Professional Documents

Culture Documents

Feasibility Study: Manufacturing of Biodegradable Shopping Bags Made Form Corn Kernels

Uploaded by

Daphne De LeonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Feasibility Study: Manufacturing of Biodegradable Shopping Bags Made Form Corn Kernels

Uploaded by

Daphne De LeonCopyright:

Available Formats

CHAPTER 1 The Problem and Its Setting

Introduction Biodegradable shopping bags are now making a trend these days. The world now tends to produce and start the usage of products that do not harm the environment. Industrialized countries are starting and an advanced extensive research on construction of biodegradable plastics has finally begun. A biodegradable shopping bag is a plastic that degrades from the action of naturally occurring microorganism, such as bacteria and fungi over a period of time. During the 1920s, Maurice Lemoigne (2013), a French researcher, discovered the first biodegradable plastic but her work went unnoticed for many years. As nations faced the reality of rising oil prices, they encouraged research for synthesizing alternatives to petroleum-based products. In the 1990s, research in biodegradable plastics has become steady and profitable. Researchers have discovered a way to make biodegradable shopping bags more environmental friendly. Years of research in pursuit of bio-based and compostable alternatives to traditional plastics has led to the development of a process that converts corn, particularly corn kernels transformed into a starch, successfully into a material which displays plastic characteristics it contains Polylactic acid (PLA) which poised to play a big role as a

2 viable, biodegradable replacement. PLA helps reduce greenhouse gas emissions. Corn plastic products look and feel like traditional petroleumbased plastic, but they are biodegradable and compostable. Corn plastic was developed as a less expensive, stronger biodegradable shopping bag that could compete with oil-based plastics. The world has experienced so many changes in the past years. There are the great technological advancements, continuous growth of the world population and a lot more. Global warming, climate and

environmental changes are just some of its effects. Improper way of disposing wastes specifically plastic which is non-biodegradable is a major problem of this world. Plastic accumulation in landfills takes up valuable space and threatens the environment. The economic and ecological drawbacks of petroleum-based plastics have pushed the proponents to develop and investigate biodegradable shopping bags as environmentally-friendly alternative. Living green has become a popular trend in the last twenty years and here in the Philippines, one way to establish an environmental advocacy is the prohibition of using plastic bags in some places in Metro Manila like Pasig City and Marikina City. Corn kernels are the primary raw materials of the shopping bag. Corn is the second largest crop in the country next to rice and the country is rich of it and can be used in saving the Mother Earth. Corn kernel is the part of the corn that people eat and is said to be a staple food in some

3 parts of the country. The production of shopping bag made from corn kernels will not greatly affect the necessity of the Filipino people to eat corn as a substitute for rice because only 20% of the Filipino people consume corn and the other 80% eats rice. This is just a few percentage compared to the number of people who eat corn as a replacement of rice. The proposed business is planning to have its own corn plantation in the next five years after it has earned enough profit to have its own production of corn and to avoid competition with the need of the Filipino people for corn. In view of this, the main objective of the study is to determine the viability of manufacturing biodegradable shopping bags from corn kernels. The results of this study will provide important information about the usefulness and marketability of the said product after presenting and comparing its benefits to existing products similar in nature. Statement of the Problem This study is aimed at determining the viability of manufacturing biodegradable shopping bags made from Corn Kernels in Baliuag, Bulacan. Specifically, the feasibility study sought to answer the following questions related to the different aspects of business operations: The Marketing Aspect 1. What are the opportunities and threats of the business?

4 2. What are the factors that could affect the business operations in the external environment? 3. Who is the target market of the business? 4. What benefits can the consumers get from the product? 5. What will be the price of the product? 6. How and where will the proponents distribute the product? 7. What promotional strategies will be used in introducing the product? The Management Aspect 1. What is the form of ownership of the business? 2. What is the nature of the business? 3. What is the schedule of the activities of the business? 4. What are the job descriptions and specifications of each personnel? 5. How will the organizational structure look like? 6. What would be the compensation scheme of the business? The Technical Aspect 1. What are the components needed to produce the product? 2. Where will the raw materials come from? 3. What are the steps in manufacturing the product? 4. What are the facilities required by the business? 5. What are the machines required for production? 6. What should be the layout of the factory to facilitate production? 7. What would be the schedule of production?

5 The Financial Aspect 1. How much will be the initial working capital? 2. How much would be the total project cost? 3. How do the financial statements perform over a 5 year operating period? 4. How much would be the anticipated return of investment in a year? 5. What are the techniques that the business will use in order to maximize its income? The Socio Economic Aspect 1. What will be the firms environmental responsibilities? 2. In what way can the firm be useful to the chosen community? 3. What are the contributions of the firm to the community? 4. How will the government benefit from the firm? 5. How can the firm contribute to the economic status of the Philippines? Objectives of the Study The study on manufacturing biodegradable shopping bags made from Corn Kernels in Baliuag, Bulacan aims: The Marketing Aspect 1. To know the opportunities and threats of the business. 2. To be familiar with the factors that could affect the business operations in the external environment. 3. To determine the target market of the business.

6 4. To identify the benefits can the consumers get from the product. 5. To determine the price of the product if sold to the market. 6. To determine how and where will the proponents distribute the product. 7. To identify promotional strategies that will be used in introducing the product. The Management Aspect 1. To identify the form of ownership of the business. 2. To determine the nature of the business. 3. To establish the job descriptions and specifications of each personnel. 4. To identify the schedule of the activities of the business. 5. To determine the organizational structure. 6. To determine the compensation scheme of the business. The Technical Aspect 1. To determine the components needed to produce the product. 2. To identify where the raw materials come from. 3. To determine the steps in manufacturing the product. 4. To know the facilities required by the business. 5. To identify the machines are required for production. 6. To establish the factorys layout where the production will be facilitated. 7. To determine the schedule of production.

