Professional Documents

Culture Documents

Hanshin Service Manual For Hs-1321 Hs-2519 Hs-9041

Uploaded by

Kaustubh ParkerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hanshin Service Manual For Hs-1321 Hs-2519 Hs-9041

Uploaded by

Kaustubh ParkerCopyright:

Available Formats

HANSHIN Service Manual HS 1321 / HS 2519 / HS 9041

HS 1321

HS 9041

HS 2519

Er. Kaustubh Kishor Parkar

ERROR!!

DONT WORRY. WE ARE HERE TO HELP YOU OUT.!!

Er. Kaustubh Kishor Parkar

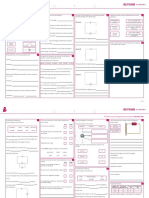

List of Errors with Description:

Error code

Description

Error 1

Water in reservoir is inadequate.

Error 2

Overheated during cycle.

Error 3

Latch unlock during cycle.

Error 4

Chamber temperature deviation has exceeded the allowable range.

Error 5

Filling time has exceeded 5 minutes.

Error 6

Heating time has exceeded 60 minutes.

Er. Kaustubh Kishor Parkar

Steps to Resolve Errors:

Error 1: Water in reservoir is insufficient for completion of cycle. 1. Inadequate water. Fill the reservoir tank with distill water till the water level indicator shows full indication. (All green LEDs are illuminated and three beep sounds are heard).

2. Float Ball problem. Check the condition of the float ball. Clean the float ball surface. Observe whether water is entering the float ball. If water enters float ball then it couldnt float. Replace or weld the float ball. Check whether the float ball is stuck at the bottom of the reservoir tank.

3. Water level sensor problem. Check the water level sensor and calibrate the same, if needed.

4. Suggest to replace the distill water in the reservoir tank once a week to avoid reservoir tank to base from getting affect.

Er. Kaustubh Kishor Parkar

Error 2: Overheated during cycle.

1. Overheat Sensor Problem. In old model the manual reset button is missing. In this case, we have to short two terminals of the overheat sensor after turning ON the machine.

Check the position of overheat sensor inside the chamber.

2. Fill solenoid valve problem. Water entering the chamber is less. This can be associated with either water level sensor or the fill valve. Clean the fill solenoid valve.

3. Heater coil problem. Check whether the heater coil is not raised above the desired height from the base of the chamber. The water entering the chamber must soak the heater coil. Ideal distance should be around 1 mm.

Er. Kaustubh Kishor Parkar

4. Solenoid valve problem. If Error 2 occurs after temperature reaches 100C then check the fill solenoid valve and vent solenoid valve. If there is bubbling from the bottom of the reservoir tank then fill solenoid valve have problem. If water leaks from the opening of condensing coil then vent valve have problem. Error can be diagnosed after 20-35 minutes.

5. Water level sensor problem. Adjust the water level sensor.

6. Heater starts heating after turning ON the machine. Turn OFF the machine. Remove the connection wires on triac and check resistance between the G and T1 terminal of triac. It should be around 65. The value between T2 and G, and T1 and T2 should be ZERO. Error can be diagnosed after 35-45 minutes. Can be caused while sterilizer in the STERILE mode. .

Er. Kaustubh Kishor Parkar

Error 3: Latch unlocked during cycle. 1. Door gasket problem. Check the door gasket. Stretch the door gasket if it has shrunk and attached it properly again. Replace it if it is in bad condition. Usually, if the door gasket is not proper then error 3 is displayed in HEAT mode at a temperature of about 120C. 2. Door lock. After closing the door, check whether the door handle is at approximately 90 and a click sound is heard while moving the door handle downwards. 3. Door switch problem. Check the door switch connection.

Er. Kaustubh Kishor Parkar

Error 4: Chamber temperature deviation has exceeded the allowable range. If the temperature variation is +/- 3C Error 4 is displayed. 1. Temperature Sensor problem. If the temperature increases suddenly without following the gradual increase procedure then temperature sensor has problem. 2. PCB/Triac problem. Temperature increases gradually but error-4 is displayed then check PCB/Triac. There might be electricity problem. Suggest a power stabilizer and check again. If problem persist then PCB/Triac has problem. 3. Water level sensor problem. Adjust the water level sensor. 4. Steam Trap problem. Function of steam trap is to remove air inside the chamber. Air inside the chamber is not suitable for sterilization as it blocks the surface of the instruments from getting sterilized. Check the pressure displayed. If it is not within the normal range then steam trap has problem.

