Professional Documents

Culture Documents

05.cement Market Peru

Uploaded by

Sunil Kumar DwivediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05.cement Market Peru

Uploaded by

Sunil Kumar DwivediCopyright:

Available Formats

MASTER PROJECT Cement Market in Peru

Carlos Ireijo Kanashiro Master of Competition and Market Regulation 2011

Contents

1. 2. 3. 4.

Motivation ........................................................................................................................ 3 The product ....................................................................................................................... 4 Caracteristic of the demand ............................................................................................... 4 Characteristics of supply ................................................................................................... 5 4.1. Chain Cement Productive .......................................................................................... 5 4.1.1. Production Process ............................................................................................. 5 4.1.2. Distribution of the product ................................................................................. 7 4.2. Geographical Market of the Suppliers ........................................................................ 8 4.3. The firms and Groups behind ..................................................................................... 9 5. Determinants of market power of the cement suppliers .................................................... 10 5.1. Concentration: market share..................................................................................... 10 5.2. Transportation costs ................................................................................................. 15 5.3. Entry Barriers .......................................................................................................... 16 5.3.1 Capital Investments ................................................................................................ 16 5.3.2 Legal Barriers ......................................................................................................... 16 5.3.3 Trade Barriers......................................................................................................... 17 5.3.4 Marketing and advertising costs .............................................................................. 17 5.4. Potential competition ............................................................................................... 18 5.5. Analysis of collusion: dynamic contexts................................................................... 18 6. Forms of competition in cement industry ......................................................................... 19 6.1. Horizontal Differentiation ........................................................................................ 19 6.2. Cournot competition: the choice of production capacity ........................................... 20 6.3. Price behavior (2000 2008) ................................................................................... 22 7. Conclusions..................................................................................................................... 24 8. References ...................................................................................................................... 26

Cement Market in Peru

1. Motivation

The cement market is a very important business in the construction industry. As many studies conclude, its demand is very cyclical and highly correlated with the economic cycles of growth. So, expansive cycles are signs of potential increases of cement orders for new infrastructure in expanding economies and with that, the big ones of this business. On the other hand, there are high fixed costs behind this product which makes it costly to be provided by several suppliers. It might be reasonable, that just one company provide the material in a geographical area. Nevertheless, that does not mean that another company should not enter in this area to compete with the first one, but certainly it would be hard for the last one to achieve the level of output of the first one from the beginning. This is a clear entry barrier in the market, which is not easily affordable. So in this context, due the important sunk costs of entry faced by the firms, there is a very concentrated market regarding to the supply and just a few ones that dominate market within a geographical location; which is determined by transport costs of both, raw material and the final product. However, as long as firms grow it is highly probable that they make arrangements in order to grow and be each time more profitable either by legal or even illegal ways. That is why this market could be a very interesting market to study. With high entry or sunk costs, a homogeneity product, high transport costs, inelastic demands, the market appears attractive to the dominant firms to collude or make cartels in order to deter entry and have the highest possible return.

2. The product

The cement is a primary hydraulic binder (as well as plaster and lime) which mixed with sand and water, allows the adhesion among different materials that will be fixed in a solid product after drying. It is obtained by pulverizing the clinker, which in turn is obtained by a calcined mixture of clay, sand and limestone that contain oxides of calcium, silicon, aluminum and iron in measured amounts, and eventually you can add uncalcined gypsum. The cement can be classified into several types depending on its uses and its strength and durability properties. The most commun is called Portland cement and its production process is developed under the Peruvian technical standards ASTM C-150, 334,009. Despite the existence of several types of cement, this is a fairly homogenous good with limited space for differentiation. While there are various types of cement and the substitution between them is feasible, is hardly replaceable by another good. Another characteristic of cement is related to its perishability: given its sensitivity to humidity, its quality can be kept intact for two months after its packaging (bagging) and stored. This feature of the product eliminates any possibility of accumulating inventories or stocks, since it is sold what it was produced.

3. Caracteristic of the demand

In general, there are three groups of cement buyers: the government (by procurement projects), the great construction (private companies running big bulding projects) and the self-construction (mainly households). The first two would explain about 40% of cement demand, while the remaining 60% for self-construction. As it is known the experts agree on qualify the cement demand as highly inelastic to the price inasmuch as there is no close substitute in the short run 1. So it is possible to

See Dumez and Jeunemaitre (2000), Rosenbaum and Sukharomana (2001), ABN-AMRO (2001).

consider inelastic almost 40% of the demand, but the part of self-construction could have some degree of elasticity in the rural areas of the country that may use quincha (a mixture of straw and mud). Morever it is important to note the sustained growth of the local demand since the beginnings of the decade, which gave a total rate of growth of 87.7% with a annual average rate of 6.9% between 2000 and 2008, which goes together also with the valuable 8% of growth of the economy.

4. Characteristics of supply

4.1.

Chain Cement Productive

There are three links or market segments that make up the production chain: input supply, production and marketing and distribution. Regarding the provision of inputs (clay and limestone), they are available in nonmetallic reserves. Peru has several no metal reserves which contain the essential inputs for the manufacture of cement and are concentrated in three areas: north, center and south (see Annex 1). Currently there are seven companies producing cement also extract nonmetallic mineral, each in a different area or region. It should be noted that extraction of the cement inputs are not free and is regulated, as it is presented later in the document. In next section it is focus more in the production and distribution links since they have more key costs of this chain. The marketing and advertisement will be developed in part 5 of the report, which treat about entry barriers.

4.1.1. Production Process Cement production is done in several stages, but they can be classified into four: (i) extraction, crushing and grinding of raw materials, (ii) homogenization and mixing of raw materials, (iii) the clinker output by calcining the raw powder, and (iv) pulverization of clinker and cement preparation. A more detailed description of the process could be seen in the table below:

5

Table 1: Stage process for the production of cement(*)

(i) Mining, crushing and milling of raw materials : the main raw materials of cement are limestone, clay and sand which contain calcium silicates and aluminates and additionally it can added iron ore and gypsum. These materials are extracted from the soil in the quarry, near which is located processing plants. Once extracted raw materials are crushed to convert them to smaller sizes and suitable for mixed. (ii) Homogenization and mixing of raw materials : in order to have an appropriate composition of raw materials, its proceeds to mix, and to obtain it uniformly it is possible to use air currents (dry) or using water (wet). (iii) Preparation of clinker: the homogenized mixture by dry is transported to the furnaces where it is burned, the product obtained is called clinker. Under the wet process, the wet mixture is transported and delivered to the furnace where it should be calcined at higher temperature (1500 C) in order to eliminate the water. This process is lengthy and costly.

(iv) Spraying of clinker and cement preparation : after

obtaining the clinker, it is crushed and pulverized to make cement. Depending on the type of cement quality and choice available, you can add additives such as gypsum, puzulana among others.

(*) BWS report (2005)

It should be noted that in Peru the manufacturing process of cement used is the dry process, except for Cementos Sur and Cementos Selva companies, which use the semiwet and wet respectively. This is important in order to differentiate the production process by the cost structures of the industry. The wet process involves higher costs as long as it needs water in order to achieve the homogenization of the additives and after that, the energy which allow to dry the wet mixture in furnaces with temperatures above 1500C. The dry process is more efficient insofar water is no needed and it requires just machinery grinding and shorter furnaces to expose the clinker to high temperatures but under less time, which makes it efficiently also in the consume of energy.

