Professional Documents

Culture Documents

Acceptance Criteria To TR1826

Uploaded by

Adisak AumpiemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance Criteria To TR1826

Uploaded by

Adisak AumpiemCopyright:

Available Formats

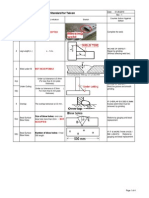

Governing document: Welding and inspection of piping

Classification: Internal

Table A.3 - Acceptance criteria for visual testing, magnetic particle testing and penetrant testing Type of defect

100 Cracks 401 Lack of fusion 402 Incomplete penetration 501 Undercut

NDT Group 1 and Group 2

NDT Group 3

2017 Surface porosity and/or cluster a

301/302 Exposed slag 517 Poor restart 515 Concave root surface (suck-up) 502 Reinforcement or internal protrusion 507 Misalignment of butt welds b 512 Symmetry of fillet welds (see Figure A.4) 606 Grinding 601 Arc strikes etc. and removal of; 605/607 temporary b attachments c Sharp edges 503 Reinforcement of fillet/partial penetration welds a (see Figure A.4) 502 Reinforcement of butt welds (see Figure A.3)

Not acceptable Not acceptable Not acceptable Not acceptable Maximum depth 1 mm or 0,2 x t, whichever is less. Not acceptable Maximum cumulative length, 38 mm for each 150 mm weld length. Maximum depth 1 mm or t/4, whichever is less. Maximum depth 0,3 mm. Maximum length of individual flaw is t/2. Maximum length of individual flaw is Maximum accumulated length in any 300 mm of t/2. Maximum accumulated length in weld is equal to t. any 300 mm of weld is equal to t. Not acceptable For t 5 mm: Not acceptable For t > 5 mm: Maximum size of single pore t/4 and 2 mm, whichever is less. Accumulated pore diameters in any area of 10 x 150 mm shall not exceed 10 mm. Not acceptable Not acceptable Acceptable if smooth transition Not acceptable The joint thickness including weld reinforcement to be greater than the wall thickness. For wall thickness 6 mm: 1,5 mm and smooth transition For wall thickness 6 mm: 3 mm and smooth transition Maximum misalignment (h): 0,15 x t or maximum 4 mm, whichever is less. "a" less or equal to 6 mm: Maximum difference, z2 z1 = 3 mm "a" greater than 6 mm, up to 13 mm: Maximum difference, z2 z1 = 5 mm "a" greater than 13 mm: Maximum difference, z2 z1 = 8 mm Grinding of base material shall not exceed 7 % of the wall thickness or maximum 3 mm. Repair welding and inspection shall be performed if removal of the base metal exceeds the specified requirements.

Minimum 2 mm radius. "a" less or equal to 10 mm "a" greater than 10 mm, up to 15 mm "a" greater than 15 mm, up to 25 mm "a" greater than 25 mm "t" less or equal to 10 mm

Maximum reinforcement h = 2 mm Maximum reinforcement h = 3 mm Maximum reinforcement h = 4 mm Maximum reinforcement h = 5 mm Maximum reinforcement h = 2 mm

514 Roughness of weld. 505 Sharp transition weld/base material

NOTE "a" is fillet weld throat thickness

"t" greater than 10 mm, up to 25 mm Maximum reinforcement h = 3 mm "t" greater than 25 mm, up to 50 mm Maximum reinforcement h = 4 mm "t" greater than 50 mm Maximum reinforcement h = 5 mm "h" shall be less than 2 mm. Weld surface shall be smooth without sharp transitions. The bottom of roughness in butt welds shall not be below the base material surface, see Figure A.1

Project development (PD)Technical and professional requirement, TR1826, Final Ver. 2, valid from 2011-06-29 Page 32 of 37 Validity area: Corporate tech. and prof. req./All locations/All value chains/On- and offshore

You might also like

- Module 5-ADocument9 pagesModule 5-Adash1991No ratings yet

- Astm A 53 BDocument4 pagesAstm A 53 BLauren BowenNo ratings yet

- Weld Acceptance Criteria1Document1 pageWeld Acceptance Criteria1sankarNo ratings yet

- NDT-Acceptance Various CodesDocument17 pagesNDT-Acceptance Various CodesShanmuga NavaneethanNo ratings yet

- Acceptance CriteriaDocument19 pagesAcceptance CriteriaAnonymous 5iv0i3cZNo ratings yet

