Professional Documents

Culture Documents

FLUID DYNAMICS AND MASS TRANSFER LAB MAINTENANCE

Uploaded by

Abdul Mannan KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FLUID DYNAMICS AND MASS TRANSFER LAB MAINTENANCE

Uploaded by

Abdul Mannan KhanCopyright:

Available Formats

ASSIGNMENT FLUID DYNAMICS& MASS TRANFER LAB MAINTENANCE

Submitted by: Roll no: 2011-CH-05 2011-CH-37 2011-CH-53 2011-CH-89 Submitted to: Sir Usman

Fluid Dynamics Lab

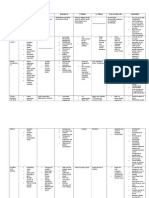

Sr No. Equipment Name Maintenance Suggestion Maintenance Type Routine NonRoutine

Lubrication of the mechanical parts Change of motor(rotary part) oil Compressible flow batch 1 Check the supply line Check erosion and corrosion on the surface Check cracks or any damage Check electrical connection Check working of motor (rotary part)

Check all electrical supply and connection Clean the hydraulic bench with any reagent to remove the adhesive particles. Flow meter calibration Check all the valve for leakage Check cracks or any damage Check the lubrication of the pump (rotary part) Check pump sound Check if there are any cracks Osborne Apparatus Check discharge, inlet pipes and valves for possible leakage Dye injection point should not be blocked

Hydraulic Bench

Sr No.

Equipment

Maintenance Suggestion

Maintenance Type Routine NonRoutine

Orifice & Jet Apparatus

Check possible leakage if any Check utilities supply lines Check valves Cleaning of the vessel

Calibration of flow meter 5 Fixed & Fluidized Bed Check pump Check motor Check electricity supply and connections Check all the valve for leakage Check all the pipes Check pump

Flow meter demonstration

Sedimentation

Cleaning of the vessel Check for cracks on the tubes

8 9

Fermenter Dead weight calibrator

Cleaning Check Corrosion and erosion Check Rusting of weights (Stationary)

10

Distilling apparatus

Tube cleaning (Stationary) Cleaning from outside (Stationary)

Check scaling and rusting of cylinder (Stationary) Sr

No.

Equipment

Maintenance Suggestion

Maintenance Type Routine NonRoutine

Check Plastic tube scaling (Stationary)

Bio sorption 11 Pump maintenance (Stationary) Motor maintenance (rotary)

12 Bernoullis apparatus Scaling of tube (Stationary)

13

Hydrostatic pressure apparatus)

Wooden Block Maintenance (Stationary Maintenance of tubes(Stationary)

Burner 14

Maintenance of burner flame filament (Stationary) Valves (Stationary) Digital meter (Stationary)

15

Centrifugal compressor demonstration unit

Compressor Maintenance Wires (Stationary) Maintenance of Fan (rotary)

16

Centrifugal fan demonstration unit

Wires (Stationary) Connectors (Stationary)

SAFETY AND BUILDING POINTS: Proper Ventilation must be ensured Light should be appropriate Equipment must be placed at safe distance Emergency exit should be there Fire Extinguishers and first aid kit must be available

Mass Transfer Lab

Sr. No Equipment Maintenance Suggestion Routine NonRoutine

Power supply Electric Connections 1 Weigh Balance calibration

Tray Dryer

Support stand

Tubes cleaning . Cleaning of inlet discharge points 2 Liquid Liquid Extraction Packing should be cleaned Check cracks or any damage Vessel must be impurities free Glass tower cracks Flow meter Calibration Trays condition should be checked Valves Batch and Continuous Distillation Column Temperature sensors must be checked Insulation must be checked

Sr No.

Equipment

Maintenance Suggestion

Maintenance Type Routine NonRoutine

Vaccum valve calibration 3 Trays wear and tear

Regeneration of the resins 4 Ion Exchanger Apparatus Regents must be replaced Conductivity metre should be checked after some time Flow meter calibration Corrosion check Flow meter check and calibration Pressure gauge and calibration Membrane cleaning and replacement Control Circuit

Reverse Osmosis

6 Fruit Concentrator

Short wiring (pump) Filter check Pressure gauge calibration Filter replacement

7 Cyclone Separator

Pressure gauge calibration Electrical pump Corrosion check

5 micron centrifuge filter check Cleaning of filter Spiral wound Reverse Osmosis Pressure gauge calibration Flow meter calibration

Engine oil should be changed Petrol pump must be well calibrated CO ratio must be check Cracks and damage to the CNG cylinder Scaling in the regulator must be removed Wiring must be checked

CNG Engine

SAFETY AND BUILDING POINTS:

