Professional Documents

Culture Documents

Aminai Katiluose

Uploaded by

Donatas Bertasius0 ratings0% found this document useful (0 votes)

52 views34 pageslkl;

Original Title

aminaiKatiluose

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlkl;

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views34 pagesAminai Katiluose

Uploaded by

Donatas Bertasiuslkl;

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 34

Do Neutralizing Amines

Have a Role in the

Treatment of High Purity

Boiler Feedwater?

J ames Robinson

Luis Carvalho

Anthony Rossi

GE Power & Water

Volatile Alkaline Treatments Are

Commonly Used To Treat High

Purity Feedwater

Boost Feedwater and Condensate pH

Boost pH in AVT Treated Boiler Water

Volatile Alkaline Treatments

Ammonia

Neutralizing Amines

Morpholine

Cyclohexylamine

Diethylaminoethanolamine

Methoxypropylamine

Ethanolamine

Advantages of Neutralizing

Amines

Distribution of Amines in 2- Phase Systems

Ability of Amines to Boost pH at the

Temperature of the System.

Steam-Water Distribution Ratio as a Function of

System Pressure -- Water pH

25C

= 9.0

0

1

2

3

4

5

6

7

0 500 1000 1500

System Pressure, PSIG

D

i

s

t

r

i

b

u

t

i

o

n

R

a

t

i

o

Ammonia

Cyclohexylamine

Ethanolamine

Common 2-Phase Systems

Boilers

Flash tanks

Heat Exchangers

Lines mixtures of steam and condensate

pH of Pure Water as a Function of Temperature

0

1

2

3

4

5

6

7

8

25 50 75 100 125 150 175 200

Temperature (C)

p

H

Increase of pH at Temperature Compared to that of

Pure Water as a Function of Boiler Operating

Pressure When pH at 25 C is Adjusted to 9.0 with

Various Alkalizing Agents

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 500 1000 1500

System Pressure, PSIG

p

H

I

n

c

r

e

a

s

e

O

v

e

r

P

u

r

e

W

a

t

e

r

Ammonia

Cyclohexylamine

Ethanolamine

Where are the differences in

distribution ratio and pH at

temperature important?

CMS

Evaluates all constituents in the system

Calculates at temperature

Acid dissociation constants

Vapor-liquid distribution constants

Uses flow data to project the concentrations

in the liquid and the vapor phases

Calculates pH

25C

and pH

t

of each stream

LP Evaps in Gas Turbine HRSGs

Many preclude the use of phosphate or caustic for

liquid phase pH control

Volatile chemicals used for pH control

2-phase FAC became a common problem

LP Evap Flow Accelerated

Corrosion Principally in the

Risers and Steam-Water

Separators

44

4/20/2010

Feedwater

3 ppb CO

2

530 ppb NH

3

pH

25

= 9.2

Blowdown

pH

25

= 9.1

pH @T = 6.5

Riser Liquid

pH

25

= 9.0

pH @T = 6.4

LP Evap Steam

NH

3

= 1990 ppb

pH

25

= 9.6

FAC

100 psig LP evaporator

Blowdown = 90% of feedwater

Replacing Ammonia with ETA

Reduces 2-Phase FAC!

45

4/20/2010

Feedwater

3 ppb CO

2

1500 ppb ETA

pH

25

= 9.2

Blowdown

pH

25

= 9.2

pH @T = 6.6

Riser Liquid

pH

25

= 9.3

pH @T = 6.7

LP Evap Steam

pH

25

= 7.8

100 psig LP evaporator

Blowdown = 90% of feedwater

What if we increase the feed of

ammonia to produce the same

pH @T (6.7) in the riser as we

have with ETA?

