Professional Documents

Culture Documents

Mathcad - Proiect Structuri Metalice

Uploaded by

Florin FlorinellCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - Proiect Structuri Metalice

Uploaded by

Florin FlorinellCopyright:

Available Formats

ORIGIN 1 := daN 10N :=

PROIECT

Hala industriala cu structura metalica

Tema proiectului

Sa se intocmeasca notele de calcul si planse de executie pentru o cladire industriala alcatuita din elemente

de otel laminat la cald. Cladirea va fi situata in zona climatica II si zona seismica....Forma in plan a cladirii

este rectangulara, cu o deschidere L(m) si 7 travei l(m).

Stalpii cadrului transversal vor fi cu sectiune constanta, incastrati in fundatie si articulati in nodul de legatura

cu rigla de cadru. Rigla de cadru va fi solutionata ca grinda cu zabrele in doua pante,ea sustinand panele de

acoperis si invelitoarea. Invelitoarea se va realiza din tabla cutata, va fi izolata sau neizolata termic, iar panta

talpii superioare a fermei va corespunde tipului de invelitoare ales.

Stalpii cadrului transversal vor fi alcatuiti din europrofile HE, iar grinda cu zabrele din sectiuni compuse cu

profile cornier cu aripi egale si inegale. Nodurile uzinate ale fermei vor fi executate in varianta sudata iar in

santier asamblarea se va realiza cu suruburi de inalta rezistenta pretensionate.

Otelurile utilizate si elementele de imbinare vor respecta prevederile SREN 10025-A1.

Etapizarea proiectului

a)Continut

1.Tema proiectului: Cladire industriala cu o deschidere ; Schita constructiva sectiune transversala si vedere

longitudinala ; sistemul de contravantuiri in planul acoperisului si intre stalpii structurii. Date personale.

2.Alacatuirea acoperisului: invelitoare , pane , tiranti. Actiuni si grupari de actiuni la nivelul acoperisului.

3.Panele acoperisului - dimensionare si verificari. Detalii de prindere si de inadire;. Plansa de executie a

panelor (Sc. 1:50 , detalii 1:10).

4. Actiuni si grupari de actiuni pe cadrul transversal in gruparea fundamentala si ingruparea speciala.

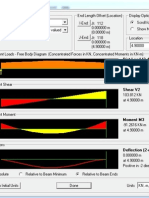

5. , 6. Calcul static al cadrului transversal cu ajutorul unui program automat de calcul.

7.Determinarea eforturilor in barele fermei consoderand efectul nedeterminarii statice.

8.Dimensionarea si verificarea barelor fermei. Verificare de rigditate a fermei.

9.Dimensionarea elementelor de prindere in noduri la grinda cu zabrele ( sudate in fabrica s bulonate in

santier).

10.Plansa grinzii cu zabrele (sc. 1:20 , detalii 1:10)

11.Determinarea eforturilor de dimensionare a stalpului.

12. Dimensionarea stalpului cu sectiune constanta.

13.Alcatuirea si calculul elementelor de rezemare ale stalpului - placa ce capitel si baza stalpului.

14.Verificare si notare finala.

Date personale:

Deschiderea : L 24m :=

Traveia : l 9m :=

Inaltimea : H 9m :=

Hala izolata

Etapa 1.

1.1 Schita constructiva

- sectiune transversala a halei

h

.

s

L

.

s

t

.

c

H

h

.

r

D

.

f

0.00

24000.00

d

- sectiune transversala grinda cu zabrele

3000.00 3000.00 3000.00 3000.00 3000.00 3000.00 3000.00 3000.00

3000.00 6000.00 6000.00 6000.00 3000.00

7

5

0

.

0

0

2

2

5

0

.

0

0

1.1.1Stabilirea lungimii stalpului

h

1

2.25m := h

2

0.75m := 0.3m := a 3.00m :=

h

s

0.4m := H 9m = D

f

0.5m :=

h

s.c

D

f

h

2

+ H + + h

s

10.15m = :=

1.1.2 Stabilirea cotei la nivelul coamei

H

c

h

s.c

h

s

+ h

1

+ 12.8m = :=

1.2. Plan contravantuiri

2

4

0

0

0

.

0

0

9000.00 9000.00 9000.00 9000.00 9000.00 9000.00 9000.00

1 2 3 4 5 6 7 8

A

B

1 2 3 4 5 6 7 8

9000.00 9000.00 9000.00 9000.00 9000.00 9000.00 9000.00

63000.00

Etapa 2.

2. Alcatuirea acoperisului : invelitoare, pane , tiranti.Actiuni si grupari de actiuni la nivelul

acoperisului

2.1. Calculul panei curente

2.1.1. Alcatuire constructiva

Pentru LT < 6m - pana cu un tirant

Pentru LT > 6m - pana cu doi tirant

3000.00 3000.00 3000.00 3000.00 3000.00 3000.00 3000.00 3000.00

3000.00 6000.00 6000.00 6000.00 3000.00

7

5

0

.

0

0

2

2

5

0

.

0

0

9

0

0

0

.

0

0

3

0

0

0

.

0

0

3

0

0

0

.

0

0

3

0

0

0

.

0

0

3000.00

2.1.2. Evaluarea incarcarilor. Valori caracteristice. Incarcari de calcul

2.1.2.1. Valori caracteristice

a.)Incarcari permanente (G)

-greutate proprie invelitoare

g

inv

16

daN

m

2

:= 2.86 := g

inv.k

g

inv

cos ( )

16.02

daN

m

2

= :=

-greutate proprie pana

g

UPN300

46.2

kg

m

:= g

p.k

g

UPN300

g

a

15.102

daN

m

2

= :=

-greutate instalatii electrice

g

ie.k

15

daN

m

2

:=

-greutate praf industrial

g

pi.k

20

daN

m

2

:=

g

ki

g

inv.k

g

p.k

+ g

ie.k

+ g

pi.k

+ 66.122

daN

m

2

= :=

b.)Incarcari variabile (Q)

-incarcarea din vant

-se evalueaza conform SREN 1991-1-4

-pentru panta acoperisului p<12% la nivelul invelitorii apar suctiunii iar actiunea vantului se neglijeaza

-incarcarea din zapada

-se evalueaza conform SREN 1991-1-3

Pentru Slatina incarcarea caracteristica din zapada pe sol este: s

ok

200

daN

m

2

:=

C

e

1 := C

t

0.8 :=

i

1 :=

S

k

C

e

C

t

i

s

ok

160

daN

m

2

= :=

2.1.2.2. Grupari de incarcari . Incarcari de calcul

S.L.S S.L.U

q

k

g

ki

S

k

+

( )

a 678.367

daN

m

= := q

d

1.35 g

ki

1.5S

k

+

( )

a 987.795

daN

m

= :=

q

z.k

q

k

cos ( ) 677.522

daN

m

= := q

z.d

q

d

cos ( ) 986.565

daN

m

= :=

q

y.k

q

k

sin ( ) 33.848

daN

m

= := q

y.d

q

d

sin ( ) 49.287

daN

m

= :=

2.1.3. Schema statica

l/3 l/3 l/3 l/3 l/3 l/3 l/3 l/3 l/3 l/3

l(LT) l(LT) l(LT)

M.y ED

M.z ED

q.yd(1.3*l/3)^2

8

q.zd*l^2

11

q.zd*l^2

16

q.zd(q.yd)

2.1.4. Calculul panei in camp curent

2.1.4.1. Eforturi sectionale de calcul

Pana cu 2 tiranti

V

z.ed

q

z.d

l

2

4439.54 daN = :=

M

y.ed

q

z.d

l

2

16

4994.483 daN m = :=

M

z.ed

q

y.d

1.3

l

3

\

|

|

8

93.706 daN m = := V

y.ed

1.1q

y.d

l

3

162.646 daN = :=

2.1.4.2. Predimensionarea sectiunii

-se determina modulul de rezistenta plastic la incovoiere , necesar

Pana cu 2 tiranti:

f

y.d

f

y

M0

= f

y

2350

daN

cm

2

:=

M0

1 := f

y.d

f

y

2350

daN

cm

2

= := k 6 :=

W

pl.y.nec

M

y.ed

k M

z.ed

+

f

y.d

236.456 cm

3

= :=

Se impune W

pl.y.efectiv

W

pl.y.nec

Aleg UPN 300 cu W

pl.y

292cm

3

:= W

pl.z

64.1cm

3

:=

h

upn

220mm := b

upn

80mm := r

1upn

12.5mm := A

upn

37.4cm

2

:= A

vz

20.62cm

2

:=

t

wupn

9mm := t

fupn

12.5mm := r

2upn

6.5mm := G

upn

29.4

kg

m

:=

2.1.4.3. Verificarea sectiunii profilului ales

-Determinarea clasei de sectiuni

a)Talpa superioara solicitata la compresiune

c

1

b

upn

t

wupn

r

1upn

58.5 mm = :=

c

1

t

fupn

9 4.625 9 Cl. 1

b)Inima sectiunii solicitata la tensiuni din

incovoiere

c

2

h

upn

2t

fupn

2r

1upn

17 cm = :=

c

2

t

wupn

72 23.6 9 Cl. 1

2.1.4.4. Verificarea la SLS

2.1.4.4.1 Verificarea la actiunea momentului incovoitor

-Pana cu 2 tiranti

M

y.ed

M

y.pl.Rd

M

z.ed

M

z.pl.Rd

+ 1 M.