Proper Ventilation must be ensured Light should be appropriate Equipment must be placed at safe distance Emergency exit should be there Fire Extinguishers and first aid kit must be available

You might also like

- GCFUND (Compatibility Mode) PDFDocument73 pagesGCFUND (Compatibility Mode) PDFLalang Dwiyoga SaktiNo ratings yet

- Pa 18 InspDocument4 pagesPa 18 InspPeter Thomas100% (1)

- Preventive Maintenance ChecklistDocument5 pagesPreventive Maintenance ChecklistshabkhaizNo ratings yet

- Bosch Service ScheduleDocument1 pageBosch Service ScheduleLuiz Souza SouzaNo ratings yet

- CLOSING UNIT INSPECTION REPORTDocument4 pagesCLOSING UNIT INSPECTION REPORTfarman ali ahmedNo ratings yet

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McNo ratings yet

- Fire Water Pump ChecklistDocument4 pagesFire Water Pump Checklistmuki10No ratings yet

- Hydraulic Power UnitsDocument5 pagesHydraulic Power UnitsKhaled ZaherNo ratings yet

- Maintenance RecommendationsDocument15 pagesMaintenance Recommendationsmsalem730% (1)

- Monthly HVAC Maint. ScheduleDocument5 pagesMonthly HVAC Maint. ScheduleTawfeeq AhmedNo ratings yet

- Maintenance and Electric ChartDocument9 pagesMaintenance and Electric Chartakamalapuri388100% (1)

- 8-6 Chapter Ignition System Operation and DiagnosisDocument27 pages8-6 Chapter Ignition System Operation and DiagnosisSapari VelNo ratings yet

- متابعة صيانة التكييف المركزيDocument52 pagesمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- Maint IPENDocument13 pagesMaint IPENosmaidaNo ratings yet

- Pneumatics DesigndataDocument132 pagesPneumatics DesigndataMohan ShanmugamNo ratings yet

- 2012 Matt GlovaDocument67 pages2012 Matt GlovaMisama NedianNo ratings yet

- Especificaciones Bomba Ventilador CATD10T - TestDocument36 pagesEspecificaciones Bomba Ventilador CATD10T - TestRafael RodriguezNo ratings yet

- 3500 Startup ChecklistDocument23 pages3500 Startup Checklistlquinter75100% (2)

- International StandardsDocument35 pagesInternational StandardsThiaga RajNo ratings yet

- Oil-Water Separator API Design Capacity 50 GPMDocument11 pagesOil-Water Separator API Design Capacity 50 GPMashoori79No ratings yet

- Plugin DTC Fault Codes PDFDocument106 pagesPlugin DTC Fault Codes PDFRafael HubnerNo ratings yet

- Maintenance checklist for medical deviceDocument1 pageMaintenance checklist for medical deviceMosab BabikirNo ratings yet

- Maintain HVDC Equipment EfficientlyDocument19 pagesMaintain HVDC Equipment EfficientlyDante FilhoNo ratings yet

- Lathe PM ChecklistDocument2 pagesLathe PM ChecklistSandeep Ghadge78% (23)

- s05nmdl2sm PDFDocument22 pagess05nmdl2sm PDFmn_aminNo ratings yet

- GENERATOR 250 HOUR SERVICE SHEETDocument3 pagesGENERATOR 250 HOUR SERVICE SHEETAmon Kiay67% (9)

- Eaton Hydraulic SystemDocument16 pagesEaton Hydraulic SystemMuthu Kumar100% (4)

- Mechanical Commissioning 2Document66 pagesMechanical Commissioning 2mohamed abd el attyNo ratings yet

- PM Check ListDocument10 pagesPM Check Listsachinsharma31No ratings yet

- Weekly Maintenance Checklist TemplateDocument3 pagesWeekly Maintenance Checklist Templateayat hidayatNo ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- Hydraulics Componets CataloqueDocument143 pagesHydraulics Componets CataloqueanemossNo ratings yet

- Reciprocating Compressor Testing GuideDocument10 pagesReciprocating Compressor Testing GuideS DasNo ratings yet

- D2882Document6 pagesD2882rimi7alNo ratings yet

- SideWinder 40 60 80 CHMCL PMP IOMDocument28 pagesSideWinder 40 60 80 CHMCL PMP IOMSH McNo ratings yet

- Hydraulic System Indication and Warning OverviewDocument22 pagesHydraulic System Indication and Warning OverviewMarcus ThianNo ratings yet

- PG Si 0039 en WebDocument2 pagesPG Si 0039 en Webb82monicaNo ratings yet

- JKR Acmv Ahu PDFDocument4 pagesJKR Acmv Ahu PDFHafiz Abdullah50% (2)

