Can Music ProgressFelipeNo ratings yet

- Savage Worlds - Beasts & Barbarians - Heroic Tale 1 - The Cliffs Queen's CourtDocument12 pagesSavage Worlds - Beasts & Barbarians - Heroic Tale 1 - The Cliffs Queen's CourtdungeonworldNo ratings yet

- EthnochoreologyDocument1 pageEthnochoreologyburnnotetestNo ratings yet

- Harp Music 02 LondDocument184 pagesHarp Music 02 Londwongyinlai50% (2)

- Word Formation: CODE:213880Document129 pagesWord Formation: CODE:213880rrg rg100% (1)

- Christmas: Live From London PodcastsDocument6 pagesChristmas: Live From London PodcastsDranNo ratings yet

- CPWI 126 Ride On in Majesty and CPWI 127 All Glory Laud and HonourDocument3 pagesCPWI 126 Ride On in Majesty and CPWI 127 All Glory Laud and HonourRian BecklesNo ratings yet

- I Think We'Re Alone Now - Tiffany CTCDocument2 pagesI Think We'Re Alone Now - Tiffany CTCCariss CrosbieNo ratings yet

- America - Razorlight: VerseDocument3 pagesAmerica - Razorlight: VerseStephen Mc GraneNo ratings yet

- Massimiliano Guido (Editor) - Studies in Historical Improvisation - From Cantare Super Librum To Partimenti-Routledge (2017) - 223Document1 pageMassimiliano Guido (Editor) - Studies in Historical Improvisation - From Cantare Super Librum To Partimenti-Routledge (2017) - 223fwqwe qwe14No ratings yet

- Birdland (Live From 8:30) : Weather ReportDocument13 pagesBirdland (Live From 8:30) : Weather ReportJakira Ebony BrophyNo ratings yet

- TansenDocument2 pagesTansenPritam MeherNo ratings yet

- University of Texas Press Latin American Music Review / Revista de Música LatinoamericanaDocument21 pagesUniversity of Texas Press Latin American Music Review / Revista de Música LatinoamericanaJohanna Suárez GonzálezNo ratings yet

- LKS 1 BingDocument5 pagesLKS 1 BingYully HurintNo ratings yet

- Eyes Open 4 Unit 1 ReviewDocument7 pagesEyes Open 4 Unit 1 ReviewRenan CarvalhoNo ratings yet

- Week 7-8 StanDocument7 pagesWeek 7-8 StanJaneyyneyyy De leonNo ratings yet

- Himig Ng Hangin Caroling Sheet MusicDocument9 pagesHimig Ng Hangin Caroling Sheet MusicArnold LumbaoNo ratings yet

- Elsas Procession To The Cathedral InfoDocument9 pagesElsas Procession To The Cathedral InfoChristin ReillyNo ratings yet

- "Immigrant Song": Led Zeppelin (John Bonham)Document2 pages"Immigrant Song": Led Zeppelin (John Bonham)Marco Lopes50% (2)