Professional Documents

Culture Documents

The Influence of Silicone Antifoam From Leather and Dying Waste Water Effluent On Turbidity and Chemical Oxygen Demand in Bompai Industrial Estate Kano Region Nigeria

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Influence of Silicone Antifoam From Leather and Dying Waste Water Effluent On Turbidity and Chemical Oxygen Demand in Bompai Industrial Estate Kano Region Nigeria

Copyright:

Available Formats

Adamu Mustapha.

, IJSIT, 2013, 2(6), 510-517

THE INFLUENCE OF SILICONE ANTIFOAM FROM LEATHER AND DYING WASTE WATER EFFLUENT ON TURBIDITY AND CHEMICAL OXYGEN DEMAND IN BOMPAI INDUSTRIAL ESTATE KANO REGION NIGERIA

Adamu Mustapha

Faculty of Earth and Environmental Sciences, Kano University of Science and Technology, Wudil, Nigeria

ABSTRACT

This study investigates the influence of silicone antifoam agent on waste water from Gashash leather and Nigerian Spinning and Dying industries (NSD). Waste water from the outlet of the industries were collected and analyzed for physicochemical parameters. Silicone antifoam was added to the wastewater to determine the impact of the silicone antifoam on turbidity and chemical oxygen demand (COD) concentrations. The result shows that both turbidity and COD values significantly increased even when small concentration of the silicone antifoam was added. Further, independent t-test was used to identify the variance between the mean value of the wastewater from leather, spinning and dying industries, the results indicated that there are no significant differences (observed t 0.544, critical t 2.015, and p value 0.589) between the waste water in leather and dying industries. Keywords: Silicone antifoam, turbidity, COD, Independent sample t-test

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

510

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517

INTRODUCTION

Industrial pollution is one of the problems facing Nigeria and effluent generated by the industries is one of the sources of surface water pollution [1, 2]. Industries consume large quantities of water and discharge considerable amount of quantities of waste water during their production process [3]. Development of industrial civilization has led to a considerable deterioration of the main element of the environment. Dynamic growth of global industrial output and an increase rate of non-renewable resources are manifestations of activities that may pose a serious threat to life on earth [4]. Industrial waste generally has assumed exponential increases as a result of rapid growth of industrial development in the urban centres where large volume of effluent are generated due to multiple production of goods in the industrial sectors [5]. Surface water of many industries in the developing countries is becoming heavily polluted by industrial effluent which is either directly discharge or partially treated in to the water body [6]. Pollution from industrial discharges and waste water are one of the main causes of irreversible ecosystem degradation [7]. Disposal of sewage to the surface water become a necessity as soon as industries are established, the outcome was a deterioration of standard of many rivers and their water become useless for either domestic consumption or industrial uses [8]. Depending on the type and amount of effluent being generated from different type of industries, it could be concluded that, areas that find its location close to industries are heavily polluted with industrial effluents and produce greater negative effects on the environment [9, 10, 11]. The gradual decline in the availability of freshwater in Kano Region is due to the rapid urbanization coupled with high population growth that leads to high demand of such resource, as a result the use of sewage and other industrial effluent for various purposes is on the rise particularly during the dry season. Kano State Environmental Protection Agency has made it mandatory for all industries operating in her jurisdiction to have primary treatment plant within their premises. The State government had since 1990's proposed to establish central secondary treatment plant that will treat all industrial waste at a central location to safe standard before release in to the environment. The problem statement is that, the absence of designated collection points where industries can safely dispose their waste has resulted in uncontrolled situation and indiscriminate dumping of waste in to the environment. This waste, besides polluting the surface water, it poses damage to environment directly or indirectly, this practice has resulted in conflict with the local people on the edge of the industrial layout. Silicone antifoams are one of the commercial silicone products which are used for form control in an aqueous system. The silicone antifoams usually consist of mixture of polydimethysiloxane and hydrophobed silica. Silicone antifoam has been widely used in many industries to control foaming problems that occur in the process systems or in waste water effluent. Silicone comprises a multitude of technical products whose 511

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517 property controlling component consist of polyorganosiloxanes which consist of linear or cyclic siloxane and represent the major portion of commercially available silicones. Foams are agglomeration of gas bubbles separated from each other by thin liquid film, they belongs to the aggregation of two phases, gases dispersion in liquid films. Silicone antifoam is used to curb surface foams from occurring in wastewater effluent. In this study, we examined the effects of the use of the antifoam on turbidity, chemical oxygen demand (COD) and silica values in the waste water effluent generated by leather and dying industries in Bompai Industrial estate Kano Region Nigeria.