y.pl.Rd

, M.

z.pl.Rd

- momentul plastic rezistent

M

y.pl.Rd

W

pl.y

f

y.d

6862 daN m = :=

M

z.pl.Rd

W

pl.z

f

y.d

1506.35 daN m = :=

M

y.ed

M

y.pl.Rd

M

z.ed

M

z.pl.Rd

+ 0.79 = 0.79 1 Conditia se verifica

2.1.4.4.2 Verificarea la actiunea fortei taietoare

V.

z.pl.Rd

, V.

y.pl.Rd

- forta taietoare plastic

rezistenta

V

z.ed.max

V

z.pl.Rd

1 V

z.pl.Rd

A

vz

f

y

3

=

V

y.ed.max

V

y.pl.Rd

1 V

y.pl.Rd

A

vy

f

y

3

= A.

vz

, A.

vy

- aria de forfecare

A

vy

A

upn

h

upn

t

wupn

2 t

fupn

r

1upn

+

( )

t

wupn

+ 22.1 cm

2

= :=

V

z.pl.Rd

A

vz

f

y

3

27976.662 daN = :=

V

z.ed

V

z.pl.Rd

0.159 =

V

y.pl.Rd

A

vy

f

y

3

29984.686 daN = :=

V

y.ed

V

y.pl.Rd

0.005 =

2.1.4.4.3. Verificarea la stabiltate generala

f

k

c

L

c

i

fz

1

c0

M

c.Rd

M

y.ed

=

lim

=

lf

- Zveltetea relativa

1

E

f

y

=

1

93.9 :=

k

c

1

1.66

0.602 = := L

c

- lungimea dintre legaturile ce impiedica pierderea stabilitatii

L

c

0.2 l 1.8m = := i

f.z

30.526mm :=

c0

0.4 0.1 + 0.5 = :=

f

k

c

L

c

i

f.z

1

0.378 = := M

c.Rd

M

y.pl.Rd

=

W

pl.y

f

y

M1

=

M

c.Rd

W

pl.y

f

y

6862 daN m = :=

lim

c0

M

c.Rd

M

y.ed

0.687 = := 0.378 0.687

2.1.4.5. Verificarea la starea limta de serviciu - SLS - verificarea rigiditatii

max

y

2

z

2

+

a

=

l

200

= I

y

2690cm

4

:= I

z

197cm

4

:=

Pentru pana cu 2 tiranti: q

y.k

0.338

daN

cm

= q

z.k

6.775

daN

cm

=

z

0.151 6.775 9

4

2690

2.495 = :=

y

0.621 0.338

9

3

|

\

|

|

197

0.086 = :=

max

a

max

y

2

z

2

+ 2.497 = :=

a

l

200

4.5 cm = :=

2.1.5. Calculul panei in camp marginal

2.1.5.1. Predimensionare

Pntru pana cu 2 tiranti: M

y.Ed.max

M

C1

=

q

z.d

l 2

11

= M

z.Ed.max

q

y.d

1.3

l

3

\

|

|

8

=

M

y.Ed.max

q

z.d

l

2

11

7264.702 daN m = := M

z.Ed.max

q

y.d

1.3

l

3

\

|

|

8

93.706 daN m = :=

W

pl.nec.CM

M

y.ED

f

y

q

z.d

l

2

11

f

y

= W

pl.nec.CM

q

z.d

l

2

11

f

y

309.136 cm

3

= :=

I

y.nec.CM

W

pl.nec.CM

z

max

= z

max

h

upn

2

11 cm = :=

I

y.nec.CM

W

pl.nec.CM

z

max

3400.499 cm

4

= :=

I

ynec

I

y.Cc

I

y.s

+ = I

y.s

I

y.nec.CM

I

y

710.499 cm

4

= :=

Pentru consolidarea cu tabla groasa :

I

s.y

t

s

h

s

3

12

= t

s

6mm , h

smax

17cm 2cm 15 cm = :=

t

s

I

y.s

12

h

smax

3

2.5 cm = :=

A

c1

32.77cm

2

:= i

zc1

3.1cm := i

yc1

7.7cm := W

pl.y.c1

440.9cm

3

:= I

yc1

3725.3cm

4

:=

W

pl.z.c1

135.3cm

3

:= I

zc1

601.6cm

4

:=

2.1.5.2. Verificarea sectiunii

Pana cu 2 tiranti:

M

y.ed.max

M

c1

=

q

z.d

l

2

11

=

M

z.ed.max

q

y.d

1.3

l

3

\

|

|

8

93.706 daN m = :=

M

y.ed.max

q

z.d

l

2

11

7264.702 daN m = :=

M

y.pl.Rd.

W

pl.y.c1

f

y.d

10361.15 daN m = :=

M

z.pl.Rd.

W

pl.z.c1

f

y.d

3179.55 daN m = :=

M

y.ed

M

y.pl.Rd.

M

z.ed

M

z.pl.Rd.

+ 0.512 = 0.512 1 Se verifica

2.1.5.3. Verificarea sagetii dezvoltate in primul camp

Pentru pana cu 2 tiranti avem:

max

y

2

z

2

+

a

=

l

200

= I

yc1

3725.3 cm

4

= I

zc1

601.6 cm

4

=

Pentru pana cu 2 tiranti: q

y.k

0.338

daN

cm

= q

z.k

6.775

daN

cm

=

yc1

0.307 6.775 9

4

3725.3

3.663 = :=

zc1

0.621 0.338

9

3

|

\

|

|

601.6

0.028 = :=

max

a

maxc1

yc1

2

zc1

2

+ 3.663 = :=

ac1

l

200

4.5 cm = :=

2.1.5.4.Determinarea lungimii de dispunere a suplimentului

-Sectiunea se consolideaza in zona in care momentul incovoitor din campul marginal depaseste valoarea

momentului incovoitir din campul curent

L

s

x

2

x

1

= -lungimea de calcul a suplimentului

x

1

0.192 l 1.728m = := x

2

0.683 l 6.147m = :=

L

sr

x

2

x

1

2 300 mm + 5.019m = := -lungimea reala a suplimentului

2.1.6. Proiectarea tirantilor

Determinarea eforturilor de intindere din tiranti

Pentru 2 tiranti avem:

N

n

n 0.5 ( ) V

y.Ed

cos

= cos 0.707 = N

4

4 0.5 ( ) V

y.ed

0.707

805.179 daN = :=

Predimensionare

N

A

f

yd

=

N

max

A

snec

f

yd

A

snec

N

max

f

yd

A

snec

N

4

f

y.d

0.343 cm

2

= :=

A

snec

N

max

f

yd

d

snec

A

snec

4

6.605 mm = := d

s.

d

snec

0.89

7.421 mm = :=

A

s

d

s

2

4

=

Se adopta d

s

8mm :=

Etapa 3.

3.1. Evaluarea incaracrilor

3.1.1.Incarcari permanente

a) La nivelul acoperisului

- greutate invelitoare

-greutate instalatii electrice

g

inv

16

daN

m

2

=

g

i.e

15

daN

m

2

:=

- greutate pane -greutate praf industrial

g

pane

10 1.15 G

upn

g

L

13.815

daN

m

2

= := g

p.i

20

daN

m

2

:=

-greutate ferma

Se calculeaza momentul de inertie necesar pentru preluarea incarcarilor , asimilind grinda cu zabrele cu o

grinda cu inima plina , luand in considerare greutatea elementelor de acoperis si zapada uniforma.

g

0

1.35 g

inv

g

i.e

+ g

pane

+ g

p.i

+

( )

l

1.5 S

k

l + 2947.504

daN

m

= :=

M

0

g

0

L

2

8

212220.265 daN m = :=

W

y

I

y

z

max

=

I

y

A 2

h

max

2

|

\

|

|

2

= A

h

max

2

2

=

I

y

A

ts

h

max

2

|

\

|

|

2

A

tsi

h

max

2

|

\

|

|

2

+ =

W

y

I

y

z

max

= A

h

max

2

2

1

0.5 h

max

= A h

max

=

A

ts

A

tsi

= A =

W

y

M

0

f

yd

= A

M

0

f

yd

h

max

=

h

max

h

1

2.25m = := A

M

0

f

y.d

h

max

40.136 cm

2

= := A

lpn.

