Professional Documents

Culture Documents

Traditionally, The MPD Documents Recommended The Use of Block Checks (Letter Checks A, B

Uploaded by

Eirick Wayne Zuñigga De-ItzelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Traditionally, The MPD Documents Recommended The Use of Block Checks (Letter Checks A, B

Uploaded by

Eirick Wayne Zuñigga De-ItzelCopyright:

Available Formats

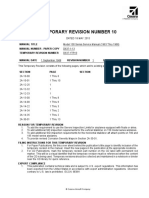

Traditionally, the MPD documents recommended the use of Block checks (letter checks A, B,

C, D), by pre-determining the packages for each letter check. However, with the Advancements in aircraft maintenance analysis brought about by the task-oriented MSG-3 And its revisions (rev.1 en rev.2)3, the Boeing Company is tending to opt for non-packaging of maintenance tasks in the MPD, leaving this open for the operator. This has been the case with the Boeing 737 Next Generation (henceforth referred to as 737NG) MPD document. The main reason for this is that the operator gets more freedom to plan maintenance based on aircraft scheduling and utilization, hence having more control over direct maintenance costs. By reviewing an operator's anticipated utilization, environmental considerations, fleet size, seasonal constraints, and other factors, it is possible to package an aircraft's maintenance program taking full advantage of the allowable utilization parameters as specified in the MPD document. The planning and execution of maintenance tasks can be boldly classified into two categories: a. Line maintenance: This can generally be defined as maintenance activities with a preflight, daily, weekly, and periodic (A Check, B Check) frequency (IAR-145 Section 2, paragraph 3.2.2). It mainly consists of visual inspections, lubrication, and general servicing of aircraft and does not require the opening of panels and access doors for detailed inspections. Line maintenance is mainly characterized by short downtime periods of twenty-four hours or less and small maintenance packages, quantified in terms of man-hours. b. Heavy maintenance: This can generally be defined as maintenance activities falling under C Checks and D checks (IAR-145 Section 2 paragraph 3.2.3), requiring panel and access doors opening and disassembly for deeper inspection and eventually repair. Base maintenance is mainly characterized by long downtime periods and large maintenance packages, quantified in terms of man-hours

Tradicionalmente, los documentos MPD recomienda el uso de cheques de bloque ( cheques de letras A, B , C , D ) , por la pre- determinacin de los paquetes para cada cheque letra. Sin embargo , con Los avances en el anlisis de mantenimiento de aviones producidos por la tarea orientada a MSG- 3 Mediante la revisin de la utilizacin prevista de un operador, consideraciones ambientales, tamao de la flota , las limitaciones estacionales y otros factores , es posible envasar programa de mantenimiento de la aeronave aprovechando al mximo los parmetros de utilizacin admisibles segn lo especificado en el documento de MPD . La planificacin y ejecucin de las tareas de mantenimiento se pueden clasificar en dos atrevidamente categoras: a . Mantenimiento de lnea: Esta se puede definir generalmente como actividades de mantenimiento con una prevuelo , diario , semanal y peridica ( un cheque, B Check) frecuencia ( IAR- 145 Seccin 2 , el apartado 3.2.2) . Se compone principalmente de las inspecciones visuales , lubricacin, y en general mantenimiento de aeronaves y no requiere la apertura de los paneles y puertas de acceso para inspecciones detalladas. Mantenimiento de lnea se caracteriza principalmente por perodos cortos de tiempo de inactividad de veinticuatro horas o menos y los pequeos paquetes de mantenimiento , cuantificado en trminos de horas-hombre. b . Mantenimiento pesado: Esta se puede definir generalmente como actividades de mantenimiento de la cada en virtud de cheques y cheques C D ( IAR- 145 Seccin 2, prrafo 3.2.3) , lo que requiere de paneles y puertas de acceso de apertura y desmontaje para la inspeccin ms profunda y eventualmente reparar . Base de mantenimiento se caracteriza principalmente por periodos de inactividad largos y grandespaquetes de mantenimiento , cuantificados en trminos de horas-hombre

You might also like

- APM - Part 2 Chapter 3CDocument25 pagesAPM - Part 2 Chapter 3CKJ DhimanNo ratings yet

