Professional Documents

Culture Documents

Dot - 39

Uploaded by

koshkeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dot - 39

Uploaded by

koshkeCopyright:

Available Formats

1

Health & Safety Executive

H S E

SPECIFICATION FOR WELDED STEEL NON REFILLABLE TRANSPORTABLE PRESSURE RECEPTACLES DOT - 39 (HSE)

DOT 39 HSE Issue 1

JANUARY 2000

CONTENTS

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18.

SCOPE CERTIFICATE OF COMPLIANCE REFERENCES PERMITTED STEEL IDENTIFICATION OF MATERIAL DEFECTS MANUFACTURE WELDING OR BRAZING WALL THICKNESS OPENINGS AND ATTACHMENTS PRESSURE RELIEF DEVICES HYDROSTATIC TESTING LEAKAGE TEST PRESSURE CYCLING TEST NEW DESIGN HYDRAULIC BURST TEST DROP TEST FLATTENING TEST

4 4 4 4 5 5 5 5 6 6 7 10 11 11 12 13 14 15

DOT 39 HSE Issue 1

JANUARY 2000

19. 18. 19.

DIMENSION CHECKS REJECTED CYLINDERS MARKING

15 16 16 18

APPENDIX 1 - INSPECTORS REPORT

DOT 39 HSE Issue 1

JANUARY 2000

1.

SCOPE

This specification details the requirements for the material, design, construction and testing of welded steel gas cylinders over 1.4 kg but not over 4.55 kg water capacity and service pressure not exceeding 155 bar.

For cylinders intended to contain toxic gases or toxic gas mixtures the water capacity shall not exceed 2 kg.

A transportable pressure receptacle has the same meaning as that given in The Carriage of Dangerous Goods (Classification, Packaging and Labelling) and Use of Transportable Pressure Receptacles Regulations 1996. In this specification, it is referred to as a cylinder.

2.

CERTIFICATE OF COMPLIANCE

The Approved Verification Body shall certify that the manufacture, inspection and testing of the cylinders is carried out in compliance with the requirements of this specification.

Note: A suitable form of certificate is shown in Appendix 1.

3.

REFERENCES

CGA-C-1 - Compressed Gas Association - Hydrostatic Testing.

4.

PERMITTED STEEL

AISI 1010 or 1020 aluminium killed steel with the following composition:-

Ladle analysis Carbon, maximum percentage Phosphorous, maximum percentage Sulphur, maximum percentage DOT 39 HSE Issue 1 0.12 0.04 0.05

Check analysis 0.15 0.05 0.06 JANUARY 2000

5.

IDENTIFICATION OF MATERIAL

The material of construction shall be identified by a suitable method agreed with the Approved Verification Body.

6.

DEFECTS

Materials with seams, cracks, laminations, or other injurious defects, are not permitted.

7.

MANUFACTURE

7.1

Cylinders must be manufactured using equipment and processes adequate to ensure that

each cylinder produced conforms to the requirements of this specification. No fissure or other defect is permitted that is likely to weaken the finished cylinder appreciably. A reasonably smooth and uniform surface finish is required. If not originally free from such defects, the surface may be machined or otherwise treated to eliminate these defects. Dirt and scale shall be removed as necessary to afford proper inspection.

8.

WELDING OR BRAZING

Brazing for any purpose whatsoever is prohibited.

8.1

Welded seams must be properly aligned and welded by a method that provides clean,

uniform joints with adequate penetration.

8.2

Welded joints must have a strength equal to or greater than the minimum strength of the

shell material in the finished cylinder.

8.3

Attachments to the cylinder are permitted by any means that will not be detrimental to the

integrity of the cylinder as agreed with the Approved Verification Body.

8.4

All welding must be completed prior to any pressure testing. JANUARY 2000

DOT 39 HSE Issue 1

8.5

Welding procedures and operators used for each cylinder must be qualified by the

Approved Verification Body.

9.

WALL THICKNESS

9.1

The thickness of each cylinder shall conform to the following:-

9.1.1

The minimum wall thickness must be such that the wall stress at the test pressure does not

exceed the yield strength of the material of the finished cylinder wall.

9.1.2

The service pressure does not exceed 80% of the test pressure.

9.1.3

Calculation shall be by the formula:

S = [ P/10 (1.3D2 + 0.4d2) ] / (D2 - d2)

where S = wall stress in Mpa

P = minimum test pressure prescribed for water jacket test - bar

D = outside diameter in mm

d = inside diameter in mm

10.