7 The Financial Aspect 1. To distinguish how much would be the initial working capital. 2. To determine the total project cost of the business. 3. To determine the performance of the financial statements perform over a 5 year operating period. 4. To determine the anticipated return of investment in a year. 5. To know the techniques that the business will use in order to maximize its income. The Socio Economic Aspect 1. To identify the responsibilities to be performed by the firm to the environment. 2. To identify the ways in which the firm can be useful to the chosen community. 3. To know the contributions of the firm to the community. 4. To know benefit of the government from the firm. 5. To identify the contributions of the firm to the economic status of the Philippines. Significance of the Study This study may serve as guide to readers by providing data concerning the manufacturing of biodegradable shopping bags from corn kernels. They will get insights into the different aspects of the business, such as marketing, management, financial, technical, and socio-economic. Those interested to undertake similar business may find this study

8 valuable for it includes information about the viability of the business, as well as the basic procedures in production. On the part of the public, this study will promote their awareness regarding what a biodegradable shopping bag could do for the environment. This will encourage the public to help the environment by using biodegradable shopping bags from corn kernels. On the part of the future researchers, this study can be their reference for their study in future. This study can be used by future entrepreneurs as a basis for putting up a new business that will offer eco-friendly products and this will guide them to assess the viability of manufacturing and selling similar products. Through this study, the manufacturers will learn and have an idea of what further enhancement they should apply in developing

biodegradable plastic shopping bags from corn kernels. Scope and Delimitations of the study This study focuses on determining the viability of manufacturing biodegradable shopping bags made from Corn kernels. It is intended to provide alternative plastics in the Philippines especially in Baliuag, Bulacan. The study covered the five components of a feasibility study particularly in marketing, management, technical, financial and socioeconomic aspects.

9 The Marketing Aspect determines the target market, and the marketing technique adopted by the firms. It also includes the marketing strategies developed by the proponents related to product, price, place and promotion. The Management Aspect identifies who are the proponents of the business. It presents the form of ownership and organizational structure used by the firms. It also discusses the different qualifications and specifications of the personnel required for the position. The Technical Aspect contains the different raw materials needed in manufacturing the product. It also includes the machines and equipment that will be used to produce the product. It also discusses the step by step process of manufacturing the product. The Financial Aspect includes the assumptions used in creating the projected financial statement. The total business capital investment in the proposed business was determined. It also determines the necessary financial arrangement to ensure that the project will have the cash needs when required. The Socio-Economic Aspect presents the benefits that the society will get from the proposed business including its effect to the economy and society. This study, however, has a limited time in completing the study due to time constraints because of its strict one- semester duration. Financial

10 resources were also limited as the proponents were students and thus, did not have their own money. Definition of Terms The terms included in this research paper were defined to facilitate easy understanding of the study. Biodegradable plastics. It is capable of being decomposed by bacteria or other living organisms. Biodegradable shopping bags. These are bags that are capable of being decomposed by bacteria or other living organisms. Biofibers. The solid material separated from the effluent stream after treatment by an anaerobic digester. This is the solid material that could not be volatilized into biogas. Bioplastic. These are plastics derived from biomass sources such as vegetable fats and oils, and starch such as corn or pea starch. Corn Kernels. It is the seeds of maize. Though technically a grain, maize kernels are used in cooking as a vegetable or starch. Dextrose. The dextrorotatory form of glucose found naturally in animal and plant tissue and derived synthetically from starch. Ecological. It is the scientific study of interactions among organisms and their environment, such as the interactions organisms have with each other and with their biotic environment.

11 ENSO Renew. It is a unique Renewable Thermo Polymer (RTP) derived from the waste process of agriculture, a high heat renewable biopolymer that provides home and industrial compost ability. ENSO Restore. It is the latest development of biodegradable additives offering superior improvements to biodegradable performance and process-ability/compatibility and eliminating the historical higher scrap rates of competing additives, creating a huge environmental and cost advantage. Global warming. This is the rise in the average temperature of Earth's atmosphere and oceans since the late 19th century and its projected continuation. Greenhouse. It is a building in which plants are grown. These structures range in size from small sheds to industrial-sized buildings. A miniature greenhouse is known as a cold frame. Lactic acid. It is a colourless syrupy carboxylic acid found in sour milk and many fruits and used as a preservative for foodstuffs, such as soft margarine, and for making pharmaceuticals and adhesives. Landfill. It is a site for the disposal of waste materials by burial and is the oldest form of waste treatment. Its been the most common methods of organized waste disposal and remains so in many places around the world.

12 Oxo-biodegradable plastic. A petroleum based plastic with metal salt additives that enables the plastic to degrade when subject to certain environment conditions. Poly-3-Hydroxybuturate. It is a polymer belonging to

the polyesters class that are of interest as bio-derived and biodegradable plastics. Polyethylene. A polymerized ethylene resin, used especially for containers, kitchenware, and tubing, or in the form of films and sheets for packaging. Polyethylene terephthalate. A synthetic resin made by

copolymerizing ethylene glycol and terephthalic acid, widely used to make polyester fibers. Polystyrene. A rigid clear thermoplastic polymer that can be molded into objects or made into foam that is used to insulate refrigerators. PLA (Polylacticacid). It is a thermoplastic aliphatic polyester derived from renewable resources, such as tapioca roots, chips or starch, or sugarcane. Thermo Polymer. These are polymers that exhibit a drastic and discontinuous change of their physical properties with temperature. Review of Related Literature and Studies This chapter includes the review of the related literature and studies which the researchers have perused to shed light on the topic under study.