4.1.2. Distribution of the product After obtaining the cement, it is distributed packaged (paper bags) or bulk. The marketing of cement bag is the most common and traditional. It is channeled through hardware stores and commercial storage primarily self builder sector. However, due to large-scale constructions, and consequently the need for greater volumes of cement, there is a growing bulk supply, an arrangement which allows to have savings from better management in the process of unloading and handling (avoidance of losses ) and better storage conditions of cement (the risks of moisture damage are minimized). Under this method, the cement is transported in tankers and is then stored in silos specially equipped2. The bulk sale will be channeled mainly to major constructors and to big industrial production of concrete (concrete mixers). Chart No. 1 shows the cement market chain since the raw material extraction until its distribution. In this sense, firms extract their raw materials and produce close to their quarry. Also, the sector forward linkages with the distribution and production of concrete segments such as bricks, pre-fabricated materials and ultimately the construction of buildings and public works:

Chart 1. Production and Distribution Chain

Cement Producers Association (ASOCEM)

Quarry (Extraction of raw materials:clay,sand and limestone) a) Raw material grinding b) Mixing and homogeneization c) Output of calcined clinker * Rizo-Patrn Group (Lima and Andino Cements) - 59% 1/ * Hochschild Group ( Pacasmayo and Selva Cements) - 23%1/ * Cementero Sur - Rodriguez Banda Consortium connected to Gloria Group ( Yura Cements and Sur) 17.7% 1/ *Progre-Sol Red (Lima Center) DINO and Dinoselva Iquitos SAC 3/ * Conchan Customs warehouse and Lurin Transports 4/

Industrial Canal (25%5/)

Manufacture of concrete and cement producs (concrete, premixed, bricks, etc)

Production

Clinker grinding and packaging Cement (sales) (6.8 mill TM) 2/ Local sales (6.7 mill TM) 2/

Storage and distribution

Ironmonger canal (75%5/) - Modern canal (3%5 ) (self-service stores) - Traditional Canal (97%5) (ironmonger and ProgreSol red)

Exports (62 TM) 2/

Imports (221.6 TM) 2/ * Latin American Trading (CEMEX) Large constructions [40% of demand] 6/ Estate (infraestructure, public works, and housing programs). Building industry (building houses, malls, private infraestructure). Little constructions [60% of demand] 6/ Selfconstruction (houses and remodeling)

Notas: 1/ information of market share of 2007 sales. 2/ Information of the 2008 year. 3/ Pacasmayo Subsidiary Cements. 4/ Lima Cement Subsidiary. 5/ Information of Lima Cement and Andino Group, the Group with the higher market share. 6/ Referential information got it of BWS (2005) which estimate a market share of self construction sector between 60% and 70%.

4.2.

Geographical Market of the Suppliers

With independence of the physical characteristics of their products, the several cement producers differ from each other regarding the geographic location of their plants, the availability of their products and the services associated with the purchases to the customers3. Due to the high costs of transport and distribution, firms rely on differentiation by geographic location of plants in order to make consumer to choice the closest product around. Figure N4 shows graphically the location of production and market for each case.

Nera Report. Static and dynamic competition in the cement industry: the case of the Philippines. 2002. P 5.

Figure N4 Regional Distribution of Cement Production

Cementos Selva Cementos Pacasmayo Caliza Cemento Inca Cementos Lima Cemento Andino

Cemento Sur Yura

Source: Based on Cement Pacasmayo (2009) - Annual Report 2008.

In the next lines the way of setting of the companies is developed in order to understand the market structure in the Peruvian cement market.

4.3.

The firms and Groups behind

In Peru there are seven producers of cement, nonetheless, the six largest firms of them belong to three economic groups (Rizo-Patron Group, Rodriguez Group and Hochschild Group). Therefore, we can say there are three major cement companies. The presence of a few companies is a feature of this market has been focused from the start of production in Peru in 1916. These six firms also extract the input (limestone and clay) from the quarries of nonmetallic minerals. Moreover, these same companies, through its subsidiaries (listed in Annex 4) have formed their distribution networks through which sell their products. Chart No. 2 presents the companies that offer cement in the domestic market (including

importers of that good), showing its participation, product brands on the market, installed capacity and some characteristics of its operation.

Chart N2. Domestic producers in the market andareas of influence

Economic Group

Sales market Name of the shares (2008) firm Cementos Lima Cemeno Andino Cementos Pacasmayo Cementos Selva

Brand

Start of Operations 1967 1/ 1956

Base (plant) Zone of influence Lima (Atocongo) Junn (Tarma) Lima (PacasmayoLa Libertad) San Martn (Rioja) Arequipa (Yura) Puno (Juliaca) Lima (Chosica) Republica Dominicana 3/

Sales market shares (2008) 42,6% 18,5%

Installed capacity MT (2009) 5.500.000 1.500.000

Sol y Atlas Andino

Center Center

Rizo-Patrn

61,1%

Pacasmayo

1949

North

19,6%

1.925.000

Hochschild

21,8%

Pacasmayo Yura

1998 19622/ 1965 2007

North South South Lima

2,3% 14,3% 1,8% 0,9%

150.000 1.800.000 340.000 n.d.

Gloria (Rodriguez Banda)

16,2%

Cementos Yura

Familia Choy

0,9%

Cementos Rumi Sur Caliza Cemento Inca Cemento Inca Latinamerican Trading 3/ Quisqueya

CEMEX

0,0%

2007

Lima

0,0%

n.d.

Total National Sales (MT)

5.878.055

100%

1/ Year in which the company operates with such a name, previously did under the name of Compaa Peruana de Cementos Portland since 1916. 2/ In 1994 it was acquired by Grupo Gloria. 3/ Cemex's subsidiary in Peru which began operations in July 2009 and imports cement from Dominican Republic Source: Proceedings of the companies, INEI, ASOCEM

5. Determinants of market power of the cement suppliers

5.1. Concentration: market share

In general, the level of sales of cement firms showed an increasend trend over the period 2003-2008 (see Figure No. 1). It should be noted that in 2008 Cementos Yura, Cementos Pacasmayo and Cementos Lima recorded growth sales of 95%, 92% and 90% respectively, higher than the sales level reached by each of them five years ago in 2003. Despite the fact that Cementos Selva and Cementos Sur showed a stable trend and even slightly declining sales but just in the last year, without doubt is a profitable market since the trend of growth is still sustainable along the time.

10

Figure N1: Total sales of cement by company

3 500 000 3 000 000

2 500 000

2 000 000 1 500 000 1 000 000 500 000 0

2003

Cementos Lima

Yura S.A.

2004

2005

Cemento Sur

2006

2007

2008

Cementos Pacasmayo

Cemento Andino

Cementos Selva

Source: INEI, Statistical Compendium 2008

In detail, the monthly evolution of cement sales shows not only the growing trend of cement production for the aggregate by group, but also by the largest firms Cementos Lima and Cemento Andino (Group Rizo-Patron) over the rest4. An additional firm, not depicted in the figure, is Caliza Cementos Inca, which has a very small but slightly increasing participation in cement sales in the center region of Peru. Its production plant operates in Cajamarquilla (Chosica, Lima) since mid-2007 (see Figure No. 2).