OPENINGS AND ATTACHMENTS

10.1

All threads are required to be clean cut, even, without cutting tool marks and to gauge.

10.2

Taper threads, when used, are to be of length not less than as specified for American

Standard taper pipe threads.

DOT 39 HSE Issue 1

JANUARY 2000

10.3

Parallel threads having at least 6 engaged threads are permitted and shall have a tight fit.

The calculated shear strength shall be at least 10 times the test pressure of the cylinder. Gaskets, adequate to prevent leakage, are required.

10.4

Openings and attachments are permitted on heads only.

10.5

All openings and their reinforcements must be within an imaginary circle, concentric to

the axis of the cylinder. The diameter of the circle may not exceed 80% of the outside diameter of the cylinder. The plane of the circle must be parallel to the plane of the circumferential weld and normal to the longitudinal axis of the cylinder.

10.6

Area replacement calculations must be carried out on each opening and where the head

has insufficient thickness, each opening must be reinforced by a securely attached fitting, boss, pad, collar or other suitable means.

10.7

Material used for welded openings and attachments must be of weldable quality and

compatible with the material of the cylinder.

11.

PRESSURE RELIEF DEVICES

11.1. General Requirements

No pressure relief device shall be fitted to a cylinder intended for the conveyance of toxic gases. However, a pressure relief device may be fitted to a cylinder intended for the conveyance of non-toxic gases.

The materials of construction for all pressure relief devices shall be compatible with the gas to be conveyed and other service conditions.

All pressure relief devices shall be so designed and fitted as to ensure that the cooling or heating effects of the contents of the cylinder during discharge shall not prevent the effective operation of the relief devices. DOT 39 HSE Issue 1 JANUARY 2000

The outlets from all pressure relief devices shall be so sited that free discharge from the devices is not impaired.

The outlets from all pressure relief devices shall be so designed and constructed as to prevent the collection of moisture or other foreign matter that could adversely affect the performance of the devices.

11.2. Pressure Relief Valves

If a pressure relief valve is fitted to a cylinder, it shall be of the spring-loaded type. Where practicable the pressure at which the relief valve is designed to start lifting shall be marked on the relief valve or the outlet valve body where the relief valve forms part of the outlet valve.

Discharge from the pressure relief valve shall be obtained at a pressure not greater than the test pressure of the container, except in the case of liquefiable petroleum gas cylinders for service in Great Britain.

Where liquefiable petroleum gas cylinders for service in Great Britain are fitted with pressure relief valves they shall be set as follows:

(a) Propane: 26 bar;

(b) Butane: 21 bar.

11.3. Bursting discs

Bursting discs if fitted, shall be constructed in accordance with BS 2915 and shall be so designed as to ensure that rupture occurs at a pressure not greater than the test pressure of the cylinder except in the case of cylinders for halons and nitrogen.

Note. A bursting disc may be fitted to any cylinder intended for the conveyance of non-toxic and non-flammable gases. The pressure at which the bursting disc is designed to rupture shall, where practicable, be stamped on the bursting disc holder. DOT 39 HSE Issue 1 JANUARY 2000

If a cylinder is liable to be subjected to vacuum conditions during service, the bursting disc shall be resistant to vacuum or be fitted with a vacuum support.

DOT 39 HSE Issue 1

JANUARY 2000

10

11.4. Cylinder valve protection.

Cylinders charged with flammable, corrosive, or noxious gases, shall have their valves protected by one of the following methods.

11.4.1. By equipping the cylinders with securely attached metal caps of sufficient strength to protect the valves from damage during transit.

11.4.2. By boxing or crating the cylinders so as to give proper protection to the valves.

11.4.3. By so constructing the cylinders that the valve is recessed into the cylinder or otherwise protected so that it will not be subjected to a blow when the cylinder is dropped on a flat surface.

11.4.4. By loading the cylinders compactly in an upright position and securely bracing in cars or motor vehicles, when loaded by the consignor and to be unloaded by the consignee.

11.4.6. By equipping with valves strong enough to avoid damage during transit for cylinders containing non liquefied gas under pressure not exceeding 20.7 bar (300 p.s.i.) at 21oC (70oF).

11.5. The protective collar or neck ring must provide protection for the valve and any other fittings against accidental functioning and damage.

12.