13 Foreign Literature In an article by Ted Duboise (2012) Bright Future Forecast for Biodegradable plastic Packaging, the demand of biodegradable plastics in United States has a big chance to expand in the year 2016. Polylactic acid (PLA) is expected to remain the most extensively used resin in the bioplastics market through 2016, Freedonia forecasts. It is made from fermented plant starch corn in the United States, tapioca in Asia, and sugarcane in the rest of world PLA-based biodegradable plastic is used in producing loose-fill packaging, compost bags, food packaging, and disposable tableware. In the form of fibers and non-woven textiles, PLA can be used to make upholstery, disposable garments, awnings, feminine hygiene products, and diapers. PLA is also used in biomedical applications, such as sutures, stents, dialysis media and drug delivery devices. It is being evaluated as a material for tissue engineering. The article shows the increasing demand of biodegradable plastics especially in the year 2016. Some Raw materials in making biodegradable plastics are Corn, Tapioca and Sugarcane; these are the source of fermented plant starch. PLA-based biodegradable plastics plastic is used for producing loose-fill packaging, compost bags, food packaging, and disposable tableware. Biodegradable plastic is now in the early stage of development, it is now making a small niche within the overall plastic industry. Technical innovations and increased production capacity should combine to enhance the properties of biodegradable plastics.it can make

14 them more competitive in the business industry. The Demand for Biobased products like the Biodegradable plastics increased when the U.S President Barack Obama announced an expanded biobased products initiative by the Federal government. The proponents resulted with the idea of using biodegradable plastics from corn kernels in the Philippines because of the succeeding forecast of biodegradable plastics in USA by the year 2016. In an article by Fiona Wagner (2010) The truth about Bioplastics, almost all of the packaging of product are made from plastic. Plastic is one of the major environmental problems because it is non-biodegradable. A biodegradable plastic breaks down and can be derived from either agricultural or petro chemical sources. Polyethylene and polystyrene come from bioplastics and fossil fuels that are made from renewable resources like corn starch. Starch is a natural polymer which can be processed directly into a bioplastic. With the use of biodegradable plastic, the nonbiodegradable plastic litters will be reduced and the quantities of plastic waste will decrease. The proponents used starch from corn kernels to manufacture biodegradable shopping bags. This will help lessen the plastic waste because it is a biodegradable shopping bags. The article published in ecoKloud.com (2012), a website that offers the highest quality eco-friendly, plant based and compostable food service products discussed biodegradable plastics on one of their articles. First is

15 its component PLA, according to the website PLA stands for Polylacticacid and is made from corn starch. Lactic acid is made from Dextrose by fermentation. Dextrose is made from corn starch, and corn starch is made from carbon dioxide and water. PLA can be formed into a variety of products. Corn plastic products look and feel like traditional petroleum-based plastic, but they are biodegradable and compostable. The article also differentiated a biodegradable plastic to a regular plastic and these are as follows: 1.) Regular plastic is made from petroleum that is pollutant and has toxins; while PLA is from derived from corn based resin, which is non-toxic and renewable resource; 2.) Regular plastic takes approximately 400 years to degrade, leaving toxicity in the environment. PLA plastic biodegrades in less than 60 days, and it is 100% biodegradable and compostable; and 3.) the article also said that the production and use of PLA, Bioplastics are generally considered as a more sustainable activity compared to petroleum based plastic production, because it relies less on fossil fuel as a carbon source, and also introduces less greenhouse gas emission when it biodegrades. They significantly reduce hazardous waste. This article is related to the proponents present study because it talked about corn plastics, mainly about its component PLA and the difference of using biodegradable plastic bags instead of regular plastics. The proponents can use this as a good basis for their study about the manufacturing of biodegradable plastic from corn kernels.

16 Local Literature The article published in Radyonation (2013) entitled The provincial government of Bulacan strictly implement the ban on use and sale of plastic bags in the entire province. The Governor of the province Wilhelmino M. Sy-Alvarado made the announcement at the launching of the implementation of the ordinance at Mc Donald's-BSU where they posted tarpaulins for public information. Alvarado signed the Implementing Rules and Regulations of the Provincial Ordinance No. 2012-09 also known as "Panlalawigang Kautusang Nagbabawal sa Paggamit ng NonBiodegradable Plastic Bags, Styrofoam at mga Kauri Nito Bilang Packaging Material sa Lalawigan ng Bulacan at Nagtatakda ng Kaparusahan sa Paglabag Nito" on the December 12, 2012. The governor said that is part of the seven-point agenda to protect the environment, health and welfare of the Bulakenyos. The ordinance prohibits the sale and use of non-biodegradable plastic bags, styrofoam and other kinds as packaging materials in the 21 towns in Bulacan and three cities in the said province.

Violators will pay a fine of Php1000 to Php5000 or imprisonment of not less than six months to one year (depending on the number of offenses done). For those who do not have the capacity to pay the fine, he/she must serve the community through environment-related services for three months or longer upon the discretion of the court.

17 This article is related in the proponents study because the setting of the study is in Bulacan. The ordinance helps the proponents to know more about the environment and the current trends in the place. The article may also help the proponents in developing the product. The article published by Estrella Z. Gallardo (2012) entitled Bt Corn Dominates Non-Bt Yellow Corn Production. This was admitted by Agriculture Assistant Secretary Edilberto de Luna, also the chief of the National Corn Program (NCP) of the Department of Agriculture (DA). De Luna revealed that the pest- and disease-resistant Bacillus thuringiensis (Bt) corn is now preferred by farmers owing to its durability and its higher yield. According to De Luna The farmers in Northern Luzon have opted for the genetically-modified Bt corn in spite of earlier resistance by many quarters that feared the crops deleterious impact on human health and the environment. De Lunas disclosure means that out of the 3.47 million metric tons (MMT) of corn harvested for the first semester, Bt corn comprised 2.082 MMT. The projected output is 7 percent better than the 2011 output of 6.97 MMT. The corn was tested first in South Cotabato but resistance led to the transfer of the testing sites. Eventually, the crop was cleared for commercialization in 2002, with farmers now producing the crop in Isabela, Pangasinan, Cagayan and other provinces. In a press briefing, De Luna said while the cultivation of the corn has been widespread in Luzon, many farmers in the Visayas and other

18 regions are hindered from planting the crop due to existing prohibitions at the provincial and city levels. Negros Occidental has a provincial ordinance banning the introduction of any genetically-modified organism (GMO), which prevents the entry of the corn and other crops. This article helped the proponents to know that there were enough resources of corn in Luzon where the setting of the study conducted. This may be used by the proponents to justify that in case of lacking in resources the proponents may get some resources from other places in Luzon. Joy M. Lazcano (2007) in her article, Biodegradable plastic now in RP, discussed about the new generation of plastic materials that decomposes along with composting plants in less than a year. She said in her article that it was unveiled recently by Japans New Energy and Industrial Technology Development Organization, and local counterpart Metals Industry Research and Development Center of the Department of Science and Technology. According to Lazcano, the new biodegradable plastic offers an environment-friendly and cost-efficient option to industries and the government in resolving the perennial garbage problem in the country. The biodegradable plastics raw materials come from renewable resource based biopolymers such as cellulose, corn, starch, and soy based plastics that is turned into powder form and mixed with a solution. She stressed that the government data showed that Metro Manila produces 600,000 tons of garbage every day, 30 percent of which is