Figure No. 2. Monthly evolution of cement sales related by group of companies, in thousands of TM (ene.2001-set.2009)

The joint production of these two companies exceeds the joint production of other four producers.

11

Miles de TM

450 400

350

300 250

200

150 100

50

0

Sep-03 Sep-04 Sep-05 Ene-06 Ene-07 Ene-08

Ene-02 Sep-02 Ene-03 Ene-04 Ene-05 Sep-06 Sep-07 Sep-08 Ene-09

May-02

May-03

May-08

Cementos Lima y Andino

Cementos Pacasmayo y Selva

Cementos Yura y Sur

Caliza Cemento Inca

Source: INEI, 2008 Statistical Compendium and statistical database.

Chart No. 3 shows the distribution of cement sales per firm, by department in 2008. As can be seen, taking the market share of the economic groups Hochschild (GH), RizoPatron (GR), Rodrguez Banda (GRB), in at least 14 departments of 24 there is no competition, but instead basically only one producer provides the good.

Chart No. 3. Distribution of cement sales per company, by department (2008)

May-09

May-04

May-05

May-06

May-07

Sep-09

12

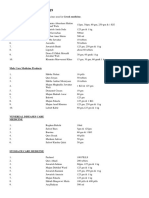

Sales Region or Area Department MT Cementos Lima

Firms (sales in MT) Cementos Cemento Pacasmayo Andino Yura S.A. Cement Cemento o Sur s Selva Caliza Cemento Inca

0 0 2 340 0 0 57 662 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Market share of Group by Department GR GH GRB CCI

Ay acucho Huancav elica Hunuco

1 1 2 389 37 809 99 486 31 4 805 395 809 2 785 080 1 23 293 45 21 3 30 528 2811 08 1 57 443 449 956 273 458 54 777 240 428 1 44 81 6 30 768 42 371 361864 258 287 56 786 51979 256 265 1 35 872

25 984 82 4 631 309 405 1 1 5 2 31 2 31 8 0 1788 0 1 21852 329 937 1 1 22 077 3 393 0 1 0 1 5 604 35 355 967 0 1803 2 651 1 0 404

0 0 0 0 0 0 0 0 1 5 052 1 57 255 1 57 1 1 4 449 01 9 273 447 0 237 035 0 30 758 0 0 0 0 0 0 0

86 392 37 727 92 51 5 32 395 694 41 5 099 1 23 293 43 425 0 2 001 0 0 0 31347 0 9 246 0 1 1633 0 862 0 0 0 0

1 3 0 0 5 368 0 0 0 0 0 0 0 0 0 0 0 0 0 1 4 881 326 509 256 458 882 50 1 76 1 85 752 1 25 468

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 253 0 0 55 904 0 67 862 0

0 0 0 0 0 0 0 0 1 5 476 0 0 0 0 1353 0 1 35 570 0 0 0 0 0 0 0 0

1 00,0% 1 00,0% 1 00,0% 98,3% 1 00,0% 97,9% 1 00,0% 1 00,0% 0,0% 44,1 % 0,2% 0,2% 0,0% 97,5% 1 ,4% 6,4% 0,0% 64,3% 9,8% 0,7% 0,0% 3,5% 1 ,0% 7,7%

0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 1 00,0% 55,9% 99,8% 99,8% 1 00,0% 2,5% 98,6% 93,6% 1 00,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0%

0,0% 0,0% 0,0% 1 ,7% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 35,7% 90,2% 99,3% 1 00,0% 96,5% 99,0% 92,3%

0,0% 0,0% 2,4% 0,0% 0,0% 2,1 % 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0% 0,0%

Center North South

Total

Ica Junn Lima Pasco Ucay ali Amazonas ncash Cajamarca La Libertad Lambay eque Loreto Piura San Martn Tumbes Apurmac Arequipa Cusco Madre de Dios Moquegua Puno Tacna

6 740 590

2 869 716

1 319 680

1 249 268 965 507 124 019

152 399

60 002

61,1%

21,8%

16,2%

0,9%

Source: INEI (2008) and CUANTO (2008).

Rizo-Patron Group (GR) that serves the central area of Peru through its brands Cementos Lima and Cementos Andino has about 60% of total national market; which is explained by its total market share in Lima almost 100%- that represents in turn the 43% of the total national market. The Hochschild Group, which operates in the north through his brands Cementos Pacasmayo and Cementos Selva, and finally the Rodrguez-Banda Group, which operates in the South with his firms Cementos Yura and Cementos Sur, follow GR in size. It can be seen that the hinterland of each producer differs one from each other, facing very low competition (or non-competition) at regional level. This is explained by the high entry costs in this industry, which also shows a strong vertical integration level of firms. Besides, a highlighting factor is the transport costs for cement delivery, which lead companies to sell their product close to its production plant avoiding the competitive interaction as much as possible. Indeed, the national cement market in Peru is highly concentrated as demostrated by the evolution of the Herfindahl-Hirschman index, which has remained high (in average, about 4500) since the 70's, as it could be seen below:

13

Figure No. 3. HHI * Cement sales 1976 - 2008

5 000 4 000

IHH

3 000 2 000

1 000 0

1976 1977 1978 1979 1980 1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008

IHH Global Lineal (IHH Global)

(*) HHI <1000 indicates unconcentrated market, 1000 <HHI <1800 moderately concentrated market and HHI> 1800 indicates high market concentration. Source: Cement Producers Association. ASOCEM

Moreover, considering that the cement supply is bounded to the nearest geographical area and that in scarce opportunities these companies compete each other in the same geographic market, market concentration is much higher: at a disaggregated level, most of the departments has only one supplier, situation that has been invariant during the period 2003-2008 as it can be seen in Chart N4. The evolution of the HHI over 8000 points (see shaded information), shows a very high regional concentration in almost all cases:

Chart N4. HHI(*) Index constructed from the amount of sales by department (2003-2008)

low/medium concentration

High concentration

6 000

14

2003 Amazonas ncash Apurmac Arequipa Ayacucho Cajamarca Cusco Huancavelica Hunuco Ica Junn La Libertad Lambayeque Lima Loreto Madre de Dios Moquegua Pasco Piura Puno San Martn Tacna Tumbes Ucayali Total 10000 6961 7145 10000 9282 9235 9913 10000 10000 6693 10000 10000 10000 9988 5110 9715 10000 10000 10000 10000 8820 5725 10000 10000 4599

2004 10000 7441 6506 9999 9884 8215 9998 10000 10000 7028 10000 10000 10000 9998 5005 10000 10000 10000 10000 10000 8986 5898 0 10000 4617

2005 10000 8246 6680 10000 9681 10000 9982 10000 10000 6600 10000 10000 10000 9995 5867 10000 10000 10000 10000 10000 8949 5914 0 10000 4560

2006 10000 8908 6994 9962 9882 10000 9900 10000 10000 7653 10000 10000 10000 10000 5394 10000 10000 10000 10000 10000 8898 5831 0 10000 4429

2007 10000 5805 6303 10000 9988 10000 9900 10000 10000 8135 10000 10000 10000 10000 5218 10000 10000 10000 10000 10000 9274 5813 0 10000 4321

2008 10000 5071 5408 8237 9998 9958 9859 10000 9541 9665 10000 9958 9999 9594 9518 10000 9330 10000 9722 9795 8805 8586 9994 10000 4473

N firms (2008) 1 2 2 2 2 1 2 1 1 2 1 1 1 2 2 1 1 1 1 1 2 2 1 1

Group Leader GH GH GRB GRB GR GH GRB GR GR GR GR GH GH GR GR GRB GRB GR GH GRB GH GRB GH GR

(*) HHI <1000 indicates unconcentrated market, 1000 <HHI <1800 moderately concentrated market and HHI> 1800 indicates high market concentration. Source: INEI, 2008 Statistical Compendium and statistical database.

