Professional Documents

Culture Documents

Turbo Chargers

Uploaded by

Shakeeb AhmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbo Chargers

Uploaded by

Shakeeb AhmedCopyright:

Available Formats

Turbochargers by Bre

The turbocharger, or a just simply the turbo, has been around now for more than a century. It was invented by Swiss engineer named Alfred Buchi in 1905 and was first used on the diesel engines of ships and locomotives from the 1920s. It was used on the engines of production airplanes from the 1930s and on truck engines from the late 1940s. But it only found its way onto the car engine of a production vehicle in 1962 when it was used on the Oldsmobile Cutlass Jetfire. As a forced induction system, a turbo is nothing more than an air pump that is driven by the exhaust gasses of a car engine. It consists of a compressor-wheel and a turbine-wheel that are connected by a common shaft. The compressor increases the density of the air that enters the intake manifold by forcing more air into the intake manifold than what the car would normally ingest. This higher intake air density contains more air molecules and produces more power when combined with the correct amount of fuel. This is similar to the way NOS allows more fuel to be burned by providing extra Oxygen as explained by Ian. The major difference between NOS and a turbo is that the turbo provides a constantsupply of extra Oxygen to the car engine while NOS only provides a limited supply. You've got three options when it comes to turbocharging a car: You can simply buy an OEM turbocharged car such as a Mitsubishi Lancer Evolution, a Nissan GT-R, a Nissan 300ZX, a Nissan Silvia spec-R, a Toyota Supra, etc. You can buy an aftermarket turbo kit for your car engine. Here there are many options to choose from. There are Garrett turbo kits, STS turbo kits, Turbonetics turbo kits, and so much more. You can also build your own turbo system, which could be the best approach to car engine turbocharging as it gives you the option to build a system that meets your performance requirements and your objectives.

A complete turbo kit consists of the turbocharger as well as the necessary parts required to bolt the turbocharger onto the car engine. This includes an exhaust manifold, intake runners (plumbing to connect the turbo to the intake manifold), and can include an intercooler as well as cooling and lubrication feed lines for the turbo. When building your own turbo system, selecting the perfect turbo for a particular application can be a real challenge as no one turbo is best suited to all applications. There are a number of things you need to consider when selecting a turbo. These include: The capacity of your engine. The number of valves. At what RPM to you want the turbo to come in. The type of fuel you plan on using. The turbo boost you plan on running. The amount of horsepower you want.

In this custom-car.us turbo guide, we'll thoroughly explain the mechanics of turbochargers and turbo systems and show you how to design and install your own turbo system. As always, the DIY route is not for everyone and if you'd rather install a turbo kit, we cover that too! For now, we'll start with the turbocharger basics ...

Turbo Basics by Bre

Approximately a of the energy produced by an internal combustion engine is lost as thermal energy that is fed out the exhaust manifold. It is this energy that is used to drive a turbocharger. When the exhaust gases are forced through the turbine-wheel, the turbine-wheel becomes a reduced-flow area in the exhaust system and causes some back pressure, which causes some loss in engine power. Of course, back pressure increases as the size of the turbo decreases and inversely, back pressure decreases as the size of the turbo increases. So a larger turbo causes a smaller loss in power, but it also requires more air-flow, and hence more RPM, to spin up or spool up and produce boost pressure (i.e. above-atmospheric pressure). This is referred to as turbo lag. So a larger turbo produces less back pressure but has more turbo lag while a smaller turbo produces more back pressure but has less turbo lag. So what is better? The answer to that depends on what you're looking for low-end torque, top-end power, or a bit of both.

A Garret Turbocharger

TURBO LAG Later on in the series we'll look at turbo sizes, but for now, let's get back to turbo lag. Turbo lag is defined as the time between the point when you hit the accelerator and the point at which the turbo produces enough boost to create boost pressure. This may sound like a bad thing but what would happen if you didn't have a turbo? You'd get no boost! So it's either no turbo lag or no boost. A simple choice, I think, especially when you consider that the loss of power due to back pressure caused by the turbine-wheel is hardly noticeable. Provided you haven't done something silly like lower your compression ratio! In years gone by car manufacturers built production turbo motors with low compression ratios to counter the thermodynamic effect of compressing air. Any time air is compressed, the temperature of the air increases. This affects the internal combustion temperatures in the engine. But when a suitable intercooler is used to cool the intake air, normal compression ratios can be used. With normal compression ratios, you're still getting close to normal aspirated performance until you get boost and then you're flying with an up to 50% increase in bhp, depending on the boost you're running! But let's not get too excited just yet, we'll go back turbo boost first. BOOST PRESSURE We've said that turbo lag is the time between the point when you hit the accelerator and the point at which the turbo produces enough boost to create above-atmospheric pressure in the intake manifold. The boost level at which the turbo produces enough boost to create above-atmospheric pressure in the intake manifold is called the boost threshold. This is the point at which the exhaust gas flow over the turbine is high enough to overcome inertia and spin the turbine-wheel fast enough so that the compressor-wheel can begin creating boost pressure. From that point on boost will increase but it is important to remember that the quality of the fuel you run and the temperature of the air pumped into the intake manifold will influence the amount of boost you can run. With normal pump fuel, a stock engine and an intercooler, you can safely run at 7-12 psi boost. A wastegate regulates the boost pressure by allowing exhaust gases to pass around the turbine-wheel so as to limit the exhaust gas flow that drives the turbine-wheel.

