Professional Documents

Culture Documents

6-Measurement While Drilling

Uploaded by

محمد سعيدOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6-Measurement While Drilling

Uploaded by

محمد سعيدCopyright:

Available Formats

MEASUREMENT WHILE DRILLING (MWD) TOOL

MWD

MEASUREMENT WHILE DRILLING (MWD) TOOL

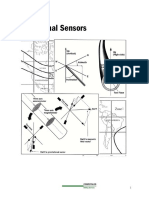

The MWD uses the same accelerometers and magnetometers as the steering tool and the electronic multishot. The difference is that it sends information to the surface on mud pulses through the drill string as illustrated in Figure 1. The electronic sensors in the MWD tool record the raw directional data. Depending upon the MWD tool, a microprocessor converts the data to a binary code or calculates the survey and converts the survey to a binary code. The layout of a typical positive pulse MWD is shown in Figure 2. The microprocessor will then send a signal to the pulser. The position of the pulser will determine if the tool is sending a one or ero. The pressure pulses will travel up the drill string and a transducer on the standpipe will change the mechanical pressure pulses to an electronic signal. The surface computer deciphers the binary code and displays the survey data. There are three different pulser systems used in the petroleum industry. !implified pulser diagrams are shown in Figure " They are positive pulse, negative pulse and continuous wave. #s illustrated, the positive pulse causes a restriction in the flow path for the mud resulting in an increased surface pressure. The negative pulse allows some of the drilling fluid to be bypassed into the annulus. This has the same effect as a hole in the drill string and the surface pressure is reduced. The continuous wave has a set of stator and rotor blades. When the blades are lined up, there is less restriction in the flow stream and the pressure is lower. When the rotor blades are not lined up with the stator blades, there is a restriction in the flow path and the surface pressure increases. The rotor blade rotates at a constant speed. The stator blade is moved $rotated% to a certain degree only, resulting in pulse position modulation. There are some advantages and disadvantages to each system. The positive pulse is more tolerant of &'M and mud solids. (t is also less affected by pump noise) however, it has the lowest data transmission rate. The negative pulse system has a slightly higher data transmission rate and pump noise is still not as much of a problem. (t also uses less power. There must be enough pressure differential between the tool and the annulus for it to wor* properly, which means bit +et selection can be limited. The significant advantage of the continuous wave is that the data transmission rate is much higher. ,ump noise is more difficult to filter out.

MWD

Figure 1. Schematic of MWD Transmission System

Figure 2. Simplified Diagram of MWD Tool

The MWD can be powered by an alternator as illustrated in Figure 2 or by lithium batteries. !ome MWD tools have both. -attery operated tools can function with the pump off) however, the tool will only operate for a finite period of time before the batteries are drained. The battery powered MWD will operate up to ".. hours depending upon temperature and the tool used. The tool life is a function of how fre/uently the information is sent to the surface especially when combined with logging while drilling. -atteries also have a temperature limitation of around ".. F $10. '%.

o o

(f the tool is powered by an alternator, the tool does not have power unless the pump is on and there is a minimum pump rate at which they will function. There is also a ma1imum pump rate. The turbines used to power the alternator can plug with lost circulation material. 2lectromagnetic MWD3s use the same directional pac*age as the mud pulse MWD. The data are sent to the surface using electromagnetic waves $low fre/uency radio waves% as shown in . # transmitter in the tool transmits the electromagnetic waves and the waves are pic*ed up at the surface with an antenna array. The data are collected with a surface computer and the surface computer displays the survey data. Data transmission rates are not substantially different than mud pulse MWD. 2lectromagnetic MWD does not wor* as deep as mud pulse MWD and is a function of the resistivity of the formation. (t wor*s better in fresh water formations. The signal is attenuated across from evaporite formations such as salt and does not wor* while in the evaporite one. 4nce the transmitter get below the one, it will wor* again.