A

2

20.068 cm

2

= :=

Aleg LPN 100 x 100 x 12 cu: A

lpn

22.7cm

2

:= g

lpn

17.8

kg

m

:=

18.00

2

.

4

4

2

.

8

1

2

.

8

1

2

.

4

4

12.02 12.02

3

.

9

9

4

.

2

4

3

.

7

5

l

i

12.02m 3.75m + 2.44m + 3.99 2 m + 2.81m + 4.24m + 9m + ( ) 2 84.48m = :=

g

f

2 g

lpn

l

i

g

L l

13.654

daN

m

2

= :=

- greutatea totala la nivelulu acoperisului

g

a.k

g

inv

g

pane

+ g

i.e

+ g

p.i

+ g

f

+

( )

l 706.225

daN

m

= :=

g

a.k.

g

inv

g

pane

+ g

i.e

+ g

p.i

+

( )

l 583.336

daN

m

= :=

b) La nivelul peretilor

- greutate panouri de inchidere

g

p.in

g

inv

16

daN

m

2

= :=

- greuate proprie rigle

g

rigle

4 G

upn

g

h

s.c

11.362

daN

m

2

= :=

- greutate contravantuiri verticale intre stalpi

g

cv

5

daN

m

2

:=

-greutate proprie stalp

g

stalp.

15

daN

m

2

h

s.c

152.25

daN

m

= := Aleg HEA 500 cu g

stalp

155

daN

m

:=

g

k.s

g

p.in

g

rigle

+ g

cv

+

( )

l g

stalp

+ 446.26

daN

m

= :=

g

k.sp

g

p.in

g

rigle

+ g

cv

+

( )

l 291.26

daN

m

= :=

3.1.2.Incarcari variabile (Q)

a) Incarcarea din zapada - SR EN 1991-1-3:2006

-zapada uniforma

S

ku

C

e

C

t

0.8 s

ok

l 1152

daN

m

= :=

- zapada aglomerata

s

k.1

C

e

C

t

0.5 0.8 s

ok

l 576

daN

m

= :=

s

k.2

C

e

C

t

0.8 s

ok

l 1152

daN

m

= :=

b) Incarcarea din vant - SR EN 1991-1-4:2006

- Conform pct. 4.2 , viteza de referinta a vantului este

c

dir

1 := c

season

1 := v

b0

30

m

s

:= 1.25

kg

m

3

:=

V

b

c

dir

c

season

v

b0

30

m

s

= :=

-Se determina valoare de baza a presiunii exercitate de vant:

q

b

1

2

V

b

2

562.5

N

m

2

= :=

- Se determina valoare de varf a presiunii vitezei , q

p

(z) , la inaltimea z, care include media si fluctuatiile pe

termen scurt ale vitezei:

C

e.z

1.3 := q

p.z

q

b

C

e.z

731.25

N

m

2

= :=

-Se determina presiunea vantului ce actioneaza pe suprafetele exterioare W

e

:

C

pe

0.8 := w

e

q

p.z

C

pe

585

N

m

2

= :=

- Reducand incarcarea la cadrul curent rezulta:

q

p.c

q

p.z

l 658.125

daN

m

= :=

c) Incarcarea din vant la nivelul peretilor - pct. 7.2.2 SR EN 1991-1-4

- Transversal

d

T

L 2 h

upn

+ 10cm + 2454 cm = :=

b

T

7 l 6300 cm = :=

h H h

1

+ h

2

+ 1200 cm = :=

Se calculeaza raportul :

h

d

T

0.489 =

Pentru zona D :

C

pe10.D

0.8 := w

D.T

q

p.c

C

pe10.D

526.5

daN

m

= :=

Pentru zona E :

C

pe10.E

0.5 := w

E.T

q

p.c

C

pe10.E

329.063

daN

m

= :=

- Longitudinal

d

L

L h

upn

+ 10cm + 2432 cm = :=

b

L

7 l 6300 cm = :=

h 1200 cm =

Se calculeaza raportul :

h

d

L

0.493 =

Pentru zona B :

C

pe10.B

0.8 := w

B.L

q

p.c

C

pe10.B

526.5

daN

m

= :=

c) Incarcarea din vant la nivelul acoperisului - pct. 7.2.2 SR EN 1991-1-4 , acoperis cu 2

pante

- Transversal !=0

Pentru zona H :

C

pe10.H

0.6 := w

H.T

q

p.c

C

pe10.H

394.875

daN

m

= :=

Pentru zona I :

C

pe10.I

0.6 := w

I.T

q

p.c

C

pe10.I

394.875

daN

m

= :=

- Longitudinal !=90

Pentru zona H :

C

pe10.H.

0.7 := w

H.L

q

p.c

C

pe10.H.

460.688

daN

m

= :=

3.1.3.Incarcari accidentale - seismul

Conf. P100-1:2006 , pct. 4.5.3.2.2. forta taietoare de baza pentru cadrul curent asimilat cu un sistem cu

1GLD are expresia:

F

b

I

S

d.T1

m =

I

1 := 1 := T

c

1s :=

T

1

C

T

H

3

4

= C

T

0.075 := H 9m = T

1

C

T

9

3

4

0.39 = := T T

B

>

"(T) - spectrul normalizat de raspuns elastic

T

B

T < T

c

< T ( )

0

= 2.75 = a

g

0.16g := q 2.5 :=

S

dT1

a

g

2.75

q

0.176 g = :=

m

tot

m

acop

m

stalp

+ m

pereti

+ m

ferma

+ m

zapada

+ =

m

acop

g

a.k.

L

g

14276.094 kg = := m

stalp

2 g

stalp

h

s.c

g

3208.537 kg = :=

m

pereti

2g

k.sp

h

s.c

g

6029.145 kg = := m

ferma

g

f

L l

g

3007.488kg = :=

m

zapada

0.4S

ku

L

g

11277.246 kg = :=

m

tot

m

acop

m

stalp

+ m

pereti

+ m

ferma

+ m

zapada

+ 37798.51 kg = :=

F

b

I

S

dT1

m

tot

6523.911 daN = :=

3.2. Reducerea incarcarilor la noduri.Scheme de incarcare

- greutate proprie cadru - incarcari permanente la nivelul acoperisului g

a

k

si peretilor g

s

k

;

g

a.k.

583.336

daN

m

= g

k.sp

291.26

daN

m

=

3000.00 3000.00 3000.00 3000.00 3000.00 3000.00 3000.00 3000.00

3000.00 6000.00 6000.00 6000.00 3000.00

7

5

0

.

0

0

2

2

5

0

.

0

0

a

1

3m :=

P

1

g

a.k.

0.5 a

1

875.004 daN = := P

2

g

a.k.

0.5a

1

0.5a

1

+

( )

1750.008 daN = :=

P

3

g

a.k.

0.5a

1

0.5a

1

+

( )

1750.008 daN = := P

4

g

a.k.

0.5a

1

0.5a

1

+

( )

1750.008 daN = :=

P

5

g

a.k.

a

1

1750.008 daN = :=

- inacarcari variabile - zapada uniforma , zapada aglomerata ,vant transversal si vant longitudinal

a) zapada uniforma

S

1u

S

ku

0.5 a

1

1728 daN = := S

2u

S

ku

0.5a

1

0.5a

1

+

( )

3456 daN = :=

S

3u

S

ku

0.5a

1

0.5a

1

+

( )

3456 daN = := S

4u

S

ku

0.5a

1

0.5a

1

+

( )

3456 daN = :=

S

5u

S

ku

a

1

3456 daN = :=

b) zapada aglomerata

S

1a

s

k.1

0.5 a

1

864 daN = := S

1a.

s

k.2

0.5 a

1

1728 daN = :=

S

2a

s

k.1

0.5a

1

0.5a

1

+

( )

1728 daN = := S

2a.

s

k.2

0.5a

1

0.5a

1

+

( )

3456 daN = :=

S

3a

s

k.1

0.5a

1

0.5a

1

+

( )

1728 daN = := S

3a.

s

k.2

0.5a

1

0.5a

1

+

( )

3456 daN = :=

S

4a

s

k.1

0.5a

1

0.5a

1

+

( )

1728 daN = := S

4a.

s

k.2

0.5a

1

0.5a

1

+

( )