But more about wastegates at a later stage; here's something to ponder on for now: A properly installed and tuned turbo operating at 10 psi can reduce the 0-60 mph time by a third, despite turbo lag! Yes, you read right a 10 second car will do 6.66 seconds if the turbo is done right! TWIN-SCROLL TURBINES Some turbochargers feature twin-scroll turbines, which is basically two scrolls mated together on the turbine side of the turbocharger that is fed by the exhaust system. When used on four cylinder engines, twin-scroll turbochargers make better use of exhaust pulses as it allows for the separation of exhaust gasses so that alternate pulses can be fed into the system. This creates better exhaust gas scavenging and higher backpressure at the turbine wheel. This in turn causes the turbine wheel to spool up faster and reduces turbo lag, which is one of the reason why the good people at Mitsubishi opted for a twin-scroll turbocharger on the Mitsubishi Lancer EVO X. We discuss backpressure and exhaust scavenging in more detail in our section on designing and building performance exhaust systems.

Turbo Selection by Bre

There are a number of factors, such as turbo lag, boost threshold, heat, back-pressure, low-end torque, and top-end power, that you must take into account when selecting a turbo. A large turbo will suffer from turbo lag and won't produce much low-end torque but it also won't put too much heat to the intake charge, won't have much back-pressure, and will produce loads of top-end power. A small turbo, on the other hand, won't have much turbo lag and will produce loads of low-end torque but will also have lots of back-pressure and will add lots of heat to the intake charge. You can't have the best of both worlds but you can select the best turbo to suit your needs. Deciding which turbocharger best suits your needs in a bit complicated. You need to know what your objectives are street car, a purpose built miler, a race car, or a rally sprint car. Once you know what you want, you should have a better idea of at what rev range you want your power band to be. Once you know that, then it becomes easier as you can select a compressor-wheel to match your rev range. SELECTING THE COMPRESSOR WHEEL The compressor-wheel is most efficient at a particular boost pressure or pressure ratio (PR) and air flow (cfm). At this point the turbo will put the least amount of heat into the intake charge; anywhere else, including at lower boost pressures or revs, it will put more heat into the intake charge. The idea id that the point of efficiency should coincide with your most useful rev range. So it's a matter of determining the bore diameter of the compressor wheel that is most efficient at your most useful rev range; and by most efficient, I mean at least 60% efficient. Each compressor-wheel has a compressor map that maps efficiency at various pressure ratios and air flow rates but you need to calculate the air flow rate for your engine. You can use the following formula to calculate the air flow rate: PR CC RPM VE In this formula, PR is the Pressure Ratio. This is the absolute pressure produced by the turbo divided by atmospheric pressure. Atmospheric pressure is 14.7 psi at sea level. If you're running 7 psi of boost, your absolute boost pressure is 21,7 psi (7 psi + atmospheric pressure). This will give you a PR of 1,47 (21,7 14,7), which means that approximately 47% more air/fuel mixture is being forced into each cylinder. We halve the RPM because a four stroke internal combustion engine requires two revolutions to

complete one power cycle CC is engine capacity but in cubic feet and not in cubic inches. Why cubic feet? Because cfm is cubic feet per minute. You can convert engine capacity to cubic feet by dividing cubic inches by 1728. VE is volumetric efficiency. This is the total amount of air/fuel mixture that each cylinder ingests during the intake stroke and is expressed as a percentage of the actual volume of the cylinder. You can calculate the VE as follows: 2 mass airflow rate air density swept volume RPM

Yes, I know, it's getting a bit complicated! Fortunately we can use a rule of thumb that states that modern engines have a VE of 80-90% while older engines like the Datsun L-series engine have a VE of 60-70%! SELECTING THE TURBINE WHEEL The turbine-wheel uses exhaust gas energy to spin the compressor-wheel fast enough to produce the required air flow rates at the desired boost pressure. A larger turbine-wheel will produce more power to spin the compressor-wheel at the required air flow rates, although s smaller turbine-wheel will spin faster. A smaller turbine-wheel will also offer greater restriction to the exhaust gas flow, causing back pressure between the turbine-wheel and the combustion chamber. So the basic size of the turbine wheel will be determined by the air flow required from the compressor-wheel. The important element here is the extruder bore size, i.e., the inner diameter of the turbine outlet. An extruder bore with a 2 inchdiameter will be sufficient for a compressor-wheel air flow of 250 cfm to 400 cfm; an extruder bore with a 2 inch diameter will be sufficient for a compressor-wheel air flow of 400 cfm to 500 cfm; an extruder bore with a 2 inch diameter will be sufficient for a compressor-wheel air flow of 500 cfm to 600 cfm; an extruder bore with a 2 inch diameter will be sufficient for a compressor-wheel air flow of 600 cfm to 800 cfm; and an extruder bore with a 3 inch diameter will be sufficient for a compressor-wheel air flow of over 700 cfm. CONSIDERING THE A/R RATIO The A/R ratio is another important consideration in choosing the turbine-wheel. The A/R ratio is the ratio between the cross-sectional area (A) of the turbine scroll at any one point and the distance or radius (R) from that point to the center of the turbine-wheel. This ratio is always constant so each point along the turbine scroll will have the same A/R ratio. A turbo with a smaller A/R ratio will tend to create more torque while a turbo with a larger A/R ratio will provide more power because more exhaust gas energy will be acting on the turbine-wheel. Generally, an A/R ratio of 0.7 will provide better low-end response, while an A/R ratio of 1.4 will provide more top-end power. OTHER CONSIDERATIONS Other important factors that you should take into account when selecting the turbo include cooling and the location of the wastegate. As I've mentioned in our turbo lubricationsection, a turbo with a water cooled bearing section will have a longer lifespan and will be more reliable because it solves a few major lubrication issues. We discuss wastegates and blow-off valves in our turbo boost control section but the short of it all is that a turbo with a remote wastegate produces more power, but a turbo with an integrated wastegateis much cheaper.