- Aircraft MaintenanceDocument5 pagesAircraft MaintenanceMussa LucasNo ratings yet

- Aac02 2023Document6 pagesAac02 2023Sawan KumarNo ratings yet

- AC 120-17A - Maintenance Control by Reliability MethodsDocument41 pagesAC 120-17A - Maintenance Control by Reliability Methodsdedoneza100% (1)

- EmpowerMX WP MSG3 ScheduleDocument4 pagesEmpowerMX WP MSG3 ScheduleMashobih HussururNo ratings yet

- Maintenance Per Block HourDocument17 pagesMaintenance Per Block HourSebastien BorelNo ratings yet

- APM - Part 2 Chapter 3CDocument24 pagesAPM - Part 2 Chapter 3CShivamSrivastavaNo ratings yet

- Office of The Director General of Civil AviationDocument18 pagesOffice of The Director General of Civil AviationRoshith KrishnanNo ratings yet

- Maint Philsp N Devlp ProgrDocument47 pagesMaint Philsp N Devlp Progrhatach100% (1)

- Maintenance Programme ChecklistDocument18 pagesMaintenance Programme ChecklistsmshaidrNo ratings yet

- Scheduled Maintenance and Inspection Program SummaryDocument10 pagesScheduled Maintenance and Inspection Program SummaryVincent LefeuvreNo ratings yet

- Office of The Director General of Civil AviationDocument4 pagesOffice of The Director General of Civil Aviationconfirm@No ratings yet

- N - 8900.410 Clarification of Inspection and Overhaul Requirements Under Part 91Document7 pagesN - 8900.410 Clarification of Inspection and Overhaul Requirements Under Part 91gerezairNo ratings yet

- Midterm Module 1Document40 pagesMidterm Module 1angeloNo ratings yet

- CAR & MOE, TPM NotesDocument75 pagesCAR & MOE, TPM Notesbirendra67% (3)

- A Study On The Outsourcing of Aircraft Maintenance ContractsDocument6 pagesA Study On The Outsourcing of Aircraft Maintenance ContractshanipNo ratings yet

- Basics of Aircraft Maintenance Programs For FinanciersDocument37 pagesBasics of Aircraft Maintenance Programs For FinanciersMaya Putri Claudhia100% (2)

- Advisory Circular: U.S. Department of TransportationDocument10 pagesAdvisory Circular: U.S. Department of TransportationAlejandro MontealegreNo ratings yet

- Corrosion Prevention and Control ProgramDocument21 pagesCorrosion Prevention and Control Programjesus francoNo ratings yet

- Maitenance Schedule 3Document15 pagesMaitenance Schedule 3BookMaggot100% (1)

- AMP ChecklistDocument14 pagesAMP ChecklistSujoy GhoshNo ratings yet

- Company Maintenance Manual (CMM) 1. GeneralDocument7 pagesCompany Maintenance Manual (CMM) 1. GeneralSiti Rizka FauziyahNo ratings yet

- AC 04006 Reliability CAAV A2009EDocument12 pagesAC 04006 Reliability CAAV A2009EThanh Hao LuongNo ratings yet

- Insp. Time Limit - StrucDocument5 pagesInsp. Time Limit - Strucjesus francoNo ratings yet

- Certification Maintenance Requirements and Airworthiness Limitations Terminology Explained PDFDocument3 pagesCertification Maintenance Requirements and Airworthiness Limitations Terminology Explained PDFHfdrhhNo ratings yet

- CFM56 5B SB Rev 72-0944 TSN.01 R 20200114Document6 pagesCFM56 5B SB Rev 72-0944 TSN.01 R 20200114Irfan05No ratings yet

- Amt 311 Mid Term Exam 17 Oct 23Document4 pagesAmt 311 Mid Term Exam 17 Oct 23Xian Gabriel GeromoNo ratings yet

- AC 91-56B - Continuing Structural Integrity Program For Airplanes (SIDS)Document12 pagesAC 91-56B - Continuing Structural Integrity Program For Airplanes (SIDS)benNo ratings yet