HYDROSTATIC TEST

12.1

The hydrostatic test shall be by the water jacket method, or other suitable methods, see

CGA-C-1, and operated so as to obtain accurate data. Pressure gauges must permit reading to an accuracy of 1 percent.

12.2

Each cylinder must be tested. Pressure must be maintained for at least 30 seconds.

12.4

Each cylinder must be tested to at least the greater of the maximum developed pressure of

the contents at 54.5 o C or 12.7 bar. DOT 39 HSE Issue 1 JANUARY 2000

11

12.5

Following the hydrostatic test, each cylinder must be dried out using a method that is

approved by the Approved Verification Body.

13

LEAKAGE TEST

13.1

Each cylinder must be subjected to a leakage test.

13.2

The leakage test must be conducted by submersion under water or by some other equally

effective measure.

13.3

If the cylinder leaks, evidences visible distortion, or any other defect, whilst under test, it

must be rejected.

14

PRESSURE CYCLING TEST

14.1

Pressure cycling tests must be performed for each new design on three cylinders. The

cylinders shall carry stamp marking in accordance with Section 21. The test shall be carried out using a non-corrosive pressurising fluid. The maximum pressure in the cycle shall either be the design test pressure of the cylinder, or 67% of this value. The minimum test pressure in the cycle shall not exceed 10% of the maximum pressure. The frequency of cycling shall not exceed 15 cycles/minute, and the temperature measured on the outside of the cylinder during the test shall not exceed 50oC.

14.2

Acceptance values for the test are:

10,000 cycles without failure when the maximum cycle pressure is the design pressure;

or,

80,000 cycles without failure when the maximum cycle pressure is 67% of the design pressure;

DOT 39 HSE Issue 1

JANUARY 2000

12

Failure shall be construed as leakage from any part of the cylinder other than at the neck/pipe joint

14.3

Following attainment of the required number of cycles:

One of the three cylinders shall continue to be pressure cycled to destruction under the same cycle conditions and the number of cycles causing destruction and the mode of failure recorded;

Two of the three cylinders shall be subjected to the hydraulic burst test of section 16.

15

NEW DESIGN

A previously approved cylinder shall be considered to be of a new design when any of the following conditions apply:

a)

It is manufactured in a different factory (see Note 1).

b)

It is manufactured by a significantly different process. A significant change is regarded as a change that would have a measurable change in the performance of the finished cylinder. The Approved Verification Body shall determine when a change in process or design or manufacture is significantly different from the original qualified design.

c)

The hydraulic test pressure has changed by more than 60% (see Note 2).

d)

The cylinder diameter has changed by more than 50%.

Note 1:

Where a factory moves to a different location with the same equipment, a reduced testing programme may be agreed with the Approved Verification Body.

DOT 39 HSE Issue 1

JANUARY 2000

13

Note 2:

A cylinder may be used and marked for a lower test pressure than stated in the original type approval without additional testing.

16

HYDRAULIC BURST TEST

16.1

Cylinders from each lot shall be subjected to a hydraulic burst test in accordance with the

table 16.1 below. The cylinders shall carry stamp marking in accordance with Section 21. The rate of pressurisation shall not exceed 5 bar/second. In the course of the test the burst pressure and burst mode shall be recorded.

Maximum Service Pressure x Volume of cylinder Minimum sampling frequency 0 to 50 51 to 300 301 to 600 601 to 1000 1/1000 1/750 1/500 1/200

Table 16.1 Minimum sampling frequency for the lot tests.

16.2

Test acceptance criteria are:

1.

The burst pressure shall be equal to or greater than 2 times the design test

pressure.

2.

The cylinder shall burst from a point within the sidewall along the

longitudinal axis.

3.

The cylinder shall remain in one piece after bursting

4.

The burst is not within the heat effected zone of any weld.

DOT 39 HSE Issue 1

JANUARY 2000

14

NB

A lot is defined as the quantity of cylinders successively produced per production shift (not exceeding 10 hours) having identical size, design, construction, material, heat treatment, finish and quality.

17.

DROP TEST

17.1

Drop tests shall be carried out on a minimum of three cylinders from each new design.

17.2

The impact surface shall be concrete block 1m by 1m by 0.1m thick, from a single cast

composed of cement, sand and gravel. It shat be protected by a sheet of 10mm thick steel. The flatness of the protective sheet shall be such that the difference in level of any two points on its surface shall not exceed 2mm. It must be changed when significantly damaged.