19 identified to be plastic materials. The mounting of daily garbage output in the metropolis is projected to swell to 800,000 tons in 2010. Lastly, Lazcano said that when combined with hemp or other biofibers, the biodegradable plastic is guaranteed to be as durable as the regular polyethylene terephthalate or PET plastics used as container for many food products including bottled water, yet it can easily be decomposed by breaking it down into its basic substances with the help of living organisms in composting plants. The technology to produce biodegradable plastic is being introduced in the Philippines through the help of NEDO-Japan. The technology is now on its trial stage at the MIRDC facility in Bicutan, Taguig City. The project is funded by NEDO-Japan in cooperation with MIRDC, leading plastic manufacturing leader Daiwa Plastic Co., Ltd., Matsuoka Institute of Technology, Kyoto Institute of Technology, and Kobe Steel Ltd. The article talked about the introduction of cellulose, corn, starch, and soy based biodegradable plastics. The study is about manufacturing of corn based plastics here in the Philippines particularly in Baliuag, Bulacan. This article also discusses that the Philippines is currently going through about garbage disposal that made a way for a solution to use of biodegradable plastics and the proponents also gave priority for the same reason in having a study to manufacture plastics that are biodegradable to lessen the plastic wastes and eventually, to have no plastic wastes at all that cause disturbance in the environment.

20 An anonymous author on his article (2013), states: ENSO Plastics Announces Biodegradable Plastic Solutions for the Philippines the article tells about the solution that ENSO Plastics has offered the Philippines its plastic ban in some places in Metro Manila particularly in Makati City. It was said in the article that in order to help manufacturers comply with the city ordinance of Makati City, ENSO Plastics announced two new biodegradable technologies for the Philippine market, ENSO RENEW and ENSO RESTORE. The author of the article defined ENSO RENEW as a unique Renewable Thermo Polymer (RTP) derived from the waste process of agriculture, with a carbon footprint 75% lower than polyethylene. It is a high heat renewable biopolymer that provides home and industrial compost ability as well as being marine degradable. It is designed to meet the needs of applications looking for renewable solutions to meet new legislative requirements utilizing fast growing plant based material and rapid biodegradation and on the other hand ENSO RESTORE is the latest development of biodegradable additives offering superior improvements to biodegradable performance and processability/compatibility and eliminating the historical higher scrap rates of competing additives, creating a huge environmental and cost advantage. ENSO RESTORE is a leading edge technology that accelerates the natural biodegradation without any disruption to disposal method or performance. ENSO Plastics solutions are quick to implement with minimal or no change in current manufacturing. Its quick and easy to

21 integrate biodegradable technologies that comply with the recently implemented laws without difficulty or expense. This article stated the mainly deals about solutions to have biodegradable plastics because of Makati Citys plastic ban ordinance. The proponents suggest biodegradable plastics made from corn kernels to use as the substitute of non-biodegradable plastics, to help protect and preserve the environment. In an article written by Justine Tagonera (2012) Sustainability #7: No more Plastic Bags in Some Philippine Cities but Education needed. She said that the Philippine House of Representatives passed the Plastic Regulation Act Last 2011. Local ordinances have been implementing bans on the use of plastic bags and Styrofoam, especially in the Business establishments like malls and supermarkets. It takes months before it was implemented in the Business establishments. To do that Business Establishments like malls and supermarkets posted several signages that indicated that plastic bags would no longer be used in the place and consumers needed to use eco-bags or be charged for using plastic bags. Some of the Business establishment use paper bags. Some people agreed about the ordinance passed by Congress. Plastic bags had a big role to play in clogging local waterways and causing more damage during floods. But businesses also opposed the ban on plastic bags. Tagonera also said that in order to solve the problem as regard to No plastic, the government should come up with the alternative solution

22 to it. The education on recycling and proper waste disposal (trash segregation) can be one of the solutions but not all are willing to do that. The article stated that the Philippines has now passed a No plastic Regulation Act of 2011, that is why the proponents want to bring the use of biodegradable plastics as an alternative for packaging materials especially in the business establishments in the country made from corn kernels. The article published in Negroschronicle.com (2012) entitled Are biodegradable Environment friendly, Now that the City Government of Dumaguete is implementing Ordinance 231 to regulate the use of plastic bags, some controversy has arisen referring to the use of the so-called biodegradable plastic bags. Biodegradable plastics refer to a packaging material that can be broken down within a reasonable amount of time into their base compounds of carbon dioxide and water. It comes from renewable sources that are plant-based using starch and/or carbohydrates from corn, cassava, wheat, potato, etc. This is safe and is a biodegradable product referred to as bio-plastics. Plastics with the prefix OXO or OXY (oxo-biodegradable, oxydegradable) are traditional petroleum-based plastics made with an additive which allows it to degrade when exposed to oxygen and sunlight. They disintegrate into pieces, but their toxic leftover still affects the environment. Only biodegradable plastic bags that conform to

23 compostability standards ASTM D6400 or EN 13432 are truly

biodegradable and can be trusted. In the article Are biodegradables environm ent-friendly?,

Negroschronicle.com clearly stated that there are biodegradable plastics which are not really biodegradable plastics. Using a certain amount of chemical, the so-called biodegradable plastic will only just fasten up the decomposition of the plastics. The proponents can make the consumers and suppliers aware about this so that they can possibly prevent their continuous usage of fake biodegradable plastics. In an article in Philippine Daily Inquirer (2011) The Plastic Problem, Plastic is one of the problems why Philippines is always flooded every time it rains. Filipinos use, reuse and throw away the plastics which clogs the sewage system. The Senate Bill 2759, authored by Sen. Loren Legarda, asks the supermarket, restaurants and retail stores to stop using plastic bags. the companies should use biodegradable bags as an alternative. In 2010, the Muntinlupa city mayor banned plastic bags and containers made from polystyrene. The business establishment used paper bags as the substitute for plastic bags. There are many plastics in the country which are nonbiodegradable. The proponents would like to propose the manufacturing of biodegradable shopping bags made from kernel which is renewable.

