Professional Documents

Culture Documents

Motor Calculos

Uploaded by

liner0 ratings0% found this document useful (0 votes)

36 views1 pageSizing short-circuit and ground-Iault protection Ior a motor branch circuit is a common source oI conIusion. Per 430.6(a), branch-circuit conductors to a single motor must have an ampacity oI not less than 125degoI the motor Iull load current (FLC) Per Table 430.148, the FLC current is 34A. 34Ax125deg / 43A.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSizing short-circuit and ground-Iault protection Ior a motor branch circuit is a common source oI conIusion. Per 430.6(a), branch-circuit conductors to a single motor must have an ampacity oI not less than 125degoI the motor Iull load current (FLC) Per Table 430.148, the FLC current is 34A. 34Ax125deg / 43A.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 pageMotor Calculos

Uploaded by

linerSizing short-circuit and ground-Iault protection Ior a motor branch circuit is a common source oI conIusion. Per 430.6(a), branch-circuit conductors to a single motor must have an ampacity oI not less than 125degoI the motor Iull load current (FLC) Per Table 430.148, the FLC current is 34A. 34Ax125deg / 43A.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

By Mike Holt, NEC Consultant

May 1, 2004 12:00 PM

What`s the correct way to size motor Ieeders and related overcurrent protection?

Part 1 oI this two-part series explained how to size overload protection devices and short-circuit and ground-Iault protection Ior motor

branch circuits. Understanding the key point oI that article, which was that motor overload protection requires separate calculations

Irom short-circuit and ground-Iault protection, clears up a common source oI conIusion and a point oI error. But another source oI

conIusion arises when it comes to sizing short-circuit and ground-Iault protection Ior a Ieeder that supplies more than one motor. Let's

look again at branch-circuit calculations and then resolve the Ieeder issues so your calculations will always be correct.

Branch-circuit conductors and protection devices. Per 430.6(A), branch-circuit conductors to a single motor must have an ampacity

oI not less than 125oI the motor Iull load current (FLC) as listed in Tables 430.147 through 430.150. To illustrate this, let's size the

branch-circuit conductors (THHN) and short-circuit ground-Iault protection device Ior a 3-hp, 115V, single-phase motor. The motor

FLA is 31A, and dual-element Iuses Ior short-circuit and ground-Iault protection are in use (Fig. 1).

Per Table 430.148, the FLC current is 34A.

34A12543A.

Per Table 310.16 (60C terminals |110.14(C)(1)(a)|), the conductor must be a 6 AWG THHN rated 55A.

Per the motor FLC listed in Table 430.52, size the branch-circuit short-circuit and

ground-Iault protection devices by using multiplication Iactors based on the type oI

motor and protection device. When the protection device values determined Irom

Table 430.52 don't correspond with the standard rating oI overcurrent protection

devices listed in 240.6(A), you must use the next higher overcurrent protection

device. To illustrate this, let's use the same motor as in the previous example.

Per 240.6(A), multiply 34A175

You need a 60A dual-element Iuse.

To explore this example Iurther, see Example No. D8 in Annex D oI the 2002 NEC.

Once you've sized the motor overloads, branch-circuit conductors, and branch-circuit

protective devices, you're ready to move on to the next step.

Motor feeder conductor calculations. From 430.24, you can see that conductors

that supply several motors must have an ampacity not less than:

125oI the highest-rated motor FLC |430.17|, plus

The sum oI the FLCs oI the other motors (on the same phase), as determined

by 430.6(A), plus

The ampacity required to supply the other loads on that Ieeder.

Use Fig. 2 and solve the Iollowing problem.

Example No. 1. For what ampacity must you size the Ieeder conductor iI it supplies

the Iollowing two motors? The terminals are rated Ior 75C.

One 7.5-hp, 230V (40A), single-phase motor

One 5-hp, 230V (28A), single-phase motor

(a) 50A

(b) 60A

(c) 70A

(d) 80A

Let's walk through the solution.

The largest motor is 40A.

40A1.2528A78A.

80A is the closest selection that's at least 78A.

What size conductor would give us this ampacity?

(a) 2 AWG

(b) 4 AWG

(c) 6 AWG

(d) 8 AWG

Per Table 310.16, a 6 AWG conductor rated at 75C provides 65A oI ampacity, so it's too small. However, a 4 AWG conductor

provides 85A oI ampacity, which will accommodate the necessary 78A. ThereIore, you need to size this Ieeder conductor at 4 AWG.

Next, we have to determine what size overcurrent protection device (OCPD) we must provide Ior a given Ieeder.