5.2.

Transportation costs

Due the relative perishability of the good and considering also his big weight, and given the inadequate and lacking transport infrastructure in Peru, long distance transport charge is expensive relative to its value 5, making it a low tradeable good for far distant markets, and therefore the distribution to closest market to the cement plants have to be the priority. It is worthy mentioning that cement is mainly transported by land, sea-transport would not be an efficient option in Peru because of two reasons: (i) the high sensitivity of cement to humidity cement requires special treatment (humid protection) and careful

5

A brief survey of freight rates, transport cement to destinations such as Lima Madre de Dios (South) or Tarapoto (north) can cost up to 34 suns per bag of cement (which has a price that hovers around 22 soles). This cost is reduced to closer destinations such as Arequipa and Trujillo, destinations, according to the surveyed companies, the cost amounts to S /. 7.65 per bag of cement transported. (The poll was conducted Transport companies Cornejo, Santa Marta and Mega Transport SRL, the first week of December 2009). 15

cargo handling that would imply higher costs and (ii) poor port infrastructure (outside of Callao) that raises the costs of freight transport logistics.

5.3.

Entry Barriers

5.3.1 Capital Investments Mining concession An important element to be considered in assessing the market entry of cement is associated to the access to raw materials: limestone and gypsum deposits. As seen in a previous section, the provision of inputs is very important to continue the production process and is therefore an activity that also makes the production of cement, thus showing a vertically integrated structure that is less expensive and efficient. In Annex N3 is detailed some basic compulsory rules stablish by the state to explote operate according to law. Capacity of plants Regarding structural barriers, the market presents economies of scale and the existence of high sunk costs that could be considered as entry barriers deterring the initiation of operations of a potential competitor e.g. the overinvestment in capacity. These sunk costs are associated with high investments in plants and the implementation of purchasing of machinery as the one used for grinding and cooking of raw materials and clinker. In addition, there are certain economies of scope associated with favorable production of clinker (as the final) and plaster, and then with the manufacture of concrete and pre-fabricated materials. 5.3.2 Legal Barriers Although there are no strong legal barriers, however it should be noted that some difficulties associated with the delay to obtaining permits, may eventually happens due to the rate of time proceedings in public administration.

16

5.3.3 Trade Barriers In the field of trade barriers, there would be no relevant barriers. There are dumping duties applied only to white Portland cement, but not for the gray Portland type which is the most traded. 5.3.4 Marketing and advertising costs Marketing Peruvian Cement companies are also directly involved in the distribution of their product; this may be associated to lower transport costs and higher cargo care. Implementing marketing campaing has been a common strategy of largest companies to ensure selling their products. A more extended description of the distribution strategy implemented for the largest firms could be seen in Annex 4. Advertisement Finally, among other strategic barriers may also be mentioned the advertising: higher expenses in advertising by established firms could make it difficult or more expensive the entry of new competitors. The threat of entry by CEMEX to the Peruvian market has not only generated reactions from established companies with greater investment in the expansion of its installed capacity, but has also significantly impacted the way in which companies approach to consumers. Two sales strategies have been remarkably applied in this sector: (i) the formation and consolidation of distribution networks, by which companies try to take a closer relationship with its customers; and (ii) an intense advertising campaign to positioning the brand and consumer loyalty. The advertising strategy would not be innovative and rather common in the Mexican market, where CEMEX has used it widely and aggressively, even by sponsoring sports teams. In parallel, Cementos Lima has been increasing spending in advertising spots in different news media (newspapers, radio and TV) directed primarily to

17

strengthen its brand preference "Sol" in the segment of self construction, which would be allocated 60% of cement produced. So, Cementos Lima spent an amount of U.S. $ 436.3 thousand for advertising in different media during 2007, and up to September 2008, this spending just on radio advertising arrived to $ 360 thousand6.

5.4.

Potential competition

With the booming construction market, the peruvian cement market is attractive, encouraging the entry of new competitors. Upon arrival of CEMEX in 2007, in the next years it would expect to come three new companies7: Cementos Portland: company created by the partnership between World Cement Group (Spanish investors) and the local investment group Portland Cementos Otorongo: subsidiary of Cimentos of Portugal CIMPOR Cementos Interocenicos 8

5.5.

Analysis of collusion: dynamic contexts

Regarding the dynamic determinants of the power market in this industry, a study of Nera 9 regarding the cements markets, identifies the followings factors related with the market structure: 1) Concentration grade or number of firms 2) Type and frequency of competitive interaction 3) Cyclical position of the demand 4) Over / under capacity added in industry 5) Multimarket contact,etc And also within the firms:

6 7

Gross basis IBOPE obtained. Idem. BCRP (2008) Research Notes: Economic Activity, BCRP, Working Paper No. 62, September 2008. Available at: http://www.bcrp.gob.pe/docs/Publicaciones/Notas-Estudios/2008/NotaEstudios-62-2008.pdf. 8 Newspaper Article "cements Interoceanic expect to compete with three brands," published in the Economics Section of the newspaper El Comercio August 6, 2008. 9 Nera Report. Static and dynamic competition in the cement industry: the case of the Philippines. 2002. P 50. 18

1) Capital cost 2) Ownership structure: degree of diversification, solvency and liquidity, etc. According with this study, these indicators, which affects positively or negatively the the discount factor, could reveal the conditions required for a sustainable collusion practice. Nevertheless in the case of the Peruvian market, the collusion would took part prior to the price competition, as we see in the Chart N3, since they would avoid the competition within the same region through an anticompetitive practice of market sharing, which is demostrated with the concentration by department. Thus this practice overrides some kind of competitive interaction and also isolates the demand between regions and rules out the importance of cyclical position of the demand. It worths to note that through this practice it is also avoided the multimarket contact, that allows price discrimination, which could be an important signal of competition. Another important fact that will be well developed in the next section, is related to the excess of capacity which owns each plant of the groups that would works as a mechanism to deter off the competition price among the companies. Regarding the lasts two dynamic determinants, about the internal factors of the companies, the firms presents similar degree of integration and also similar financial stability since all of them are Peruvian Groups, so it is posible to dismiss any kind of advantage related this issue.

6. Forms of competition in cement industry

6.1. Horizontal Differentiation

So the cement market is characterized by an oligopolistic market structure where firms produce a fairly homogenous good. As it was already demonstrated, the six largest producers is differentiated by region or geographical zones according the location of its plants, which were decided in the beginning of the Peruvian cement business.

19

Thus, there are three different geographical markets: northern, central and southern region; each region is dominated by each of the three economic groups already identified (Group Rizo-Patron Rodriguez Group and Grupo Hochschild-Banda).