24 Foreign Studies AsafKleopasSugih (2008) had a study entitled The synthesis and properties of starch-based biomaterial. It has the general overvie w of starch properties given with the potential to be a starting material for a wide range of green biomaterials. Different routes to modify starch to improve the product properties and to extend the application range were also provided in the study. Sugihs study is related to present study because his study defended starch as a material to produce green biomaterials and the present study is a starch based material which is a biodegradable plastic. The proponents used this as a proof that corn is viable as a raw material in producing biodegradable plastics that can really be a factor to help in the greeneration of the environment. Brian Momani (2009) , in his study on Assessment of the Impacts of Bioplastics: Energy Usage, Fossil Fuel Usage, Pollution, Health Effects, Effects on the Food Supply, and Economic Effects Compared to Petroleum Based Plastics discussed biodegradable plastics can be a substitute to petroleum based plastic. They are made from the renewable materials like vegetable oils and starch. He made an analysis regarding the societal issues involving bioplastics that has been carried out. Health, economic, and environmental concerns related to a switch to bioplastics were studied. Brian Momami stated the possible impacts on energy

25 usage, petroleum usage, and food production, including land usage were studied. Bioplastics were found to be superior to petroplastics in terms of energy efficiency, petroleum consumption, and carbon emissions, but inferior to petroplastics in cost and applicability. Negative effects on the food supply were also predicted with a switch to bioplastics. Pollution and safety varied on a plastic-to-plastic basis but in general bioplastics were found to be safer. It has been concluded that bioplastics are not viable for wide scale use in their current form. The proponents can use this as a basis for manufacturing the biodegradable plastics from corn and its impact in the Philippines in terms of Energy Usage, Fossil Fuel Usage, Pollution, Health Effects, Effects on the Food Supply, and Economic Effects Compared to Petroleum Based Plastics for this will be of a big help in making the study feasible in the market. In the study conducted by Kathryn Palko (2005) entitled Shifting the Pollution Problem: Recycling Plastics in Southern China, she included that even recycling is integrated into the global market system. As she discovered working in the Solid Waste-Resource of the Nova Scotia Department of Environmental and Labor, decisions determining the fate of the material from North Americas recycling programs are based on economic, rather than environmental goals. As a result, some of the plastic bottles and bags that environmentally conscious consumers place

26 diligently into their blue bags or boxes are sent to other nations for recycling often in Asia. The export of these materials is the result of decisions made by variety of economic actors in an intricate global trading network in plastic waste. This study is quite critical especially to the people living in Asia. As stated in the article, such plastic wastes are sent to other nation specifically in Asia. This is relevant in the proponents research since it makes them aware that the production of biodegradable plastics made from corn will truly help and lessen the use of petroleum-based plastics. Local Studies Bravo (2012) had a study that aimed to produce biodegradable plastic using cassava starch as its main component. Cassava starch was mixed with water, epoxidized soya bean oil (ESBO), glycerol, and polyvinyl alcohol (PVA). The mixture was then compressed and tested. Three preparations were made from the mixture. The first preparation contained 50 grams starch, 50 grams water, 50 grams PVA, 2.5 grams ESBO, and 2.5 grams glycerol. The second preparation contained 65 grams starch, 65 grams water, 50 grams PVA, 2.5 grams ESBO, and 2.5 grams glycerol. The third preparation contained 80 grams starch, 80 grams water, 50 grams PVA, 2.5 grams ESBO, and 2.5 grams glycerol. The first preparation exhibited the most desirable mechanical properties. It was concluded that the material produced was proven to be

biodegradable.

27 The study is about starch-based biodegradable plastics. The proponents may use this as the basis in manufacturing biodegradable plastics from corn kernels. According to Rona Joy Alderite (2012), in their review Effects of the mechanical and biological control strategies in sweet corn production in Davao City, they found out that Corn is an important crop in the Philippines. Just like rice, it is also a staple food for Filipinos specifically those from the Southern Philippines. Data from the Bureau of Agricultural Statistics reveal that the country is almost sufficient in corn at 99%. The sufficiency ratio has gone up over the years from 96% in 2001 to 99% in 2004-2005. However, if one looks at the countrys needs on a per corn variety basis, the country is deficient in yellow corn production. The general varieties of corn planted are yellow and white corn. Yellow corn is the one used for feeds. The requirement for yellow corn for feeds is pegged at 3.414 MMT in 2005while production was at 3.01 MMT only. This places the self-sufficiency ratio for yellow corn at 88%. The demand for feeds is around 64% of the total demand for corn and only about 22% of supply is consumed as food. Other uses of corn are for seeds (1%) and processing (13%).The production doesnt seem to match this demand for yellow corn. About 43%of the total corn production is devoted to white while the rest is for yellow. In terms of production areas, 61% of the total area for corn is devoted to white corn production and only 39% was devoted for yellow corn production. The corn sector is a vital industry.