MATERIALS AND METHODS

Two stations were selected which includes Gashash Tannery and Nigerian Spinning and Dying (NSD) industries in Bompai Industrial estate, Kano Region, Nigeria. Samples were carried out at the effluent outlet from discharge pipe at both station and the frequency of sampling was once daily in the morning on the alternate days each month for two consecutive months. Samples were collected in triplicates at each station. Samples were collected using grab sampling in clean polyethylene bottle after proper rinsing 2-3 times. All samples were kept in a 1 L glass bottle which has been rinsed with the samples. 6 beakers each containing 200 mL of sample were treated with 6 different concentration of silicone antifoams at 0.01 mg/L, 0.03 mg/L, 0.05 mg/L, 0.10 mg/L, and 0.20 mg/L. In order to provide greater data confidence from the analytical procedure regarding bias and variability appropriate quality-assurance and quality-control (QA/QC) on water samples were ensured. The QA/QC were followed to ensure that data products are of documented high quality and reproducible. The overall data quality is assessed through precision, accuracy and comparability. An Independent sample t-test was used to compare the mean (average value) of two variables. The null hypothesis says that the two means do not differ from one another significantly (there are no differences between the mean) against alternative hypothesis that the two means are not the same. Calculated t-value can be computed using the equation below:

x x s sx n

x is the mean sample, is the population means, S

Where t is the test statistics (Students t distribution) for

is the standard deviation of the sample and n is the sample size. Independent sample t-test can be computed using the equation below when unequal variance is assumed.

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

512

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517

x1 x2

2 2 s1 s2 n1 n2

When equal variance is assumed independent t-test can be computed using the equation below:

x1 x2 s2 p n1 s2 p n2

Where t test statistic (Students t distribution),

p

x is the mean of the paired difference for the

sample, s 2 is the standard error of the mean of the paired differences for the sample and n1 and n2 are the number of the paired difference values.

RESULT AND DISCUSSIONS

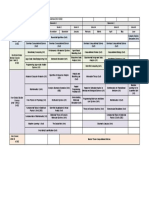

Table 1 presents the results water samples of laboratory analysis from Gashash tannery and Nigerian Spinning and Dying industries. The given values are the average of 3 samples. The turbidity values of 4.1667 NTU was recorded in leather waste water which was slightly lower when compared with effluent from dying industry. The COD value was much higher in Gashash leather waste water with 56.475 mg/L as compared to NSD industry with 25.033 mg/L.

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

513

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517

Parameter Turbidity pH COD BOD5 TSS Hg Cd Cr+6 As Cn Pb Cr+3 Cu Mn Ni Sn Zn B Fe Phenol Free Chlorine SO4 Oil &Grease Foam

unit NTU

Gashash Leather 4.1667 7.389

NSD Dyeing 4.25 7.115 25.033 6.95 5.625 0.0056 0.001 0.01 0.0026 0.02 0.02 0.015 0.0625 0.04 0.02 0.43 0.095 0.03 0.4425 0.138 0.21 0.3 7.025 yes

mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L

56.475 15.409 3.8 0.00675 0.01 0.001 0.001 0.01 0.064 0.01 0.1044 0.043 0.275 0.305 0.174 0.775 0.735 0.192 0.2675 0.02 2 yes

Table 1: Result of laboratory analysis of Gashash and NSD waste water Table 2 presented the concentration of silicone antifoam (ppm) which indicated that small amount of concentration of silicone antifoam increase the the mean of turbidity value. The turbidy level was 4,667 NTU when there is no addition of silcone antifoam, when 0.01 ppm of antifoam was added the turbidity level increased to 16.333 NTU. The higher the concentration of silicone antifoam added, the more tubib the wastewater effluent became.

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

514

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517 Silicone Antifoam Conc (ppm) 0(control) 0.01 0.03 0.05 0.1 0.15 0.2 Turbidity (NTU) 4.667 16.333 36.667 56.667 102.167 154.667 184.333

Table 2: The influence of silicone antifoam on turbidity level

Figure 1: The relationship between concentration of silicone antifoam and turbidity value The silicone antiform concentration in relation to chemical oxygen demand showed that the antiform concentration at 0.01, 0.03,0.05, 0.1, 0.15 and 0.20 increased (Table 3). Antifoarm concentration of 0.01 increased COD with 50%, at 0.03 ppm of silicone antifoam COD increase to138.3% which exceeded the value of World Health Organization of COD in wastewater. Figure 2 spresent the high slope value which indicated that the addition of silicone antifoam significantly increasess the wastewater effluent COD value.