6.2. Cournot competition: the choice of production capacity

Importants models as two steps ones proposed by Kreps and Scheinkman (1983) could help to understand more these markets that in the first step firms choose capacity and then prices in order to compete with prices over marginal costs. As these capacities could be observed they may be used to build credible commitments 10. Consequently, investment in machinery and expansion of idle capacity can be considered as strategic barriers imposed by firms in the sector: the excess of capacity of cement industry surpasses the 11 million tons according to 2009 estimates, which is more than 50% domestic demand for that product (approximately 7 million tons in 2008). This feature would affect the market structure, since it can be adequately supplied by existing firms. In line with this, taking the ratio of total dispatch and total idle capacity as a proxy indicator of the rate of capacity utilization (see Chart No. 5), we observe that out of Cemento Andino and Cementos Selva the rest of companies produced using less than 70% of their total capacity, so one might think that recent investments in capacity expansion are not only related to a growing demand needs, but also coincide with the threat of entry of international firms like CEMEX.

10

Juan Jose Ganuza. Dynamic Games and Industrial Organization lectures. Barcelonagse.

20

Chart N 5. Indicator of capacity utilization *

Firm 2007 2008 C. Lima S.A. 57,1% 65,30% C. Andino S.A. 97,4% 83,40% C. Pacasmayo S.A. 63,5% 68,70% C. Selva S.A. 95,0% 100% Yura S.A. 51,6% 51,50% C. Sur S.A. 46,4% 36,20% * Ratio between the amount of cement shipped and idle capacity Source: ASOCEM & INEI

Excessive capacity can raise a barrier against the threat of price competition if it reaches. Lately, companies such as Cementos Pacasmayo and Cementos Lima have initiated major investment projects to expand their plants. The first had expanded its capacity by 22% and the other would be investing to expand capacity by 52%. Yura also planned to invest U.S. $ 500 million to double its installed capacity. Also, during 2007-2008 Cemento Andino, and especially, Cementos Sur increased its installed capacity:

Chart N6. Investments in Capacities by Cement Firms

2007 Firm C. Lima S.A. C. Andino S.A. C. Pacasmayo S.A.A. C. Selva S.A. Yura S.A. C. Sur S.A. Clinker 3.600.000 1.050.000 1.100.000 120.000 590.000 Cement 4.500.000 1.250.000 1.925.000 150.000 1.800.000 180.000 Clinker 3.600.000 1.180.000 1.175.000 120.000 590.000 330.000 2008 Cement 4.500.000 1.500.000 1.925.000 150.000 1.800.000 340 000

3

2009 Clinker 4.800.000 1.180.000 1.175.000 120.000 1 190 000 330.000

2

2010 Cement 5.500.000 1.500.000 1.925.000 150.000 1.800.000 340.000 Clinker 4.800.000 1.180.000 1.175.000 120.000 1.190.000 330.000 Cement 5.500.000 1.500.000 2 925 000 150.000 1.800.000 340.000

1

Source: ASOCEM

On the other hand, the possession or control of a distribution network may also be considered as a strategic behavior. On one hand, Cementos Pacasmayo through DINO ensures its distribution network in the North, while in the center; Cementos Lima has begun an aggressive acquisition strategy through affiliated retail network Progresol Hardware since May 2008. Again, this activity could raise the entry costs and discourage the entry of potential competitors.

21

6.3.

Price behavior (2000 2008)

In order to observe the evolution of the annual prices of the cement in the Peruvian market across regions, and since there is not databases of cement prices by region, Chart No.7 was made using the available information of Government Procurement collected by the Electronic Government Procurement (SEACE) for the period ene.2005-set.2009. As seen in the mentioned table, differences of the average prices accross regions were found. In general, the South region has not only the highest average price but also shows an increasing trend in comparison to the other regions. This can be explained due to more difficulties for transporting the product in the South of Peru.

Chart N7 Annual evolution of the average price of a bag of Portland Cement Type I, by department and region (2005-set.2009)

22

Zone o region

Group Leader

Department Ayacucho Huancavelica Hunuco Ica Junn Lima Pasco Ucayali Amazonas Ancash Cajamarca La Libertad Lambayeque Piura San Martn Tumbes Loreto Apurimac Arequipa Cusco Madre de Dios Moquegua Puno Tacna

2005 22,02 20,71 19,10 15,55 18,37 18,23 19,36 18,96 18,95 19,57 19,99 20,38 17,88 19,03 19,73 18,84 21,00 18,93 19,70 22,14 18,95 20,82 18,41 20,75 18,20 19,81 19,48

2006 21,99 21,01 20,39 18,76 18,27 18,59 19,77 19,11 19,26 20,78 20,60 21,85 19,85 19,06 20,23 20,47 21,27 20,00 20,48 25,26 19,90 22,92 28,50 21,06 21,64 20,21 21,86 20,53

2007 22,90 20,84 19,51 18,66 18,52 17,67 20,23 23,25 19,89 21,75 20,39 21,52 20,04 19,49 21,49 20,52 22,25 26,10 21,51 24,15 19,23 24,37 25,48 20,94 20,73 20,90 21,92 21,11

2008 23,32 21,29 19,83 18,23 18,59 17,97 20,87 25,92 20,13 24,32 20,77 21,82 20,96 19,75 21,88 21,32 22,08 25,46 21,58 25,14 22,42 26,00 28,40 23,78 23,46 23,99 24,46 22,06

2009 22,96 21,32 21,03 17,40 18,62 17,93 19,69 24,49 20,35 25,79 21,03 21,88 21,36 19,60 22,08 21,44 23,91 21,64 21,72 22,44 24,73 27,04 22,25 22,55 21,96 23,03 21,67

Centro

Rizo-Patrn Group (Cementos Lima y Cemento Andino)

Average price central

Norte

Hochschild Group (Cementos Pacasmayo y Cemntos Selva)

Grupo Rizo-Patrn Average price north

Sur

Grupo Rodriguez Banda (Cementos Yura y Cemento Sur)

Average price south National average

Note: Average prices have been obtained from a unit-cost award for the purchase of bags (42.5 kg each) of Portland cement Type I by government agencies. Source: obtained from the base of the Electronic Procurement System (SEACE)

Again it is possible to identify the clear overlap between the geographical region and the leading producer in each area (with the exception of Loreto, where although it belongs to a northern region, is attended by the center leader producer). It should be also noted that unlike what happens in the north and the south, in the center there are more marked differences between prices by departments, taking the lowest price in Lima and neighboring departments. In general, the price differences could be explained by the distance and several difficulties in the access to farther areas that finally increases the transportation costs and therefore makes prices higher. Moreover, it is worthy noting that price series does not shows any kind of competiton among regions since there are not overlaps inter groups departments, probably due to anticompetitive practices such as market sharing, as shown above. This practice woul be also confirmed by the absence of any discriminatory prices policy, which is usually

23

used to expand their geographical markets. As it was noted before, prices in the departments where the companies (economic groups in this case) locate their plants are not higher than the rest of the cities in the same region, probably because of the absence of the threat of a competitor.