17.3

Cylinders for use with liquefiable gases shall be filled to the maximum water capacity of

the cylinder. Cylinders used for permanent gases shall be filled with water to 40% of the water capacity of the cylinder.

17.4

No cylinder shall be pressurised for the drop test.

17.5

The drop test procedure shall be :

i)

One cylinder shall be dropped from a height of 1.2m with the bottom of the

cylinder striking the impact surface of 17.2.

ii)

One cylinder shall be dropped from a height of 1.2m with its sidewall striking the

impact surface of 17.2

iii)

One cylinder shall be dropped from a height of 1.2m with the cylinder cap, collar.

guard or other valve protection striking the impact surface at a 45 o degree angle.

17.6

The acceptance criteria for the drop tests shall be :-

DOT 39 HSE Issue 1

JANUARY 2000

15

i)

For cylinders test to 17.5 i) and ii), the cylinder shall exhibit no leakage, and then

the cylinder shall pass the burst test of section 16.

ii)

For cylinders tested to 17.5 iii), the cylinder shall exhibit no leakage, the valve

shall remain operational and the cylinder shall pass the burst test of section 16.

18.

FLATTENING TEST

18.1

Cylinders from each lot shall be subjected to a flattening test in accordance with table

16.1 after the cylinders have been hydrostatically tested.

18.2

A ring taken from the cylinder may be flattened as a alternative to a test on a complete

cylinder. The test ring must include the heat affected zone.

18.3

The flattening must be by placing the cylinder between wedge shaped knife edges having

60o included angle, rounded to 13mm radius. The longitudinal axis of the cylinder must be at a 90o angle to knife edges during the test.

18.4

Cylinders and test rings may not crack when flattened so that their outer surfaces are not

more than six times wall thickness apart.

18.5

If any cylinder or test ring cracks when subjected to the flattening test, the lot of cylinders

represented by the test must be rejected.

19.

DIMENSIONAL CHECKS

19.1 checks.

Cylinders from each lot in accordance with table 16.1 shall be subject to dimensional

19.2

The cylinder shall be longitudinally sectioned into sufficient pieces to determine the

minimum thickness in the cylinder shell. Alternatively ultrasonic measurement or any other equally sensitive method, as approved by the Approved Verification Body, may be used. DOT 39 HSE Issue 1 JANUARY 2000

16

19.3

The minimum thickness shall not be less than the minimum thickness calculated in

section 9.

19.4

The nominal outside diameter, length and head radii shall be measured and be in

accordance with the design drawings.

19.5

Each completed cylinder shall be placed on a scale to determine the cylinder tare weight.

Each cylinder shall then be filled with liquid to the maximum volume of the cylinder to determine the water capacity. The cylinder tare weight and water capacity shall be recorded.

19.6

Cylinders not meeting the design tare weight or water capacity must be rejected.

20.

REJECTED CYLINDERS

Rejected cylinders must conform to the following requirements :-

i)

If the cause for the rejection of the lot is determinable, and if by test or inspection

defective cylinders are eliminated from the lot, the remaining cylinders, with written agreement from the Approved Verification Body, must be qualified as a new lot.

ii)

Repairs to welds are permitted. Following repair, a cylinder must pass the pressure

test specified in section 12.

iii)

If a cylinder made from seamless steel tubing fails the flattening test describe in

section 18, heat treatment shall be performed to a procedure agreed in writing with the Approved Verification Body on each cylinder in the lot. All tests must be performed subsequent to this heat treatment.

21.

MARKING

21.1

Each cylinder which complies with the requirements of this specification shall be marked

in a durable and waterproof manner on the shoulder, top head or neck, with the following: DOT 39 HSE Issue 1 JANUARY 2000

17

(a)

DOT - 39(HSE)

(b)

NRC

(c)

The service pressure in bar

(d)

The identification mark(s) of the approved Inspection Body.

(e)

Hydrostatic Test Pressure in bar.

(f)

The date of the hydrostatic test in bar.

(g)

The design water capacity as specified in the design drawing in kg.

(h)

This cylinder must not be refilled.

21.2

The marks shall be at least 3 mm in height and displayed sequentially.