Er. Kaustubh Kishor Parkar

Error 5: Filling time has exceeded 5 minutes. Normally, around 2 minutes is sufficient to complete FILL mode. 1. Fill solenoid valve problem. Check supply between black and yellow wire on the main PCB. It should show 230V during FILL mode, if not then replace the fill valve. Clean the fill solenoid valve.

2. Fill line problem. Water filling is obstructed by dirt during the FILL mode. Clean the fill pipe, connected to the chamber through the fill solenoid valve. Suggest to refill the reservoir tank with new distill water once in a week.

Er. Kaustubh Kishor Parkar

Error 6: Heating time has exceeded 60 minutes. Normally desired temperature is achieved within 20-25 minutes in the first cycle.

1. Temperature Sensor Problem. The temperature inside the chamber is not sensed properly by the temperature sensor. Remove all the tie-up connected with temperature sensor. Remove the connector from the PCB. Disassemble the Temperature Sensor using spanner, clean it and fix it back properly. Connect the connector to the PBC.

2. Water Level Sensor Problem. Usually Error-6 is displayed at 120C - 130C if it is associated with water level sensor. Adjust the water level sensor.

3. Steam Trap Problem. Check the pressure displayed. If it is not within the normal range then steam trap has problem.

4. Heater Coil Problem. Check the heater coil condition. If temperature does not exceed 60C - 70C then heater coil has problem.

5. Triac problem. Heater coil doesnt get the supply. Check the supply on the triac. Usually the temperature doesnt increase at all and remains 30C for 60minutes if triac has problem.

Er. Kaustubh Kishor Parkar

Mostly Diagnosed Errors:

Er. Kaustubh Kishor Parkar

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Manual de Servicio Impact 754Document142 pagesManual de Servicio Impact 754Ricardo MedellinNo ratings yet

- Pressure Canning for Beginners: The Ultimate Guide on How to Can Meals, Vegetables and Meat in a JarFrom EverandPressure Canning for Beginners: The Ultimate Guide on How to Can Meals, Vegetables and Meat in a JarRating: 3 out of 5 stars3/5 (2)

- Olympus PSD-10 ESU - User Manual PDFDocument28 pagesOlympus PSD-10 ESU - User Manual PDFanhhp8xNo ratings yet

- BBI Series Electronic Balances GuideDocument100 pagesBBI Series Electronic Balances GuideHalffaNo ratings yet

- Iics90 BR 9050454 enDocument8 pagesIics90 BR 9050454 enRafa TejedaNo ratings yet

- Manual de Usuario Electrocardiografo Edan SE12Document206 pagesManual de Usuario Electrocardiografo Edan SE12anayencyramosNo ratings yet

- Operon Dfut-374 Freezer ManualDocument6 pagesOperon Dfut-374 Freezer ManualLoc50% (2)

- SK100C - 110C Instruction Manual Ver2.0Document27 pagesSK100C - 110C Instruction Manual Ver2.0Julio Ever Elizalde Mora100% (1)

- Humidificado Aquecido Marca Vapotherm Modelo Precision FlowDocument32 pagesHumidificado Aquecido Marca Vapotherm Modelo Precision FlowEng. Edelson MartinsNo ratings yet

- Cavitron Bobcat Pro - Manual de Servicio (Ingles)Document33 pagesCavitron Bobcat Pro - Manual de Servicio (Ingles)Betancur AlejandroNo ratings yet

- H30 QC and Calibration SOP v1.1Document26 pagesH30 QC and Calibration SOP v1.1Romuald Eric TefongNo ratings yet

- Monitor Signos Vitales Goldway Ut4000aDocument2 pagesMonitor Signos Vitales Goldway Ut4000asolcarwxNo ratings yet

- Extend XT - Folleto ComercialDocument6 pagesExtend XT - Folleto ComercialMuhamadZuhdiAlWaliNo ratings yet