7. Conclusions

The Peruvian Cement market is not different from the general cement markets. It is caracterizated by a fairly homogeneous product with low space to differentiation by physical characteristics. Facing a growing economy with an increasing demand for construction and therefore for cement, firms bet to horizontal differentiation in order to expand their market shares. There are six largest firms which belongs to just three financial groups with virtually shares all the cement market in Peru. The firms Cementos Lima and Cementos Pacasmayo which belongs to Rizo-Patrn Group, are the two dominants firms in the North region of the country. While Cementos Pacasmayo and Cementos Selva of the Hochschild Group are the two dominants firms in the Center region and finally, Cementos Yura and Cementos Sur of the Gloria Group (Rodrguez Banda Group) are dominants in the South region. About the determinants of market power of the cement suppliers in this market, the study found a highly concentrated market at national level by these six largest firms, even more the strong concentration is not only obtained by region but also by department since a HHI index applied in each department, which conform a region, is dominate by a single firm in the majority of the cases. Furthermore it has been found a very clear allocation of the regions by Group, since a single dominant Group has an almost complete region of the country to serve. Additionally high important costs of transport also increase the market power of each firm in its local market, and even worse if the alternative by sea is not possible. The entry barriers also encourage their market power since it is demostrated the presence of important sunk costs along the vertically integrated chain production, which works as a mechanism to deter entry like big capital investments, through considerable costs of marketing and advertisement until the distribution strategy in the the final part of the

24

chain, but preventing of potential entry at the same time, notwithstanding the presence of new competition already in the market, and more additional entrants expected in the coming years. Another important fact to understand the absence of any competition might be the overinvestment in capacity as a strategic barrier, which could deter of a war price between the firms. Furthermore, the price behavior reviewed of the period 2000 2008 shows the lack of any kind of discriminatory price policy that can reveal any strategy to expand their market shares or hereby, competition itself. So based on all the characteristics of this market and the indicators showed along this market research, it is highly likely the presence of market sharing of regions in function of the geographical locations of their plants, where there is no competitive interaction or multimarket contact yet, in the majority of the departments and even worse at regional levels. But in order to confirm the existence of the practice with greater certainty a survey of information on each region would be useful to have incriminatory plus information of the agents in order to fulfill also with concrete evidence, which leaves study materials to be covered may be in future reports.

25

8. References

NERA (2002). Static and dynamic competition in the cement industry: the case of the Philippines. 2002. ARORA Ritu Raj y Runa SARKAR (s.f.) Detecting Cartels in the Indian cement industry: An Analytical Framework, Industrial and Management Engineering Department, IIT Kanpur. APOYO&ASOCIADOS (2009a) Cementos Lima S.A, Empresas Anlisis de Riesgo, Apoyo & Asociados, abril de 2009. APOYO&ASOCIADOS (2009b) Cementos Pacasmayo S.A.A. (CPSAA),

Financiamiento Estructurado, Apoyo & Asociados, mayo de 2009. APOYO&ASOCIADOS (2009c) Cemento Andino S.A.A., Empresas Informe Trimestral, Apoyo & Asociados, diciembre de 2009. ASOCEM (1985) The Cement Industry Technology and Development, a document drawn from the presentation by Mr. Manuel Gonzales de la Cotera, Executive Director of Asocem the October 17, 1985. Cement Producers Association - Asocem. ASOCEM (2009) Per: General overview of the construction industry, Cement Producers Association - Asocem, January 2009, Lima AVALOS, M. y ACHATAN, C. (2004) Condiciones de competencia en el contexto internacional Cemento, azcar y fertilizantes en Centroamrica, Tecnolgico de Monterrey Documento de Trabajo, EGAP-2004-08, Mxico DF. BWS (2004) Reporte Empresarial: Cementos Pacasmayo S.A.A., Departamento de Estudios Econmicos, Banco Wiese Sudameris (ahora Scottiabank), mayo 2004, Lima. BWS (2005) La industria de cemento en el Per: Favorables perspectivas de crecimiento en el largo plazo, Departamento de Estudios Econmicos, Banco Wiese Sudameris (ahora Scottiabank), Lima. CRDENAS, M., C. MEJA y F. GARCA (2007) La industria del Cemento, Fedesarrollo, Documento de trabajo No. 33, Enero de 2007, Colombia. CARRASCO, G. (2009) Informe elaborado para la Gerencia de Estudios Econmicos INDECOPI sobre la Industria de Cementos, Documento de consultora, Mimeo. Mayo 2009. CEMENTOS LIMA (2009) Memoria Anual 2008, Cementos Limas S.A., Lima. 26

CLASS&ASOCIADOS (2009a) Fundamentos de clasificacin de riesgo: Yura S.A., Class&Asociados Clasificadora de riesgo, Informacin a diciembre 2008, Lima. CLASS&ASOCIADOS (2009b) Fundamentos de clasificacin de riesgo: Cemento Lima S.A., Class&Asociados Clasificadora de riesgo, Informacin a marzo 2009, Lima. DNP (s.f.) Cemento y sus aplicaciones, Departamento nacional de Planeacin DNP. EQULIBRIUM (2009) Cemento Andino S.A., Inforem de Clasificacin, Equilibrium Clasificadora de Riesgo, diciembre de 2009.. ICPC (2008) Evolucin reciente del sector cementero en Amrica Latina, Jefatura de Investigaciones Instituto Colombiano de Productores de Cemento, Julio de 2008, Bogot. MINEM (2005) GUIAS MINERAS 2005 MINERIA NO METALICA, Direccin de Promocin y Desarrollo Minero, Sub Sector Minera, Ministerio de Energa y Minas MINEM, julio 2005, Lima. PROEXPORT (1999) Perfil de Mercado: Cemento en Chile, Proexport Colombia, inteligencia de mercados, Bogot. RATING PCR (2009) Cementos Pacasmayo S.A.A., Rating PCR, mayo de 2009. SCOTIABANK (2006) Reporte Empresarial: cementos Pacasmayo S.A.A., Departamento de Estudios Econmicos, Banco Scotiabank, octubre de 2006, Lima.

27

ANNEX N 1 Location of the non-metallic reservoirs in Peru

28

ANNEX N 3

Some basic requirements established by the Peruvian government for the exploitation of mines:

For quarrying nonmetallic requires a mining concession granted by the Peruvian government. To this end, the holder must apply for such concession to the Institute of Geology, Mining and Metallurgical INGEMMET (ex-National Institute of Concessions and Mining Cadastre-INACC) through the filing of a request the payment of Effective Law for the first year (which is equivalent to USD 3.00 per acre requested that in case of small miners and artisanal miners were reduced to USD 1.00 and USD 0.5 per hectare, respectively), and payment of processing fee (equivalent to 10% of the UIT.) Once approved by the INGEMMET, the Ministry of Energy and Mines (MINEM) makes public assessment and the approval through a ministerial resolution.

Mining concessions grant the holder the right to exploration and exploitation of mineral resources in the subsoil of the area granted. Such concessions may include extensions 100 to 1,000 hectares in grid or set of adjacent grids by at least one side.

Furthermore, the requests for areas designated for urban expansion goals must also be approved by the provincial municipality under its jurisdiction with the corresponding complementary technnical information.

For quarrying for building materials the right holder shall comply with the requirements stipulated in the Ministerial Resolution No. 188-97-EM, which are related to the limits of depth, height, length, volume and even time In order to avoid damage to the ecosystem and the population.

The working of quarries to building materials the right holder shall comply with the requirements stipulated in the Ministerial Resolution No. 188-97-EM, which are related to the limits of depth, height, length, volume and even time In order to avoid damage to the ecosystem and the population.