Turbo Bearings and Lubrication by Bre

Lubricating the shaft inside the turbo is not too difficult and most turbo manufactures provide adequate oil feeds to the shaft's bearing housing. However, the extremely high temperatures that the turbine creates will cause the oil in the bearing housing to disintegrate and loose its viscosity and lubricating qualities and will cause coking in the turbo bearing housing. Coking will impede the flow of oil to the bearing and will exacerbate the problem. Four things contribute to coking: High temperatures in the turbo's bearing housing Using engine oil that is not capable of operating in high temperatures Using engine oil that has a wide multi-viscosity range the additives used to achieve multiviscosity are the material that causes coking Not changing the engine oil frequently enough

There are two simple solutions to this problem: Change the engine oil more frequently Get a turbo with a water jacket around the bearing housing. It might be a good idea to look out for a turbo with a water jacket around the bearing housing when selecting a turbo

The best engine oil you can use in your turbo engine is a synthetic, straight viscosity oil that is suitable for the temperature range of both the climate in the area that you live, and the engine. The important thing is to change the engine oil and oil filter regularly. Even if the turbo has a water jacket around the bearing housing, you should still change the engine oil more frequently than on naturally aspirated engines, and you need to do this diligently! Changing the engine oil every 2,000 miles should do the trick. You also need to ensure that the oil pressure to the turbo does not exceed 70 psi or else that oil will push past the oil seals in the turbo and cause frequent, if not continuous, smoking. If your oil pump produces more oil pressure than the turbos seals can handle, you should install a restrictor in the oil feed line, or a bypass system to reduce the oil pressure to the turbo. A bypass system is more reliable but in both cases you must ensure that the oil pressure to the turbo is adequate at idle and at full operation. The oil seals in the turbo do not operate properly if they are bathed in oil, therefore, you should ensure that the oil return line to your oil sump is big enough to allow for proper drainage. The oil return line should have an inner diameter of at least a inch. The oil drain hole in the turbo should also be aligned as near vertically downward as possible. Best practice to ensure that your turbo lasts is to cruise at low RPM where no boost pressure is created for the last 15 minutes of your journey to let the turbo cool down properly. Some people suggest that you let the engine idle for 30 seconds before turning off the engine, or install a turbo timer to automate the task, but the oil pressure at idle speeds is too low to provide sufficient lubrication. You need at least 1,500 RPM for enough oil pressure to ensure that the bearings and shaft receives sufficient lubrication while the turbo cools down. It is for this reason that we do not recommend installing a turbo timer. You should also change the engine oil every 2,000 miles, and use a high-quality, synthetic, straight viscosity oil. These three simple things will ensure that you prolong the life of your turbo and that you never need worry about coked up turbo bearing failure again.

Journal bearings vs Ball bearings by Bre

Journal or sleeve bearings have long been used on turbochargers but lately improvements in ball bearing technology has made ball bearings a viable option. However, when it comes to choosing between a turbocharger with a journal or sleeve bearing and a turbocharger with a ball bearing, there's only one

choice the turbocharger with a ball bearing. In almost every aspect, the latter is the better choice. Understanding the advantages of the ball bearings over journal bearings requires that we first understand how the two bearings work. Let's begin with the traditional journal bearing system. JOURNAL BEARINGS Journal bearings have traditionally been used on turbochargers. This bearing system consists of two short journal bearing at either end of the turbocharger's main shaft. These two bearing are usually copper bushes with oil holes. A thin film of oil is fed through the bushes to provide clearance between the bush and the main shaft, with the contact area between the bush and the main shaft being fairly large. In addition, a metal thrust bearing with a similar coat of oil is used to carry the thrust load on the main shaft. In some designs the two bushes are replaced by a longer sleeve with a scalloped center area resulting in a very similar basic design. BALL BEARINGS The ball bearings on the other hand consists of either a single cartridge design with a row of tapered ball bearing on either end, or two separate ball bearing to support either end of the turbocharger's main shaft. These bearing are also lubricated by an oil feed but the actual rotating area between the main shaft and the bearing is greatly reduced. This means that less lubriction is required in the ball bearing design. In addition, the use of a tapered ball bearing eliminates the need for thrust bearings as the taper design carries the thrust load on the main shaft. ADVANTAGES OF BALL BEARINGS OVER JOURNAL BEARINGS From this description, we can easily see why ball bearings are better. Firstly, the ball bearings have a far smaller contact area and thus have a lower frictional drag coefficient. In turn, less frictional drag means better response and less power consumption. As a result, the turbo can spool up much faster, which reduces turbo-lag and offers a majorperformance advantage over journal bearing turbochargers at lower to mid turbocharger speeds. And, secondly, the reduced contact area of the ball bearings means that it requires far less lubrication, allowing for lower oil pressure feeds. This makes the turbocharger more reliable in terms of lowering the chance of seal leakage, and reducing the chance of turbo failure during engine shut down. The elimination of the thrust bearing also makes the ball bearing turbocharger more reliable.