- Noa III Infusion Pump Service ManualDocument65 pagesNoa III Infusion Pump Service ManualCristian Andres Valencia100% (1)

- Drager Babytherm 8004 8010 Error ListDocument31 pagesDrager Babytherm 8004 8010 Error Listbioserviceltda2022100% (1)

- Penlon A-200 SP Circle Absorber - User ManualDocument40 pagesPenlon A-200 SP Circle Absorber - User ManualAnonymous oWnCVtEUQCNo ratings yet

- VISION 4000 Portable Ultrasound System Service ManualDocument42 pagesVISION 4000 Portable Ultrasound System Service ManualRko OrtonNo ratings yet

- Camera systems catalogقائمة اسعار الكميراتDocument21 pagesCamera systems catalogقائمة اسعار الكميراتabdNo ratings yet

- Baño María PolyscienceDocument19 pagesBaño María PolyscienceSebastian Martinez CuautencoNo ratings yet

- EC100 User ManualDocument43 pagesEC100 User Manualcristhian7cz356100% (1)

- CarePlus Service Manual PDFDocument232 pagesCarePlus Service Manual PDFohmedicalNo ratings yet

- Jenway 6400, 6405 Spectrophotometer - Service Manual PDFDocument96 pagesJenway 6400, 6405 Spectrophotometer - Service Manual PDFLuther QuispeNo ratings yet

- PDFsam - BIOBASE Part 1.1Document68 pagesPDFsam - BIOBASE Part 1.1cuma mencobaNo ratings yet

- Aircon Respiratory HumidifierDocument4 pagesAircon Respiratory HumidifierhecatoonNo ratings yet

- Bci-Cat-9200 Advisor Vital Signs MonitorDocument2 pagesBci-Cat-9200 Advisor Vital Signs MonitorAbraham AlmirudisNo ratings yet

- Saturn Evo Color FolletoDocument2 pagesSaturn Evo Color FolletoEva TelloNo ratings yet

- Frank's Guide to Electrosurgery Service ManualsDocument6 pagesFrank's Guide to Electrosurgery Service Manualsmike milgrauNo ratings yet

- Bili Blanket Ohmeda Manual ServiceDocument48 pagesBili Blanket Ohmeda Manual ServiceCarolina LondoñoNo ratings yet

- 1088 HD Camera Operating ManualDocument46 pages1088 HD Camera Operating ManualSn Dayanidhi100% (1)

- ACM 603 Operation and Service ManualDocument26 pagesACM 603 Operation and Service Manualhluevano100% (1)

- DIGITAL BIOMETRIC RULER PACSCAN 300 SERIESDocument2 pagesDIGITAL BIOMETRIC RULER PACSCAN 300 SERIESAbiNo ratings yet

- Monitor Multiparametro Edan m50 - ManualDocument185 pagesMonitor Multiparametro Edan m50 - Manualjessika100% (1)

- Vyaire Carefusion Avea VentilatorDocument3 pagesVyaire Carefusion Avea Ventilatorสุมิตตา อ่อนมั่งคงNo ratings yet

- Huntleigh BD4000 Fetal Monitor - Service ManualDocument76 pagesHuntleigh BD4000 Fetal Monitor - Service Manualanayencyramos50% (4)

- Manual Maquina Anestesia Heinen Lowestein Leon PlussDocument451 pagesManual Maquina Anestesia Heinen Lowestein Leon Plusshernan mezaNo ratings yet

- Bilibed Instructions 2000100CDocument18 pagesBilibed Instructions 2000100CHarry FebryantoNo ratings yet

- Technical Seminar For Intra-Aortic Balloon Pumping System 98/98XTDocument43 pagesTechnical Seminar For Intra-Aortic Balloon Pumping System 98/98XTGabriel MorilloNo ratings yet

- MTV 1000 VENTILADOR DE TRANSPORTE EMERGENCIADocument2 pagesMTV 1000 VENTILADOR DE TRANSPORTE EMERGENCIAFernando Trujillo100% (1)

- Foco - Berchtold Chromophare D-300,530,650 - User ManualDocument40 pagesFoco - Berchtold Chromophare D-300,530,650 - User ManualRafael AlbuquerqueNo ratings yet