3456 daN = :=

S

5a

s

k.1

0.5 a

1

s

k.2

0.5 a

1

+ 2592 daN = :=

c) vant transversal

W

1T

w

H.T

0.5 a

1

592.313 daN = := W

1a.

w

I.T

0.5 a

1

592.313 daN = :=

W

2T

w

H.T

0.5a

1

0.5a

1

+

( )

1184.625 daN = := W

2a.

w

I.T

0.5a

1

0.5a

1

+

( )

1184.625 daN = :=

W

3T

w

H.T

0.5a

1

0.5a

1

+

( )

1184.625 daN = := W

3a.

w

I.T

0.5a

1

0.5a

1

+

( )

1184.625 daN = :=

W

4T

w

H.T

0.5a

1

0.5a

1

+

( )

1184.625 daN = := W

4a.

w

I.T

0.5a

1

0.5a

1

+

( )

1184.625 daN = :=

W

5

w

H.T

0.5 a

1

w

I.T

0.5 a

1

+ 1184.625 daN = :=

w

D.T

526.5

daN

m

= w

E.T

329.063

daN

m

=

d) Vant longitudinal

W

1L

w

H.L

0.5 a

1

691.031 daN = :=

W

2L

w

H.L

0.5a

1

0.5a

1

+

( )

1382.063 daN = :=

w

B.L

526.5

daN

m

=

W

3L

w

H.L

0.5a

1

0.5a

1

+

( )

1382.063 daN = :=

W

4L

w

H.L

0.5a

1

0.5a

1

+

( )

1382.063 daN = :=

W

L

w

H.L

a

1

1382.063 daN = :=

- incarcarea accidentala

F

b

6523.911 daN =

Etapa 4. Dimensionarea si verificarea barelor grinzii cu zabrele

4.1. Bare comprimate

4.1.1.Determinarea lungimii de flambaj

T.s - L

cry

l

i

= D L

cry

0.9l

i

=

M

L

crz

l

i

=

L

crz

l

i

2l

i

,

( )

=

N

max.Ts

60329.5daN := l

9_6

3.00m := L

cry.ts

l

9_6

3m = := L

crz.ts

l

9_6

3m = :=

N

maxTi

60416.5daN := l

8_16

3.00m := L

cry.ti

l

8_16

3m = := L

crz.ti

l

8_16

3m = :=

N

max.di

40653.8daN := l

5_2

3.75m := L

cry.di

0.9l

5_2

3.375m = :=

L

crz.di

l

5_2

3.75m = :=

N

max.dc

25579.5daN := l

5_10

3.986m := L

cry.dc

0.9l

5_10

3.587m = :=

L

crz.dc

l

5_10

3.986m = :=

N

max.m

7546.5daN := l

5_7

2.437m := L

cry.m

0.9l

5_7

2.193m = :=

L

crz.m

l

5_7

2.437m = :=

4.1.2. Predimisionare si verificarea barelor

- Pentru talpa superioara

N

max.Ts

603.295 kN = t

g1

12mm := N

max.Ed.1

N

max.Ts

60329.5 daN = :=

N

max.Ed

N

b.Rd

1 N

b.Rd

o

A

nec

f

yd

=

o

0.6 :=

A

nec

N

max.Ed.1

o

f

y.d

42.787 cm

2

= := Aleg 150 x 100 x 14 cu: A

ts

66.4cm

2

:=

i

y.ts

7.31cm := i

z.ts

2.82cm :=

Verificare sectiune:

N

b.Rd.ts

c

A

ts

f

y.d

=

y.ts

L

cry.ts

i

y.ts

41.04 = :=

z.ts

L

crz.ts

i

z.ts

106.383 = :=

max.

max

y.ts

z.ts

,

( )

106.383 = :=

max

a

120 =

max

106.383 :=

1

0.49 :=

bar1

max

93.9

1.133 = :=

1

0.5 1

1

bar1

0.2

( )

+

bar1

2

+

1.37 = :=

c.1

1

1

1

2

bar1

2

+

0.467 = :=

N

b.Rd.ts

c.1

A

ts

f

y.d

72873.253 daN = :=

N

max.Ed.1

N

b.Rd.ts

0.828 =

- Pentru diagonale si montanti

-diagonala comprimata

N

max.dc

255.795 kN = t

g2

12mm := N

max.Ed.2

N

max.dc

25579.5 daN = :=

N

max.Ed

N

b.Rd

1 N

b.Rd

o

A

nec

f

yd

=

o2

0.6 :=

A

nec2

N

max.Ed.2

o

f

y.d

18.141 cm

2

= := Aleg 100 x 100 x 10 cu: A

dc

38.4cm

2

:=

i

y.dc

4.57cm := i

z.dc

3.04cm :=

Verificare sectiune:

N

b.Rd.ti

c

A

dc

f

y.d

=

y.dc

L

cry.dc

i

y.dc

78.499 = :=

z.dc

L

crz.dc

i

z.dc

131.118 = :=

max2

max

y.dc

z.dc

,

( )

131.118 = :=

max

a

150 =

1

0.49 =

bar2

max2

93.9

1.396 = :=

2

0.5 1

1

bar2

0.2

( )

+

bar2

2

+

1.768 = :=

c.2

1

2

2

2

bar2

2

+

0.351 = :=

N

b.Rd.dc

c.2

A

dc

f

y.d

31635.484 daN = :=

N

max.Ed.2

N

b.Rd.dc

0.809 =

-montant

N

max.m

75.465 kN = t

g3

12mm := N

max.Ed.3

N

max.m

7546.5 daN = :=

N

max.Ed

N

b.Rd

1 N

b.Rd

o

A

nec

f

yd

=

o3

0.6 :=

A

nec3

N

max.Ed.3

o

f

y.d

5.352 cm

2

= := Aleg 50 x 50 x 12 cu: A

m

13.12cm

2

:=

i

y.m

2.57cm := i

z.m

1.49cm :=

Verificare sectiune:

N

b.Rd.ti

c

A

m

f

y.d

=

y.m

L

cry.m

i

y.m

85.342 = :=

z.m

L

crz.m

i

z.m

163.557 = :=

max3

max

y.m

z.m

,

( )

163.557 = :=

max

a

150 =

1

0.49 =

bar3

150

93.9

1.597 = :=

3

0.5 1

1

bar3

0.2

( )

+

bar3

2

+

2.118 = :=

c.3

1

3

3

2

bar3

2

+

0.285 = :=

N

b.Rd.m

c.3

A

m

f

y.d

8785.438 daN = :=

N

max.Ed.3

N

b.Rd.m

0.859 =

4.2. Bare intinse

- Pentru talpa inferioara

N

maxTi

604.165 kN = t

g4

12mm := N

max.Ed.4

N

maxTi

60416.5 daN = :=

N

max.Ed

N

t.Rd

1 N

t.Rd

A

nec

f

yd

=

A

nec4

N

max.Ed.4

f

y.d

25.709 cm

2

= := Aleg 120 x 80 x 10 cu: A

ti

38.2cm

2

:=

i

y.ti

5.90cm := i

z.ti

2.24cm :=

Verificare sectiune:

N

t.Rd.ti

A

ti

f

y.d

89770 daN = :=

N

max.Ed.4

N

t.Rd.ti

0.673 =

-diagonala intinsa

N

max.di

406.538 kN = t

g5

12mm := N

max.Ed.5

N

max.di

40653.8 daN = :=

N

max.Ed

N

t.Rd

1 N

t.Rd

A

nec

f

yd

=

A

nec5

N

max.Ed.5

f

y.d

17.299 cm

2

= := Aleg 70 x 70 x 8 cu: A

di

21.2cm

2

:=

i

y.di

3.36cm := i

z.di

2.11cm :=

Verificare sectiune:

N

t.Rd.di

A

di

f

y.d

49820 daN = :=

N

max.Ed.5

N

t.Rd.di

0.816 =

4.3. Prinderea zabrelelor in noduri

a) Repartizarea eforturilor din diagonala (montanti ) in cordoanele de sudura

M

i

0 = N

1

e N

2

h

c

e

( )

0 =

N

1

N

ed

N

2

=

F

x

0 = N

1

N

2

+ N

Ed

0 =

N

1

N

Ed

h

c

e

( )

h

c

= N

2

N

Ed

e

h

c

=

- dimensionarea C.S.1 - D 10-8

N

ed.1

11475.4daN :=

Impun aw.1: 3mm a

w1

min 0.7t

g

0.85t

c

,

( )

LPN 70 x 70 x 8 t

g

12mm := t

c

8mm :=

min 0.7t

g

0.85t

c

,

( )

6.8 mm = h

c

70mm := e

1.