Example No. 2. Using a slightly more complex example, try sizing the Ieeder

conductor (THHN) and protection device (inverse-time breakers, 75C terminal

rating) Ior the Iollowing motors (Fig. 3):

Three 1-hp, 120V, single-phase motors

Three 5-hp, 208V, single-phase motors

One wound-rotor, 15-hp, 208V, 3-phase motor

ReIer to 240.6(A), 430.52(C)(1), Table 430.148, and Table 430.52. Start by

determining the ampacities required Ior each size oI motor, then walk through each

step until you arrive at the correct OCPD size.

1-hp motor: FLC is 16A.

16A25040A

5-hp motor: FLC is 30.8A.

30.8A25077A (Next size up is 80A.)

15-hp motor: FLC is 46.2A.

46.2A150(wound-rotor)

569A (Next size up is 70A.)

Now, let's look at the Ieeder

conductor. Conductors that

supply several motors must

have an ampacity oI not less

than 125oI the highest-rated

motor FLC (430.17), plus the

sum oI the other motor FLCs

|430.6(A)| on the same phase

(Fig. 4).

Continuing with this example,

add up all the ampacities,

multiplying the highest rated

motor by 125. Thus:

(46.2A1.25)

30.8A30.8A16A136A.

Table 310.16 shows you need 1/0 AWG THHN because at 150A it's the smallest conductor that accommodates the 136A oI ampacity

we're working with. When sizing the Ieeder conductor, be sure to include only the motors that are on the same phase. For that reason,

these calculations only involve Iour motors.

You must provide the Ieeder with a protective device with a rating or setting not greater than the largest rating or setting oI the branch-

circuit short-circuit and ground-Iault protective device (plus the sum oI the Iull-load currents oI the other motors oI the group) |430.62

(A)|. Remember, motor Ieeder conductors must be protected against the overcurrent that results Irom short circuits and ground Iaults

but not those that result Irom motor overload.

When sizing the Ieeder protection, be sure to include only the motors that are on the same phase.

ReIer to Fig. 5 Ior this sample motor Ieeder protection calculation.

Example No. 3. What size Ieeder protection (inverse-time breaker) do you need Ior

the Iollowing two motors?

5-hp, 230V, single-phase motor

3-hp, 230V, single-phase motor

(a) 30A breaker

(b) 40A breaker

(c) 50A breaker

(d) 80A breaker

Let's walk through the solution.

Step 1. Get the motor FLC Irom Table 430.148.

A 5-hp motor FLC is 28A.

A 3-hp motor FLC is 17A.

Step 2. Size the branch-circuit protection per the requirements oI 430.52(C)(1), Table

430.52, and 240.6(A)

5-hp: 28A2.570A

3-hp: 17A2.542.5A (Next size up is 45A.)

Step 3. Size the Ieeder conductor per 430.24(A).

The largest motor is 28A.

(28A1.25)17A52A

Table 310.16 shows 6 AWG rated 55A at 60C as the smallest conductor with suIIicient ampacity.

Step 4. Size the Ieeder protection per 430.62.

It must not be greater than the 70A protection oI the branch circuit plus the 17A oI the other motor, which is the total oI all

loads on that Ieeder.

70A17A87A

Choose the next size down, which is 80A.

How can you be saIe iI you're selecting the next size down instead oI the next size up? Remember, you've already accounted Ior all the

loads, and the NEC requires that you not exceed the protection oI the branch circuit. Again, keep in mind that you aren't calculating Ior

motor overload protection. Motor calculations are diIIerent Irom other calculations. With motor Ieeders, you're calculating Ior

protection Irom short circuits and ground Iaults, only not overload.

Putting it all together. Motor calculations get conIusing iI you Iorget there's a division oI responsibility in the protective devices. To

get your calculations right, you must separately calculate the motor overload protection (typically near the motor), branch-circuit

protection (Irom short circuits and ground Iaults), and Ieeder-circuit protection (Irom short circuits and ground Iaults). Remember that

overload protection is only at the motor.

Any time you Iind yourselI conIused, just reIer to NEC Figure 430.1. It shows the division oI responsibility between diIIerent Iorms oI

protection in motor circuits. Example D8 in Annex D oI the 2002 NEC illustrates this with actual numbers. Keeping this division oI

responsibility in mind will allow you to make correct motor calculations every time.

Fig. 1. Don`t make the mistake oI using a motor`s

FLA nameplate rating when using the short-circuit

and ground-Iault protection devices. You must use

the FLC rating given in Table 430.148.

Fig. 2. Motor Ieeder conductors shall be sized not

less than 125oI the largest motor FLC plus the

sum oI the FLCs oI the other motors on the same

phase.