- Uni-Vent Eagle 754 Portable Ventilator (Rev. 1.85S 06-07)Document104 pagesUni-Vent Eagle 754 Portable Ventilator (Rev. 1.85S 06-07)Marc LaBarberaNo ratings yet

- Nova en Autoclave Tuttnauer PDFDocument12 pagesNova en Autoclave Tuttnauer PDFerikaNo ratings yet

- GE Procare B40 Supplies and AccessoriesDocument20 pagesGE Procare B40 Supplies and AccessoriesRoman RufoNo ratings yet

- Kappa IEC Technical Service Manual: Kappa Patient Monitor Monitor SystemDocument136 pagesKappa IEC Technical Service Manual: Kappa Patient Monitor Monitor SystemAdriano R. OrtizNo ratings yet

- NKV-330 enDocument12 pagesNKV-330 enmauricioNo ratings yet

- E-CUBE 5 CatalogueDocument6 pagesE-CUBE 5 CatalogueeduardoNo ratings yet

- Patient Monitor User ManualDocument85 pagesPatient Monitor User Manualdanniel9090100% (1)

- X8000 Light SourceDocument32 pagesX8000 Light SourceAnne Stephany ZambranoNo ratings yet

- Trio Service Manual DomesticDocument81 pagesTrio Service Manual DomesticGiovanny RamirezNo ratings yet

- I15 Upgrade InstructionDocument12 pagesI15 Upgrade InstructionosamaNo ratings yet

- DeVilbiss IntelliPAP-AutoAdjust SleepCubeDocument11 pagesDeVilbiss IntelliPAP-AutoAdjust SleepCubeDan VladNo ratings yet

- Manual de Uso de Kls Martin Me mb2 PDFDocument36 pagesManual de Uso de Kls Martin Me mb2 PDFmelvin100% (1)

- MR850 Humidifier User ManualDocument2 pagesMR850 Humidifier User ManualnahuediazNo ratings yet

- Confidential LCD Module Spec SheetDocument45 pagesConfidential LCD Module Spec SheetRohit SainiNo ratings yet

- Service Manual: Defibrillator/MonitorDocument172 pagesService Manual: Defibrillator/MonitorArya BondanNo ratings yet

- Dyonics 640 User ManualDocument52 pagesDyonics 640 User ManualAbdul RahmanNo ratings yet

- Phoenix Infant Radiant Warmer NWS 101Document2 pagesPhoenix Infant Radiant Warmer NWS 101Chandan ChinnaNo ratings yet

- HMTS 80 Plasma Sterilizer Rev2022Document33 pagesHMTS 80 Plasma Sterilizer Rev2022Fernando Lourenço100% (1)

- PaceDocument1 pagePacePrabhat SagarNo ratings yet

- Código de Erro Statim G4Document5 pagesCódigo de Erro Statim G4Rafael OliveiraNo ratings yet

- DerivativesDocument1 pageDerivativesniniamicanNo ratings yet

- Router Vs SwitchDocument2 pagesRouter Vs SwitchKaustubh ParkerNo ratings yet

- Sem IDocument1 pageSem IKaustubh ParkerNo ratings yet

- Syllabus BIOM Sem 7 Rev.Document12 pagesSyllabus BIOM Sem 7 Rev.Kaustubh ParkerNo ratings yet

- Am FMDocument28 pagesAm FMAnonymous 3smLyf6vEwNo ratings yet

- Catalogo TécnicoDocument56 pagesCatalogo TécnicolezellerNo ratings yet

- SP30Document287 pagesSP30Ajoy Mc100% (1)

- Diagnostico Backup Switch 320D GKLDocument11 pagesDiagnostico Backup Switch 320D GKLDavid Ceron60% (5)

- Basic Ladder Logic ProgrammingDocument53 pagesBasic Ladder Logic ProgrammingVikashKeshavNo ratings yet

- k222 Compass GpsDocument43 pagesk222 Compass GpsjucamenNo ratings yet

- PM-ENG-012 FD322 User's Manual Rev GDocument32 pagesPM-ENG-012 FD322 User's Manual Rev GCarlos Fernando MondragonNo ratings yet