13.6mm :=

a

w1

7mm :=

N

1

A

cs1

f

vwd

f

vwd

2078.46

daN

cm

2

:= A

cs1

2a

w1.

l

wd1

= l

wd1

N

1

2a

w1.

f

vwd

l

wd1

N

ed.1

h

c

e

1.

( )

h

c

2a

w1

f

vwd

32 mm = := l

w1

l

wd1

a

w1

2 + 46 mm = :=

- dimensionarea C.S.2 - D 10-8

Impun aw.1: 3mm a

w1

min 0.7t

min

( )

min t

g

t

c

,

( )

8 mm = 0.7 t

c

5.6 mm =

a

w2

a

w1

7 mm = :=

N

2

A

cs1

f

vwd

f

vwd

2078.46

daN

cm

2

= A

cs2

2a

w2

l

wd2

= l

wd2

N

2

2a

w2

f

vwd

l

wd2

N

ed.1

e

1.

h

c

2a

w2

f

vwd

8 mm = := l

w2.

l

wd2

a

w2

2 + 22 mm = :=

l

w2

40mm Aleg l

w2

40mm :=

Deoarece

4.4. Imbinarea de montaj a tronsoanelor grinzii cu zabrele

Grinda cu 8 panouri

- Nod talpa inferioara:

120 x 80 x 10

4.4.1. Dimensionarea imbinarii

Impunem: A

e

A

c

h

e

h

c

dar t

e

t

c

LPN 135 x 65 x 10 t

c.Ti

10mm :=

-determinarea diametrului surubului

Conditie d

min

: d 5 t

min

0.2cm t

min

t

c

=

M

16

M

18

, M

20

, M

24

, M

30

,

( )

d 5 0.8 0.2 1.8 = := d 18mm := Rezulta surub M18 si grupa 10.9

f

ub

10000

daN

cm

2

:=

-determinarea diametrului gaurii

d

o

d 2mm + = d

o

d 2mm + 20 mm = :=

Conform SR EN 1993-1-8:2006 rezulta:

1.2 d

o

e

1

e

2

4 t

min

40mm + 72mm =

( )

, e

1

e

2

2 d

o

= ,

2.2 d

o

p

1

p

2

14 t

min

200mm 112mm = , 200mm ,

( )

, p

1

p

2

3 = , 3.5 d

o

..

e

1

2 d

o

40 mm = := e

2

e

1

40 mm = :=

p

1

3 d

o

60 mm = := p

2

p

1

60 mm = :=

-Numarul de suruburi

n

o

n

v

+

F

Ed

F

Rd

F

Ed

N

max.Ti

2

= F

Rd

min F

b.Rd

F

s.Rd

,

( )

=

M2

1.25 :=

M7

1.1 :=

f

u

3600

daN

cm

2

:= (pt. f

u

S235) t t

c.Ti

=

F

b.Rd

d

k

1

min

t

\

|

|

d f

u

M2

=

k

1

min 2.8

e

2

d

o

1.7 1.4

p

2

d

o

1.7 , 2.5 ,

|

\

|

|

d

min

e

l

3 d

o

p

1

3 d

1

4

, 1 ,

|

\

|

|

d

min

e

1

3 d

o

p

1

3 d

1

4

, 1 ,

|

\

|

|

0.667 = := k

1

min 2.8

e

2

d

o

1.7 1.4

p

2

d

o

1.7 , 2.5 ,

|

\

|

|

2.5 = :=

F

b.Rd

d

k

1

t

c.Ti

d f

u

M2

8640 daN = :=

0.5 :=

F

s.Rd

n

f

F

pc

M2

= F

pc

0.7 A

s.Ti

f

ub

M7

= d

s.Ti

0.89 d =

A

s.Ti

d

s

2

4

=

n

f

1 :=

d

s.Ti

0.89 d 16.02 mm = :=

A

s.Ti

d

s.Ti

2

4

201.565 mm

2

= :=

F

pc

0.7 A

s.Ti

f

ub

M7

12826.857 daN = := F

s.Rd

n

f

F

pc

M2

5130.743 daN = :=

F

Rd

min F

b.Rd

F

s.Rd

,

( )

5130.743 daN = :=

F

Ed

N

maxTi

2

30208.25 daN = :=

n

o

n

v

+

F

Ed

F

Rd

F

Ed

F

Rd

6 = n

o

4 := n

v

3 :=

-Verificarea sectiunii nete

F

Ed

N

net Rd ,

N

net.Rd

A

net.Ti

f

y

M0

= f

y

2350

daN

cm

2

= A

c.ti

A

ti

2

19.1 cm

2

= :=

A

neta.Ti

min A

neta.1

A

neta.2

,

( )

= s 0.5 p

1

30 mm = := e

z

48mm := e

y

38mm :=

A

neta.1

A

c.ti

t

c.Ti

d

o

17.1 cm

2

= := A

neta.2

A

c.ti

t

c.Ti

2 d

o

s

2

4 e

z

e

y

+

( )

(

(

(

15.362 cm

2

= :=

A

neta.Ti

min A

neta.1

A

neta.2

,

( )

15.362 cm

2

= :=

N

net.Rd

A

neta.Ti

f

y

36099.826 daN = := F

Ed

30208.25 daN =

verificare "severifica" F

Ed

N

net.Rd

if

"nuseverifica" F

Ed

N

net.Rd

if

:=

verificare "severifica" =

- Nod talpa Superioara

4.4.2. Dimensionarea imbinarii

T.s = 150 x 100 x 14 cu:

Impunem: A

e

A

c

h

e

h

c

dar t

e

t

c

t

c.Ts

14mm :=

LPN 135 x 65 x 10

-determinarea diametrului surubului

Conditie d

min

: d 5 t

min

0.2cm t

min

t

c

=

M

16

M

18

, M

20

, M

24

, M

30

,

( )

d

.

5 1.4 0.2 2.446 = := d

ts

24mm := Rezulta surub M24 si grupa 8.8

f

ub.

8000

daN

cm

2

:=

-determinarea diametrului gaurii

d

o

d 2mm + = d

o.ts

d

ts

2mm + 26 mm = :=

Conform SR EN 1993-1-8:2006 rezulta:

1.2 d

o

e

1

e

2

4 t

min

40mm + 72mm =

( )

, e

1

e

2

2 d

o

= ,

2.2 d

o

p

1

p

2

14 t

min

200mm 112mm = , 200mm ,

( )

, p

1

p

2

3 = , 3.5 d

o

..

e

1.ts

2 d

o.ts

52 mm = := e

2.ts

e

1.ts

52 mm = :=

p

1.ts

3 d

o.ts

78 mm = := p

2.ts

p

1.ts

78 mm = :=

-Numarul de suruburi

n

o

n

v

+

F

Ed.ts

F

Rd.ts

F

Ed.ts

N

max.Ts

2

= F

Rd.ts

min F

b.Rd.ts

F

s.Rd.ts

,

( )

=

t t

c.Ts

=

M2

1.25 =

M7

1.1 =

(pt. f

u

S235)

F

b.Rd.ts

d

k

1

min

t

\

|

|

d f

u

M2

=

d

min

e

l

3 d

o

p

1

3 d

1

4

, 1 ,

|

\

|

|

=

d.ts

min

e

1.ts

3 d

o.ts

p

1.ts

3 d

ts

1

4

, 1 ,

|

\

|

|

0.667 = :=

k

1

min 2.8

e

2

d

o

1.7 1.4

p

2

d

o

1.7 , 2.5 ,

|

\

|

|

= k

1.ts

min 2.8

e

2.ts

d

o.ts

1.7 1.4

p

2.ts

d

o.ts

1.7 , 2.5 ,

|

\

|

|

2.5 = :=

F

b.Rd.ts

d.ts

k

1.ts

t

c.Ts

d

ts

f

u

M2

16128 daN = :=

0.5 =

F

s.Rd.ts

n

f

F

pc.ts

M2

= F

pc.ts

0.7 A

s.Ts

f

ub

M7

= d

s.Ts

0.89 d

ts

=

A

s.Ts

d

s

2

4

=

n

f

1 =

d

s.Ts

0.89 d

ts

21.36 mm = :=

A

s.Ts

d

s.Ts

2

4

358.338 mm

2

= :=

F

pc.ts

0.7 A

s.Ts

f

ub

M7

22803.302 daN = := F

s.Rd.ts

n

f

F

pc.ts

M2

9121.321 daN = :=

F

Rd.ts

min F

b.Rd.ts

F

s.Rd.ts

,

( )

