Professional Documents

Culture Documents

AN1895 - L6562 375W Step by Step

Uploaded by

betodias30Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AN1895 - L6562 375W Step by Step

Uploaded by

betodias30Copyright:

Available Formats

AN1895 Application note

EVAL6562-375W Evaluation Board L6562-based 375W FOT-controlled PFC Pre-regulator

Introduction

This application note describes a 375W evaluation board based on the L6562 Transitionmode Power Factor Correction (PFC) controller (order code: EVAL6562-375W). The board implements a 375W, wide-range mains input, PFC pre-regulator that is suitable for a 300/350W ATX12V power supply unit (PSU). To enable the use of a low-cost device like the L6562 at a power level that is usually prohibitive for this device, the chip operates with a Fixed-Off-Time (FOT) control system. This allows Continuous Conduction Mode operation, normally achievable with more expensive control chips and more complex control architectures.

EVAL6562-375W evaluation board

August 2006

Rev 3

1/16

www.st.com

Contents

AN1895

Contents

1 2 3 4 Board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Power stage design procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Setting up FOT control with the L6562 . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Getting started with the evaluation board . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Testbench results and significant waveforms . . . . . . . . . . . . . . . . . . . . . . . 9

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix A Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/16

AN1895

Board description

Board description

The EVAL6562-375W evaluation board includes a Power Factor Correction (PFC) preregulator for a 300W ATX 12V power supply unit (PSU). It is able to deliver 375W continuous power on a regulated 400V rail from a wide range of mains voltage. This rail will be the input for the cascaded isolated DC-DC converter (typically a forward converter) that will provide the output rails of the silver box. Although the ATX specification envisages air cooling, typically realized with a fan capable of an airflow in the range of 25-35 CFM, this is not allowed for in the design of this evaluation board. Enough heat sinking will be provided to allow full-load operation in still air. With an appropriate airflow and without any change in the circuit, the evaluation board can easily deliver up to 400-420W. The L6562 controller chip is designed for Transition-Mode (TM) operation where the boost inductor works next to the boundary between Continuous (CCM) and Discontinuous Conduction Mode (DCM). However, with a slightly different usage, the chip can operate so that the boost inductor works in CCM, hence surpassing the limitations of TM operation in terms of power handling capability. The gate-drive capability of the L6562 (0.8A min.) is also adequate to drive the MOSFETs used at higher power levels. This approach, which couples the simplicity and cost-effectiveness of TM operation with the high-current capability of CCM operation, is the Fixed-Off-Time (FOT) control. The control modulates the ON-time of the power switch, while its OFF-time is kept constant. More precisely, it will be used the Line-Modulated FOT (LM-FOT) where the OFF-time of the power switch is not rigorously constant but is modulated by the instantaneous mains voltage. Please refer to [2] for a detailed description of this technique. Table 1 summarizes the electrical specification of the application and Table 3 lists transformer specifications. The electrical schematic is shown in Figure 1 and the PCB layout in Figure 2. Appendix A lists the bill of materials. Table 1. Electrical specifications

Parameter Line voltage range Minimum line frequency (fL) Regulated output voltage Rated output power Maximum 2fL output voltage ripple Hold-up time Maximum switching frequency (@ VIN = 90 VAC, POUT = 375 W) Minimum estimated efficiency (@ VIN = 90 VAC, POUT = 375W) Maximum ambient temperature Value 90 to 265 VAC 47 Hz 400 V 375 W 20V pk-pk 17 ms 100 kHz 90% 50 C

3/16

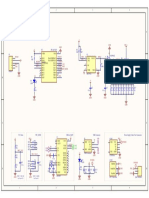

Board description Figure 1. Electrical schematic diagram

AN1895

Figure 2.

PCB layout, silk + bottom layer (top view) (150 x 81.5 mm)

4/16

AN1895

Power stage design procedure

Power stage design procedure

The step-by-step procedure of an LM-FOT controlled PFC pre-regulator outlined in [2] will be followed. The design will be done on the basis of a ripple factor (the ratio of the maximum current ripple amplitude to the inductor peak current at minimum line voltage) Kr=0.3. 1. The range of k (kmin kmax) associated to the line voltage range is:

k min = Vin (RMS ) min - = 2 ---------------------------------Vout 902 --------= 0.318, k max = 400 Vin (RMS ) max -= 2 ----------------------------------Vout 265 - = 0.937 . 2 --------400

2.