DOT 39 HSE Issue 1

JANUARY 2000

18

APPENDIX 1 INSPECTORS REPORT Manufacturing Location ............................................................................................... Consigned to ................................................................................................................ Address ........................................................................................................................ Quantity ....................................................................................................................... Size ................................................... mm outside diameter by .................................. mm long Marks on the cylinder are: Specification ............................................................................................................. Serial numbers ............................................................. to ....................................... inclusive Inspectors mark ...................................................................................................... Identifying Symbol (registered) ............................................................................... Test Date ................................................................................................................. Capacity ........................................................................................................... Other Marks (if any) ............................................................................................... These cylinders were made by process of .............................................................. ................................................................................................................................. The cylinders were heat treated by the process of ................................................. ................................................................................................................................ The material used was identified by the following ......................................................... DOT 39 HSE Issue 1 JANUARY 2000

19

(heat-purchase order) numbers ........................................................................................ The material used was verified as to chemical analysis and record thereof is attached hereto. The heat numbers ....................................................................................................................

(were - were not) marked on the material. All material, such as seamless tubing, was inspected and each cylinder was inspected both before and after closing the ends; all that was accepted was found free from seams, cracks, laminations and other defects which might prove injurious to the strength of the cylinder. The processes of manufacture and heat treatment of cylinders were supervised and found to be efficient and satisfactory. The cylinder walls were measured and the minimum thickness noted was ........ mm. The outside diameter was determined by a close approximation to be .......... mm. The wall stress was calculated to be ........ N/mm2 under an internal pressure of .................... bar.

Hydrostatic tests, flattening tests, and other tests, as prescribed in this specification made in the presence of the Approved Verification Body and all material and cylinders accepted were found to be in compliance with the requirements of this specification. Records thereof are attached hereto. I hereby certify that all of these cylinders proved satisfactory in every way and comply with the requirements of specification No: DOT - 39 (HSE).

Signed: ...............................................................................................

(Approved Verification Body)

(Place) ...............................................................................................

(Date) ...............................................................................................

DOT 39 HSE Issue 1

JANUARY 2000

You might also like

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Tumble Dryer T232 - 256 8 110 KGDocument5 pagesTumble Dryer T232 - 256 8 110 KGHiranthaGunarathneNo ratings yet

- PRES-E-03 Electrical Equipment - Motor & GeneratorDocument2 pagesPRES-E-03 Electrical Equipment - Motor & GeneratorsalamlinNo ratings yet

- K-FLEX HVAC Applications Installation ManualDocument63 pagesK-FLEX HVAC Applications Installation ManualMohammad TaheriNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistphilipyap100% (1)

- Factors Contributing To Foarming Crude OilDocument11 pagesFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- Grade Certificate 004dp44Document1 pageGrade Certificate 004dp44Krishna Aashray EximNo ratings yet

- Equipment Specification Project - RFQ - #: XXXXXX XXXXX ES-223116Document17 pagesEquipment Specification Project - RFQ - #: XXXXXX XXXXX ES-223116Calin SeraphimNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Start-Up Check ListDocument3 pagesStart-Up Check ListgustavoespinosamNo ratings yet

- Broiler Preventive Maintenance ChecklistDocument5 pagesBroiler Preventive Maintenance ChecklistFaysbuk KotoNo ratings yet

- Lub-Oil en 1602Document19 pagesLub-Oil en 1602Raúl Oscar LedesmaNo ratings yet

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- Testing and Adjusting Adjusting Valve ClearanceDocument8 pagesTesting and Adjusting Adjusting Valve ClearanceJose Cruz Martinez MedinaNo ratings yet

- Saudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05Document1 pageSaudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05philipyapNo ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Tipping Cylinder Leakage 15,700 OMR TR00097 2011 6 Year/ 3-AXLEDocument47 pagesTipping Cylinder Leakage 15,700 OMR TR00097 2011 6 Year/ 3-AXLEHari Hara SuthanNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Hydro TestDocument1 pageHydro TestMilan BanerjeeNo ratings yet

- Mueller Water Distribution Products BrochureDocument12 pagesMueller Water Distribution Products BrochureForum PompieriiNo ratings yet

- Amercoat 68hs - Ingles 2015Document6 pagesAmercoat 68hs - Ingles 2015Peter CallánNo ratings yet

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13Document2 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13PradeepNo ratings yet

- SP 2154Document26 pagesSP 2154Anoop gokhaleNo ratings yet

- Final - Rotary Pre-CommissioningDocument3 pagesFinal - Rotary Pre-CommissioningLENINROMEROH4168No ratings yet

- MuellerCo HydrantReferenceGuide 12000 WebDocument85 pagesMuellerCo HydrantReferenceGuide 12000 Websugiarto MarpaungNo ratings yet