9121.321 daN = :=

F

Ed.ts

N

max.Ts

2

30164.75 daN = := n

o

n

v

+

F

Ed.ts

F

Rd.ts

F

Ed.ts

F

Rd.ts

3 = n

o.ts

4 := n

v.ts

3 :=

-Verificarea sectiunii nete

F

Ed

.ts N

net.Rd.ts

N

net.Rd.ts

A

net.Ts

f

y

M0

= f

y

2350

daN

cm

2

= A

c.ts

A

ts

2

33.2 cm

2

= :=

A

neta.Ts

min A

neta.1

A

neta.2

,

( )

= s

ts

0.5 p

1.ts

39 mm = := e

z.ts

54mm := e

y.ts

51mm :=

A

neta.1.ts

A

c.ts

t

c.Ts

d

o.ts

29.56 cm

2

= :=

A

neta.2.ts

A

c.ts

t

c.Ts

2 d

o.ts

s

ts

2

4 e

z.ts

e

y.ts

+

( )

(

(

(

26.427 cm

2

= :=

A

neta.Ts

min A

neta.1.ts

A

neta.2.ts

,

( )

26.427 cm

2

= :=

N

net.Rd.ts

A

neta.Ts

f

y

62103.45 daN = := F

Ed.ts

30164.75 daN =

verificare "se verifica" F

Ed.ts

N

net.Rd.ts

if

"nu se verifica" F

Ed.ts

N

net.Rd.ts

if

:=

verificare "severifica" =

Etapa 5. Calculul stalpului

5.1 Predimensionare

5.1.1.Eforturi sectionale

N

Ed.max.1

30186daN := N

Ed.cor.2

22618.8daN := N

Ed.cor.3

15043.2daN :=

V

z.Ed.cor.1

194.5daN := V

z.Ed.max.2

7540daN := V

z.Ed.cor.3

7540daN :=

M

y.Ed.cor.1

1974.2daN m := M

y.Ed.cor.2

25802.5daN m := M

y.Ed.max.3

35854.9daN m :=

5.1.2. Lungimi critice de flambaj

L

cry.st

h

s.c

10.15m = := L

crz.st

L

cry.st

10.15m = := h

s.c

10.15m =

5.1.3. Predimensionarea din conditia de flambaj

g

stalp

155

daN

m

= rezulta

HEA 500 A

st.

198cm

2

:= i

y.

21cm := i

z.

7.24cm := W

y.pl.st.

3550cm

3

:=

Deoarece nu se verifica aleg noul profil HEA

HEA 400 A

st

159cm

2

:= i

y

16.8cm := i

z

7.34cm := W

y.pl.st

2310cm

3

:=

N

Ed.max

N

Ed.max.1

30186 daN = := N

Ed.max

A

st

f

y

M

y.Ed.cor

W

y.pl.st

f

y

+ 0.7

Ipoteza I:

N

Ed.cor

N

Ed.cor.2

22618.8 daN = :=

M

Ed.y.max

M

y.Ed.max.3

35854.9 daN m = :=

Ipoteza II:

N

Ed.cor

A

st

f

y

M

Ed.y.max

W

y.pl.st

f

y

+ 0.7

M

y.Ed.cor

M

y.Ed.cor.2

25802.5 daN m = :=

verificare1 "se verifica"

N

Ed.max

A

st

f

y

M

y.Ed.cor

W

y.pl.st

f

y

+ 0.7 if

"nu se verifica"

N

Ed.max

A

st

f

y

M

y.Ed.cor

W

y.pl.st

f

y

+ 0.7 if

:=

verificare1 "se verifica" =

N

Ed.max

A

st

f

y

M

y.Ed.cor

W

y.pl.st

f

y

+ 0.556 =

verificare2 "se verifica"

N

Ed.cor

A

st

f

y

M

Ed.y.max

W

y.pl.st

f

y

+ 0.7 if

"nu se verifica"

N

Ed.cor

A

st

f

y

M

Ed.y.max

W

y.pl.st

f

y

+ 0.7 if

:=

verificare2 "nu se verifica" =

N

Ed.cor

A

st

f

y

M

Ed.y.max

W

y.pl.st

f

y

+ 0.721 =

5.2. Verificarea sectiunii

5.2.1. Verificarea clasei de sctiune

t

w

11mm := t

f

19mm := h

hea

390mm := b

hea

300mm := r

hea

27mm :=

Clasa 1: 0.5 >

d

t

w

396

13 1

<

f

y

235

= 1 = d

hea

h

hea

2 t

f

2 r

hea

=

d

hea

h

hea

2 t

f

2 r

hea

298 mm = :=

1

2

1

N

Ed.max

d

hea

t

w

f

y

+

|

\

|

|

0.696 = :=

d

hea

t

w

27.091 =

396

13 1

49.21 =

d

t

w

396

13 1

< Rezulta Clasa 1

5.2. Verificari de rezistenta

a) Verificarea la actiunea fortei axiale -N

M0

1 =

N

Ed.max

N

pl.Rd

1 N

pl.Rd

A

st

f

y

M0

373650 daN = :=

N

Ed.max

N

pl.Rd

0.081 =

verificare3 "se verifica"

N

Ed.max

N

pl.Rd

1 if

"nu se verifica"

N

Ed.max

N

pl.Rd

1 if

:=

verificare3 "se verifica" =

b) Verificarea la actiunea fortei taietoare - V

M0

1 =

A

vz.

A

st

2 b

hea

t

f

2

1

2

t

f

t

w

2 r

hea

+

( )

+ :=

V

z.Ed.max

V

z.pl.Rd

0.5 V

z.pl.Ed

A

vz.

f

y

3

M0

=

A

vz.

57.35 cm

2

=

V

z.pl.Rd.

A

vz.

f

y

3

M0

77810.939 daN = := V

z.Ed.max

V

z.Ed.max.2

7540 daN = :=

V

z.Ed.max

V

z.pl.Rd.

0.097 =

verificare4 "se verifica"

V

z.Ed.max

V

z.pl.Rd.

0.5 if

"nu se verifica"

V

z.Ed.max

V

z.pl.Rd.

0.5 if

:=

verificare4 "se verifica" =

c) Verificarea la actiunea momentului incovoitor -M

M0

1 = M

Ed.y.max

35854.9 daN m =

M

Ed.y.max

M

y.pl.Rd..

1 M

y.pl.Rd..

W

y.pl.st

f

y

M0

54285 daN m = :=

M

Ed.y.max

M

y.pl.Rd..

0.66 =

verificare5 "se verifica"

M

Ed.y.max

M

y.pl.Rd..

1 if

"nu se verifica"

M

Ed.y.max

M

y.pl.Rd..

1 if

:=

verificare5 "se verifica" =

Daca :

N

Ed.cor

0.25 N

pl.Rd

0.25 N

pl.Rd

93412.5 daN = N

Ed.cor

22618.8 daN =

N

Ed.cor

0.5 d

hea

t

w

f

y

0.5 d

hea

t

w

f

y

38516.5 daN =

Amandoua conditiile se verifica

5.2.3- Verificari de stabilitate

-verificarea prin pierderea voalarii inimii

daca

h

w

t

w

72

< h

w

h

hea

2t

f

352 mm = :=

h

w

t

w

32 = 1.2 :=

72 1

60 = rezulta 32 60 < Nu exista risc de pierdere a stabilitatii prin voalare

Ipoteze de verificare:

I : N

Ed.max

; #

y.Ed.cor

II : N

Ed.cor

; #

y.Ed.max

N

Ed.max

N

byRd

K

yy

C

my

M

y.Ed.cor

M

byRD

+ 1

N

Edcor

N

bzRd

K

yz

M

Ed.y.max

M

byRD

+ 1

a$ %lam&a' in raport cu axa ()(;

L

cry.st

10.15m = i

y

168 mm =

1

93.9 =

y

1

y

y

2

bar

2

+

=

y

0.5 1

y

bar

0.2

( )

+

bar

2

+

=

conditie if

h

hea

b

hea

1.2 > "curbele a si b" , "curbele b si c" ,

|

\

|

|

"curbele a si b" = :=

h

hea

b

hea

1.3 =

t

f

19 mm = t

f

40mm Pt. curba "a" dupa axa y-y rezulta Conf. SR EN 1-1:2006 tab. 6.2:

y

0.21 :=

y

L

cry.st

i

y

60.417 = :=

bar

1

0.643 = :=

1

93.9 =

y

0.5 1

y

bar

0.2

( )

+

bar

2

+

0.754 = :=

y

1

y

y

2

bar

2

+

0.873 = :=

N

b.y.Rd

y

A

st

f

y

326105.961 daN = :=

&$ %lam&a' in raport cu axa (*(;

N

bzRd

z

A f

yd

=

z

1

z

z

2

bar

2

+

=

z

0.5 1

z

bar

0.2

( )