MWD

The main advantage of the electromagnetic MWD is that it will wor* in underbalanced drilling operations. The data can still be transmitted in air, mist, foam and aerated fluid. 5se of a downhole motor in air and mist drilling is still very hard on the MWD e/uipment. There needs to be sufficient fluid to dampen the vibrations if a motor is used. The MWD comes pac*aged in a non6magnetic drill collar and loo*s li*e a non6magnetic drill collar that you cannot see through. (f the MWD tool fails, it must be pulled from the hole with the drill string. There are some MWD3s, where a portion of the tool can be pulled from the non6magnectic drill collar with a wireline, serviced and replaced. #lso, if the MWD tool becomes stuc* in the hole, at least a portion of some tools can be retrieved with the wireline. MWD tools also give toolface data along with the survey. Toolface data is usually updated every ". seconds to one minute depending upon how the tool is preprogrammed. Most MWD3s ma*e up to the deflecting tool and the toolface of the MWD tool usually does not align with the toolface of the downhole motor. The difference between the tools is measured and entered into the surface computer. The surface computer corrects the toolface reading of the MWD to that of the motor. The declination is also entered into the surface computer and the surface computer automatically corrects the surveys. (f MWD tools are lost in the hole, they can be very e1pensive. 7ars are usually run with the MWD tool) although, +arring with an MWD tool may damage the tool. The significant advantages of the MWD tool are8 1. # savings in rig time. (t ta*es three to five minutes to obtain a survey with an interruption in drilling of less than two minutes usually on connections. (t reduces the time necessary to orient downhole motors, because the tools transmit a new toolface at least every 2 minutes. The tools will also perform the same function as a steering tool, so the need for a steering tool and wireline operations are eliminated. The tools eliminate the need to condition the hole prior to surveying because they transmit data with the pump on. 2. # reduction in drilling ha ards. The ris* of stic*ing the pipe is reduced. 'irculation is maintained while surveying and only 19 minutes without pipe movement are re/uired to ta*e the survey. ". The tools are compatible with current drilling operations. The tools do not need any special devices or procedures for installation. The tools are housed in their own non6 magnetic drill collar, and they can be substituted for the non6magnetic collar used with other survey methods. The drill string can be rotated with the MWD in the hole. Without a wireline in the hole, the drill string can be rotated. Thus, the MWD enabled the development of the steerable .motor assembly .:

MWD

Figure 2 ,ulser diagram of MWD transmitter

Figure : 2lectromagnetic MWD

Though the MWD system can save rig time, the cost of the MWD also has to be considered. The MWD is only cost effective if the overall cost of the drilling operation is reduced. The higher the daily operating cost, the more li*ely an MWD system will be economical. (n almost any normal directional drilling operation, the MWD is cost effective.

MWD

You might also like

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Introduction To MWDDocument55 pagesIntroduction To MWDConstantine Toby100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- What Is Measuring While Drilling (MWD) ?: Source: Accu Tech The MWD CompanyDocument3 pagesWhat Is Measuring While Drilling (MWD) ?: Source: Accu Tech The MWD CompanyAnonymous AkV8maWxGN0% (1)

- 5 - Measurement While Drilling - 2 - 6 - 2020Document28 pages5 - Measurement While Drilling - 2 - 6 - 2020hkaqlqNo ratings yet

- 3) +DGA Pre-Read TelemetryDocument22 pages3) +DGA Pre-Read TelemetryyuriiNo ratings yet

- Formation Testing: Supercharge, Pressure Testing, and Contamination ModelsFrom EverandFormation Testing: Supercharge, Pressure Testing, and Contamination ModelsNo ratings yet

- TelemetryDocument26 pagesTelemetryWassef MBNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- MWD Directional Survey Training ManualDocument103 pagesMWD Directional Survey Training ManualFernando ColinaNo ratings yet

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesFrom EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesNo ratings yet

- MWD GEDocument4 pagesMWD GEErick AlarconNo ratings yet

- MWDDocument8 pagesMWDShamia Essam100% (1)

- 1a MWD Survey MeasurementsDocument22 pages1a MWD Survey MeasurementsAli AhmedNo ratings yet

- Azimuthal GammaDocument10 pagesAzimuthal GammaTom ArnoldNo ratings yet

- Hole Problem Data PackageDocument154 pagesHole Problem Data PackageAhmed Mamdouh100% (1)