46

4/20/2010

Feedwater

3 ppb CO

2

2300 ppb NH

3

pH

25

= 9.6

Blowdown

pH

25

= 9.5

pH @T = 6.8

Riser Liquid

pH

25

= 9.4

pH @T = 6.7

LP Evap Steam

NH

3

= 9890 ppb

pH

25

= 9.9

100 psig LP evaporator

Blowdown = 90% of feedwater

45

4/20/2010

Feedwater

3 ppb CO

2

1200ppb MEA

300 ppb NH

3

pH

25

= 9.3

Blowdown

pH

25

= 9.2

pH @T = 6.6

Riser Liquid

pH

25

= 9.3

pH @T = 6.7

LP Evap Steam

pH

25

= 9.4

100 psig LP evaporator

Blowdown = 90% of feedwater

High Pressure Evaporators

47

4/20/2010

Feedwater

20 ppb CO

2

5 ppb Cl

pH

25

= 9.4

Cat Cond = 0.17 uS/cm

0.5% Blowdown

1 ppm Cl

Riser Liquid

1500 PSIG Steam

48

3/30/2010

Fe

3

O

4

Ammonia Feedwater Treatment to pH of 9.4

10 Concentrations Under Deposit

Porous Iron Deposit

Water

Steam

Heat

NH

3

=560 ppb

Cl = 1000 ppb

pH

25

= 8.26

pH

t

= 4.95

pH

25

= 3.7

pH

t

= 3.8

49

3/30/2010

Fe

3

O

4

ETA Feedwater Treatment to pH = 9.4

10 Concentrations Under Deposit

Porous Iron

Water

Steam

Heat

MEA =9500 ppb

Cl = 1000 ppb

pH

25

= 9.6

pH

t

= 6.0

pH

25

= 9.4

pH

t

= 5.3

48

3/29/2010

Fe

3

O

4

Ammonia Feedwater Treatment to pH of 9.4

10 Concentrations Under Deposit

TSP to 0.5 ppm PO4 + 0.5 ppm NaOH

Porous Iron Deposit

Water

Steam

Heat

NH

3

=400 ppb

Cl = 1000 ppb

pH

25C

= 8.6

pH

t

= 5.4

pH

25C

= 4.1

pH

t

= 4.4

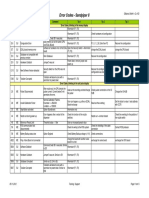

Treatment

Program

pH

t

in Boiler

Tube

pH

t

Beneath

Deposit

Low-Level

Phosphate-NaOH-

NH

3

5.4 4.4

AVT - ETA

6.0 5.7

5 ppb Acidic Chloride Contamination

of Boiler Feedwater

50

3/24/2010

Fe

3

O

4

Ammonia Feedwater Treatment to pH = 9.4

TSP to 6 ppm PO

4

in Boiler Water

10 Concentrations Under Deposit

Porous Iron

Water

Steam

Heat

Cl = 1000 ppb

pH

25

=9.8

pH

t

=7.7

pH

25

= 10.4

pH

t

8.7

Steam Turbines

Steam Inlet

CO

2

20 ppb

Chlorides 5 ppb

pH

25C

= 9.4

1

st

Condensate

Temperature 212F

Effect of % Steam Condensation on the pH at

Temperature of the First Turbine Condensate

(St eam Inlet - pH

25C

= 9.4 f or Ammonia and ETA, Chlor ide = 5 ppb)

0

2

4

6

8

10

0.001 0.01 0.1 1

Percent of Steam Condensed in the

First Condensate

p

H

a

t

T

e

m

p

e

r

a

t

u

r

e

Pure Water

Ammonia

ETA

Limitation of Neutralizing

Amines

Thermal Decomposition

Boilers

Superheaters and reheaters

Thermal Decomposition Products

Carbon dioxide

Formate, Acetate, Proprionate, etc.

Ammonia

Affect of Decomposition

Products on Corrosion

Carbon dioxide corrosion problems are well

known

Limited reports of organic acid corrosion as

well

Priority for control of this corrosion is to

maintain pH throughout.

Affect of Decomposition

Products on Cation Conductivity

Carbon dioxide and organic acids contribute

to cation conductivity

Reduces effectiveness for detecting

feedwater contamination

Exceeds turbine manufacturers steam purity

specifications

Steam Purity Monitoring

Turbine manufacturers specify steam cation

conductivity limits, usually of 0.2 or 0.3 uS/cm.

0.2 to 0.3 uS/cm is equivalent to 16 to 25 ppb of

chloride in otherwise pure water!