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Fire Pump System ChecklistDocument4 pagesFire Pump System ChecklistAhmed Sayed Abdel Tawab100% (1)

- SpringchecklistDocument1 pageSpringchecklistmcjuddyNo ratings yet

- Maintenance of Plastics Processing & Testing Machinery Unit 1Document41 pagesMaintenance of Plastics Processing & Testing Machinery Unit 1Mohsin Alam100% (5)

- s1fnmdl3sm PDFDocument26 pagess1fnmdl3sm PDFmn_aminNo ratings yet

- LavDocument93 pagesLavPamela RodriguezNo ratings yet

- EXPERIMENT and Latest EquipmentDocument10 pagesEXPERIMENT and Latest EquipmentMaria Cecille Sarmiento GarciaNo ratings yet

- WB 760Document149 pagesWB 760Paul MartinNo ratings yet

- Wet Sprinkler ReportDocument4 pagesWet Sprinkler ReportAntony JebarajNo ratings yet

- Equipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardDocument4 pagesEquipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardmuhammadfurQanmirzaNo ratings yet

- Sg10 Sizing & Selection ManualDocument104 pagesSg10 Sizing & Selection ManualiaintNo ratings yet

- Preventive Maintenance Introduction: For Centrifugal Pump SystemsDocument13 pagesPreventive Maintenance Introduction: For Centrifugal Pump SystemsZaenal AripinNo ratings yet

- Checklist of Rig EquipmentDocument11 pagesChecklist of Rig EquipmentKachur AlekseyNo ratings yet

- 0 Hvac ChecklistDocument13 pages0 Hvac ChecklistAssem Elhajj100% (1)

- Ewp Annual or Third Party Inspection ChecklistDocument5 pagesEwp Annual or Third Party Inspection ChecklistScott BoogemansNo ratings yet

- Maintaining Pipes and Hoses SafelyDocument6 pagesMaintaining Pipes and Hoses SafelyDinu Aditya SaputraNo ratings yet

- Valves Valve LeakageDocument5 pagesValves Valve Leakagearson5646100% (1)

- Flow Measuring Instruments & Level Indicators from ISO 9001 CompanyDocument4 pagesFlow Measuring Instruments & Level Indicators from ISO 9001 CompanyI. Murali KrishnaNo ratings yet

- Lampiran 1 Standar InspectionDocument7 pagesLampiran 1 Standar InspectionFitra SNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- TableDocument1 pageTableAbdul Mannan KhanNo ratings yet

- Process Chemistry Process Selection: (2n + 1) H + N CO NH O+ C HDocument1 pageProcess Chemistry Process Selection: (2n + 1) H + N CO NH O+ C HAbdul Mannan KhanNo ratings yet

- Ammonia Flows Vs ProducitonDocument3 pagesAmmonia Flows Vs ProducitonAbdul Mannan KhanNo ratings yet

- Stream Data for Multiple Process StreamsDocument2 pagesStream Data for Multiple Process StreamsAbdul Mannan KhanNo ratings yet

- Parameters Light Sweet Crude OilDocument10 pagesParameters Light Sweet Crude OilAbdul Mannan KhanNo ratings yet

- 090Document6 pages090Abdul Mannan KhanNo ratings yet

- ElDocument16 pagesElAbdul Mannan KhanNo ratings yet

- Reactor PresenationDocument25 pagesReactor PresenationAbdul Mannan KhanNo ratings yet

- MS TH & Lab Attendance 2011 CH Sec ADocument12 pagesMS TH & Lab Attendance 2011 CH Sec AAbdul Mannan KhanNo ratings yet

- How To Get Good Grades FinalDocument12 pagesHow To Get Good Grades FinalAbdul Mannan KhanNo ratings yet

- AspeDocument19 pagesAspeAbdul Mannan KhanNo ratings yet

- Genigraphics Poster Template Sidebar 24x36Document1 pageGenigraphics Poster Template Sidebar 24x36Abdul Mannan KhanNo ratings yet

- Modelling & Simulation Lab Assignment: Submitted By: H. Saad Naseer 2011-CH-53Document8 pagesModelling & Simulation Lab Assignment: Submitted By: H. Saad Naseer 2011-CH-53Abdul Mannan KhanNo ratings yet

- Fun Games IcebreakersDocument21 pagesFun Games IcebreakersMTaylor1234No ratings yet

- Abdul Mannan KPIsDocument3 pagesAbdul Mannan KPIsAbdul Mannan KhanNo ratings yet

- Process DynamicsDocument1 pageProcess DynamicsAbdul Mannan KhanNo ratings yet

- Niff RulesDocument2 pagesNiff RulesAbdul Mannan KhanNo ratings yet

- Plants: 150 Applied Process Design For Chemical and PetrochemicalDocument1 pagePlants: 150 Applied Process Design For Chemical and PetrochemicalAbdul Mannan KhanNo ratings yet