The required tOFFmin is derived from the specification on the maximum switching frequency (on the top of the line voltage sinusoid) fswmax at minimum line voltage:

k min 0.318 - = 3.18 s t OFFmin = ------------------ = ----------------------3 f sw max 100 10

3.

The maximum expected input power Pin0 = Pout0/ and the maximum line peak current, Ipkmax are:

2Pin 0 2 417 - = 6.56A = ---------------------------Pin 0 = 375 --------- = 417W; Ipk max = ------------------------k min Vout 0.318 400 0.9

4.

The ripple amplitude on the top of the sinusoid at minimum line voltage, assuming it is 75% of the maximum specified, will be:

6Kr 6 0.3 I Lpk = -----------------Ipk max = ----------------------- 6.56 = 1.66A 8 3Kr 8 3 0.3

5.

The required inductance L of the boost inductor is:

6 Vout 400-t L = ( 1 k min ) ------------= ( 1 0.318 ) --------- 3.18 10 = 523 H I Lpk OFFmin 1.66

This value will be rounded up to 550 H; the resulting value of Kr will be slightly smaller than 0.3, but we will go on using the target value, this will give some additional margin. 6. The maximum inductor peak current, ILpkmax, is calculated:

8 8 - 6.56 = 7.39A I Lpkmax = -----------------lpk max = -----------------------8 3Kr 8 3 0.3

7.

The maximum sense resistor Rsensemax is:

1.6 - = ---------1.6- = 0.216 R sense max = -------------------I Lpkmax 7.39

(1.6V is the minimum value of the pulse-by-pulse current limiting threshold on the current sense pin of the L6562). It will be realized with four 0.68, 1W-rated paralleled resistors, for a total resistance of 0.17. This provides some extra power capability. The inductor peak current that the inductor must be able to carry without saturating will be:

1.8- = 10.6A I Lpksat = ---------0.17

8.

From the formulae in [2], table 4, the MOSFET RMS current is:

Pin 0 16k min 417 16 0.318 - = ---------------------------2 ------------------------- = 3.96A I Q ( rms ) = ------------------------- 2 -----------------k min Vout 0.318 400 3 3

5/16

Power stage design procedure The diode RMS current is:

Pin 0 16k min 417 - 16 0.318 - = ---------------------------------------------------- = 2.41A I Q ( rms ) = ------------------------- -----------------0.318 400 k min Vout 3 3

AN1895

The dissipation on the sense resistor will be 0.173.962=2.7W, which justifies the use of four resistors; the selected MOSFET is the STP12NM50, a 0.3/500V MDmesh type from STMicroelectronics, housed in a TO220 package; two of them will be paralleled to handle the rated power; the selected diode is an STTH806DTI, an 8A/600V Tandem diode, again from STMicroelectronics, housed in a TO220 package. All of them must be dissipated to keep their temperature within safe limits. As for the inductor, the core size will be determined by saturation since the ripple is relatively low. Assuming a peak flux density Bmax=0.3T, the minimum required AreaProduct is:

1 k min Kr Pin 0 t OFF - ------------------------ AP min 186 --------------------------B max k min Kr

1.31

1 0.318 0.3 417 3.18 10 - ------------------------------------ -----------------------------------------= 186 0.318 0.3 0.3

6 1.31

= 2.92 [cm ]

An E42 core (AP = 3.15 cm4) has been chosen. See table 3 for the complete inductor spec. The output capacitor is determined by the hold-up time requirement. Assuming a minimum voltage of 300V after the line drop, a minimum of 180 F is needed and a 220F/450V capacitor will be used. 9. The peak multiplier bias voltage VMULT @90V mains must meet the condition:

I Lpkmax R sense V in ( RMS ) min ---------------------------------------- V MULTpk 3 ---------------------------------1.65 V in ( RMS ) max

where 1.65 is the minimum slope of the multiplier characteristic associated to the error amplifier saturated high (see Figure 9 in [1]). With the selected value for Rsense (0.17 ):

907.39 0.17 = 0.761 V ----------------------------------MULTpk 3 265 = 1.02 1.65

Choosing the ratio of the resistor divider that biases the multiplier input (pin 3, MULT) KP = 810-3 lets the peak voltage on the multiplier pin will go from 1V to 3V, thus meeting the above condition. The high-side resistor of the output divider that sets the output voltage is chosen on the basis of the maximum allowed overvoltage on the output. Considering 40V overvoltage, the high-side resistor must be 1M (see [3] for details, in this respect the L6561 and the L6562 are exactly equal). The low-side resistor will then be 1M (400/2.5 - 1) = 6.29k; the 6.34k standard value will be used. Based on the model given in [2], a compensation network made with an RC series (R = 6.8 k, C = 1 F) guarantees a minimum of 25 phase margin (with 9 Hz bandwidth) at minimum line and a bandwidth not exceeding 20 Hz (with 50 phase margin) at maximum line.

6/16

AN1895

Setting up FOT control with the L6562

Setting up FOT control with the L6562

FOT control is implemented with the L6562 using the circuit shown in Figure 3, which shows some significant waveforms as well. Before starting the design, the desired value of tOFF at the maximum line voltage must be specified. Application note AN1792 shows that to reduce high-voltage distortion, tOFF must be greater than 7s, hence we choose tOFF = 8s.

Figure 3.

Circuit implementing FOT control with the L6562 and relevant timing waveforms.

Following the design procedure given in AN1792, with the aid of the diagram of Figure 4: 1. The ratio of the maximum tOFF value to the minimum tOFF value is:

8 10 - = 2.52 = --------------------------6 3.18 10

6

2.

Consider the value of VMULTpk at minimum line voltage (VMULTpk = 1V), in Figure 4 draw a horizontal line located at = 2.52 (on the left vertical axis) as long as it intercepts the curve relevant to the value VMULTpk=1V in P1. The abscissa of P1 gives the value K1=0.891. From P1 draw a vertical line as long as it intercepts the K2 curve relevant to VMULTpk=1 in P2. The ordinate of P2 (on the right vertical axis) gives the value K2=4.17. The required time constant is:

6 t OFFmin 6 3.18 10 = --------------------= --------------------------- = 0.76 10 s K2 4.17

3. 4.

5.

A capacitor C = 560 pF is selected, then the associated resistance value will be:

- = ---------------------------0.76 10 - = 1357 R' = -- 12 C 560 10

6

6.

R1 and R2 will be respectively:

R' - = ----------------------1357 - = 12450 R1 = ---------------1 K1 1 0.891 R'- = -------------1357- = 1523 R2 = -----K1 0.891

the standard values R1 = 12k and R2 = 1.5k will be chosen.

7/16

Setting up FOT control with the L6562 7.

AN1895

Assuming that the VCC voltage never falls below 14-15V, the limiting resistor Rs can be selected according to:

V GDx V ZCDclamp V F Rs > ------------------------------------------------------------------------------------------------------------------------------------------------------------------------V ZCDclamp R2 + ( V ZCDclamp V MULTpkmax V BE ) R1 I ZCDx + --------------------------------------------------------------------------------------------------------------------------------------------------R1R2

where VGDx = 15V is the maximum clamp value of the gate drive voltage, VZCDclamp 5.7V is the clamp value of the ZCD pin voltage, VF 0.5V the forward drop on the diode, IZCDx = 10mA the maximum ZCD clamp current D and VBE 0.55V the emitterto-base forward drop of T. Substituting:

15 5.7 0.5 - = 739 Rs > -------------------------------------------------------------------------------------------------------------------------- 3 5.7 1500 + ( 5.7 3 0.55 ) 12000 10 10 + --------------------------------------------------------------------------------------------1500 12000

in this case a 1.5k resistor will be chosen 8. Cs will be selected according to the relationship:

V ZCDclamp 12 5.7 ---------------------------------- = 363pF Cs < C ---------------------------------------------------------------- = 560 10 V GDx V ZCDclamp V F 15 5.7 0.5

a standard value Cs=330 pF will be used. Figure 4. Diagrams for the design of the circuit of Figure 3 (valid for wide-range mains operation).