+

bar

2

+

=

L

crz.st

10.15m = i

z

73.4 mm =

1

93.9 =

z

L

crz.st

i

z

138.283 = :=

Pt. curba "b" dupa axa z-z rezulta Conf. SR EN 1-1:2006 tab. 6.2:

z

0.34 :=

bar.1

1

1.473 = :=

z

0.5 1

z

bar.1

0.2

( )

+

bar.1

2

+

1.801 = :=

z

1

z

z

2

bar.1

2

+

0.352 = :=

N

b.z.Rd

z

A

st

f

y

131705.875 daN = :=

M

byRD

LT

W

ypl

f

yd

=

LT

1

LT

LT

2

LT

2

+

=

LT

0.5 1

LT

LT

0.2

( )

+

LT

2

+

LT

0.21 :=

C

1

1.77 := I

z.st

8560cm

4

:= I

t.st

190cm

4

:= I

w

2942000cm

6

:= G 810000

daN

cm

2

:=

E 2.1 10

6

daN

cm

2

:=

M

cr

C

1

2

E I

z.st

h

s.c

2

G I

t.st

2

E I

w

h

s.c

2

+

|

\

|

|

|

107221.669 daN m = :=

LT

W

y.pl.st

f

y

M

cr

0.712 = :=

LT

0.5 1

LT

LT

0.2

( )

+

LT

2

+

0.807 = :=

W

y.pl.st

2310 cm

3

=

LT

1

LT

LT

2

LT

2

+

0.842 = :=

M

byRD

LT

W

y.pl.st

f

y

45721.896 daN m = :=

Conf. SR EN 1993 1-1:2006 rezulat:

C

my

0.6 := N

rk

A

st

f

y

373650 daN = :=

M1

1 :=

K

yy

C

my

1 0.8

N

Ed.max

y

N

rk

M1

+

|

\

|

|

|

|

0.644 = := K

zy

1

0.1

bar.1

N

Ed.max

C

my

0.25

( )

z

N

rk

M1

(

(

(

(

0.904 = :=

M

Ed.y.max

35854.9m daN = N

Ed.max

N

b.y.Rd

K

yy

C

my

M

y.Ed.cor

M

byRD

+ 0.311 =

N

Ed.cor

N

b.z.Rd

K

zy

M

Ed.y.max

M

byRD

+ 0.88 =

Capitelul stalpului

Propunem t

f

19 mm = t

w

11 mm = t

c.

t

f

19 mm = := t

r

1.5 t

w

16.5 mm = :=

h

hea

390 mm = b

hea

300 mm =

b

r

t

r

15 25 cm = :=

b

r

t

r

15

b

r

t

r

15 =

Verificarea cordonului de sudura aw1 si lw1

f

vwd

2078.46

daN

cm

2

=

N

Ed.max

F

w1Rd

F

w1Rd

a

w1

l

w1d

f

vwd

=

a

w1

N

Ed.max

l

w1d

f

vwd

l

w1d.

2 h

hea

2t

f

( )

4 b

hea

+ 4 b

r

0.7 t

w

2 10mm

( )

+ 2.79m = :=

N

Ed.max

30186 daN =

a

w1.

N

Ed.max

l

w1d.

f

vwd

0.52 mm = := Impun: a

w1..

3mm := 3mm a

w1

0.7t

min

F

w1Rd

a

w1..

l

w1d.

f

vwd

174116.751 daN = :=

N

Ed.max

0.4

F

w1Rd

0.069 = 0.4 1

Determinarea inaltimii rigidizarii hr t

min

0.7 t

r

12 mm = :=

Impunca a

w2.

t

min

:=

N

Ed.max

F

vwRD

4 a

w2

l

w2d

f

vwd

=

l

w2d

N

Ed.max

4 a

w2

f

vwd

5 cm = :=

h

r

l

w2d

2 a

w2.

+ 10mm + 8 cm = :=

Baza stalpului

d

0

22mm := impun b

1

2.5 d

0

5.5 cm = :=

t

p

1.5 t

f

= t

p

20mm :=

Verificarea la compresiune f

y

2350

daN

cm

2

=

N

edmax

F

jRd

= F.jRd - capacitatea portanta a betonului

F

jRd

f

jd

A

eff

= f

jd

100

daN

cm

2

:=

c t

p

f

y

3 f

jd

5.6 cm = := b

1.

c 55.976 mm = :=

b

pl

2 b

1.

b

hea

+ 2 t

r

+ 44 cm = := a

pl

2 b

1.

h

hea

+ 50 cm = :=

A

eff

b

pl

a

pl

2233.449 cm

2

= :=

F

jRd

f

jd

A

eff

223344.897 daN = :=

You might also like

- Probleme Speciale de Geotehnica Si FundatiiDocument16 pagesProbleme Speciale de Geotehnica Si FundatiiMaruska MariusNo ratings yet

- Calculul SarpanteiDocument29 pagesCalculul SarpanteiCozmin Paloş100% (1)

- Model Diploma Licenta Structura Constructii UTCBDocument36 pagesModel Diploma Licenta Structura Constructii UTCBVlad Padina100% (2)

- Armare RADIERDocument22 pagesArmare RADIERSzenyes Szilárd100% (3)

- Calcul Hala LemnDocument15 pagesCalcul Hala LemnKrinu ZaharescuNo ratings yet

- Fundatii Radier-ExplicatiiDocument7 pagesFundatii Radier-ExplicatiiCristina IliesNo ratings yet

- Proiect Fundatii Tema 3Document30 pagesProiect Fundatii Tema 3Mihai BolinteanuNo ratings yet

- Ivan Daniel Proiect BetonDocument62 pagesIvan Daniel Proiect Betonfinding_neverland_124652No ratings yet

- Tema 2 - Fundatii - Zid de Sprijin - CCIADocument9 pagesTema 2 - Fundatii - Zid de Sprijin - CCIANikolin KoçaNo ratings yet

- Proiect Metal FinalDocument25 pagesProiect Metal FinalnicotinbuhaNo ratings yet

- Breviar Calcul HalaDocument7 pagesBreviar Calcul HalaDavid SolomonNo ratings yet

- Model Calcul SarpantaDocument17 pagesModel Calcul SarpantaMihai IonutNo ratings yet

- Evaluare IncarcariDocument11 pagesEvaluare IncarcariZinveliu FeliciaNo ratings yet

- Proiect Metal 3Document26 pagesProiect Metal 3robert spanii100% (2)

- L4 Ex.3-Grinda Cu ZabreleDocument8 pagesL4 Ex.3-Grinda Cu ZabreleCodrut Asavinei100% (1)

- Calcul AutomatDocument19 pagesCalcul AutomatMirelaNo ratings yet

- Mathcad Calcul Vant ZapadaDocument23 pagesMathcad Calcul Vant Zapadazeus59903647No ratings yet

- Licenta - Calculul Sarpantei - PT CalinDocument21 pagesLicenta - Calculul Sarpantei - PT CalinlauraiepureNo ratings yet

- Armare StalpDocument12 pagesArmare StalpLavinia LaviniaNo ratings yet

- Evaluarea IncarcarilorDocument1 pageEvaluarea IncarcarilorNicu Tataru100% (1)

- Mathcad - Armare RadierDocument19 pagesMathcad - Armare Radierttnicu100% (1)

- Proiect Beton Anul IV Facultatea de Constructii Si Instalatii IasiDocument37 pagesProiect Beton Anul IV Facultatea de Constructii Si Instalatii IasiSepciu Claudiu100% (1)

- Calcul RezistentaDocument9 pagesCalcul RezistentaFerdi Osman0% (1)

- Calculul Contravantuirilor VerticaleDocument10 pagesCalculul Contravantuirilor VerticaleAdrian SibistianuNo ratings yet

- Aplicatii Lemn P100Document20 pagesAplicatii Lemn P100Korponai CatalinNo ratings yet

- Proiect Metalice CciaDocument26 pagesProiect Metalice CciaCamelia GeorgianaNo ratings yet

- Grinda Supusa La Incovoiere Si TorsiuneDocument13 pagesGrinda Supusa La Incovoiere Si TorsiuneCampean Ioachim100% (1)

- Calculul SarpanteiDocument21 pagesCalculul SarpanteiMihai JurjNo ratings yet

- Hala Industriala Cu Structura Metalica - Etapa 2Document15 pagesHala Industriala Cu Structura Metalica - Etapa 2Katy MironNo ratings yet

- Proiect Iulia Constructii IndustrialeDocument6 pagesProiect Iulia Constructii IndustrialeFlorin Florinell100% (1)

- Calcul PlacaDocument44 pagesCalcul PlacaGeorgescu Claudiu CristianNo ratings yet