- 747Document12 pages747Lucky IsmailovNo ratings yet

- Cessna 152-TR10Document26 pagesCessna 152-TR10Muhammad Subhan100% (1)

- Maintenance Steering GroupDocument33 pagesMaintenance Steering Groupengineering sepehranNo ratings yet

- Time Limits / Maintenance Checks A. GeneralDocument6 pagesTime Limits / Maintenance Checks A. GeneralAlexis CabreraNo ratings yet

- 05 00 00 inDocument8 pages05 00 00 inÜmit KazanNo ratings yet

- 05 20 00 SchedchkDocument27 pages05 20 00 SchedchkSaid AdingniNo ratings yet

- CPCP, Sid S Cessna Model 188 SeriesDocument155 pagesCPCP, Sid S Cessna Model 188 Seriesvilladazafabian713100% (1)

- 05 20 00 SchedchkDocument31 pages05 20 00 SchedchkSaid AdingniNo ratings yet

- EASA - AMP Aircraft Maintenance ProgrammeDocument10 pagesEASA - AMP Aircraft Maintenance ProgrammeGuy Ulrich DouoguiNo ratings yet

- Samson Angelo D. ACTIVITY 31Document2 pagesSamson Angelo D. ACTIVITY 31David RamirezNo ratings yet

- Fast46 6 Repair Design PDFDocument10 pagesFast46 6 Repair Design PDFJokenny WilliamNo ratings yet

- Acb G550 013Document34 pagesAcb G550 013Marty SmallwoodNo ratings yet

- Semana 18 Inglés Técnico 2Document26 pagesSemana 18 Inglés Técnico 2Jefferson Quispe vargasNo ratings yet

- 05 00 00 inDocument4 pages05 00 00 inMarco Antonio PrietoNo ratings yet

- CAR M QuestiondDocument8 pagesCAR M QuestiondHarshit SrivastavaNo ratings yet

- Basics of Aircraft Maintenance Programs For Financiers v1Document23 pagesBasics of Aircraft Maintenance Programs For Financiers v1Denilson Ribeiro100% (2)

- MODEL 210 SERIES (1977 - 1984) : Inspection Time Limits - Structure 1. ScopeDocument5 pagesMODEL 210 SERIES (1977 - 1984) : Inspection Time Limits - Structure 1. ScopesandyNo ratings yet

- Types of Checks Used in Aircraft MaintenanceDocument3 pagesTypes of Checks Used in Aircraft MaintenanceNikiNo ratings yet

- AC 09-006 Reliability Methods GCAA NOV 2018Document12 pagesAC 09-006 Reliability Methods GCAA NOV 2018syahrul yazidNo ratings yet

- Temp Rev 5 - 152 Service ManualDocument200 pagesTemp Rev 5 - 152 Service ManualKamal Jit DhimanNo ratings yet

- Amm 5Document762 pagesAmm 5dsenpen100% (2)

- Amc GM To Part 21 - Issue 2 Amendment 12Document29 pagesAmc GM To Part 21 - Issue 2 Amendment 12Enrico Miguel AquinoNo ratings yet

- 14.3.7 Calculation of DOC Cost Elements - Maintenance CostsDocument1 page14.3.7 Calculation of DOC Cost Elements - Maintenance CostsAhmadNo ratings yet

- Ac33 70-1Document23 pagesAc33 70-1kalyan239No ratings yet

- A320 Maintenance Cost AnalysisDocument8 pagesA320 Maintenance Cost AnalysisIbrahim KhalilNo ratings yet

- Time Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralDocument2 pagesTime Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralRizqi PerdanaNo ratings yet

- Ata 05 Time Limit: Training HandbookDocument9 pagesAta 05 Time Limit: Training Handbookmohamad TomcatNo ratings yet

- Airworthiness Advisory Circular: AAC NO. 5 OF 2020Document8 pagesAirworthiness Advisory Circular: AAC NO. 5 OF 2020Abhishek Terminator100% (1)

- Aeronautical Engineering-51-75Document25 pagesAeronautical Engineering-51-75Natural RawshortNo ratings yet