Turbochargers and Intercoolers by Bre

Intercoolers reduce intake heat

Although it is not a performance part per se, an intercooler is nevertheless a fundamental part of a turbocharger system. While there are two types of intercoolers on the market air-to-air and air-to-water intercoolers, only air-to-air intercoolers are practical on street and endurance type racing cars. Air-towater intercoolers work wonders on extremely short runs and are ideal for drag cars. You can think of an as a radiator that cools the compressed air that compressor-wheel pumps into the intake manifold. This compressed air is referred to as the intake charge. Heat is a byproduct of the compression of air and whenever air is compressed, such as when turbochargers and other forced induction systems are used, the air (intake charge) is heated. This is called the thermodynamic effect of compressing air. On an internal combustion, air temperature is important because it affects air density and because too much heat will result in pre-ignition, knocking and detonation. The role of the intercooler is to reduce the temperature of the intake charge. Cooling the intake charge provides two major benefits: it makes the intake charge denser denser air produces more power; and it inhibits detonation. However, the intercooler has one major disadvantage: it causes adrop in boost pressure! This is inescapable; the best you can do is to minimize the pressure loss caused by the intercooler. There are a number of things you can do when designing your intercooling system to keep pressure loss at a minimum. You can incorporate a plate-and-shell core rather than an extruder core as the plate-andshell core produces less flow resistance. The internal flow area of the core also affects pressure loss. Selecting an intercooler with the correct internal flow area is important to keep pressure loss at a minimum. Here I have found that a turbo system that produces a flow rate of 400 cfm requires an internal flow area of approximately 20 sq in. You can use the following graph to estimate the required internal flow area based on your turbo's flow rate.

Once you've estimated an idea of what internal flow area you require, you can determine the actual core size that you require. This is a bit tricky. Typically, only about 45% of the intake charge will come into contact with the heat exchange elements of the intercooler core. So we must first divide the required internal flow area by 45% then divide the result by the core thickness. This gives us the following formula: internal flow area 0.45 core thickness While we're talking about core thickness, remember that the intake charge flows through the length of the core and the cooling, ambient air flows through the thickness of the core but that every subsequent inch of core thickness is 40% less effective as the air flowing through it heats up. Thus, a thinner core intercooler with a larger fontal area is more efficient than a thicker intercooler with a smaller frontal area.

You can also improve the efficiency of your intercooler by fitting a duct to it. Without a duct, approximately 25% of the air molecules will pass through the core; the rest will follow the path of least resistance around the core. Any improvement here will greatly increase the efficiency of your intercooler. If you're running high boost pressures on 91-93 octane gas and a fairly high compression ratio, you may also want to supplement your intercooler with a water injection system.

Water Injection by Bre

On turbocharged cars water injection can also be used to cool the intake charge and reduce the possibility of detonation by spraying atomized water droplets into the induction system. While some engine tuners to frown upon this practice, it is something worth considering if you're running high boost or experiencing detonation. Water has a very highspecific heat capacity, which means it can absorb a lot of heat energy when it changes from one state to another without causing an increase in temperature. The result is a reduction air temperature when water changes from liquid to vapor. For this reason, water injection systems have been around in one form or the other since the 1930s and were also used on a variety of turbocharged aircraft engines that were used during World War II. However, water injection is only required if you're running high boost of more than 12 psi, and should be used in conjunction with a good intercoolerrather than as an alternative to an intercooler. The water injection system basically consists of a plastic storage tank, a water injector, which is similar to a fuel injector and is responsible for atomizing the water droplets, a high pressure pump, a pressure sensor connected to the intake manifold, and an intake air temperature sensor. Calling it water injection is possibly inaccurate as it can either be pure water, preferably distilled water, or a mixture of water and methanol. Either way, atomized liquid is usually injected into the intake system when the intake air temperature is exceeding a certain value and the engine is on boost. It is usually injected into the intake runner three to six inches before the throttle body but can also be injected directly into the combustion chamber. Another option is to have the inject point downstream of the intercooler to assist in pre-cooling, but this can cause condensation and water damming up in the intercooler if the injector does not provide sufficient atomization.

A Water/Methanol Injection Kit.