28 Addressing the needs of the corn sector would also lead to benefiting its allied industries livestock and poultry sectors, etc. The competitive advantage of local livestock and poultry in the domestic and export markets will depend on the cost-efficiency of the domestic corn industry. Corn, on the other hand will have to contend with cheaper imported corn and feed substitutes. Corn in terms of importance, remains second only to rice. The sector received very little public investment compared to rice. In this study they stated that the Philippines has a good source of corn, So it would be easy for the proponents to establish the manufacturing of biodegradable plastics from corn kernels because of the viability of raw materials in the Philippines. Solid waste disposal has become a big problem especially in urban areas. With the rapid increase in population and industrialization, the problem will rise faster. In the study conducted by Salvacion S. Tidon (2000) entitled Management and Utilization of Urban Solid Waste, she stated that urban or growth centerspread now facing the problem of waste disposal. The large concentration of people, animals, manufactured goods, automobiles, and all kinds of commodities, altogether contributes to waste management problem. If not properly disposed of, domestic and industrial waste can look ugly, emit foul smell and become a haven of insects, rats and animals that spread diseases. These kinds of waste are called agricultural waste, industrial waste, and municipal waste. This study also included waste

29 management that includes four options: 1. Waste reduction by preventing its creation/accumulation, 2. Land filling waste, 3. Incinerate waste or treat it in other ways to reduce volume, 4. Recycle and produce compost as much as possible. This study is relevant to the proponents research since plastic wastes are considered as industrial waste. The use of biodegradable plastic from corn kernels can be a solution to the fast growing problem in using non biodegradable plastics. Research Methodology The proponents used a combination of descriptive methods, which is normally conducted to illustrate and determine patterns or

characteristics of variables in particular instances or events. It is a method in which characteristic of situations can be identified, and relationship between behaviours can be documented through carefully constructed observations. Moreover, it is a process which includes gathering, analyzing, classifying and tabulating data about prevailing conditions, practices, beliefs, processes, trends, and cause-effect relationship and the making adequate and accurate interpretations about such data which or without the aid of statistical method. Instruments and Techniques Used The proponents used the questionnaires in gathering data from the respondents in Baliuag, Bulacan. The type of questionnaires have short

30 Yes or No and multiple choices that are easy for the respondents to complete. Each questionnaire was divided into two parts: Part I which aims to obtain the profile of the respondents regarding the name of the business, the type of their business and their location. Part II aims to determine the preferences of the respondents regarding various items packaging materials use in the different business establishments. Copies of the questionnaires were distributed to the business establishments operating in Baliuag, Bulacan. After the accomplishment of copies, the researchers retrieved the answered questionnaires

immediately to prevent biases. The data gathered were arranged in quantitative form and were expressed in frequencies and proportions. The questionnaire were pre-tested by distributing copies to the classmates of the proponents who are not included in the actual survey. Sampling Procedure The proponents used the purposive sampling, taking a portion of the population that is appropriate for the study. The proponents chose this sampling technique for its simplicity that makes it relatively easy to interpret the data collected. There are 223 business establishments in Baliuag, Bulacan, and they were classified into group like dry goods, restaurants, Fast food chains, grocery stores, and Supermarkets. The method of computing the number of respondents needed in the study is through the Slovens formula, which is:

31 n= N 1 + N (e)2 Where n= Represents the sample size N= Total population E= Margin of error (5%)

n=

712 1 + 712 (0.05)2

n=

712 1 + 1.78

n=

256.12 or 257 business establishment respondents

Note: The proponents used Purposive Sampling Technique Method that is why the Feasibility adviser recommends not use the Slovens Formula.

Computation of 70% Disqualification 498 = Number of Business Establishments in Baliuag, Bulacan not using Shopping Bags in their transactions 721 = Number of Business Establishments in Baliuag, Bulacan using Shopping Bags in their transactions. 498/721 X 100 = 70%

Computation in Solving the number of respondents 721 498 = 223 number of respondents

32 Statistical Treatment of Data Upon collection of survey questionnaires, the proponents used the following statistical formulas which are the Percentage formula in order to determine the weight or magnitude of the responses for an item in the questionnaire and Frequency distribution to show the frequency of facts of each possible outcome.

You might also like

- Business Plan Plastic TilesDocument34 pagesBusiness Plan Plastic TilesAcecream LampitocNo ratings yet

- Institute of Arts Business and FinanceDocument91 pagesInstitute of Arts Business and Finance`ynah100% (1)

- BIOSTAR Business Plan FixDocument32 pagesBIOSTAR Business Plan FixYusuf RaharjaNo ratings yet

- Bioplastic PreDocument22 pagesBioplastic PreJohn M. Beato100% (1)

- Rotolo di Pizza Feasibility StudyDocument13 pagesRotolo di Pizza Feasibility StudyAliDawn RPGPIENo ratings yet

- On Biodegradable Plastics. Sapp (2019) in Her Article Named, "Philippines PlasticDocument6 pagesOn Biodegradable Plastics. Sapp (2019) in Her Article Named, "Philippines PlasticNancy Quiozon0% (1)

- Feasibility Study - Banana Peel CreamDocument55 pagesFeasibility Study - Banana Peel Creamlindsay93% (15)

- Project ProposalDocument7 pagesProject ProposalMaryjoy Perdigones-Palos50% (4)

- The Feasbility of Zea Mays (Corn) and Manihot Esculenta (Cassava)Document79 pagesThe Feasbility of Zea Mays (Corn) and Manihot Esculenta (Cassava)Angelica Janoy100% (1)

- Complete Chapter 1 6 Edited 1 2Document71 pagesComplete Chapter 1 6 Edited 1 2F Arah Tolentino Nami100% (4)

- Feasibility Study of Producing Bioplastic From Flower Stalk of Musa ParadisiacaDocument28 pagesFeasibility Study of Producing Bioplastic From Flower Stalk of Musa ParadisiacaLeah Rose Figueroa Paras100% (3)

- Seaweed As Bioplastic: Research Chapter 3 and BibliographyDocument18 pagesSeaweed As Bioplastic: Research Chapter 3 and Bibliographyjustin_domingo_2100% (9)

- CHAPTER 4 Management Aspect FINALDocument18 pagesCHAPTER 4 Management Aspect FINALPatrick Kyle AgraviadorNo ratings yet

- Potato Starch Bioplastic 2Document31 pagesPotato Starch Bioplastic 2Yang JungwonNo ratings yet

- FeasibilityDocument82 pagesFeasibilityJoyce Nievera89% (19)

- Eco-brick feasibility study QuezonDocument2 pagesEco-brick feasibility study QuezonMichelle Cruzado LagumayNo ratings yet

- Eco BagDocument29 pagesEco BagAj RosalNo ratings yet

- COMOS Piña Fiber Wallets & PursesDocument1 pageCOMOS Piña Fiber Wallets & PursesJoy Jarin100% (2)