29

ANNEX N 4

Cementos Pacasmayo DINO and Dinoselva Iquitos are subsidiaries of Cementos Pacasmayo that are responsible for distribution and marketing of building materials including cement. DINO has 11 branches and 72 distribution partners. Supported by selling products Pacasmayo, DINO offers through its dealers, other benefits to users in the form of technical advice. About 67% of total sales invoiced by DINO in 2008 are explained by the products supplied by Cementos Pacasmayo. Different situation occurs with Dinoselva, where 92.5% of sales products offered come from other companies, and only 7.5% corresponded to the products supplied by Cementos Selva. In 2001, Dino was reported to the Free Competition Commission (CLC) for alleged abuse of dominant position in the forms of price discrimination and tied sales by the companies Warehouse Santa Beatriz SRL, SRL Eleodoro Ramos Quiroga Quiroga and Trade SRL Piura market. After a market investigation, the CLC declared the complaint to Dino unfounded because the company contracts were not coercive, since there was a space before deciding to join or not, also did not show sales practices tied as the products sold were related to general construction market, a sector that is dedicated to the complaint. By signing the affiliation agreement, Dino gives free use of its logo, provides the member of the company's advertising material, commercial and technical supports and offers special prices for the purchase of their products. The affiliate, on the other side, undertakes to buy minimum amounts of products exclusively to Dino, serves as an advertising medium Dino brand, and provides information on their amount of sales, stocks and financial statements. Cementos Pacasmayo has the following subsidiaries:

30

Cementos Selva SAC, responsible for the production of cement in the northeastern part of Peru, Distribuidora Norte Pacasmayo ERL (DINO) began operations in 1995 to sell building materials. At the time, this distributor has 11 branches and a network of 70 distribution partners, covering 32 cities of Peru. Cementos Pacasmayo, also has ready-mix plants in three northern cities (Pacasmayo, Trujillo and Piura) and in the Jungle, plants used for the production of bricks for different uses (roof, wall and floor)and also has six plants of concrete (Piura, Chiclayo, Cajamarca, Pacasmayo, Trujillo and Chimbote each one with necessary equipment as units concrete mixers and truck providers. Iquitos Dinoselva also involved in the distribution and marketing of building materials (cement and products derived from it).

Tinku Generation S.A.C constituted in April 2008 and is dedicated to project development and investment, particularly in the energy sector, hydrocarbons, infrastructure, transportation, and communications, among others. It has also beendesigned to develop activities of generation, transmission and marketing of electric power in general.

SA CORIANTA founded in 1994 dedicated to prospecting, exploration and operation of concessions and mining rights in Peru, which provides raw materials to CementosPacasmayo.

Cementos Lima Cementos Lima commercializes its products in paper bags (42.5 kg bag) and bulk. The type of distribution depends on the type of cement, Portland cement sold in bags (brands and ATLAS SOL) and the rest (Portland cement type I, IP, II and type V) in bulk. It is noteworthy that Type I Portland cement accounts for 75% of sales of the company, and it is distributed through the channel hardware dealer using the modern form (self-service stores) and the traditional mode (independent hardware stores and hardware stores Progresol Network), modalities through which sold 3% and 97% of GDP, respectively.

31

Also, the Portland cements which are sold by the Industrial Canal are sold in bulk (by the advantages in handling and efficiency of storage and use) to companies which produce ready mixed concrete and other cement products. By implementing Progresol Network Hardware Stores, Cementos Lima enhanced its retail channel; Progresol currently has more than 120 independent subdistributors dealers present in Lima (covering up to Casma on the north and Nazca on the south), Ancash, Ica, Ayacucho and Apurimac departments who collectively consume the 50.2% of the cement sold domestically. By Red Progresol, Cementos Lima can ensure products for the consumers with the exact weight (42.5 kg) and mantain direct contact with the representatives (owners). In this sense, Cementos Lima asserts that the members of its distribution system can access higher profit margins, to information systems and billing, and training the point of sale for master builders and self builders. Also, to strengthen its presence, Cementos Lima has implemented a sales commission system, which is granted whenever sales exceed a certain number of sacks in a period of time. This mechanism encourages, in turn, the hardware to implement their own sales strategies and expand its scope. At the time, only the department of Lima (among the list of Hardware Stores available in the directory of Yell Peru), it has been counted 132 establishments affiliated to theRed Progresol, of whom 103 are located in Lima and distributed in 36 of its 43districts. With more than seven branches in San Martin de Porres, St. Juan deLurigancho, La Victoria, San Juan de Miraflores and Villa Mara del Triunfo. Cementos Lima has the following subsidiaries: Concrete and Allied Investment SA-INVECO, who also owns UNICON, both dedicated to the sale of concrete Atocongo electrical generation, which provides electricity to Cementos Lima Conchan Customs Warehouse which also provides storage services to the cement factory El Platanal Electric Company Skanon Investments Inc. and through it to Drake Cement LLC, which operate in the United States

32

Prefabricated Andean Peru SAC, where Cementos Lima owns 50% of the shares. Lurin Transport S.A and Conchn Naviera SA

Cementos Yura Due to the announced entry of Cementos Otorongo (a subsidiary of Portugal Cimento CIMPOR) and Cementos interoceanic the south - which would begin operations in 2010 and 2011 respectively, which together would produce 2.25 million MT per year (twice what is currently Yura and Cementos Selva produced together) - Yura will invest U.S. $ 500 million to double its current production capacity to attend growing domestic demand and to export its product to Brazil through the Inter-Oceanic Highway, also the economic group Rodriguez Banda (Gloria group), as well as Cementos Lima, has begun its distribution network, "TO Build", a mechanism which seeks loyalty of customers and retailers. Through the system of distribution, the company's strategy has not only supported the direct delivery of its product (ensuring freshness and quality), but seeks to retain customers through the implementation of a system which gives them access to credit; to do this the company has signed agreements with local banks in Arequipa and Cusco. Through its network affiliation, the company also offers to the dealers the conditioning of their locals and training in construction issues. Yura Cements, which at the same time is a subsidiary of the Consorcio Cementero del Sur and has the following companies in which hold a 93.77% and 99.98% respectively: Cemento Sur SA (Cesur), founded in 1952 and dedicated to primarily at the production and sale of cement and lime. This activity also includes the extraction, processing and transport of metallic and nonmetallic minerals from its quarries to its production plant in Puno.

33

Cachimayo INDUSTRIES S.A.C founded in 2002 and devoted primarily to manufacturing and selling of various types of ammonium nitrate at its plant in Cuzco.