HOW WATER INJECTION WORKS Atomized water rather, that vaporized water is injected into the air intake system as water only boils at 212 F at sea level while temperature of the intake charge would be much lower, having already passed through the intercooler. When water is injected into the air intake system it absorbs quite a bit a heat from the intake charge. When the atomized water, together with the intake charge, enters the combustion chamber, the high temperature of the combustion chamber causes the atomized water droplets to vaporize. During the process of vaporization a large amount of heat energy is absorbed, resulting in anther drop in intake charge temperature! Unfortunately, vaporized water also displaces a large volume that would have been filled with air molecules, but the lowered temperature in the combustion chamber more than makes up for this loss in volume. Indeed, the lowered temperature in the combustion chamber allows us to run higher boost pressures and, consequently, allows us to make more power! DISADVANTAGES OF WATER INJECTION There are some disadvantages to using a water injection system, some of which can be catastrophic! Firstly, a failure in your water injection system would mean a complete lack of detonation suppression, which could quickly lead to engine failure! To prevent such a scenario, you need a failsafe system that will cut engine power when the intake charge temperature downstream from the water injector reaches a certain threshold. Secondly, the minerals in tap water will quickly clog up the water injector and will result in a failure to deliver the correct amount of water. For this reason you should use distilled water in your water injection system. As with any other system, you need to ensure that only quality hoses and clamps are used in order to ensure the reliability of you water injection system. Finally, determining the correct amount of water that needs to be injected can be pretty tricky as you do not want high boost pressure with too little detonation suppression! The safest way of reaching the correct amount of water injection for a particular application is to start with a lower boost pressure and slowly increase boost pressure. If detonation occurs, back off immediately and increase the water injection if a greater boost pressure is required. WATER AND METHANOL INJECTION As an alternative to straight water injection, some engine tuners use a mixture of water and methanol. Usually 50% methanol by weight is used. Water and methanol injection provides the same detonation suppression as just water while it also provides the potential for extra horsepower. Methanol is both hygroscopic, which means it absorbs water, andmiscible, which means it mixes well with water. It is also much more volatile than water, which means it vaporizes much quicker than water. This means that the methanol will vaporize before the intake charge enters the combustion chamber unless it is injected directly into the combustion chamber. This vaporization reduces the temperature of the intake charge, and once the intake charge reaches the combustion chamber, the atomized water droplets will vaporize to further reduced the temperature of the intake charge in the combustion chamber. But methanol has another advantage; it is also a fuel that effectively increases the octane rating of gasoline, which helps reduce detonation and allows you to increase the compression pressure for an extra bit of horsepower as well.

Boost Control by Bre

A turbocharger increases its airflow rate much faster than an internal combustion engine can adapt to the increase in airflow. If left unchecked, the turbo will almost instantaneously produce extremely high boost pressures with catastrophic results on the engine. To prevent this catastrophe, we need to regulate the boost pressure that the turbo can produce so as to prevent overboosting. This is where the wastegate and Blow-Off valve (BOV) comes in.

THE WASTEGATE A wastegate is a mechanical device that controls boost pressure by regulating the exhaust gas energy that flows around the turbine-wheel by bleeding off excess exhaust gas energy. In so doing the wastegate controls the speed at which the turbine-wheel can spins. The turbine-wheel drives the compressor-wheel, which in turn produces boost pressure. The wastegate is held shut by a spring. As boost builds, the wastegate actuator diaphragm pushes the wastegate open against the spring. The size of the diaphragm and strength of the spring determine how much boost is required to open the wastegate. There are two types of wastegates on the market: integral wastegates that are built into the turbo; and remote wastegates that are integrated into the exhaust system ahead of the turbo. The remote wastegate allows for a bigger valve and a smoother flow path which provides better boost control and produces better performance. A remote wastegate can also be controlled by a manual boost controller or by an electronic boost controller. The manual boost controller begins opening gradually as the boost pressure builds up. This affects the efficiency of the turbo system and increases turbo lag. An electronic boost controller, on the other hand, can be programmed to open at a preset boost pressure and can even be programmed for increased boost under certain circumstances. Needless to say, the electronic boost controller is the way to go! The exhaust feed for the remote wastegate should be integrated into the exhaust header so that it is exposed to as much of the pressure in the exhaust system as possible. This means that the pipe for the wastegate should be connected at or after the collector where all the primary exhaust pipes join together, or after the last exhaust port on a log-type header. Also, the wastegate should be located at an angle that does not restrict exhaust gas flow to the wastegate. The exhaust gas must be able to flow to the wastegate so that the wastegate can detect the correct exhaust pressure in the system. A Y-pipe that provides symmetry and easy flow paths would be ideal. The exhaust gas flow from the wastegate into the tailpipe should also not interfere with the gas flow from the turbine. Any interference will increase back pressure! For best performance, the pipe that feeds exhaust gas from the wastegate to the tailpipe should be at least 18 inches long. A completely separate tailpipe for the wastegate exhaust gas would be even better as this provides the best wastegate response and the lowest back pressure. When going this route remember to allow for tailpipe expansion as the tailpipe from the wastegate will experience fluctuations in temperature. However, in most road cars legislation requires that your wastegate feed back into the main exhaust system ahead of the catalytic converter. Whether you use an electronic boost controller or not, you should have an emergency boost control device in case the wastegate fails. This device can be a simple vent valve or a boost-sensitive electronic switch that cuts the fuel supply. A boost-sensitive electronic switch that cuts the fuel supply can be set to 1 or 2 psi above the wastegate setting. Should the wastegate fail, the cut-out switch will stop the fuel supply, which will cause the boost pressure to drop.