- Feasibility Study On Street Food KioskDocument56 pagesFeasibility Study On Street Food KioskMeeko Angelo Reprado50% (2)

- JPs Coconut Wine Manufacturing Co.Document34 pagesJPs Coconut Wine Manufacturing Co.Amber Christine CadaNo ratings yet

- Environmental ScanningDocument5 pagesEnvironmental ScanningMaria Ruella LachicaNo ratings yet

- Group 1 Feasibility Study Chapter 1 3Document8 pagesGroup 1 Feasibility Study Chapter 1 3Ruth Vironic Abrogal0% (1)

- Executive SummaryDocument11 pagesExecutive Summarykhurt handrieNo ratings yet

- Management AspectDocument12 pagesManagement AspectEmmanuelle_Ang_3670100% (9)

- Chapter 2 Market StudyDocument7 pagesChapter 2 Market StudyRamir SamonNo ratings yet

- Bioplastic IncDocument11 pagesBioplastic IncMikaella Manzano33% (3)

- Pre-Feasibility Study for Starting a Meat Shop (Rs. 1.24 MillionDocument19 pagesPre-Feasibility Study for Starting a Meat Shop (Rs. 1.24 Millionmustafakarim100% (1)

- Bioplastic Sample Project PDFDocument23 pagesBioplastic Sample Project PDFVighnesh Manoj100% (4)

- Feasibility StudyDocument33 pagesFeasibility Studyeasy easyNo ratings yet

- Compostable Plates Made From Ssugarcane BagasseDocument37 pagesCompostable Plates Made From Ssugarcane BagasseJewely Ilaya100% (1)

- Chapter One Marketing StudyDocument48 pagesChapter One Marketing StudyBab Sita100% (1)

- Feasibility Study BrowniesDocument24 pagesFeasibility Study BrowniesEsjei Dwen0% (2)

- Biodegradable PlasticsDocument7 pagesBiodegradable PlasticsMousey100% (6)

- Hand Sanitizer FSDocument16 pagesHand Sanitizer FSAnonymous luJAICfQD020% (5)

- Product Feasibility Study of Seapack CompanyDocument299 pagesProduct Feasibility Study of Seapack CompanyAllyza PunsalanNo ratings yet

- Feasibility Study - SamplesDocument14 pagesFeasibility Study - SamplesAi Zy67% (3)

- Acknowledgement Sample (Feasibility)Document1 pageAcknowledgement Sample (Feasibility)Cristina AblanidaNo ratings yet

- Final Draft. THESISDocument54 pagesFinal Draft. THESISLucina AquinoNo ratings yet

- BioplasticDocument11 pagesBioplasticWeng Bartolini100% (1)

- Berger Paints Bangladesh Financial AnalysisDocument20 pagesBerger Paints Bangladesh Financial Analysisarian11No ratings yet

- Financial AssumptionsDocument4 pagesFinancial AssumptionsMarianne Dell Oberes100% (1)

- Project Feasibility Study of Producing Banana VinegarDocument233 pagesProject Feasibility Study of Producing Banana VinegarRaniag Pwd67% (3)

- Final FeasibDocument105 pagesFinal FeasibJoshua CabinasNo ratings yet

- Feasibility Study Updated FinaleDocument52 pagesFeasibility Study Updated FinaleEnirethac LlrettocNo ratings yet

- Business Plan for Manufacturing Bags from Banana Fibers in UgandaDocument41 pagesBusiness Plan for Manufacturing Bags from Banana Fibers in UgandaSajja Phillip100% (6)

- Socio Economic StudyDocument10 pagesSocio Economic StudyAntonette Desear50% (2)

- Bagong Barrio Caloocan City Leche Flan BusinessDocument36 pagesBagong Barrio Caloocan City Leche Flan Businessdyenniepoh200050% (12)

- Banana Peelings As Dishwasher Science Investigatory ProjectDocument6 pagesBanana Peelings As Dishwasher Science Investigatory ProjectJamaica Kim AsuncionNo ratings yet

- Management Finals 2Document21 pagesManagement Finals 2Judy Ann BagulingNo ratings yet

- 1.0 - 4.0 Management FeasibilityDocument18 pages1.0 - 4.0 Management FeasibilityRommel MananguitNo ratings yet

- CassavaDocument19 pagesCassavaMaria Cristina Peradilla Magpantay100% (3)

- Feasibility Study on Using Waste Materials for Hollow Block ProductionDocument42 pagesFeasibility Study on Using Waste Materials for Hollow Block ProductionKenneth Mendez0% (1)

- Bamboo Cutlery Entrepreneurial Idea ProposalDocument17 pagesBamboo Cutlery Entrepreneurial Idea ProposalAnne AsuncionNo ratings yet

- (Edit) Feasibility StudyDocument47 pages(Edit) Feasibility StudyJames Paulo AbandoNo ratings yet

- Zest O CorporationDocument22 pagesZest O CorporationCarlo MedenillaNo ratings yet

- Cassava and Arrow Starch As BioplasticDocument18 pagesCassava and Arrow Starch As BioplasticDenise MarquezNo ratings yet

- Bsba Feasibility StudyDocument18 pagesBsba Feasibility StudySebastienne Salazar100% (1)

- Oyster Mushroom PolvoronDocument14 pagesOyster Mushroom PolvoronMark Lloyd Argis100% (3)

- Filipino Snack Business FeasibilityDocument10 pagesFilipino Snack Business FeasibilityChristian Miguel Avila AustriaNo ratings yet

- Title:: Sustainability The Key Driver For InnovationDocument3 pagesTitle:: Sustainability The Key Driver For InnovationShailesh JadhavNo ratings yet

- List of Figures Chapter 2 Marketing ResearchDocument2 pagesList of Figures Chapter 2 Marketing ResearchDaphne De LeonNo ratings yet

- Done-Gantt Chart Chapter 567 EditedDocument1 pageDone-Gantt Chart Chapter 567 EditedDaphne De LeonNo ratings yet

- DONE-Chapter 7 CompleteDocument8 pagesDONE-Chapter 7 CompleteDaphne De LeonNo ratings yet