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

515

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517 Silicone Antifoam Conc (ppm) 0(control) 0.01 0.03 0.05 0.1 0.15 0.20 COD (mg/L) 49.67 90.50 138.83 248.66 469.83 723.17 931.17

Table 3:The influence of silicone antifoam on Chemical Oxygen Demand (COD) level

Figure 2: The relationship between concentration of silicone antifoam and COD value An Independent t-test was applied on the data set to test the hypothesis that there is significant differences in the mean value of waste water between Gashash leather and Nigerian Spinning and dying industries. The result obtained was presented on Table 4. Difference t (Observed value) |t| (Critical value) DF p-value (Two-tailed) alpha 1.495 0.544 2.015 44 0.589 0.05

Table 4:Independent t- test result

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

516

Adamu Mustapha., IJSIT, 2013, 2(6), 510-517 The decision was that, the null hypothesis was fail to be rejected because the critical t value was greater than the observed t value and the p of 0.589 value was greater that the alpha value of 0.05. This showed that the concentration of waste water in Gashash leather industry is the same with the waste water in the Nigeria Spinning and dying (NSD) industry.

CONCLUSION

Turbidity and chemical oxygen demand showed a positive gradient with silicone antifoam concentration. Industrial waste generally has assumed an exponential increases as a result of rapid growth of industrial development in the urban centres where large volume of effluent are generated due to multiple production of goods in the industrial sectors. Surface water of many industrial countries are becoming heavily polluted by industrial effluent which are either directly discharge or partially treated in to the water body. Polluting industrial discharges and waste water are one of the main causes of irreversible ecosystem degradation. Depending on the type and amount of effluent being generated from different type of industries, it could be concluded that, areas that find its location close to industries are heavily polluted with industrial effluents and produce greater negative effects on the environment.

REFERENCES

1. 2. 3. 4. 5. 6. 7. 8. 9. R. O. Yusuff and J. A. Sonibare 2004. Global Nest The International Journal, 6(3):212-221. L. Shakir, S. Ejaz, M. Ashraf, N. Ahmad and A. Javeed. 2012. Environmental Science and Pollution Research, 19(1):492-501. J. Ma, Z. Ding, G. Wei, H. Zhao, and T. Huang. 2009, Environmental Research, 109(3):245-257. A. Astel, S. Tsakovski, V. Simeonov and E. Reisenhofer 2008, Analytical and Bioanalytical Chemistry, 390:1283-1292. S. Srinivasa Gowd and P.K. Govil. 2008, Environmental Monitoring and Assessment, 136(1):197-207. A. Mustapha and A.Z. Aris. 2012, Journal of Environmental Science and Health Part A, 47(10):14551465. T. Rajaram and A. Das. 2008, Future, 40(1): 56-69. P. Satheeshkumar, and D. Senthilkumar. 2011, Journal of Environment and Earth Science, 1(1)30-48. A. Mustapha and A.Z. Aris. 2012, Polish Journal of Environmental Studies, 21(5):1359-1367. A, 47(11)1551-1560. 11. A. Mustapha and A.B. Nabegu. 2011, Australian Journal of Basic and Applied Sciences, 5(12): 1507.

10. A. Mustapha, A.Z. Aris, M.F. Ramli, H. Juahir. 2012, Journal of Environmental Science and Health Part

IJSIT (www.ijsit.com), Volume 2, Issue 6, November-December 2013

517

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Curriculum Master Computational Science 2021-2022Document1 pageCurriculum Master Computational Science 2021-2022Kiran MenonNo ratings yet

- The Olympic Stadium in Munich, GermanyDocument13 pagesThe Olympic Stadium in Munich, GermanykmarshalNo ratings yet

- Digital Designer's Guide To Linear Voltage Regulators & Thermal Management - SLVA118 - 2003Document25 pagesDigital Designer's Guide To Linear Voltage Regulators & Thermal Management - SLVA118 - 2003Kevin PlayerNo ratings yet

- How To Manage Inbound Outbound Route On UCMDocument23 pagesHow To Manage Inbound Outbound Route On UCMEmilio I WildeNo ratings yet