Degassed cation conductivity measurement is

gaining in popularity

No form of cation conductivity detects caustic

contamination

Conclusions

Yes, neutralizing amines provide improved

corrosion protection compared to ammonia

in many applications

Thermal instability limits amine

applications mostly because of the effect on

cation conductivity measurements

Improved steam purity monitoring methods

are needed

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Rover V8 Fuel Injection SystemsDocument16 pagesRover V8 Fuel Injection SystemsClint Cooper100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Free Energy Devices Zero PDocument8 pagesFree Energy Devices Zero PibeskosNo ratings yet

- Lifeboat Engine Operation Manual 380JDocument29 pagesLifeboat Engine Operation Manual 380JDuarte100% (2)

- Armeen 18 DDocument5 pagesArmeen 18 DDonatas BertasiusNo ratings yet

- WARNING SIGNS OF KICKSDocument45 pagesWARNING SIGNS OF KICKSMartin RiwuNo ratings yet

- Steam and Water Analysis System (SWAS) An OverviewDocument16 pagesSteam and Water Analysis System (SWAS) An OverviewDonatas Bertasius100% (1)

- wph11 01 Que 20230111Document28 pageswph11 01 Que 20230111Sanjeev NNo ratings yet

- Beer Processing SolutionsDocument28 pagesBeer Processing SolutionsDonatas BertasiusNo ratings yet

- Unofficial Errata NewDocument194 pagesUnofficial Errata NewjohnNo ratings yet

- Hach 8009 Zinc Ed 08Document6 pagesHach 8009 Zinc Ed 08Beth AlvaradoNo ratings yet

- Darco h2s 8 Ways BrochureDocument8 pagesDarco h2s 8 Ways BrochureDonatas BertasiusNo ratings yet

- DR 890 Colorimeter Procedures ManualDocument614 pagesDR 890 Colorimeter Procedures ManualArmin MajerNo ratings yet

- Do Wi One ChangeDocument210 pagesDo Wi One ChangeDonatas BertasiusNo ratings yet

- 27 36Document6 pages27 36Donatas BertasiusNo ratings yet

- 2 Electrodes Conductivity Sensor K 0,01 3/4NPT Thread With TDocument1 page2 Electrodes Conductivity Sensor K 0,01 3/4NPT Thread With TDonatas BertasiusNo ratings yet

- Total Organic Carbon Measurement: Portable, Real-Time, ContinuousDocument8 pagesTotal Organic Carbon Measurement: Portable, Real-Time, ContinuousDonatas BertasiusNo ratings yet

- Industrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDocument3 pagesIndustrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDonatas BertasiusNo ratings yet

- Doc316 53 01053Document8 pagesDoc316 53 01053Veronica BoydNo ratings yet

- Monitor Sodium levels with POLYMETRON 9245 AnalyserDocument2 pagesMonitor Sodium levels with POLYMETRON 9245 AnalyserDonatas BertasiusNo ratings yet

- Industrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDocument3 pagesIndustrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDonatas BertasiusNo ratings yet

- Reliable Online Silica Analyser Saves Time & EffortDocument2 pagesReliable Online Silica Analyser Saves Time & EffortDonatas BertasiusNo ratings yet

- Chemical Guidelines For Water / Steam CycleDocument47 pagesChemical Guidelines For Water / Steam CycleparatonerqNo ratings yet

- Injection and Sample Quills: Specifications & FeaturesDocument2 pagesInjection and Sample Quills: Specifications & FeaturesDonatas BertasiusNo ratings yet

- Man Turbin No S Reika LV ImaiDocument8 pagesMan Turbin No S Reika LV ImaiDonatas BertasiusNo ratings yet

- Imac Hp336 LDocument2 pagesImac Hp336 LDonatas BertasiusNo ratings yet

- Polymetron 9582 Dissolved Oxygen: User ManualDocument28 pagesPolymetron 9582 Dissolved Oxygen: User ManualDonatas BertasiusNo ratings yet

- Hot FiltrationDocument8 pagesHot FiltrationDonatas BertasiusNo ratings yet

- 5 Epa As Course Coag and PPT Processes YujungchangDocument63 pages5 Epa As Course Coag and PPT Processes YujungchangDonatas BertasiusNo ratings yet

- AWT2009 Pres - Enviro Brom 20LDocument25 pagesAWT2009 Pres - Enviro Brom 20LDonatas BertasiusNo ratings yet