THE BLOW-OFF VALVE (BOV)

A GReddy Blow-Off Valve

The Blow-Off valve (BOV), or compressor bypass valve, performs a related function on the air inlet side of the turbocharger. The purpose of the BOV is to relieve intake pressure and to reduce compressor surge that occurs when the throttle is opened and closed suddenly. When the throttle is closed suddenly, the airflow in the intake is greatly reduced, which causes airflow and pressure fluctuations. These fluctuations cause compressor surge which places high loads on the compressor wheel and the thrust bearing. Left unchecked, this will lead to thrust bearing failure and is where the BOV comes in. The Blow-Off valve (BOV) should located between the compressor outlet and the throttle body, or between the intercooler and throttle body if and intercooler is fitted. It uses the manifold pressure signal and spring force to detect boost pressure fluctuations in the air intake that is caused by the sudden closure if the throttle. When it detects pressure fluctuations, the BOV vents the boost pressure to atmosphere to reduce compressor surge.

You might also like

- Intake and Exhaust System TuningDocument15 pagesIntake and Exhaust System TuningAmir Izham100% (1)

- Gas Turbine DIYDocument37 pagesGas Turbine DIYDavide CiavattiNo ratings yet

- Carburetor Tuning: Understanding CarburetionDocument11 pagesCarburetor Tuning: Understanding CarburetionMuhammad Rashid Jaidon ⎝⏠⏝⏠⎠80% (5)

- Garrett Turbo System OptimizationDocument11 pagesGarrett Turbo System OptimizationlaaliautoNo ratings yet

- How to rejet a Honda Shadow ACE VT1100C2 motorcycle carburetorDocument5 pagesHow to rejet a Honda Shadow ACE VT1100C2 motorcycle carburetorheartofdixieNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Garrett Diesel TechDocument10 pagesGarrett Diesel TechRazvan SecarianuNo ratings yet

- TurbochargerDocument17 pagesTurbochargerAravindhRaj100% (1)

- TurbochargerDocument64 pagesTurbochargerAmanpreet Singh100% (22)

- Pub - The Physics of The Standard Model and Beyond PDFDocument314 pagesPub - The Physics of The Standard Model and Beyond PDFEduardo Gareca100% (2)

- Music GcseDocument45 pagesMusic GcseAimee DohertyNo ratings yet

- Welcome To Car Tuning TipsDocument60 pagesWelcome To Car Tuning TipsVeer HondaNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- TurbochargerDocument17 pagesTurbochargerdinucv83% (6)

- Functions of an Exhaust ManifoldDocument5 pagesFunctions of an Exhaust Manifoldjameel babooram100% (1)

- Cec 103. - Workshop Technology 1Document128 pagesCec 103. - Workshop Technology 1VietHungCao92% (13)

- Corky Bell Maximum BoostDocument207 pagesCorky Bell Maximum BoostAerankasNo ratings yet

- GX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Document64 pagesGX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Stasio80No ratings yet

- Turbo Tech 101 (Basic) : How A Turbo System WorksDocument6 pagesTurbo Tech 101 (Basic) : How A Turbo System Workscogit0No ratings yet

- Twin-Scroll TurbochargerDocument24 pagesTwin-Scroll TurbochargerJih Yan LaiNo ratings yet

- DIY.a.gas Turbine - Engine.from - An.autornobile - Turbocharger.rules - Of.thumbDocument36 pagesDIY.a.gas Turbine - Engine.from - An.autornobile - Turbocharger.rules - Of.thumbAlex CheeNo ratings yet

- ICE Turbocharger BasicsDocument18 pagesICE Turbocharger Basicssafwansd750% (2)

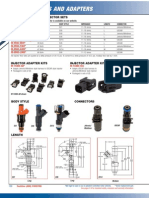

- Fuel Injectors and AdaptorsDocument6 pagesFuel Injectors and AdaptorsPeter Piper100% (1)

- Exxon Mobil Corporation: Company ProfileDocument39 pagesExxon Mobil Corporation: Company Profileamitanand009100% (3)

- Dynamic Modeling of GE 1.5 andDocument31 pagesDynamic Modeling of GE 1.5 andErtuğrul ÇamNo ratings yet

- Curtis CatalogDocument9 pagesCurtis CatalogtharngalNo ratings yet

- LTE and SchedulingDocument25 pagesLTE and SchedulingKrunoslav IvesicNo ratings yet

- Jarless Con Door DriveDocument16 pagesJarless Con Door DriveRoyal Akash100% (6)

- ASTM D 1510 - 02 Carbon Black-Iodine Adsorption NumberDocument7 pagesASTM D 1510 - 02 Carbon Black-Iodine Adsorption Numberalin2005100% (1)

- Intro. To TurboDocument8 pagesIntro. To TurboKevin GutierrezNo ratings yet

- Race Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeDocument7 pagesRace Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeharryNo ratings yet

- Turbo Basics ExplainedDocument5 pagesTurbo Basics ExplainedPawan Kumar SinghNo ratings yet

- Supercharger Turbo 3.31Document6 pagesSupercharger Turbo 3.31larasmoyoNo ratings yet

- HowATurboWorks PDFDocument5 pagesHowATurboWorks PDFNikhil KanojiNo ratings yet

- Engine Science Its More Than Just Engine PartsDocument6 pagesEngine Science Its More Than Just Engine Partshsingh1990No ratings yet