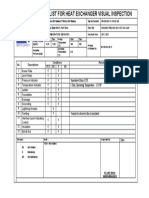

- Checklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSDocument1 pageChecklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSRizqiNo ratings yet

- Scope: Method Statement For Welding ControlDocument6 pagesScope: Method Statement For Welding ControlSIBINNo ratings yet

- 32 Samss 008Document26 pages32 Samss 008naruto256100% (1)

- Compliance Certificate For Fastners FormatDocument1 pageCompliance Certificate For Fastners FormatRudra PanditNo ratings yet

- Hvac Plant Do'S and Don'Ts Air Handling UnitDocument1 pageHvac Plant Do'S and Don'Ts Air Handling UnitSYED SHAHBAZNo ratings yet

- A60 - 780 - 3 - C4-Pressure Relief Valve Instrument Data Sheet & PDFDocument109 pagesA60 - 780 - 3 - C4-Pressure Relief Valve Instrument Data Sheet & PDFSoumiyaNo ratings yet

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- Chapter 2 - Air Conditioning System - Part 2Document23 pagesChapter 2 - Air Conditioning System - Part 2khairul izzudinNo ratings yet

- Trane Submittal CVGF 650Document10 pagesTrane Submittal CVGF 650jun005No ratings yet

- Fujitsu Mini-Split Start-Up Check List PDFDocument1 pageFujitsu Mini-Split Start-Up Check List PDFXUAN CUONG PHANNo ratings yet

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDocument2 pagesWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17ziaNo ratings yet

- Eska ValveDocument34 pagesEska Valveariel_mira12345No ratings yet

- Glidermatic GRD Programming New or Additional HandsetsDocument1 pageGlidermatic GRD Programming New or Additional HandsetsJames100% (1)

- Painting Maual For Power Sector ErectionDocument32 pagesPainting Maual For Power Sector Erectionnagarathinam82No ratings yet

- 13 Samss 003 PDFDocument7 pages13 Samss 003 PDFMohamed SolimanNo ratings yet

- Compressor Maintenance LogDocument1 pageCompressor Maintenance Logsohel rana100% (1)

- Boiler Safety Checklist &Document185 pagesBoiler Safety Checklist &Steve WanNo ratings yet

- INS T 004, Tol - OvalityDocument4 pagesINS T 004, Tol - OvalityDeepakNo ratings yet

- 1-Check List CF PumpDocument2 pages1-Check List CF PumpStarla HillNo ratings yet

- Fire Inspection ChecklistDocument2 pagesFire Inspection ChecklistMedhat ElhagrasiNo ratings yet

- GL5603Document2 pagesGL5603Yairton Vargas MuñozNo ratings yet

- Schematic Diagram For Hydrotest.Document1 pageSchematic Diagram For Hydrotest.vsNo ratings yet

- Válvula 2 Stage Step StopDocument34 pagesVálvula 2 Stage Step Stopmichelin25No ratings yet

- G - 1 - A1 General Arrangment DrawingDocument1 pageG - 1 - A1 General Arrangment Drawingjonodo89No ratings yet

- Area 1Document16 pagesArea 1Camille LachicaNo ratings yet

- Band Saw2Document2 pagesBand Saw2Piyush VyasNo ratings yet

- Acid Number - A Comprehensive GuideDocument11 pagesAcid Number - A Comprehensive Guiderajeevup2004No ratings yet

- D62 - 740 - 3 - C4-Pressure Gauge General Arrangement Drawing PDFDocument6 pagesD62 - 740 - 3 - C4-Pressure Gauge General Arrangement Drawing PDFSoumiyaNo ratings yet

- 01 33 00 - Submittal ProceduresDocument5 pages01 33 00 - Submittal ProceduresSteve LezamaNo ratings yet

- 2.FIT-UP & 3. Welding ReportDocument2 pages2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- Dot - 3E (Hse) : Specification For Seamless SteelDocument15 pagesDot - 3E (Hse) : Specification For Seamless SteelsajawalNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- ACE/HCP4A: Angular Contact Ball Bearings, Super-PrecisionDocument5 pagesACE/HCP4A: Angular Contact Ball Bearings, Super-PrecisionkoshkeNo ratings yet

- 707 ACE/HCP4AH: Angular Contact Ball Bearings, Super-PrecisionDocument5 pages707 ACE/HCP4AH: Angular Contact Ball Bearings, Super-PrecisionkoshkeNo ratings yet