- MWD Academy 1Document2 pagesMWD Academy 1shie_jeanelaNo ratings yet

- Drilling AnalysisDocument36 pagesDrilling Analysisgplese0No ratings yet

- TeleSCOPE Telemetry While Drilling (TWD)Document3 pagesTeleSCOPE Telemetry While Drilling (TWD)LoganBohannonNo ratings yet

- Rotary Steerable SystemDocument29 pagesRotary Steerable Systemakshitppe11100% (2)

- Introduction To Measurement While Drilling (MWD) : Study QuestionsDocument55 pagesIntroduction To Measurement While Drilling (MWD) : Study Questionssong LiNo ratings yet

- Mwd-Manual PDFDocument151 pagesMwd-Manual PDFmanu pratap singhNo ratings yet

- QA - QC Surveying MWDDocument6 pagesQA - QC Surveying MWDdell1234boy100% (3)

- Monitoring Drilling Bit Parameters Parameters Allows Optimization of Drilling RatesDocument16 pagesMonitoring Drilling Bit Parameters Parameters Allows Optimization of Drilling RatesAnmol JassalNo ratings yet

- 1 IntrotoDrilling ESCertification v1 1 6180305 01Document79 pages1 IntrotoDrilling ESCertification v1 1 6180305 01Ricardo VillarNo ratings yet

- SPE-143623-MS-Torque and Drag Software Model Comparison Impact On Application and Calibration of Field DataDocument11 pagesSPE-143623-MS-Torque and Drag Software Model Comparison Impact On Application and Calibration of Field DataHassaanAhmedNo ratings yet

- Sperry Sun - LWD and LWD ServicesDocument8 pagesSperry Sun - LWD and LWD ServicesBAS100% (1)

- A Directional Drilling BHA Presentation SonatrachDocument0 pagesA Directional Drilling BHA Presentation SonatrachKHALEDFEKAIRNo ratings yet

- Planning For External Magnetic Interference: An MWD Surveying Case StudyDocument11 pagesPlanning For External Magnetic Interference: An MWD Surveying Case StudyOscar Salinas JimenezNo ratings yet

- Directional Drilling HydraulicsDocument36 pagesDirectional Drilling HydraulicsdohlalaNo ratings yet

- Mud Logging InfoDocument55 pagesMud Logging InfoYoucef BenferdiNo ratings yet

- 09 Icruise Best Practice v2Document45 pages09 Icruise Best Practice v2Nelson RamirezNo ratings yet

- DataLog Drilling Fluids ManualDocument57 pagesDataLog Drilling Fluids ManualJohnSmithNo ratings yet

- PDC Bit Running Procedures DDIDocument39 pagesPDC Bit Running Procedures DDImaicrv100% (1)

- EDT Drilling SummaryReleaseNotes 5000.15Document210 pagesEDT Drilling SummaryReleaseNotes 5000.15tariq82ali100% (1)

- Bit Hydraulics OptimizationDocument24 pagesBit Hydraulics OptimizationRebar Kaka100% (1)

- Baker Hughes 43018 Axcelerate in Gom CHDocument1 pageBaker Hughes 43018 Axcelerate in Gom CHArumugam RajendranNo ratings yet

- 511 NewscoDocument58 pages511 NewscoMEUBRONo ratings yet

- Kick-Off Techniques: Hassan AlemiDocument52 pagesKick-Off Techniques: Hassan Alemimagoankit50% (2)

- MPD UBD ReportDocument76 pagesMPD UBD ReportArjit KumarNo ratings yet

- MWD LWDDocument57 pagesMWD LWDHamza HamzaNo ratings yet

- MWD LWD GeosteeringDocument57 pagesMWD LWD GeosteeringAnonymous rey6aU3ZNo ratings yet

- Logging While Drilling 1Document4 pagesLogging While Drilling 1vishalpeddarpethkarNo ratings yet

- Rotary Bha Ingold r3xDocument56 pagesRotary Bha Ingold r3xUsama Bin Sabir100% (2)

- Directional Drilling - Manual E - SchlumbergerDocument44 pagesDirectional Drilling - Manual E - SchlumbergerAli Azmat Khan100% (1)

- Drilling Dynamics Sensors Opt BR PDFDocument16 pagesDrilling Dynamics Sensors Opt BR PDFhamed1725No ratings yet