- Definition EssayDocument5 pagesDefinition Essayhondarider909No ratings yet

- Under Construction!!!! 1/25/08: SuperchargingDocument9 pagesUnder Construction!!!! 1/25/08: SuperchargingTalha Bin MujahidNo ratings yet

- Turbocharger and SuperchargerDocument16 pagesTurbocharger and SuperchargerPrajwal ZinjadeNo ratings yet

- Auto ZineDocument191 pagesAuto ZineJulie BrownNo ratings yet

- Basic Introduction To TurbochargingDocument6 pagesBasic Introduction To TurbochargingAngelino Martini de LeonNo ratings yet

- Turbocharger MatchingDocument24 pagesTurbocharger MatchingheideNo ratings yet

- TURBOCHARGERDocument5 pagesTURBOCHARGERAnand Raju100% (1)

- Turbo ChargerDocument28 pagesTurbo ChargerCharles ChivengahNo ratings yet

- 03-Supercharging and TurbochargersDocument7 pages03-Supercharging and TurbochargersAHMADNo ratings yet

- Operating PrincipleDocument6 pagesOperating PrincipleGedan CristianNo ratings yet

- Turbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDocument19 pagesTurbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDeepak Satpathy0% (1)

- Turbo Manifold Designs by Engine BasicsDocument17 pagesTurbo Manifold Designs by Engine BasicsJam Bab100% (1)

- Supercharging and TurbochargingDocument8 pagesSupercharging and TurbochargingMudassir Hussain100% (1)

- Turbo Charger Jet Engines Springers MDocument50 pagesTurbo Charger Jet Engines Springers MMolay Karmakar100% (2)

- Supercharger VS TurbochargerDocument25 pagesSupercharger VS TurbochargerAllen CastorNo ratings yet

- TurbochargerDocument10 pagesTurbochargernavle krushnaNo ratings yet

- Supercharging and TurbochargingDocument3 pagesSupercharging and Turbocharging13311A0341 S SHIVA SAI KIRANNo ratings yet

- The BG Tuning ManualDocument7 pagesThe BG Tuning ManualNidhin JoseNo ratings yet

- Diesel Lucas DPCN Fuel Adjustment and Turbo Boost CompensationDocument4 pagesDiesel Lucas DPCN Fuel Adjustment and Turbo Boost CompensationDayanandNo ratings yet

- How To Read Compressor MapDocument1 pageHow To Read Compressor MapPepenauta InternautaNo ratings yet

- ProperlySelectingEFIComp PDFDocument5 pagesProperlySelectingEFIComp PDFEduardo VilchezNo ratings yet

- Engine Modifications: Air in (Induction)Document5 pagesEngine Modifications: Air in (Induction)Muhammad TalhaNo ratings yet

- Mechanical Project TurbochargerDocument12 pagesMechanical Project Turbochargerinduscad100% (6)

- Unit II - Turbo Super ChargerDocument14 pagesUnit II - Turbo Super ChargerdrkbalaNo ratings yet

- Engine Modifications: Air in (Induction)Document5 pagesEngine Modifications: Air in (Induction)Muhammad TalhaNo ratings yet

- TurboDocument31 pagesTurboWaqas SadiqNo ratings yet

- Engish 202 Turbocharger Technical DescriptionDocument3 pagesEngish 202 Turbocharger Technical DescriptionMuthukumar GovindasamyNo ratings yet

- Turbocharger: and How It WorksDocument17 pagesTurbocharger: and How It Workskeithdcosta81No ratings yet

- Final Turbohargr ReportDocument32 pagesFinal Turbohargr ReportPooja BanNo ratings yet

- Advancement in AutomobileDocument14 pagesAdvancement in AutomobileVardhan ChipperNo ratings yet

- Turbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Document25 pagesTurbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Vinod SubramaniamNo ratings yet

- Asas TurbochargerDocument14 pagesAsas TurbochargerMeetheeran Elang KovanNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Section A (40 Marks) 2Q Choose 1Document3 pagesSection A (40 Marks) 2Q Choose 1Shakeeb AhmedNo ratings yet

- International Corporate FinanceDocument2 pagesInternational Corporate FinanceShakeeb AhmedNo ratings yet

- Mcdonalds MarketDocument49 pagesMcdonalds Marketmax_virgoNo ratings yet

- Business EnvironmentDocument22 pagesBusiness EnvironmentShakeeb Ahmed100% (1)

- Assignment QuestionsDocument3 pagesAssignment QuestionsShakeeb AhmedNo ratings yet

- Logbook entry for week 1Document3 pagesLogbook entry for week 1Shakeeb AhmedNo ratings yet

- Human Resource ManagementDocument11 pagesHuman Resource ManagementShakeeb AhmedNo ratings yet

- Assignment CoverDocument1 pageAssignment CoverShakeeb AhmedNo ratings yet

- Individual Report Technology Park Malaysia BM014-3-3 DMKG Decession Making UC3F-1110-IBMDocument1 pageIndividual Report Technology Park Malaysia BM014-3-3 DMKG Decession Making UC3F-1110-IBMShakeeb AhmedNo ratings yet