8/16

AN1895

Getting started with the evaluation board

Getting started with the evaluation board

The AC voltage, generated by an AC source ranging from 90 to 265 VAC, will be applied to the input connector, located close to the bottom left-hand corner. The 400 VDC output is located close to the bottom right-hand corner and will be connected to the load. If an electronic load is going to be used pay attention to the right polarity: the (+) output terminal is that located closer to the corner.

Warning:

Like in any offline circuit, extreme caution must be used when working with the application board because it contains dangerous and lethal potentials. The application must be tested with an isolation transformer connected between the AC mains and the input of the board to avoid any risk of electrical shock.

4.1

Testbench results and significant waveforms

The following diagrams summarize the results of certain testbench evaluations. A number of waveforms under different load and line conditions are shown for user's reference.

Figure 5.

Evaluation data

9/16

Getting started with the evaluation board Figure 6. Compliance with JEIDA-MITI & EN61000-3-2 standards

AN1895

Figure 7.

Harmonic emissions at light load (70W)

Figure 8.

Line current waveforms @ POUT = 375W

10/16

AN1895 Figure 9. Line current waveforms @ POUT = 180W

Getting started with the evaluation board

Figure 10. Line current waveforms @ POUT = 70W

Note:

Note that input LC filter is provided only to clean the line current waveform enough to prevent the measurement system from being misled by an excessive noise level. The filter is not designed nor tested for EMI compliance. The board, as is, is able to handle properly an output load as low as 15 W. With lower load levels, the system will not start up correctly at low line because the OVP generated at startup lasts so long that the VCC voltage drops below the UVLO of the L6562 (e.g. with 4W load the system would stop for 600 ms @ VIN = 90VAC). Load transients from the maximum load to levels below 15W may cause the VCC to be lost as well. If supplying the L6562 with an external source, the minimum load that can be handled properly drops to virtually zero.

11/16

References

AN1895

References

[1] "L6562 Power Factor Corrector" Datasheet. [2] "Design of Fixed-Off-Time-Controlled PFC Pre-regulators with the L6562", AN1792. [3] L6561, Enhanced Transition-Mode Power Factor Corrector, AN966.

12/16

AN1895

Bill of materials

Appendix A

Table 2.

Bill of materials

Bill of material for EVAL6562-375W evaluation board

Symbol Value 120 k 620 k 10 k 47 6.8 k 6.8 0.68 1.5 k 12 k 499 k 6.34 k 330 330 nF 1 F 10 nF 47 F 1 F 330 pF 560 pF 470 nF 220 F TOR73 E4218 KBU8M 1N4148 1N5406 STTH806DTI 1N5248B L6562 BC557 BS237 ----OS512 630V, EPCOS B32653 or equivalent 450V, Electrolytic Nichicon LS or equivalent 3.9 mH / 6A, supplied by ITACOIL s.r.l. Boost inductor. See spec on table 3. Supplied by ITACOIL s.r.l. 8A / 1000V, GI or equivalent 0.3A / 75V, glass case, Vishay or equivalent 3A / 600V, D0201, ON Semiconductor or equivalent 8A / 600V, Tandem Hyperfast, TO220, ST 18V / 500mW Zener, ON Semiconductor or equivalent TM PFC controller, DIP8, ST PNP, 0.1A / 45V, TO92, On Semiconductor or equivalent NTC 2.5 , EPCOS or equivalent 8A, 250V FR-4, Cu single layer 35m, 150 x 81.5 mm 2.12 C/W, Extrusion Profile, Aavid Thermalloy 25V electrolytic EPCOS B81131 or equivalent 400V, EPCOS B32653 or equivalent Metal film, 1W Note

R1A and R1B R2A and R2B R3 R4 R5 R6 and R13 R7A, R7B, R7C and R7D R8 and R12 R9 R10A and R10B R11 R14 CX1 and CX2 C1 C2 and C4 C3 C5 C6 and C10 C7 C8 C9 L1 T1 BRIDGE D1, D2, D3 and D4 D5 D6 DZ1 U1 M1 and M2 TR1 NTC1 F1 PCB Heat sink

STP12NM50FP 0.3 / 500V, MDmesh TM, TO220FP, ST

Note:

If not otherwise specified, all resistors are 1%, W, all capacitors are ceramic or plastic film. The Bridge, M1, M2 and D6 all share the same heat sink.