- WellPlan Exercie Book PDFDocument115 pagesWellPlan Exercie Book PDFMJ arab100% (1)

- MWD BosDocument15 pagesMWD Bosarifin ubaidNo ratings yet

- Logging While DrillingDocument8 pagesLogging While Drillingmay16forhenry4906100% (2)

- Dynamic Model For Stiff String Torque and DragDocument16 pagesDynamic Model For Stiff String Torque and DragMOHAMED ALi IBRAHIM HASSANNo ratings yet

- 4) +DGA Pre-Read DirectionalDocument19 pages4) +DGA Pre-Read DirectionalyuriiNo ratings yet

- Logging While DrillingDocument2 pagesLogging While DrillingFranz Gustavo Vargas MamaniNo ratings yet

- Training & Development: MWD Class Pre-ReadDocument43 pagesTraining & Development: MWD Class Pre-Readyurii100% (1)

- Evaluation of Measurement-While-Drilling, Telemetry Methods and Integration of Control SystemsDocument77 pagesEvaluation of Measurement-While-Drilling, Telemetry Methods and Integration of Control SystemsTran Dang SangNo ratings yet

- MWD Mud-Pulse System SperrySunDocument77 pagesMWD Mud-Pulse System SperrySunkfranovsky100% (1)

- 10 - UiTM Presentation Bit BHA Drilling Technology RevCDocument10 pages10 - UiTM Presentation Bit BHA Drilling Technology RevCNaufal Syafiq Mohd IsaNo ratings yet

- Sperry Sun - MWD Services MnemonicsDocument10 pagesSperry Sun - MWD Services MnemonicsBASNo ratings yet

- 10 Answers PDFDocument22 pages10 Answers PDFمحمد سعيدNo ratings yet

- Lectures 1-2 - Natural Gas Production-I (1) - 2Document23 pagesLectures 1-2 - Natural Gas Production-I (1) - 2محمد سعيدNo ratings yet

- Liquid Flow in Control Valves Portland ISADocument40 pagesLiquid Flow in Control Valves Portland ISAمحمد سعيدNo ratings yet

- Casing Design ADocument4 pagesCasing Design AMuhammad Naufal Nazhib KhanNo ratings yet

- Casing Design Manual - BG (2001)Document51 pagesCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- Casing Design CalculationDocument10 pagesCasing Design CalculationNurul Aishah100% (3)

- Chapter 3-OCW PDFDocument52 pagesChapter 3-OCW PDFمحمد سعيدNo ratings yet

- Well Test - Buildup Week 04 PDFDocument24 pagesWell Test - Buildup Week 04 PDFمحمد سعيدNo ratings yet

- Volumetric CalculationsDocument9 pagesVolumetric CalculationsFuad MohamedNo ratings yet

- w5 Well Test - Multi-Rates Week 05Document18 pagesw5 Well Test - Multi-Rates Week 05kameliooNo ratings yet

- Formation EvaluationDocument35 pagesFormation EvaluationÁlvaro ChSaNo ratings yet

- Drilling Fluid Product List PDFDocument55 pagesDrilling Fluid Product List PDFمحمد سعيدNo ratings yet

- 7 Neutron PDFDocument30 pages7 Neutron PDFمحمد سعيدNo ratings yet

- Well Test - Drawdown Week 03 PDFDocument13 pagesWell Test - Drawdown Week 03 PDFمحمد سعيدNo ratings yet

- 1 DrillFluids PDFDocument69 pages1 DrillFluids PDFمحمد سعيدNo ratings yet

- An Introduction To Directional DrillingDocument86 pagesAn Introduction To Directional DrillingSerag Gamal80% (15)

- Well Test Procedures ManualDocument108 pagesWell Test Procedures Manualapi-2693096593% (29)

- Wellcontrol Basic PDFDocument16 pagesWellcontrol Basic PDFمحمد سعيدNo ratings yet

- Drilling FormulasDocument87 pagesDrilling Formulaswhydowelove89% (9)

- Oil and Gas Site Preparation TaskDocument6 pagesOil and Gas Site Preparation Taskapi-3707212No ratings yet

- Fundamentals of Reservoir Properties PDFDocument57 pagesFundamentals of Reservoir Properties PDFمحمد سعيد100% (1)