- L004E CommerceDocument27 pagesL004E CommerceShakeeb AhmedNo ratings yet

- Delivering Customer Value: Just-In-Time (JIT)Document34 pagesDelivering Customer Value: Just-In-Time (JIT)Shakeeb AhmedNo ratings yet

- Managing People & Performance.: ApiitDocument12 pagesManaging People & Performance.: ApiitShakeeb AhmedNo ratings yet

- Lecture 6 Learning OrgDocument17 pagesLecture 6 Learning OrgShakeeb AhmedNo ratings yet

- Exteuatig Circumstaces (Ec) : Part A: Modules AffectedDocument4 pagesExteuatig Circumstaces (Ec) : Part A: Modules AffectedShakeeb AhmedNo ratings yet

- FYP Proposal WritingDocument17 pagesFYP Proposal WritingShakeeb AhmedNo ratings yet

- Lecture 6 Learning OrgDocument17 pagesLecture 6 Learning OrgShakeeb AhmedNo ratings yet

- Shift FRM PC To ECDocument4 pagesShift FRM PC To ECShakeeb AhmedNo ratings yet

- Individual Assignment on Delivering Customer ValueDocument1 pageIndividual Assignment on Delivering Customer ValueshakbeeNo ratings yet

- Steneden Univ Qatar Topics Acct & FinDocument2 pagesSteneden Univ Qatar Topics Acct & FinShakeeb AhmedNo ratings yet

- Green Marketing - A Case Study of British AirwaysDocument82 pagesGreen Marketing - A Case Study of British AirwaysNogara CivNo ratings yet

- Glass Second DraftDocument9 pagesGlass Second DraftShakeeb AhmedNo ratings yet

- Mcdonalds MarketDocument49 pagesMcdonalds Marketmax_virgoNo ratings yet

- Human Resource ManagementDocument11 pagesHuman Resource ManagementShakeeb AhmedNo ratings yet

- Individual Assignment IB (AMZ) 27july2012Document9 pagesIndividual Assignment IB (AMZ) 27july2012Shakeeb AhmedNo ratings yet

- Logbook entry for week 1Document3 pagesLogbook entry for week 1Shakeeb AhmedNo ratings yet

- Individual Assignment on Delivering Customer ValueDocument1 pageIndividual Assignment on Delivering Customer ValueshakbeeNo ratings yet

- Challenges Faced by Expatriate Workers in GCC CountriesDocument6 pagesChallenges Faced by Expatriate Workers in GCC CountriesAbdullah I. MohamedNo ratings yet

- Front Panel & Display Technical Data: User ManualDocument2 pagesFront Panel & Display Technical Data: User ManualJulio PorleyNo ratings yet

- Eurotech IoT Gateway Reliagate 10 12 ManualDocument88 pagesEurotech IoT Gateway Reliagate 10 12 Manualfelix olguinNo ratings yet

- Tech Note 14Document2 pagesTech Note 14meteohrNo ratings yet

- View DsilDocument16 pagesView DsilneepolionNo ratings yet

- dp0 PDFDocument4 pagesdp0 PDFSimonNo ratings yet

- Tips and Tricks I: Getting the Most Out of ArcGIS DesktopDocument108 pagesTips and Tricks I: Getting the Most Out of ArcGIS Desktoptanja222No ratings yet

- MSYS-1 0 11-ChangesDocument3 pagesMSYS-1 0 11-ChangesCyril BerthelotNo ratings yet

- Recommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Document38 pagesRecommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Crismaruc Maria-madalinaNo ratings yet

- Apriori AlgorithmDocument13 pagesApriori AlgorithmKiran JoshiNo ratings yet

- e-GP System User Manual - Tender Evaluation Committee UserDocument82 pagese-GP System User Manual - Tender Evaluation Committee UserMd. Jakaria ApuNo ratings yet

- IMChap 014 SDocument14 pagesIMChap 014 STroy WingerNo ratings yet

- Seksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDocument1 pageSeksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDukagjin Ramqaj100% (1)

- Spesifikasi Produk SL-500Document2 pagesSpesifikasi Produk SL-500tekmed koesnadiNo ratings yet

- Excel Dynamic Arrays: Department Item Quantity Price Total $Document5 pagesExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousNo ratings yet

- 0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateDocument13 pages0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateAnonymous AZGp1KNo ratings yet

- Capsule Proposal TemplateDocument5 pagesCapsule Proposal Templatematain elementary SchoolNo ratings yet

- Onishi T Ed Quantum Science The Frontier of Physics and ChemDocument498 pagesOnishi T Ed Quantum Science The Frontier of Physics and ChemStrahinja DonicNo ratings yet

- Module 4 - What Is The Required Rate of ReturnDocument2 pagesModule 4 - What Is The Required Rate of ReturnEthics BAENo ratings yet

- Haidarali-MR-2011-PhD-Thesis 01 PDFDocument378 pagesHaidarali-MR-2011-PhD-Thesis 01 PDFIbrahim KhanNo ratings yet

- Design Plan: A Performance Task in GeometryDocument12 pagesDesign Plan: A Performance Task in GeometryRobert Ryan SantiagoNo ratings yet

- Material Balance of Naphtha Hydrotreater and Reformer ReactorsDocument22 pagesMaterial Balance of Naphtha Hydrotreater and Reformer ReactorsSukirtha GaneshanNo ratings yet