- DONE-Chapter 6 CompleteDocument3 pagesDONE-Chapter 6 CompleteDaphne De LeonNo ratings yet

- Done DedicationDocument2 pagesDone DedicationDaphne De LeonNo ratings yet

- Done-Chapter 4 PP 84-110Document27 pagesDone-Chapter 4 PP 84-110Daphne De LeonNo ratings yet

- Position # Daily Rate Basic Salary Sss Philhealth Pgib Monthly AnnualDocument2 pagesPosition # Daily Rate Basic Salary Sss Philhealth Pgib Monthly AnnualDaphne De LeonNo ratings yet

- DONE-Chapter 5Document13 pagesDONE-Chapter 5Daphne De LeonNo ratings yet

- Done-Chapter 3 PP 63-83Document19 pagesDone-Chapter 3 PP 63-83Daphne De LeonNo ratings yet

- Done-Chapter 2 PP 32-62Document30 pagesDone-Chapter 2 PP 32-62Daphne De LeonNo ratings yet

- DONE Chap 5 117 - 119Document4 pagesDONE Chap 5 117 - 119Daphne De LeonNo ratings yet

- Feasibility Study: Manufacturing of Biodegradable Shopping Bags Made Form Corn KernelsDocument32 pagesFeasibility Study: Manufacturing of Biodegradable Shopping Bags Made Form Corn KernelsDaphne De Leon83% (6)

- DONE Approval Sheet Acknowledgements AbstractDocument8 pagesDONE Approval Sheet Acknowledgements AbstractDaphne De LeonNo ratings yet

- DONE - Chapter 5 123Document2 pagesDONE - Chapter 5 123Daphne De LeonNo ratings yet

- Landor Associates On IndiaDocument6 pagesLandor Associates On IndiaameygokarnNo ratings yet

- Homepage Brochure31Document14 pagesHomepage Brochure31Haider AliNo ratings yet

- Status of Dairy SectorDocument12 pagesStatus of Dairy SectorRamindra SuwalNo ratings yet

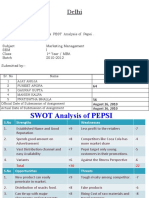

- Swot and Pest-PepsiDocument3 pagesSwot and Pest-Pepsipuneet_aroraNo ratings yet

- AmulDocument50 pagesAmulAnjana BaruahNo ratings yet

- Australian Storiesof Social Enterprise FINALDocument142 pagesAustralian Storiesof Social Enterprise FINALBrodie McCullochNo ratings yet

- Project PPT Recovered)Document18 pagesProject PPT Recovered)Pawan Puroli100% (1)

- THE POWER OF FERMENTATIONDocument62 pagesTHE POWER OF FERMENTATIONCheng Si Jing100% (1)

- Is 1010 1968Document19 pagesIs 1010 1968akNo ratings yet

- Ramada Marketing Report (Full)Document9 pagesRamada Marketing Report (Full)Haider SaleemNo ratings yet

- Business Advantage Intermediate WorksheetsDocument16 pagesBusiness Advantage Intermediate WorksheetsBaruch BenítezNo ratings yet

- Chewing Gum: Strawberry LemonDocument16 pagesChewing Gum: Strawberry LemonSucreNo ratings yet

- Bright Farms ProjectDocument13 pagesBright Farms Projectapi-364112475No ratings yet

- Arun Ice CreamDocument3 pagesArun Ice CreamAslam Khan0% (1)

- 16 Brilliant Facts About Mumbai Dabbawalas You Absolutely Need To KnowDocument12 pages16 Brilliant Facts About Mumbai Dabbawalas You Absolutely Need To KnowPk TripathiNo ratings yet

- Module On Banquet and CateringDocument169 pagesModule On Banquet and Cateringbarabas skyNo ratings yet

- "Coromandel International Limited Q1 FY2020 Earnings Conference Call" July 23, 2019Document23 pages"Coromandel International Limited Q1 FY2020 Earnings Conference Call" July 23, 2019mealokranjan9937No ratings yet

- Ocean Alexander & Tiara Yachts 2nd Quarter NewsletterDocument12 pagesOcean Alexander & Tiara Yachts 2nd Quarter Newsletterhmaddy6433No ratings yet

- The Fat Girl 297rfhc PDFDocument8 pagesThe Fat Girl 297rfhc PDFAlejandra BentzNo ratings yet

- At The Restaurant Vocabulary Matching Exercise WorksheetDocument2 pagesAt The Restaurant Vocabulary Matching Exercise WorksheetMarian Pascual100% (1)

- Guidelines On Quality Assurance For Pharmacy-Prepared Sterile ProductsDocument19 pagesGuidelines On Quality Assurance For Pharmacy-Prepared Sterile ProductsStratós Investigación & ComunicaciónNo ratings yet

- World: Oats - Market Report. Analysis and Forecast To 2020Document7 pagesWorld: Oats - Market Report. Analysis and Forecast To 2020IndexBox MarketingNo ratings yet

- Sugar TechnologyDocument2 pagesSugar Technologymorgoth_nazgul2241100% (1)

- Leading Indian Nonprofit Expands Nutrition Services with Community-Based Social VenturesDocument33 pagesLeading Indian Nonprofit Expands Nutrition Services with Community-Based Social VenturesWaheed MohammedNo ratings yet

- Banana Market in EthiopiaDocument38 pagesBanana Market in EthiopiaPrasanna KumarNo ratings yet

- Egg PowderDocument9 pagesEgg PowderGisel Ingrid Puma Torrez60% (5)

- Events Management Services NC3: "Modern Filipiniana-Themed Graduation Day"Document42 pagesEvents Management Services NC3: "Modern Filipiniana-Themed Graduation Day"jennifer mirandaNo ratings yet

- Jollibee SWOTDocument5 pagesJollibee SWOTceistNo ratings yet

- MCDONALDS FRANCHISEDocument14 pagesMCDONALDS FRANCHISEKhánh ChúcNo ratings yet

- Remote Environment - Global & DomesticDocument9 pagesRemote Environment - Global & DomesticAnkur PathakNo ratings yet