- Drilling Engineering Laboratory ManualDocument98 pagesDrilling Engineering Laboratory ManualFima Molly100% (1)

- Mud EngineeringDocument21 pagesMud EngineeringJorge VidaurreNo ratings yet

- Drilling FormulasDocument87 pagesDrilling Formulaswhydowelove89% (9)

- Mud EngineeringDocument21 pagesMud EngineeringJorge VidaurreNo ratings yet

- Volumetric MethodDocument26 pagesVolumetric MethodbachhvaNo ratings yet

- Oil Well CementingDocument18 pagesOil Well Cementingginozky67% (6)

- Product Data: - Quality Worldwide Since 1968Document2 pagesProduct Data: - Quality Worldwide Since 1968محمد سعيدNo ratings yet

- Tabel Kimia Additiv SementDocument1 pageTabel Kimia Additiv SementAry RachmanNo ratings yet

- CementingDocument53 pagesCementingUgochukwu Fidelis100% (1)

- Hands On - Docker Coreos - Docker - Kubernetes Deployment With ForemanDocument14 pagesHands On - Docker Coreos - Docker - Kubernetes Deployment With ForemanpepeqfNo ratings yet

- Masibus 409-S RPM - R1F - 0914 - Digital RPM Monitor PDFDocument2 pagesMasibus 409-S RPM - R1F - 0914 - Digital RPM Monitor PDFkaleesuwariNo ratings yet

- Controls, Start-Up, Operation, Service, and TroubleshootingDocument242 pagesControls, Start-Up, Operation, Service, and TroubleshootingAnonymous uEOZ7raPkzNo ratings yet

- EASA AC Redesign Manual V.0214-0815 PDFDocument140 pagesEASA AC Redesign Manual V.0214-0815 PDFDon FreemanNo ratings yet

- Test Certificates Repair Instructions Service Bulletins (Idms) ConversionsDocument394 pagesTest Certificates Repair Instructions Service Bulletins (Idms) ConversionsGABRIELNo ratings yet

- ISO 26262-10-2012-Road Vehicles Functional Safety Guideline On ISO 26262Document100 pagesISO 26262-10-2012-Road Vehicles Functional Safety Guideline On ISO 26262Cycy Hm100% (1)

- CHAPTER - 1 - MapReduceDocument27 pagesCHAPTER - 1 - MapReduceDhana Lakshmi BoomathiNo ratings yet

- Intoduction To DO-178 (Software Standard)Document14 pagesIntoduction To DO-178 (Software Standard)Sooraj V VNo ratings yet

- Repuestos Equipos PesadosDocument71 pagesRepuestos Equipos PesadosIng YÔrland R. BlancoNo ratings yet

- Multi Bio700 User ManualDocument104 pagesMulti Bio700 User ManualDarrel Espejo VallesNo ratings yet

- Bard - Site Rite - Ultrasound-EnDocument42 pagesBard - Site Rite - Ultrasound-EnVicNo ratings yet

- Digital Marketing and CommunicationDocument9 pagesDigital Marketing and CommunicationKezaiahNo ratings yet

- Mms 101 Functions 3applicationsDocument16 pagesMms 101 Functions 3applicationsPatricia KalambaNo ratings yet

- Fourc's 21st CenturyDocument5 pagesFourc's 21st CenturyZeus OngNo ratings yet

- Computer Science Paper Scheme (Marks Distribution)Document4 pagesComputer Science Paper Scheme (Marks Distribution)Honey BunnyNo ratings yet

- Job Description Oacett Experience Requirements - Revised November 2021Document6 pagesJob Description Oacett Experience Requirements - Revised November 2021Deepak MasaunNo ratings yet

- JCB 550-80 & 560-80 Brochure - Set96414422 PDFDocument20 pagesJCB 550-80 & 560-80 Brochure - Set96414422 PDFYutub RichardxdNo ratings yet

- Pegasus PDFDocument103 pagesPegasus PDFbospanker100% (1)

- Slem Housekeeping Grades 9 10 Week - 8Document9 pagesSlem Housekeeping Grades 9 10 Week - 8Anne AlejandrinoNo ratings yet