- Klasifikasi Visual Defects Dan Acceptance CriteriaDocument13 pagesKlasifikasi Visual Defects Dan Acceptance Criteriaunnamed10100% (2)

- NDT AcceptanceDocument62 pagesNDT Acceptancebommakanti srinivasNo ratings yet

- Anexo 1: Thickness of Base MetalDocument2 pagesAnexo 1: Thickness of Base MetalJesus TecNo ratings yet

- Acceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1Document7 pagesAcceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1MJ Magdy100% (1)

- PEM Self Locking Fasteners Nylon InsertDocument6 pagesPEM Self Locking Fasteners Nylon InsertAce Industrial SuppliesNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesdhasdjNo ratings yet

- ASME B31.3 Acceptance Criteria - Tab 341.3.2ADocument2 pagesASME B31.3 Acceptance Criteria - Tab 341.3.2Avsnaiduqc90% (21)

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesNavanitheeshwaran Sivasubramaniyam100% (3)

- Acceptance Criteria of Weld DefectsDocument17 pagesAcceptance Criteria of Weld DefectsvikasNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShankar Pl GowdaNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrNo ratings yet

- Tolerances As Per Aws D1.1: Structural Welding CodeDocument34 pagesTolerances As Per Aws D1.1: Structural Welding Codeegy pureNo ratings yet

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafieNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesMidhun K Chandrabose96% (24)

- Standard HFRW PDFDocument3 pagesStandard HFRW PDFGuidoColomboNo ratings yet

- RT Acceptance CriteriaDocument3 pagesRT Acceptance CriteriaAndry Rimanov89% (18)

- NDT ACC CriteriaDocument6 pagesNDT ACC Criteriavsnaiduqc100% (1)

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocument18 pagesAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNo ratings yet

- TWI Training CSWIP 3.1 PlateDocument8 pagesTWI Training CSWIP 3.1 PlateSepthian DS100% (2)

- SUBTEXT On Weld Defect For AWS Standard.Document2 pagesSUBTEXT On Weld Defect For AWS Standard.fammacat100% (1)

- Welding Standard Ver1Document4 pagesWelding Standard Ver1Sowmen ChakrobortyNo ratings yet

- Tata Steel Bulb Flats BroDocument11 pagesTata Steel Bulb Flats BroMd. Rafique HassanNo ratings yet

- NDT ACC. CriteriaDocument6 pagesNDT ACC. CriteriaBalakumar100% (5)

- ASME B31 3 Acceptance Criteria Tab 341-3-2ADocument2 pagesASME B31 3 Acceptance Criteria Tab 341-3-2Aadel100% (1)

- Table 6.1 AWS D1.1 D1.1M-2010Document1 pageTable 6.1 AWS D1.1 D1.1M-2010gigiphi75% (8)

- Formulas For Designing Press ToolsDocument21 pagesFormulas For Designing Press ToolsKarthik Gopal86% (35)

- Tolerances To BS en 10296Document4 pagesTolerances To BS en 10296matteo2009No ratings yet

- Things Site Engineers Must Know About Reinforcement and Steel BarsDocument4 pagesThings Site Engineers Must Know About Reinforcement and Steel BarsMohammad Irshad AlamNo ratings yet

- ASME Sec VIII Div 1 Ed 2010 471 PDFDocument9 pagesASME Sec VIII Div 1 Ed 2010 471 PDFStephen Maloba100% (1)

- Asme PCCDocument6 pagesAsme PCCajaysharma_1009100% (2)

- En 10029Document3 pagesEn 10029hamoody_007100% (1)

- Defects Acceptance CriteriaDocument1 pageDefects Acceptance CriteriahakamaffaqNo ratings yet

- Outside: Factory-Made Wrought Buttwelding Fittings ASME B16.9-2001Document1 pageOutside: Factory-Made Wrought Buttwelding Fittings ASME B16.9-2001Panchal ShaileshNo ratings yet

- VT Acceptance Criteria PDFDocument10 pagesVT Acceptance Criteria PDFKalaivel ThandavarayanNo ratings yet

- Aws d1.1 2010 Table 6.1 VT PT MTDocument1 pageAws d1.1 2010 Table 6.1 VT PT MTRonel John Rodriguez Custodio0% (1)

- FIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )Document10 pagesFIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )mahmoud_allam3No ratings yet

- Thikness TolerenceDocument5 pagesThikness TolerencemuneeshwaraperumalNo ratings yet

- CSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetDocument4 pagesCSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetOnur Altuntaş100% (2)

- Percntage of ReinforcementDocument3 pagesPercntage of ReinforcementFalak Sher BuzdarNo ratings yet

- Standard EN10029Document4 pagesStandard EN10029Florin JipaNo ratings yet

- API 1104 2014 EditionDocument17 pagesAPI 1104 2014 EditionekkyNo ratings yet

- ASME Section VIII Division 1 C - AceptacionDocument9 pagesASME Section VIII Division 1 C - AceptacionAngela Buitrago100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Nzs Steel Grades Web SML PDFDocument40 pagesNzs Steel Grades Web SML PDFAdisak AumpiemNo ratings yet

- Arcelormittal 9 Percent NickelDocument5 pagesArcelormittal 9 Percent NickelAdisak AumpiemNo ratings yet

- 316ti Equinox PDFDocument3 pages316ti Equinox PDFAdisak AumpiemNo ratings yet

- 07references Biography PDFDocument8 pages07references Biography PDFAdisak AumpiemNo ratings yet

- Nzs Steel Grades Web SML PDFDocument40 pagesNzs Steel Grades Web SML PDFAdisak AumpiemNo ratings yet

- 9 NiDocument7 pages9 NiAdisak AumpiemNo ratings yet

- Plates - S420G2 M PDFDocument2 pagesPlates - S420G2 M PDFAdisak AumpiemNo ratings yet

- Welders Certification Designation Acc. To EN ISO 9606-1Document1 pageWelders Certification Designation Acc. To EN ISO 9606-1vonipko100% (9)

- Risk Oxidation ChartDocument1 pageRisk Oxidation ChartAdisak AumpiemNo ratings yet

- A Guide To The EU Pressure Equipment Directive: NIST GCR 04-870Document93 pagesA Guide To The EU Pressure Equipment Directive: NIST GCR 04-870beeee19No ratings yet

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13h100% (1)

- P-Numbers Base Metal (Typical or Example)Document2 pagesP-Numbers Base Metal (Typical or Example)Adisak AumpiemNo ratings yet

- Welding Consumables: Insert Lot and Sertificate in Aibel Standard ToolsDocument7 pagesWelding Consumables: Insert Lot and Sertificate in Aibel Standard ToolsAdisak AumpiemNo ratings yet

- 127 - Doc - 142 - Ewf 654 13 Ewf Guide For Transition 287 To 9606Document11 pages127 - Doc - 142 - Ewf 654 13 Ewf Guide For Transition 287 To 9606rodofgodNo ratings yet

- SteelTubeHandbook February2012Document120 pagesSteelTubeHandbook February2012Adisak AumpiemNo ratings yet

- QS Assessment Checklist - PEDDocument8 pagesQS Assessment Checklist - PEDAdisak AumpiemNo ratings yet

- Steel Standard ComparisonDocument3 pagesSteel Standard ComparisonSarvesh AhluwaliaNo ratings yet

- Plates - S420G2 MDocument2 pagesPlates - S420G2 MAdisak AumpiemNo ratings yet

- 2016 Course SummaryDocument1 page2016 Course SummaryAdisak AumpiemNo ratings yet

- Wem 50Document6 pagesWem 50Adisak AumpiemNo ratings yet

- Oxidation of Weld Stainless SteelDocument1 pageOxidation of Weld Stainless SteelAdisak AumpiemNo ratings yet

- Pttme SP T 001 000Document47 pagesPttme SP T 001 000Adisak AumpiemNo ratings yet

- 30day To Be RichDocument201 pages30day To Be RichAdisak AumpiemNo ratings yet

- Experimental Validation of Relationship Between Fracture 2015 PDFDocument11 pagesExperimental Validation of Relationship Between Fracture 2015 PDFAdisak AumpiemNo ratings yet

- National Geographic USA June 2013Document174 pagesNational Geographic USA June 2013voxpop51No ratings yet

- AISC - Inspection of Welded and Bolted JointsDocument26 pagesAISC - Inspection of Welded and Bolted JointsAdisak AumpiemNo ratings yet

- Olympus Probe Catalog PDFDocument52 pagesOlympus Probe Catalog PDFcutefrenzy100% (4)

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- The Procedure Handbook of Arc Welding (Twelfth Edition)Document742 pagesThe Procedure Handbook of Arc Welding (Twelfth Edition)Adisak Aumpiem100% (1)