- ACCOLIFT CLH Electric Chain Hoists Installation Operation Maintenance and Parts ManualDocument98 pagesACCOLIFT CLH Electric Chain Hoists Installation Operation Maintenance and Parts ManualMiguel Alfonso Ruiz Mendez100% (1)

- Gentviglion 456Document190 pagesGentviglion 456Sooraj VsNo ratings yet

- TM 11-6625-583-12 - Radio - Test - Set - AN - ARM-71 - 1964 PDFDocument44 pagesTM 11-6625-583-12 - Radio - Test - Set - AN - ARM-71 - 1964 PDFWurzel19460% (1)

- F (C) D Mini Float Level Switch - B0Document28 pagesF (C) D Mini Float Level Switch - B0Tu WentingNo ratings yet

- Cummins: Fault Code: 444 PID: S232 SPN: 620 FMI: 3 or 4Document7 pagesCummins: Fault Code: 444 PID: S232 SPN: 620 FMI: 3 or 4Enrrique LaraNo ratings yet

- Plano Hidráulico Retroexcavadora 420fDocument13 pagesPlano Hidráulico Retroexcavadora 420fgerardo92% (13)

- KS3 Electricity and Magnetism Revision EssentialsDocument4 pagesKS3 Electricity and Magnetism Revision EssentialsMargarida SeromenhoNo ratings yet

- Unica MGU3.505.18 PDFDocument2 pagesUnica MGU3.505.18 PDFraniaNo ratings yet

- Engineering Data EC - ECL v3.0Document29 pagesEngineering Data EC - ECL v3.0Kim WongNo ratings yet

- Bissell Proheat 2x Repair GuideDocument22 pagesBissell Proheat 2x Repair GuideslappyrodriguezNo ratings yet

- Range Rover Maunual ElectricsDocument146 pagesRange Rover Maunual ElectricsLouise RogersNo ratings yet

- VP-2025JV0P10112-000-O94-001 - 2 - (Technical Installation, Operating & Maintenance Manual FOR Guichon Special Valves (Catalytic Service)Document22 pagesVP-2025JV0P10112-000-O94-001 - 2 - (Technical Installation, Operating & Maintenance Manual FOR Guichon Special Valves (Catalytic Service)Vasilica Barbarasa100% (1)

- 45RSX2 Speed Control ReallyDocument8 pages45RSX2 Speed Control ReallyejazNo ratings yet

- Ersa i-CON 1V & i-CON 2V: Soldering StationDocument58 pagesErsa i-CON 1V & i-CON 2V: Soldering StationtodorloncarskiNo ratings yet

- Commercial Office Operating ManualDocument41 pagesCommercial Office Operating ManualPatricio Guerrero100% (1)

- Cat - Dcs.sis - Controllerm316c Hydraulic PDFDocument2 pagesCat - Dcs.sis - Controllerm316c Hydraulic PDFMehdi Chakroune100% (2)

- Installation, Operation & Maintenance Instructions: 1100°C - 1200°C Chamber Furnaces Types CSF, BOF & RHFDocument12 pagesInstallation, Operation & Maintenance Instructions: 1100°C - 1200°C Chamber Furnaces Types CSF, BOF & RHFthexsamNo ratings yet

- Y3 - Module 3 - Drafting Electrical and Electronic Layout and DetailsDocument71 pagesY3 - Module 3 - Drafting Electrical and Electronic Layout and DetailsRod Aquino78% (9)

- NS Series Network Sensors: DescriptionDocument7 pagesNS Series Network Sensors: Descriptiondivyendu shekharNo ratings yet

- Check List Technam p2008jfDocument2 pagesCheck List Technam p2008jfGourav DasNo ratings yet

- Sharp R-969 Microwave Oven Service ManualDocument56 pagesSharp R-969 Microwave Oven Service ManualImraan Ramdjan100% (1)

- MXG 30 50 Manual Usa Etl 09-07Document77 pagesMXG 30 50 Manual Usa Etl 09-07Sanu PhilipNo ratings yet

- AAL-ICQCC-2021, Team PragathiDocument42 pagesAAL-ICQCC-2021, Team PragathiAnirudh Shenoy KNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual BcsDocument22 pages2003 Nissan Altima 2.5 Serivce Manual BcsAndy Dellinger100% (1)