- Week 3 - Divergence Theorm and Maxwell First EqDocument6 pagesWeek 3 - Divergence Theorm and Maxwell First EqjefriNo ratings yet

- Zipf 1945 The Meaning-Frequency Relationship of WordsDocument8 pagesZipf 1945 The Meaning-Frequency Relationship of WordsIker SalaberriNo ratings yet

- How To Crack Selenium WebDriver InterviewsDocument5 pagesHow To Crack Selenium WebDriver InterviewsJaydeep MateNo ratings yet

- XAM IDEA Mathematics Sample Papers Class 10 2023Document238 pagesXAM IDEA Mathematics Sample Papers Class 10 2023anonymousNo ratings yet

- Radio 2219 PDFDocument2 pagesRadio 2219 PDFdsfasdf dfg100% (1)

- 4c516 Wistron Yukon r1 Schematics PDFDocument44 pages4c516 Wistron Yukon r1 Schematics PDFBong BernalNo ratings yet

- ECO 391-007 Lecture Handout For Chapter 15 SPRING 2003 Regression Analysis Sections 15.1, 15.2Document22 pagesECO 391-007 Lecture Handout For Chapter 15 SPRING 2003 Regression Analysis Sections 15.1, 15.2Noah HNo ratings yet

- 3.5.2.4 Packet Tracer - Learn To Use Packet TracerDocument2 pages3.5.2.4 Packet Tracer - Learn To Use Packet TracerJodiGinandraPaksiNo ratings yet

- Harmony Xb7 Xb7nd33Document6 pagesHarmony Xb7 Xb7nd33elborniNo ratings yet

- UM CML720 en 50119589Document197 pagesUM CML720 en 50119589Julian David Rocha OsorioNo ratings yet

- Fire Sentry FS24X Flame DetectorsDocument4 pagesFire Sentry FS24X Flame DetectorsGabriel CalderonNo ratings yet

- Chemical Resistance List EnglishDocument11 pagesChemical Resistance List EnglishdpaoluccNo ratings yet

- SAES-E-004 02-18-2018 FinalDocument35 pagesSAES-E-004 02-18-2018 Finalsaleem naheedNo ratings yet

- In Uence Des Milieux de Conservation Sur Les Propriétés Physico-Mécaniques de Béton de Sable de DunesDocument9 pagesIn Uence Des Milieux de Conservation Sur Les Propriétés Physico-Mécaniques de Béton de Sable de DunesAbderraouf KamelNo ratings yet

- Programming Worksheet 7Document2 pagesProgramming Worksheet 7potholemaryNo ratings yet

- CICS Training July 2009Document175 pagesCICS Training July 2009Ivan Petrucci100% (2)

- 2009ZX-6R Racing Kit ManualDocument62 pages2009ZX-6R Racing Kit Manualjunzok100% (1)

- Range Maistro: Resistors Resistors Millbypass Capacitors Capacitors Range Master PARTS LIST Brian May T-Boost PARTS LISTDocument1 pageRange Maistro: Resistors Resistors Millbypass Capacitors Capacitors Range Master PARTS LIST Brian May T-Boost PARTS LISTRegis BarcelosNo ratings yet

- Practical Report Template On TrolleyDocument3 pagesPractical Report Template On TrolleyYong Junseng Alson yjsNo ratings yet

- Iodine SpectrumDocument10 pagesIodine SpectrumRachel Shaver0% (1)

- Manual HPOD 100 KDocument86 pagesManual HPOD 100 KLuis Guillermo SandovalNo ratings yet

- Bomba Calpeda Cat - 60hz2004Document172 pagesBomba Calpeda Cat - 60hz2004brenossNo ratings yet

- Power Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Document64 pagesPower Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Irina VarzouNo ratings yet

- A Brain Tumor Detection Using Image ProcessingDocument5 pagesA Brain Tumor Detection Using Image ProcessingIJRASETPublicationsNo ratings yet

- Voice Over Internet Protocol (VOIP) : Overview, Direction and ChallengesDocument12 pagesVoice Over Internet Protocol (VOIP) : Overview, Direction and ChallengesJuscal KwrldNo ratings yet

- Tips For Predicting Speed With Propexpert: A Hydrocomp Technical ReportDocument2 pagesTips For Predicting Speed With Propexpert: A Hydrocomp Technical ReporthaujesNo ratings yet