Fig. 3. To size overcurrent protection devices Ior

each Ieeder, start by determining the ampacities

required Ior each motor and move on Irom there.

Fig. 4. Each motor`s FLC will come into play when

sizing the conductor.

Fig. 5. In this example, the largest branch-circuit

Iuse or circuit breaker allowed Ior Motor 1 is 70A.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Asi X Packer 105243965Document3 pagesAsi X Packer 105243965Esteban RochaNo ratings yet

- PACK PAR BoilersDocument31 pagesPACK PAR BoilersJosé MacedoNo ratings yet

- SUMMER TRAINING REPORT AT Elin Electronics Ltd. Gzb.Document54 pagesSUMMER TRAINING REPORT AT Elin Electronics Ltd. Gzb.Ravi Kumar100% (3)

- Noise Fundamentals ExplainedDocument26 pagesNoise Fundamentals ExplainedMuhamad FuadNo ratings yet

- CV for Mechanical Inspector and Welding InspectorDocument28 pagesCV for Mechanical Inspector and Welding InspectorAJMAL KAREEMNo ratings yet

- Expert Office 365 Notes From The FieldDocument289 pagesExpert Office 365 Notes From The FieldYohanna Monsalvez100% (1)

- Evaluating SWOT's Value in Creating Actionable, Strategic IntelligenceDocument94 pagesEvaluating SWOT's Value in Creating Actionable, Strategic IntelligenceMJFinnegan4100% (4)

- Appointment Reciept GDocument3 pagesAppointment Reciept GSanNo ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Practice Exam - CXC CSEC English A Exam Paper 1 - CaribExams2Document6 pagesPractice Exam - CXC CSEC English A Exam Paper 1 - CaribExams2Sam fry0% (1)

- Hydran 201ti Gea12933 HRDocument2 pagesHydran 201ti Gea12933 HRlxd.hepNo ratings yet

- Host 1Document6 pagesHost 1Lukman FafaNo ratings yet

- PLSQL 4 2 Practice RodrigoDocument6 pagesPLSQL 4 2 Practice RodrigoRodrigoRojasHuerta100% (1)

- SwephprgDocument94 pagesSwephprgAbhisekAcharyaNo ratings yet

- 12 585 Rov Latches Brochure v3 Web 1 PDFDocument8 pages12 585 Rov Latches Brochure v3 Web 1 PDFIZayvenkoNo ratings yet

- Section 3.3.4 Neutral Earthing Resistors R1Document7 pagesSection 3.3.4 Neutral Earthing Resistors R1waelabouelelaNo ratings yet

- 16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalDocument34 pages16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalJou Power50% (2)

- An Introduction To Marketing Research by SmithDocument448 pagesAn Introduction To Marketing Research by SmithKali Das100% (1)

- Part 3B - Energy Balance - Open SystemDocument23 pagesPart 3B - Energy Balance - Open SystemHarold SumagaysayNo ratings yet

- Marine Fuel Stability and Compatibility IssuesDocument4 pagesMarine Fuel Stability and Compatibility IssuesRebekah SchmidtNo ratings yet

- Synopsis Mobile Banking AdministrationDocument24 pagesSynopsis Mobile Banking AdministrationRaj BangaloreNo ratings yet

- CMM49 14 01 MtocDocument2 pagesCMM49 14 01 MtocMichail K100% (1)

- Zero Energy Architecture-2Document45 pagesZero Energy Architecture-2Avjeet SinghNo ratings yet

- Enterprise, Innovation Creativity 2018-19 S3 CourseworkDocument7 pagesEnterprise, Innovation Creativity 2018-19 S3 CourseworkSajidNo ratings yet

- Fast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsDocument13 pagesFast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsSraVanKuMarThadakamallaNo ratings yet

- 4 Thermodynoamics ExercisesDocument25 pages4 Thermodynoamics ExercisesGoran MaliNo ratings yet

- Nov-23 Main Fcom QRH FCTM Changes A320Document17 pagesNov-23 Main Fcom QRH FCTM Changes A320Joe FalchettoNo ratings yet

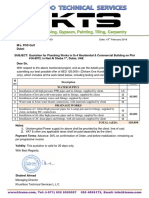

- KTS Quotation Meidan Building Plumbing Works PDFDocument1 pageKTS Quotation Meidan Building Plumbing Works PDFShakeel Ahmad100% (1)

- Microstation GuideDocument158 pagesMicrostation GuideMishra KirtiwardhanNo ratings yet

- Ztree 2 StataDocument3 pagesZtree 2 StataDaniel Felipe ParraNo ratings yet