- S7002 CE/P4A: Angular Contact Ball Bearings, Super-PrecisionDocument4 pagesS7002 CE/P4A: Angular Contact Ball Bearings, Super-PrecisionkoshkeNo ratings yet

- SKF Slim Thin BearingsDocument139 pagesSKF Slim Thin Bearingsaghamdi2206No ratings yet

- Lock Nuts With Integral Locking: DimensionsDocument3 pagesLock Nuts With Integral Locking: DimensionskoshkeNo ratings yet

- Precision Lock Nuts: DimensionsDocument3 pagesPrecision Lock Nuts: DimensionskoshkeNo ratings yet

- Kmfe 7: Lock Nuts With Integral LockingDocument3 pagesKmfe 7: Lock Nuts With Integral LockingkoshkeNo ratings yet

- SCP Catalogue 2006 enDocument76 pagesSCP Catalogue 2006 enkoshkeNo ratings yet

- Izbor Ovo E987C-WWEN PDFDocument76 pagesIzbor Ovo E987C-WWEN PDFkoshkeNo ratings yet

- S71907 CD/P4A: Angular Contact Ball Bearings, Super-PrecisionDocument4 pagesS71907 CD/P4A: Angular Contact Ball Bearings, Super-PrecisionkoshkeNo ratings yet

- Clock 1Document12 pagesClock 1zotsenko85% (20)

- Echnical Pecifications: Ford C-Max & Grand C-Max SpecificationsDocument19 pagesEchnical Pecifications: Ford C-Max & Grand C-Max SpecificationskoshkeNo ratings yet

- Woodenclock Gears-Pl PDFDocument8 pagesWoodenclock Gears-Pl PDFstaticfactory928178% (9)

- Online Shop For High Precise Drive Systems by Maxon - Maxon GroupDocument4 pagesOnline Shop For High Precise Drive Systems by Maxon - Maxon GroupkoshkeNo ratings yet

- 3 D OrnamentsDocument9 pages3 D Ornamentsjefferson.lages4941No ratings yet

- TRP-4010-1xA: Premium TransponderDocument2 pagesTRP-4010-1xA: Premium TransponderkoshkeNo ratings yet

- TRP-4010-1xA.: Premium TransponderDocument2 pagesTRP-4010-1xA.: Premium TransponderkoshkeNo ratings yet

- Surge Counter IP8262 PDFDocument1 pageSurge Counter IP8262 PDFkoshkeNo ratings yet

- Workshop ManualDocument59 pagesWorkshop ManualkoshkeNo ratings yet

- Model Number Structure: Enclosed SwitchDocument22 pagesModel Number Structure: Enclosed SwitchkoshkeNo ratings yet

- TNCR024 PDFDocument7 pagesTNCR024 PDFkoshkeNo ratings yet

- Manuale D'uso Alcatel 4018Document31 pagesManuale D'uso Alcatel 4018masiar_laschaiNo ratings yet

- Model Number Structure: Enclosed SwitchDocument22 pagesModel Number Structure: Enclosed SwitchkoshkeNo ratings yet

- Helicoil Plus en 0100Document56 pagesHelicoil Plus en 0100vaseaNo ratings yet

- Senzor Nivoa VodeDocument0 pagesSenzor Nivoa VodekoshkeNo ratings yet

- B8 - Contactors - EN (Web) PDFDocument120 pagesB8 - Contactors - EN (Web) PDFkoshkeNo ratings yet

- New Products Additional To Catalogue 42 PDFDocument24 pagesNew Products Additional To Catalogue 42 PDFkoshkeNo ratings yet

- MAEDLER Katalog42 EN PDFDocument872 pagesMAEDLER Katalog42 EN PDFkoshkeNo ratings yet

- DOT 39 Disposable CylindersDocument1 pageDOT 39 Disposable CylinderskoshkeNo ratings yet

- Range Guard ManualDocument2 pagesRange Guard ManualKus MadiNo ratings yet

- Aeon8800A Service ManualDocument229 pagesAeon8800A Service ManualArtur Florián100% (2)

- Fillpac R 12 SpoutDocument380 pagesFillpac R 12 SpoutjklmohapatraNo ratings yet

- SAE-400 DC Arc Welding Power Source: Operator's ManualDocument31 pagesSAE-400 DC Arc Welding Power Source: Operator's ManualGabino Ubilio MurilloNo ratings yet