13/16

Bill of materials Table 3.

Core Bobbin Air gap

AN1895

EVAL6562-375W: boost inductor specification (part# E4218, made by ITACOIL s.r.l.)

E42/21/7, N67 Material or equivalent Horizontal mounting, 10 pins 1.9 mm for an inductance 1-10 of 550 H Pin Start/End 1/10 6/5 Winding Main Aux Wire 20xAWG32 AWG32 Turns Notes

Windings Spec & Build

58 (N1) Pins 1 & 2, pins 10 & 9 are shorted on the PCB 6 (N2) Evenly spaced

14/16

AN1895

Revision history

Revision history

Table 4.

Date 20-May-2004 28-Aug-2006

Document revision history

Revision 2 3 Initial release. Corrected Equation 1. on page 5. Minor editing changes. Changes

15/16

AN1895

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (ST) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to STs terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN STS TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USERS OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

2006 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com

16/16

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Forward Design 300W STmicroelectronics App NoteDocument10 pagesForward Design 300W STmicroelectronics App Notecristi7521No ratings yet

- 90W Smps For Monitors With Constant Power Limiting Function: AN1133 Application NoteDocument11 pages90W Smps For Monitors With Constant Power Limiting Function: AN1133 Application NoteMadein ChinaNo ratings yet

- Str-A606xh Ds enDocument28 pagesStr-A606xh Ds enGiovanni Carrillo VillegasNo ratings yet

- Slup083 PDFDocument7 pagesSlup083 PDFlu1agpNo ratings yet

- AND8241/D A 5.0 V/2.0 A Standby Power Supply For INTEL Compliant ATX ApplicationsDocument16 pagesAND8241/D A 5.0 V/2.0 A Standby Power Supply For INTEL Compliant ATX ApplicationsJonatan LunaNo ratings yet

- Summary ClockDocument39 pagesSummary ClockmikcomiNo ratings yet

- LNK605 DatasheetDocument18 pagesLNK605 DatasheetdgujarathiNo ratings yet

- 161 20551 0 FS7M0880Document16 pages161 20551 0 FS7M0880Edwin Vitovis TorresNo ratings yet

- Single Ended Active Clamp/Reset PWM: Features DescriptionDocument16 pagesSingle Ended Active Clamp/Reset PWM: Features Descriptioncatsoithahuong84No ratings yet

- AppNote03 Uc3842Document14 pagesAppNote03 Uc3842Heriberto Flores AmpieNo ratings yet

- Slua 143Document15 pagesSlua 143Tonia KataNo ratings yet

- Aplicacion Uc3842Document15 pagesAplicacion Uc3842Gian Mejia100% (1)

- Datasheet T2117Document16 pagesDatasheet T2117Radovan RasaNo ratings yet

- (Year) : (Pick The Date)Document43 pages(Year) : (Pick The Date)Akhil Andres Mehta0% (1)

- An1683x Flyback DesignDocument25 pagesAn1683x Flyback Designnico_15_91No ratings yet

- Voltage To Frequency ConverterDocument7 pagesVoltage To Frequency ConverterRodfer SorianoNo ratings yet

- D D D D D D D: TL7700 Supply-Voltage SupervisorDocument12 pagesD D D D D D D: TL7700 Supply-Voltage SupervisorToni BioscaNo ratings yet

- TL 496 DatasheetDocument7 pagesTL 496 DatasheetAnonymous vKD3FG6RkNo ratings yet

- Ucc 3818Document32 pagesUcc 3818jeyachadranaNo ratings yet

- Simple 1.5-V Boost Converter For MSP430 - Slaa105Document7 pagesSimple 1.5-V Boost Converter For MSP430 - Slaa105Daniel ZancoNo ratings yet