- GE Polyamine TechnologyDocument17 pagesGE Polyamine TechnologyDonatas BertasiusNo ratings yet

- Ammonia StrippingDocument15 pagesAmmonia StrippingFaiqoh NahareyNo ratings yet

- Cond CO2Document18 pagesCond CO2Donatas BertasiusNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentDonatas BertasiusNo ratings yet

- Exploded ScorpionT 10Document1 pageExploded ScorpionT 10Donatas BertasiusNo ratings yet

- 33 12 530 Adjusting BacklashDocument2 pages33 12 530 Adjusting BacklashDonatas BertasiusNo ratings yet

- V-3111-002-A-711 - 2 Method Statement For Water Well WorkDocument14 pagesV-3111-002-A-711 - 2 Method Statement For Water Well WorkWidya PrasetyaNo ratings yet

- B S T Year 5Document9 pagesB S T Year 5INCREASE & ABUNDANT SCHOOLSNo ratings yet

- Vat Rates enDocument27 pagesVat Rates enpacocastroNo ratings yet

- Bài Tập Đọc Hiểu Tiếng Anh Lớp 9 HKIIDocument4 pagesBài Tập Đọc Hiểu Tiếng Anh Lớp 9 HKIIPhương Thu Vũ ThịNo ratings yet

- LSA47 3-Install&MaintenDocument28 pagesLSA47 3-Install&MaintenCao HieuNo ratings yet

- HuwaSan BrochureDocument8 pagesHuwaSan BrochureWilly CalmaNo ratings yet

- Solar Electric Tiffin Box (1) - 2Document36 pagesSolar Electric Tiffin Box (1) - 2imrashi18kNo ratings yet

- IEC Fuses 5x20 Low Breaking Capacity 5ST Time Lag: DimensionsDocument2 pagesIEC Fuses 5x20 Low Breaking Capacity 5ST Time Lag: DimensionsrNo ratings yet

- ONGC Ar201718Document454 pagesONGC Ar201718Vrind JainNo ratings yet

- Chapter 3 - Work Energy and PowerDocument22 pagesChapter 3 - Work Energy and PowerKenny Jay LabianoNo ratings yet

- BBBV3 ForegroundReading Solar UPS MarineDocument7 pagesBBBV3 ForegroundReading Solar UPS MarineSaibal BhattacharyyaNo ratings yet

- Master Plan For Delhi: Dr. Mayank MathurDocument40 pagesMaster Plan For Delhi: Dr. Mayank MathurJay PrakashNo ratings yet

- ATSDocument8 pagesATSserban_elNo ratings yet

- Compressed Gas Systems: Ee-527: MicrofabricationDocument34 pagesCompressed Gas Systems: Ee-527: MicrofabricationsambasivammeNo ratings yet

- 9 Electronics TDocument44 pages9 Electronics TBieonWongNo ratings yet

- Hyundai XG350 3.5L V6 Specs & TolerancesDocument185 pagesHyundai XG350 3.5L V6 Specs & TolerancesAngie Bravo CangasNo ratings yet

- GM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesDocument55 pagesGM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesBrian NormanNo ratings yet

- Curved Data KEW PUMP KSSE 3 1Document1 pageCurved Data KEW PUMP KSSE 3 1Haryono SyalimNo ratings yet

- PH1031 Wednesday Batch July-Dec 2016Document2 pagesPH1031 Wednesday Batch July-Dec 2016devajithNo ratings yet

- Miroljub Todorović - ApeironDocument25 pagesMiroljub Todorović - Apeiron"Mycelium" samizdat publishersNo ratings yet

- Presentation On Salient Features of The Electricity Act 2003 1231332387635957 1Document14 pagesPresentation On Salient Features of The Electricity Act 2003 1231332387635957 1Anonymous m8oCtJBNo ratings yet

- Cooling Tower Research PaperDocument13 pagesCooling Tower Research PaperBhaskar KumarNo ratings yet

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocument5 pagesTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNo ratings yet

- Aeroshell Ascender: Performance, Features & Benefits Main ApplicationsDocument3 pagesAeroshell Ascender: Performance, Features & Benefits Main ApplicationsRicardo LacskoNo ratings yet