- Stabilirea Preturilor Pentru Proiectele de ConstructiiDocument7 pagesStabilirea Preturilor Pentru Proiectele de ConstructiihansaiulianNo ratings yet

- Proiect FundatiiDocument53 pagesProiect FundatiiGabriel_86No ratings yet

- Proiect Structuri Metalice GoroveiDocument9 pagesProiect Structuri Metalice GoroveiFlorin FlorinellNo ratings yet

- Tema 1 - Fundatii - Dig de Pamant - CCIADocument5 pagesTema 1 - Fundatii - Dig de Pamant - CCIANikolin Koça100% (1)

- Evaluare Incarcari Hala MetalicaDocument12 pagesEvaluare Incarcari Hala MetalicaIoan-Alexandru Ciolan100% (2)

- Silozuri Si Celule de DepozitareDocument15 pagesSilozuri Si Celule de DepozitareAdrian Baloš Toša100% (1)

- Proiect Metal IuliaDocument24 pagesProiect Metal IuliaFlorin Florinell0% (1)

- Breviar de Calcul BlocDocument9 pagesBreviar de Calcul BlocOctavian Cicu100% (1)

- Tema 3 - Fundatii - Fundatie Izolata - CCIADocument15 pagesTema 3 - Fundatii - Fundatie Izolata - CCIANikolin KoçaNo ratings yet

- Proiect Metal ConstantinescuDocument22 pagesProiect Metal ConstantinescuFlorin FlorinellNo ratings yet

- Grinda PrincipalaDocument9 pagesGrinda PrincipalaAdrian SibistianuNo ratings yet

- Calcul Stalp Central Ax B5Document35 pagesCalcul Stalp Central Ax B5Cristi Fekete100% (1)

- Exemplu Grinda CompozitaDocument8 pagesExemplu Grinda CompozitacrusanuNo ratings yet

- Proiect 3Document21 pagesProiect 3Darius DanNo ratings yet

- Nota de Calcul-Ferme MetaliceDocument8 pagesNota de Calcul-Ferme MetaliceAlexandrescuDanNo ratings yet

- Exemplu de Proiectare Structura in Cadre Din Beton ArmatDocument74 pagesExemplu de Proiectare Structura in Cadre Din Beton ArmatGherda Iulian100% (2)

- Breviar CalculDocument10 pagesBreviar CalculFlorin FlorinellNo ratings yet

- Subiecte Dinamica 1 1Document8 pagesSubiecte Dinamica 1 1Damaschin Cristian-AndreiNo ratings yet

- Proiect Metal 3Document26 pagesProiect Metal 3robert spaniiNo ratings yet

- BC - Calculul Planseului Mixt Otel-Beton-3Document3 pagesBC - Calculul Planseului Mixt Otel-Beton-3Santiago_Maresca77No ratings yet

- Desen Tehnic CB 2020 Datcu CostelDocument19 pagesDesen Tehnic CB 2020 Datcu CostelFlorin FlorinellNo ratings yet

- Exemplu de Calcul La Colaps ProgresivDocument35 pagesExemplu de Calcul La Colaps ProgresivEmilia GogaNo ratings yet

- Linca Alexandru Plot Proiect MetalDocument73 pagesLinca Alexandru Plot Proiect MetalCristian MitreaNo ratings yet

- Exemplu Modelare Perete Cu Response 2000Document3 pagesExemplu Modelare Perete Cu Response 2000Dorinel SchiopuNo ratings yet

- Contravantuiri VerticaleDocument13 pagesContravantuiri VerticaleAlice ZainelNo ratings yet

- Mathcad Proiect Structuri MetaliceDocument31 pagesMathcad Proiect Structuri MetaliceAnonymous zvQGXzNo ratings yet

- Mathcad - Calcul Lungimii de Ancoraj A Barelor de ArmDocument9 pagesMathcad - Calcul Lungimii de Ancoraj A Barelor de ArmttnicuNo ratings yet

- Cursuri StaticaDocument55 pagesCursuri StaticaDany BiberechiNo ratings yet

- Beton ArmatDocument54 pagesBeton ArmatAlex B.100% (1)

- Note de Calcul-Zidarie+stalpiDocument4 pagesNote de Calcul-Zidarie+stalpitikianNo ratings yet

- Aplicatie Alfa CriticDocument8 pagesAplicatie Alfa Criticadela2012No ratings yet

- Curs03 DsisDocument12 pagesCurs03 DsisFlorin FlorinellNo ratings yet

- Teste Licenţa Tep Rom Noi 2018 v2Document4 pagesTeste Licenţa Tep Rom Noi 2018 v2Tudor-Vlad MateiNo ratings yet

- Constructii MetaliceDocument40 pagesConstructii MetaliceLudmila VisnevscaiaNo ratings yet

- Sap GrindaDocument1 pageSap GrindasteliantsvNo ratings yet

- Capitolul - 7 - Statica Structurilor Continue Tip PlacaDocument10 pagesCapitolul - 7 - Statica Structurilor Continue Tip PlacaMedu AsaveiNo ratings yet

- Capitolul 5 Statica Cadrelor PlaneDocument16 pagesCapitolul 5 Statica Cadrelor PlaneFlorin FlorinellNo ratings yet

- Capitolul 4 Statica Grinzilor ContinueDocument14 pagesCapitolul 4 Statica Grinzilor ContinueFlorin FlorinellNo ratings yet

- Capitolul - 3 - Statica Structurilor Cu Z-ÂbreleDocument14 pagesCapitolul - 3 - Statica Structurilor Cu Z-ÂbreleFlorin FlorinellNo ratings yet

- Sectiune Transversala A3Document1 pageSectiune Transversala A3Florin FlorinellNo ratings yet

- Capitolul - 1 - Introducere La Metoda Elementelor FiniteDocument6 pagesCapitolul - 1 - Introducere La Metoda Elementelor FiniteAndrei BulaiNo ratings yet

- Capitolul - 2 - Fundamentele Staticii Matriceale ClasiceDocument8 pagesCapitolul - 2 - Fundamentele Staticii Matriceale ClasiceFlorin FlorinellNo ratings yet

- Curs04 DsisDocument16 pagesCurs04 DsisFlavia2301No ratings yet

- Capitolul - 6 - Statica Structurilor Continue Tip +ƒaib-ÂDocument17 pagesCapitolul - 6 - Statica Structurilor Continue Tip +ƒaib-ÂFlorin FlorinellNo ratings yet

- Mathcad - Proiect SosoDocument19 pagesMathcad - Proiect SosoFlorin FlorinellNo ratings yet

- Capitolul 0 Coperta Curs MEFDocument1 pageCapitolul 0 Coperta Curs MEFBogdan PavelNo ratings yet

- Curs07 DsisDocument12 pagesCurs07 DsisCorina CretzulinaNo ratings yet

- Cursul 06 Dinamica PDFDocument12 pagesCursul 06 Dinamica PDFciocolattayoNo ratings yet

- Curs08 DsisDocument5 pagesCurs08 DsisCorina CretzulinaNo ratings yet

- ProiectDocument4 pagesProiectFlorin FlorinellNo ratings yet

- Curs05 DsisDocument17 pagesCurs05 DsisStas ChirilaNo ratings yet

- Conţinutul Cadru Al Memoriului de PrezentareDocument3 pagesConţinutul Cadru Al Memoriului de Prezentare1671107044497No ratings yet

- Calculul Structurilor Metalice Si Mixte Otel Beton La Actiunea FoculuiDocument5 pagesCalculul Structurilor Metalice Si Mixte Otel Beton La Actiunea FoculuiAnca ChiraNo ratings yet

- Curs02 - Dsis-Aurel Stratan Facultatea de Construcții Din TimișoaraDocument10 pagesCurs02 - Dsis-Aurel Stratan Facultatea de Construcții Din TimișoaraCornel VoicuNo ratings yet

- Proiect Lemn - Acoperis Tip Sarpanta Pentru Cladire de LocuitDocument11 pagesProiect Lemn - Acoperis Tip Sarpanta Pentru Cladire de LocuitPredescu DarieNo ratings yet

- Model Anunt Public Titular Depunere Solicitare AcordDocument1 pageModel Anunt Public Titular Depunere Solicitare AcordFlorin FlorinellNo ratings yet

- Model NOTIFICARE AcordDocument2 pagesModel NOTIFICARE AcordFlorin FlorinellNo ratings yet

- Model Cerere Pentru Solicitare AcordDocument1 pageModel Cerere Pentru Solicitare AcordAndrei KolozsvariNo ratings yet

- r3 - Grinda de Fundare Axa 1-A3Document1 pager3 - Grinda de Fundare Axa 1-A3Florin FlorinellNo ratings yet