- 12 Volt Smps Circuit DiagramDocument7 pages12 Volt Smps Circuit DiagramAnura MaddumageNo ratings yet

- A6251 6252Document7 pagesA6251 6252Giovanni Carrillo VillegasNo ratings yet

- Low-Power Economy Bicmos Current-Mode PWMDocument26 pagesLow-Power Economy Bicmos Current-Mode PWMmigsayalNo ratings yet

- HT7A6003 EMI-Improved Green Mode PWM Controller With Integrated ProtectionsDocument10 pagesHT7A6003 EMI-Improved Green Mode PWM Controller With Integrated ProtectionsEnéas BaroneNo ratings yet

- TL 497 ADocument20 pagesTL 497 AJoaoNo ratings yet

- Datasheet MC3334Document6 pagesDatasheet MC3334odipasNo ratings yet

- Sine Wave GenerationDocument18 pagesSine Wave GenerationIfedayo OladapoNo ratings yet

- Book DrsstcpreviewDocument21 pagesBook DrsstcpreviewNevia SilićNo ratings yet

- A4989 DatasheetDocument17 pagesA4989 DatasheetGopalkrishnan Nadar100% (1)

- Application Note: Tda 16888: Multioutput Single Transistor Forward Converter 150W / 100KhzDocument20 pagesApplication Note: Tda 16888: Multioutput Single Transistor Forward Converter 150W / 100KhzManuel Alejandro Espinosa FarfanNo ratings yet

- BM2596Document9 pagesBM2596Anton AdrianNo ratings yet

- Green-Mode PWM Controller: General Description FeaturesDocument10 pagesGreen-Mode PWM Controller: General Description FeaturesLuis Luis GarciaNo ratings yet

- STK400 040Document10 pagesSTK400 040Carlos Milton Martinez GaleanoNo ratings yet

- Restricted Earth Fault Technical ReportDocument10 pagesRestricted Earth Fault Technical ReportEBENo ratings yet

- Ucc3580 4Document20 pagesUcc3580 4vanhuong87No ratings yet

- UC3845 Technical ExplanationDocument15 pagesUC3845 Technical ExplanationankurmalviyaNo ratings yet

- Oz9938 PDFDocument12 pagesOz9938 PDFCarlosNo ratings yet

- Mtw8n60e DDocument9 pagesMtw8n60e DAtiqurrehman UmairNo ratings yet

- P1027P65 (SMPS)Document30 pagesP1027P65 (SMPS)Jesus Silva67% (3)

- Application Note AN6016: LCD Backlight Inverter Drive IC (FAN7311)Document18 pagesApplication Note AN6016: LCD Backlight Inverter Drive IC (FAN7311)Osama YaseenNo ratings yet

- DatasheetDocument19 pagesDatasheetSwapnica GarreNo ratings yet

- SW - Buck - 1 Application Report: Topology: Non Synchronous Buck Converter Controller: Texas Instruments TPS40200Document25 pagesSW - Buck - 1 Application Report: Topology: Non Synchronous Buck Converter Controller: Texas Instruments TPS40200Ion AvramNo ratings yet

- UC3879Document9 pagesUC3879Christina Tio TrisnasariNo ratings yet

- Restricted Earth Fault Application GuideDocument12 pagesRestricted Earth Fault Application GuidementongNo ratings yet

- Project On Ac Voltage Controller Using TriacDocument33 pagesProject On Ac Voltage Controller Using Triackatul830486% (7)

- DatasheetDocument12 pagesDatasheetDjalma MoreiraNo ratings yet

- CA3059, CA3079: Description FeaturesDocument12 pagesCA3059, CA3079: Description FeaturesMiltongrimi GrimilNo ratings yet

- OZ9939GNDocument12 pagesOZ9939GNEduardo SierraNo ratings yet

- CA3059Document13 pagesCA3059Luis Miguel BarrenoNo ratings yet

- MW Inverter IC RM6203Document7 pagesMW Inverter IC RM6203KybernetikumNo ratings yet