- User Manual Prima 465 Anaesthetic Machine: Anaesthesia SolutionsDocument108 pagesUser Manual Prima 465 Anaesthetic Machine: Anaesthesia SolutionsЛеонидNo ratings yet

- Biox O2 ProcedimentosDocument9 pagesBiox O2 ProcedimentosClaudia E Luis GonçalvesNo ratings yet

- 6-Jsa - For - Welding & Fitup VVSPL Process AreaDocument5 pages6-Jsa - For - Welding & Fitup VVSPL Process AreaManish PandeyNo ratings yet

- Site Safety PlanDocument39 pagesSite Safety PlanSundeep Kumar Mehta100% (2)

- Aws A5.32m-2021Document40 pagesAws A5.32m-2021Carlos Ceja100% (1)

- Millermatic 175-O1324c - MilDocument52 pagesMillermatic 175-O1324c - MilRoberto MoctezumaNo ratings yet

- Medical Liquid Oxygen Tcm410-55834Document12 pagesMedical Liquid Oxygen Tcm410-55834Geetha SoundaryaNo ratings yet

- PEFS Maintenance Manual V2.2Document60 pagesPEFS Maintenance Manual V2.2Dedy hermawanNo ratings yet

- LPG Properties (Liquefiable Petroleum Gas or LP Gas)Document4 pagesLPG Properties (Liquefiable Petroleum Gas or LP Gas)qaraman100% (1)

- General Product Catalogue ENG WEBDocument50 pagesGeneral Product Catalogue ENG WEBJamdade LaxmanNo ratings yet

- C822444-COR-HS-FRM-0014 Compressed Gas Cylinders Daily Pre-Use InspectionDocument1 pageC822444-COR-HS-FRM-0014 Compressed Gas Cylinders Daily Pre-Use InspectionAndrianto Bakri0% (1)

- Om EnglishDocument41 pagesOm EnglishMarc ChartrandNo ratings yet

- Hydraulik-Diagram - Hydraulic-Diagram - Hydraulik-Diagramm Ommelift 2100 Ebz-P 2100 Ebz-DDocument21 pagesHydraulik-Diagram - Hydraulic-Diagram - Hydraulik-Diagramm Ommelift 2100 Ebz-P 2100 Ebz-DStianNo ratings yet

- External Seam Welders ManualDocument56 pagesExternal Seam Welders ManualHéctor H. SamaniegoNo ratings yet

- PPE-5 Respiratory Protection: Blanchard Refining Company LLC Galveston Bay RefineryDocument29 pagesPPE-5 Respiratory Protection: Blanchard Refining Company LLC Galveston Bay RefineryAhmed BachayNo ratings yet

- Dangerous Goods Regulations: TABLE 2.3.A Provisions For Dangerous Goods Carried by Passengers or Crew (Subsection 2.3)Document2 pagesDangerous Goods Regulations: TABLE 2.3.A Provisions For Dangerous Goods Carried by Passengers or Crew (Subsection 2.3)LoseTheWarNo ratings yet

- Operating+Instruction SCBADocument40 pagesOperating+Instruction SCBAUlises ContrerasNo ratings yet

- Guidelines On Gas Piping Systems at Laundrettes and Similar InstallationsDocument28 pagesGuidelines On Gas Piping Systems at Laundrettes and Similar Installationskel boyNo ratings yet

- OchureDocument8 pagesOchureSachin DarneNo ratings yet

- 1 - Project HSE Plan - IMC-1 ProjectDocument95 pages1 - Project HSE Plan - IMC-1 ProjectJamalYousufNo ratings yet

- Rotarex - Changeover ManifoldDocument60 pagesRotarex - Changeover ManifoldLit Phen TuNo ratings yet

- 40 - Sec 5 - Cylinder Identification 2Document48 pages40 - Sec 5 - Cylinder Identification 2ahmedNo ratings yet

- Instruction Manual: Small Cylinder DryerDocument20 pagesInstruction Manual: Small Cylinder DryerJohn Néstor Ramirez CalderónNo ratings yet

- 900 Lb. FM-200 Cylinder: FeaturesDocument2 pages900 Lb. FM-200 Cylinder: FeaturesLogan Marquez AguayoNo ratings yet

- Perfect Flame Vertical Gas Smoker GS-2001 Owners ManualDocument68 pagesPerfect Flame Vertical Gas Smoker GS-2001 Owners ManualMatthew Leingang67% (3)