- Alginate: DR Avreet SandhuDocument58 pagesAlginate: DR Avreet Sandhuwaheguru13he13No ratings yet

- 6 Dyeing With Reactive DyeDocument19 pages6 Dyeing With Reactive DyeLuk Ming YinNo ratings yet

- Spaghetti Challenge - 2022-0Document2 pagesSpaghetti Challenge - 2022-0diegoNo ratings yet

- Flange Isolating Gasket Kits: To Order Please Specify The FollowingDocument8 pagesFlange Isolating Gasket Kits: To Order Please Specify The Followingmoch ardiansyahNo ratings yet

- Checklist - FFS Inlet HeaderDocument3 pagesChecklist - FFS Inlet HeaderRamalingam PrabhakaranNo ratings yet

- Chemical Waste Log Book 2011 PDFDocument15 pagesChemical Waste Log Book 2011 PDFVictor AniekanNo ratings yet

- Questioned: Document ExaminationDocument4 pagesQuestioned: Document ExaminationApple AsneNo ratings yet

- Exp.5 - Helical SpringDocument7 pagesExp.5 - Helical SpringG. Dancer GhNo ratings yet

- Technical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesDocument117 pagesTechnical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesJankoNo ratings yet

- Din 580-Lifting Eye Bolts PDFDocument1 pageDin 580-Lifting Eye Bolts PDFAntohi CatalinNo ratings yet

- Plastic and SyntheticsDocument104 pagesPlastic and SyntheticsShah ChenzenNo ratings yet

- Astm G109Document6 pagesAstm G109AlbertoNo ratings yet

- Additive Sunset YellowDocument2 pagesAdditive Sunset YellowMohammad RofikNo ratings yet

- 730 UlfmDocument4 pages730 UlfmTobias Alberto Gonzalez PeresNo ratings yet

- HSN7471-75 R449A t0 - 35 TC 45Document2 pagesHSN7471-75 R449A t0 - 35 TC 45KritsdaNo ratings yet

- Technical Brief: Avoiding Bolt Failures: F E A T U R EDocument2 pagesTechnical Brief: Avoiding Bolt Failures: F E A T U R EkanosriNo ratings yet

- The Eur o P e An Uni o N: EDI CT OF GovernmentDocument105 pagesThe Eur o P e An Uni o N: EDI CT OF GovernmentBanuta GabrielNo ratings yet

- MADICA 2018 ProgramDocument17 pagesMADICA 2018 ProgramathmaniNo ratings yet

- Manganese/Cerium Clusters Spanning A Range of Oxidation Levels and Cemn, Ce MN, and Ce MN Nuclearities: Structural, Magnetic, and Epr PropertiesDocument12 pagesManganese/Cerium Clusters Spanning A Range of Oxidation Levels and Cemn, Ce MN, and Ce MN Nuclearities: Structural, Magnetic, and Epr PropertiesBrayan Solano CedeñoNo ratings yet

- Module 3Document27 pagesModule 3justineNo ratings yet

- Standards Catalog: Astm InternationalDocument23 pagesStandards Catalog: Astm InternationalPYDNo ratings yet

- ARKI ALE Structural NotesDocument5 pagesARKI ALE Structural Notesiloilocity100% (1)

- A Review On The Extensive Skin Benefits of Mineral OilDocument8 pagesA Review On The Extensive Skin Benefits of Mineral OilChiper Zaharia DanielaNo ratings yet

- Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingDocument2 pagesMonth Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingJatin SharmaNo ratings yet

- I. Read Each Question Carefully. Write The Letter of The Correct AnswerDocument3 pagesI. Read Each Question Carefully. Write The Letter of The Correct AnswerAchmabNo ratings yet

- Ed0754a 50a10 Ab4dDocument3 pagesEd0754a 50a10 Ab4dRocco SozeNo ratings yet

- Clickductor EngDocument20 pagesClickductor EngmahmoudglobaltechNo ratings yet

- Bearing Capacity of Shallow Foundation by Terzhaghi TheoryDocument13 pagesBearing Capacity of Shallow Foundation by Terzhaghi TheoryramNo ratings yet

- Objective Type Questions With AnswersDocument29 pagesObjective Type Questions With AnswersNikka LopezNo ratings yet

- Catálogo TEXSA Completo PDFDocument36 pagesCatálogo TEXSA Completo PDFbdromeiraNo ratings yet