- D D D D D D D D D D D D D D D: SN65ALS180, SN75ALS180 Differential Driver and Receiver PairsDocument21 pagesD D D D D D D D D D D D D D D: SN65ALS180, SN75ALS180 Differential Driver and Receiver PairsjohnysonycumNo ratings yet

- Linkcv Family DatasheetDocument18 pagesLinkcv Family DatasheetaisanasNo ratings yet

- Very Wide Input Voltage Range-Flyback (90V To 600V AC)Document12 pagesVery Wide Input Voltage Range-Flyback (90V To 600V AC)senkum812002No ratings yet

- Uc 3854Document12 pagesUc 3854Leandro CoradiNo ratings yet

- MLP2N06CL Smartdiscretes Mosfet 2 Amps, 62 Volts, Logic LevelDocument9 pagesMLP2N06CL Smartdiscretes Mosfet 2 Amps, 62 Volts, Logic LevelEcurepair BrasilNo ratings yet

- AN1060 Flyback L6561Document12 pagesAN1060 Flyback L6561Armando SánchezNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- A1324 5 6 DatasheetDocument12 pagesA1324 5 6 DatasheetJuan Pablo Merck SifontesNo ratings yet

- DECODING HT6P20 WITH Attachinterrupt Arduino Forum PDFDocument6 pagesDECODING HT6P20 WITH Attachinterrupt Arduino Forum PDFbetodias30No ratings yet

- Ah49e 1317872Document11 pagesAh49e 1317872betodias30No ratings yet

- NTC ncp18Document10 pagesNTC ncp18betodias30No ratings yet

- Active Load PAL Tester Schematic v0.6Document1 pageActive Load PAL Tester Schematic v0.6betodias30No ratings yet

- Infineon Ikcm20l60ga Ds v02 03 enDocument17 pagesInfineon Ikcm20l60ga Ds v02 03 enbetodias30No ratings yet

- 3000 Problemas de CircuitosDocument768 pages3000 Problemas de Circuitosbetodias30No ratings yet

- Display 20x4 TC2004A-01Document2 pagesDisplay 20x4 TC2004A-01betodias30No ratings yet

- Debugger stm8 PDFDocument23 pagesDebugger stm8 PDFbetodias30No ratings yet

- Measuring Speed and Position With A Quadrature EncoderDocument3 pagesMeasuring Speed and Position With A Quadrature Encoderbetodias30No ratings yet

- MAX038Document17 pagesMAX038Brane PetkoskiNo ratings yet

- AN650 - Max038 PDFDocument15 pagesAN650 - Max038 PDFbetodias30No ratings yet

- 1 - 14110208 - MT7605Document7 pages1 - 14110208 - MT7605betodias30No ratings yet

- Manual Altium 2014 PDFDocument630 pagesManual Altium 2014 PDFbetodias30No ratings yet

- An-1215 - Iram256-1067aDocument28 pagesAn-1215 - Iram256-1067abetodias30No ratings yet

- Display 20x4 TC2004A-01 PDFDocument18 pagesDisplay 20x4 TC2004A-01 PDFbetodias30No ratings yet

- 1724-Motion Detection - Dual AnalogueDocument2 pages1724-Motion Detection - Dual Analoguebetodias30No ratings yet

- Gu0104 Shortcut KeysDocument16 pagesGu0104 Shortcut Keysbetodias30No ratings yet

- MDP Cnvecad enDocument76 pagesMDP Cnvecad enbetodias30No ratings yet

- Altium Designer Keyboard ShortcutsDocument1 pageAltium Designer Keyboard Shortcutsbetodias30No ratings yet

- EDR Type CoresDocument1 pageEDR Type Coresbetodias30No ratings yet

- 2 STMicroelectronics LED Solutions PDFDocument92 pages2 STMicroelectronics LED Solutions PDFbetodias30No ratings yet

- 1 - 07161815 - MT7601Document8 pages1 - 07161815 - MT7601betodias30No ratings yet

- Application L6562Document4 pagesApplication L6562betodias30No ratings yet

- Bob-09579-Isd1900 - Modulo de Voz PDFDocument29 pagesBob-09579-Isd1900 - Modulo de Voz PDFbetodias30No ratings yet