- 3D Vision Guided Robotic Charging Station For ElecDocument7 pages3D Vision Guided Robotic Charging Station For ElecAnanya SinghNo ratings yet

- CharCoat CC - Cable Coating - Fireproof Coating - Cable RepairDocument5 pagesCharCoat CC - Cable Coating - Fireproof Coating - Cable RepairnaveedfndNo ratings yet

- BPAG 172 Solved AssignmentDocument6 pagesBPAG 172 Solved AssignmentDivyansh BajpaiNo ratings yet

- Upay Department: Frequently Asked Questions (Faqs) - CustomersDocument13 pagesUpay Department: Frequently Asked Questions (Faqs) - CustomerstanvirNo ratings yet

- Unit 9 - Lesson D: Identity Theft: Touchstone 2nd Edition - Language Summary - Level 3Document2 pagesUnit 9 - Lesson D: Identity Theft: Touchstone 2nd Edition - Language Summary - Level 3Janeth GuerreroNo ratings yet

- Helpshift Digital Support Benchmark Report 2022Document28 pagesHelpshift Digital Support Benchmark Report 2022vladilNo ratings yet

- Data Sheet 24 V Batterie DataDocument4 pagesData Sheet 24 V Batterie DataMichel De Souza CorreaNo ratings yet

- Termux Tutorial Complete Termux Commands - CodeDocument3 pagesTermux Tutorial Complete Termux Commands - CodeDavid Burkhouse100% (4)

- Edbr341317b (En)Document684 pagesEdbr341317b (En)Antonio EvangelistaNo ratings yet

- Chapter 4 - Electricity Intake (2020 Edition)Document20 pagesChapter 4 - Electricity Intake (2020 Edition)bibinbibinNo ratings yet

- Subcontracting in SAPDocument6 pagesSubcontracting in SAPmoorthykem100% (1)

- STEM Labs for Physical Science, Grades 6 - 8From EverandSTEM Labs for Physical Science, Grades 6 - 8Rating: 3.5 out of 5 stars3.5/5 (6)

- How to Teach Nature Journaling: Curiosity, Wonder, AttentionFrom EverandHow to Teach Nature Journaling: Curiosity, Wonder, AttentionRating: 4.5 out of 5 stars4.5/5 (3)

- A-level Biology Revision: Cheeky Revision ShortcutsFrom EverandA-level Biology Revision: Cheeky Revision ShortcutsRating: 5 out of 5 stars5/5 (5)

- Lower Secondary Science Workbook: Stage 8From EverandLower Secondary Science Workbook: Stage 8Rating: 5 out of 5 stars5/5 (1)

- Nature-Based Learning for Young Children: Anytime, Anywhere, on Any BudgetFrom EverandNature-Based Learning for Young Children: Anytime, Anywhere, on Any BudgetRating: 5 out of 5 stars5/5 (1)

- Nature Play Workshop for Families: A Guide to 40+ Outdoor Learning Experiences in All SeasonsFrom EverandNature Play Workshop for Families: A Guide to 40+ Outdoor Learning Experiences in All SeasonsRating: 4 out of 5 stars4/5 (4)

- Interactive Science Notebook: The Human Body WorkbookFrom EverandInteractive Science Notebook: The Human Body WorkbookRating: 4 out of 5 stars4/5 (2)

- Quantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityFrom EverandQuantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityRating: 2 out of 5 stars2/5 (1)

- How Do Cell Phones Work? Technology Book for Kids | Children's How Things Work BooksFrom EverandHow Do Cell Phones Work? Technology Book for Kids | Children's How Things Work BooksNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Interactive Notebook: Life Science, Grades 5 - 8From EverandInteractive Notebook: Life Science, Grades 5 - 8Rating: 5 out of 5 stars5/5 (4)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- A-Level Chemistry Revision: Cheeky Revision ShortcutsFrom EverandA-Level Chemistry Revision: Cheeky Revision ShortcutsRating: 4 out of 5 stars4/5 (5)

- Nature Preschools and Forest Kindergartens: The Handbook for Outdoor LearningFrom EverandNature Preschools and Forest Kindergartens: The Handbook for Outdoor LearningRating: 3.5 out of 5 stars3.5/5 (3)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)