34

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Hamdard Medicine List 2019Document4 pagesHamdard Medicine List 2019DrRaghvendra Kumar SinghNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- 30 Iconic Velomobile Designs From The Past 85 YearsDocument26 pages30 Iconic Velomobile Designs From The Past 85 YearsJulian Aleuy Santana100% (3)

- BOQ FinancialDocument26 pagesBOQ FinancialRajesh ChowhanNo ratings yet

- S.O.P.E.P. + S.M.P.E.P. emergency plansDocument10 pagesS.O.P.E.P. + S.M.P.E.P. emergency plansmavericksailor100% (1)

- State-of-the-Art of An Induction Furnace: Design, Construction and ControlDocument7 pagesState-of-the-Art of An Induction Furnace: Design, Construction and ControlSunil Kumar DwivediNo ratings yet

- State-of-the-Art of An Induction Furnace: Design, Construction and ControlDocument7 pagesState-of-the-Art of An Induction Furnace: Design, Construction and ControlSunil Kumar DwivediNo ratings yet

- State-of-the-Art of An Induction Furnace: Design, Construction and ControlDocument7 pagesState-of-the-Art of An Induction Furnace: Design, Construction and ControlSunil Kumar DwivediNo ratings yet

- Registered ContractorsDocument19 pagesRegistered ContractorsAnuraj VakavayalilNo ratings yet

- Break Even Analysis of Mining ProjectsDocument60 pagesBreak Even Analysis of Mining ProjectsAnil Kumar100% (1)

- Demag Standard Crane Manual Highlights EfficiencyDocument160 pagesDemag Standard Crane Manual Highlights Efficiencylcorao100% (1)

- European Standards For Metallic MaterialsDocument16 pagesEuropean Standards For Metallic MaterialsClaudia Mms0% (1)

- Ship ParticularsDocument5 pagesShip ParticularsdonmkeNo ratings yet

- Cement Formula BookDocument47 pagesCement Formula Bookgvrr195482% (11)

- Pre-Feasibility Study For The Development of A Mini Cement Plant in ColombiaDocument158 pagesPre-Feasibility Study For The Development of A Mini Cement Plant in ColombiaSunil Kumar Dwivedi100% (3)

- Special Mission Aircraft Briefing: Air Ambulance Configurations for Hawker and Beechcraft ModelsDocument22 pagesSpecial Mission Aircraft Briefing: Air Ambulance Configurations for Hawker and Beechcraft ModelsBernardoNo ratings yet

- If-CC-TMT Consumption Factor - Gupta JiDocument18 pagesIf-CC-TMT Consumption Factor - Gupta JiSunil Kumar DwivediNo ratings yet

- Bill For Engineering and DesignDocument1 pageBill For Engineering and DesignSunil Kumar DwivediNo ratings yet

- Project - Report Libre UreaDocument65 pagesProject - Report Libre UreaSunil Kumar DwivediNo ratings yet

- Five Point Someone1 PDFDocument153 pagesFive Point Someone1 PDFIonut MihaiNo ratings yet

- Induction Furnace - A ReviewDocument9 pagesInduction Furnace - A ReviewUZAIR.KZNo ratings yet

- Induction Furnace - A ReviewDocument9 pagesInduction Furnace - A ReviewUZAIR.KZNo ratings yet

- 1924 January The Adventure of The Sussex VampireDocument11 pages1924 January The Adventure of The Sussex VampireSunil Kumar DwivediNo ratings yet

- Csna14828enc 001Document72 pagesCsna14828enc 001Sunil Kumar DwivediNo ratings yet

- Developing A Minerals Processing Project - Thomas W. Hedrick P.E.Document16 pagesDeveloping A Minerals Processing Project - Thomas W. Hedrick P.E.Sunil Kumar DwivediNo ratings yet

- Five Point Someone1 PDFDocument153 pagesFive Point Someone1 PDFIonut MihaiNo ratings yet

- 96 10 30Document38 pages96 10 30Sunil Kumar DwivediNo ratings yet

- Dps Talent Exam Papers 2013-2014Document16 pagesDps Talent Exam Papers 2013-2014Sunil Kumar DwivediNo ratings yet

- 96 10 30Document38 pages96 10 30Sunil Kumar DwivediNo ratings yet

- Affidavit by The Student GuardianDocument4 pagesAffidavit by The Student GuardianSunil Kumar DwivediNo ratings yet

- TATA BFG Operator Training R1Document56 pagesTATA BFG Operator Training R1Rupesh VermaNo ratings yet

- APP Booklet of Cement TechnologyDocument232 pagesAPP Booklet of Cement TechnologySunil Kumar DwivediNo ratings yet

- TATA BFG Operator Training R1Document56 pagesTATA BFG Operator Training R1Rupesh VermaNo ratings yet

- GATE Electrical Engineering - 2008Document24 pagesGATE Electrical Engineering - 2008Pramod ReddyNo ratings yet

- Ratio Analysis PROJECT in Steel PlantDocument89 pagesRatio Analysis PROJECT in Steel PlantSunil Kumar DwivediNo ratings yet

- 09 Ironmaking MM BF Burden CalculationDocument1 page09 Ironmaking MM BF Burden CalculationSunil Kumar Dwivedi100% (1)

- OTE Outotec Sintering Technologies Eng WebDocument8 pagesOTE Outotec Sintering Technologies Eng WebSunil Kumar DwivediNo ratings yet

- 7075 Aluminum Sheet SuppliersDocument13 pages7075 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- LNG W000370451 enDocument37 pagesLNG W000370451 enClaude BouillotNo ratings yet

- CASR Part 135 Amdt. 11 - 135.329 Flight RecorderDocument3 pagesCASR Part 135 Amdt. 11 - 135.329 Flight RecorderHarry Nuryanto100% (1)

- International Agribusiness Park PresentationDocument16 pagesInternational Agribusiness Park PresentationWatertown Daily TimesNo ratings yet

- Lista MDocument240 pagesLista MMaria MagicdNo ratings yet

- CodeDocument5 pagesCodeAlbert MusabyimanaNo ratings yet

- Document 1Document26 pagesDocument 1dom100% (1)

- Chapter 20 - PPT OutlineDocument5 pagesChapter 20 - PPT OutlineJanice TangNo ratings yet

- Lec 5 Introduction To Railway PDFDocument40 pagesLec 5 Introduction To Railway PDFIrfanButtNo ratings yet

- Transportation, Energy and EnvironmentDocument19 pagesTransportation, Energy and EnvironmentDr. Akepati Sivarami ReddyNo ratings yet

- Selecting and Distributing Fire ExtinguishersDocument28 pagesSelecting and Distributing Fire ExtinguishersEhab SaadNo ratings yet

- A424A424M-09a Standard Specification For Steel, Sheet, For Porcelain EnamelingDocument3 pagesA424A424M-09a Standard Specification For Steel, Sheet, For Porcelain Enamelingtjt4779100% (1)

- RLT 01 Ba File 2Document14 pagesRLT 01 Ba File 2colorado2014No ratings yet

- Coatema Prepreg EquipmentDocument30 pagesCoatema Prepreg EquipmentyigitilgazNo ratings yet

- Duplex Stainless Grade DatasheetDocument12 pagesDuplex Stainless Grade DatasheetLuan NguyenNo ratings yet

- Studies On Tractor Related Injuries inDocument8 pagesStudies On Tractor Related Injuries insln_rjNo ratings yet

- Lysaght Roofing SolutionDocument16 pagesLysaght Roofing SolutionardikurniawanNo ratings yet

- Cooling CurvesDocument7 pagesCooling CurvesAvinash RampariyaNo ratings yet

- 【Brochure】Sinoteam Logistics Co.,Ltd - ChinaDocument9 pages【Brochure】Sinoteam Logistics Co.,Ltd - ChinaHarveybw LeeNo ratings yet

- Panama Real Estate, Azuero Peninsula.Document34 pagesPanama Real Estate, Azuero Peninsula.Cubita Wyndham Grand ChitreNo ratings yet