- 2001 Ford F150 ManualDocument296 pages2001 Ford F150 Manualerjenkins1100% (2)

- Compact 1.8" Height Standardized Installation 9 Months To Flight Powerful and LightweightDocument2 pagesCompact 1.8" Height Standardized Installation 9 Months To Flight Powerful and LightweightStanley Ochieng' OumaNo ratings yet

- Principles To Action (Short)Document6 pagesPrinciples To Action (Short)nsadie34276No ratings yet

- ICU General Admission Orders: OthersDocument2 pagesICU General Admission Orders: OthersHANIMNo ratings yet

- Module 2Document7 pagesModule 2karthik karti100% (1)

- JBF Winter2010-CPFR IssueDocument52 pagesJBF Winter2010-CPFR IssueakashkrsnaNo ratings yet

- BA 4722 Marketing Strategy SyllabusDocument6 pagesBA 4722 Marketing Strategy SyllabusSri GunawanNo ratings yet

- Current Surgical Therapy 13th EditionDocument61 pagesCurrent Surgical Therapy 13th Editiongreg.vasquez490100% (41)

- IPS PressVest Premium PDFDocument62 pagesIPS PressVest Premium PDFLucian Catalin CalinNo ratings yet

- SKF Shaft Alignment Tool TKSA 41Document2 pagesSKF Shaft Alignment Tool TKSA 41Dwiki RamadhaniNo ratings yet

- Work Site Inspection Checklist 1Document13 pagesWork Site Inspection Checklist 1syed hassanNo ratings yet

- Antifraud PlaybookDocument60 pagesAntifraud PlaybookDani UsmarNo ratings yet

- LSL Education Center Final Exam 30 Minutes Full Name - Phone NumberDocument2 pagesLSL Education Center Final Exam 30 Minutes Full Name - Phone NumberDilzoda Boytumanova.No ratings yet

- April 2021 BDA Case Study - GroupDocument4 pagesApril 2021 BDA Case Study - GroupTinashe Chirume1No ratings yet

- Chestionar 2Document5 pagesChestionar 2Alex AndruNo ratings yet

- What Is Product Management?Document37 pagesWhat Is Product Management?Jeffrey De VeraNo ratings yet

- Zambia National FormularlyDocument188 pagesZambia National FormularlyAngetile Kasanga100% (1)

- Yarn HairinessDocument9 pagesYarn HairinessGhandi AhmadNo ratings yet

- MiddleWare Technology - Lab Manual JWFILESDocument171 pagesMiddleWare Technology - Lab Manual JWFILESSangeetha BajanthriNo ratings yet

- FDD Spindle Motor Driver: BA6477FSDocument12 pagesFDD Spindle Motor Driver: BA6477FSismyorulmazNo ratings yet

- Introduction To AmplifierDocument8 pagesIntroduction To AmplifierElaine BicolNo ratings yet

- Navi-Planner User ManualDocument331 pagesNavi-Planner User ManualRichard KershawNo ratings yet

- DOST-PHIVOLCS Presentation For The CRDRRMC Meeting 15jan2020Document36 pagesDOST-PHIVOLCS Presentation For The CRDRRMC Meeting 15jan2020RJay JacabanNo ratings yet

- Chapter 13Document15 pagesChapter 13anormal08No ratings yet

- Wins Salvacion Es 2021Document16 pagesWins Salvacion Es 2021MURILLO, FRANK JOMARI C.No ratings yet

- PNGRB - Electrical Safety Audit ChecklistDocument4 pagesPNGRB - Electrical Safety Audit ChecklistKritarth SrivastavNo ratings yet

- Steel Price Index PresentationDocument12 pagesSteel Price Index PresentationAnuj SinghNo ratings yet

- ATAL Selected FDPs AY 2023 24Document15 pagesATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- ANS145 - Beef Cattle ProductionDocument52 pagesANS145 - Beef Cattle ProductionEgie BulawinNo ratings yet

- ArrowrootDocument8 pagesArrowrootSevi CameroNo ratings yet