- Ssid Doc For 180Document60 pagesSsid Doc For 180Pankaj SharmaNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Hexcel Prepreg TechnologyDocument34 pagesHexcel Prepreg TechnologyCaruso0100% (1)

- Progress in Aerospace Sciences: Mehdi Ghoreyshi, Adam Jirásek, Russell M. CummingsDocument51 pagesProgress in Aerospace Sciences: Mehdi Ghoreyshi, Adam Jirásek, Russell M. CummingsEirick Wayne Zuñigga De-ItzelNo ratings yet

- Heat Transfer Analysis and Numerical Simulation of A Parabolic Trough Solar Collector (AA Hachicha, I Rodriguez) 2013 (Paper)Document12 pagesHeat Transfer Analysis and Numerical Simulation of A Parabolic Trough Solar Collector (AA Hachicha, I Rodriguez) 2013 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Composites ASTMDocument5 pagesComposites ASTMEirick Wayne Zuñigga De-ItzelNo ratings yet

- Modeling and Co-Simulation of A Parabolic Trough Solar Plant For Industrial Process Heat (R Silva, M Perez) 2013 (Paper)Document14 pagesModeling and Co-Simulation of A Parabolic Trough Solar Plant For Industrial Process Heat (R Silva, M Perez) 2013 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Progress in Aerospace Sciences: S.L. Chernyshev, A.M. Gaifullin, Yu.N. SviridenkoDocument17 pagesProgress in Aerospace Sciences: S.L. Chernyshev, A.M. Gaifullin, Yu.N. SviridenkoEirick Wayne Zuñigga De-ItzelNo ratings yet

- A Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Document9 pagesA Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Vic 22 NovDocument11 pagesVic 22 NovEirick Wayne Zuñigga De-ItzelNo ratings yet

- A Life-Size Test Loop For Parabolic Trough Collectors (J Leon, J Clavero, L Valenzuela) 2014 (Paper)Document9 pagesA Life-Size Test Loop For Parabolic Trough Collectors (J Leon, J Clavero, L Valenzuela) 2014 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- 1 s2.0 S0376042114000323 MainDocument28 pages1 s2.0 S0376042114000323 MainEirick Wayne Zuñigga De-ItzelNo ratings yet

- DelfimDocument6 pagesDelfimEirick Wayne Zuñigga De-ItzelNo ratings yet

- Guia Overhaul 212Document13 pagesGuia Overhaul 212Eirick Wayne Zuñigga De-ItzelNo ratings yet

- 1 s2.0 S0038092X11004294 MainDocument10 pages1 s2.0 S0038092X11004294 MainEirick Wayne Zuñigga De-ItzelNo ratings yet

- Cat OneDocument15 pagesCat OneEirick Wayne Zuñigga De-ItzelNo ratings yet

- D 2583 - 95 Curados PDFDocument4 pagesD 2583 - 95 Curados PDFEirick Wayne Zuñigga De-ItzelNo ratings yet

- Bench Marketing HelicopterosDocument8 pagesBench Marketing HelicopterosEirick Wayne Zuñigga De-ItzelNo ratings yet

- Analisis PDFDocument15 pagesAnalisis PDFEirick Wayne Zuñigga De-ItzelNo ratings yet

- Guia Overhaul 212Document13 pagesGuia Overhaul 212Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Guia Overhaul 212Document13 pagesGuia Overhaul 212Eirick Wayne Zuñigga De-ItzelNo ratings yet

- AlaDocument63 pagesAlaEirick Wayne Zuñigga De-ItzelNo ratings yet

- Bench Marketing HelicopterosDocument8 pagesBench Marketing HelicopterosEirick Wayne Zuñigga De-ItzelNo ratings yet

- AlaDocument63 pagesAlaEirick Wayne Zuñigga De-ItzelNo ratings yet

- Universidad Politécnica Metropolitana de Hidalgo.: Área de Ingeniería. Ingeniería en AeronáuticaDocument2 pagesUniversidad Politécnica Metropolitana de Hidalgo.: Área de Ingeniería. Ingeniería en AeronáuticaEirick Wayne Zuñigga De-ItzelNo ratings yet

- Possibility of Living On MarsDocument11 pagesPossibility of Living On MarsNevin AntonyNo ratings yet

- Vintage Airplane - May 1995Document36 pagesVintage Airplane - May 1995Aviation/Space History LibraryNo ratings yet

- Fundamentals of Wind Tunnel DesignDocument11 pagesFundamentals of Wind Tunnel DesignAnshul Khandelwal100% (1)

- Model: No. 0304/IV/13: Rocket Propelled Grenade - Scale 1:1Document22 pagesModel: No. 0304/IV/13: Rocket Propelled Grenade - Scale 1:1German RodriguezNo ratings yet

- Development of ADN-based Minimum Smoke PropellantsDocument8 pagesDevelopment of ADN-based Minimum Smoke PropellantsBojan TanaskovskiNo ratings yet

- UnnatiDocument8 pagesUnnatiSandip PawarNo ratings yet

- Spacecraft Electrical Harness DesignDocument3 pagesSpacecraft Electrical Harness Designe1094739No ratings yet

- Sae AdcDocument60 pagesSae AdcVamsiTejaNo ratings yet

- Space Exploration ScrapbookDocument16 pagesSpace Exploration ScrapbookLAU YAN YU MoeNo ratings yet

- UFOs EssayDocument3 pagesUFOs EssayiTzDaxusProS7zZNo ratings yet

- Flight Mechanics - Part 1Document44 pagesFlight Mechanics - Part 1Muhamad ShafiqNo ratings yet

- 2020 Open Innovation at NASADocument28 pages2020 Open Innovation at NASADmitry PaysonNo ratings yet

- 04 Physics 11se Ch04Document32 pages04 Physics 11se Ch04pecan_lisa38No ratings yet

- The Northern LightsDocument8 pagesThe Northern LightsRonaliza GayatinNo ratings yet

- Astrological Methods of Forecasting The Djia: by Carol MullDocument6 pagesAstrological Methods of Forecasting The Djia: by Carol Mullpaparock34100% (2)

- (AIAA Education Series.) Brian J. Cantwell-Aircraft and Rocket Propulsion-Stanford University (2010)Document335 pages(AIAA Education Series.) Brian J. Cantwell-Aircraft and Rocket Propulsion-Stanford University (2010)awarialocksNo ratings yet

- The Official Newsletter of The Naval Airship AssociationDocument36 pagesThe Official Newsletter of The Naval Airship Associationgustavojorge12No ratings yet

- Astronauts Fact Sheet June 1982Document28 pagesAstronauts Fact Sheet June 1982Bob AndrepontNo ratings yet

- Vintage Airplane - Jan 2007Document44 pagesVintage Airplane - Jan 2007Aviation/Space History LibraryNo ratings yet

- Flirtey Unveils The Future of Drone DeliveryDocument3 pagesFlirtey Unveils The Future of Drone DeliveryZac SlotemakerNo ratings yet

- Snapshot Billy Meier Ufo Case 3Document1 pageSnapshot Billy Meier Ufo Case 3GetPeaceRightNo ratings yet

- D7 - Progeny-Role of PlanetsDocument2 pagesD7 - Progeny-Role of Planetsjk.dasguptaNo ratings yet

- Structural Loads: V-N DiagramsDocument11 pagesStructural Loads: V-N Diagramsa320neoNo ratings yet

- M 12Document2 pagesM 12Andrés Garza0% (1)

- Elon Musk SpeechDocument4 pagesElon Musk Speechvinod malhotra100% (1)

- Ielts ReadingDocument19 pagesIelts ReadingSherif Goda100% (1)

- The Mysteries of Plato: Lunar NotebookDocument2 pagesThe Mysteries of Plato: Lunar NotebookDavor BatesNo ratings yet

- W 8Document6 pagesW 8x_M_xNo ratings yet

- Feliz NavidadDocument13 pagesFeliz NavidadDel rosarioNo ratings yet

- Team Moon: How 400,000 People Landed Apollo 11 On The MoonDocument4 pagesTeam Moon: How 400,000 People Landed Apollo 11 On The MoonAmparo Sánchez FariñaNo ratings yet