- NIFF Themes and PrizesDocument2 pagesNIFF Themes and PrizesAbdul Mannan KhanNo ratings yet

- NIFF Themes and PrizesDocument2 pagesNIFF Themes and PrizesAbdul Mannan KhanNo ratings yet

- Discover Elevator Pitch GuidelinesDocument4 pagesDiscover Elevator Pitch GuidelinesAbdul Mannan KhanNo ratings yet

- Cooling Tower Effect On ChillerDocument6 pagesCooling Tower Effect On ChillermajortayNo ratings yet

- CocDocument4 pagesCocAbdul Mannan KhanNo ratings yet

- Pressure Changers and Sensitivity AnalysisDocument20 pagesPressure Changers and Sensitivity AnalysisAbdul Mannan KhanNo ratings yet

- Lecture No1Document24 pagesLecture No1Abdul Mannan KhanNo ratings yet

- Organization and ManagementDocument31 pagesOrganization and ManagementAbdul Mannan KhanNo ratings yet

- Types of Maintenance Strategies for Optimal CostsDocument31 pagesTypes of Maintenance Strategies for Optimal CostsAbdul Mannan KhanNo ratings yet

- Astm D189Document7 pagesAstm D189sayonara_3No ratings yet

- University of Engineering and Technology, Lahore Chemical DepartmentDocument1 pageUniversity of Engineering and Technology, Lahore Chemical DepartmentAbdul Mannan KhanNo ratings yet

- D 88 - 94 SayboltDocument7 pagesD 88 - 94 SayboltAbdul Mannan KhanNo ratings yet

- How To Make WPSDocument113 pagesHow To Make WPSSrimanta Kumar DasNo ratings yet

- CE 616 Structural Dynamics Homework Problems 1-3Document1 pageCE 616 Structural Dynamics Homework Problems 1-3Kaushal KumarNo ratings yet

- P-17004 - Final Report - Bearing LP Turbine 3&4Document18 pagesP-17004 - Final Report - Bearing LP Turbine 3&4Komang Khrisna Satya NarayanaNo ratings yet

- PNS 1990 2004 Hot-Dip Zinc-Coated Carbon Steel SheetsDocument23 pagesPNS 1990 2004 Hot-Dip Zinc-Coated Carbon Steel SheetsStandpro Testing CenterNo ratings yet

- Radijarski KarateristikiDocument4 pagesRadijarski Karateristikidejanoski_aNo ratings yet

- Plant Design 02 PDFDocument10 pagesPlant Design 02 PDFNazar AhmedNo ratings yet

- Batangas State University: T 300K H 50 W/M KDocument2 pagesBatangas State University: T 300K H 50 W/M KNixon LagrisolaNo ratings yet

- Catalog - o Ring Handbook - Ode5705 GB PDFDocument164 pagesCatalog - o Ring Handbook - Ode5705 GB PDFJeffrie Nagara NasutionNo ratings yet

- Graphene-Based Conducting Inks 2Document3 pagesGraphene-Based Conducting Inks 2VishnuTejaChundiNo ratings yet

- 5 Methods To Determine Preheat TemperatureDocument5 pages5 Methods To Determine Preheat TemperatureNapoleon DasNo ratings yet

- Soil and Water EngineeringDocument147 pagesSoil and Water EngineeringBrian kNo ratings yet

- ABCD &hermite Gaussian Beams 2019Document37 pagesABCD &hermite Gaussian Beams 2019Marco ValerdiNo ratings yet

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocument10 pagesFreezing Points of High-Purity Hydrocarbons: Standard Test Method ForPavan KumarNo ratings yet

- A Predictive Approach To Fitness-For-Service Assessment of Pitting CorrosionDocument9 pagesA Predictive Approach To Fitness-For-Service Assessment of Pitting CorrosionMaría Vaquero TxapartegiNo ratings yet

- Electrical ProperitiesDocument66 pagesElectrical ProperitiesGabito EssienNo ratings yet

- Sae Technical Paper Series: Alan P. Druschitz, Thomas E. Prucha, Adam E. Kopper and Thomas A. ChadwickDocument9 pagesSae Technical Paper Series: Alan P. Druschitz, Thomas E. Prucha, Adam E. Kopper and Thomas A. ChadwickAliakbar SaifeeNo ratings yet

- Lecture 2Document12 pagesLecture 2Sima KumariNo ratings yet

- Rock properties affecting conical pick performance and comparison of experimental and theoretical cutting resultsDocument38 pagesRock properties affecting conical pick performance and comparison of experimental and theoretical cutting resultsFranceth Castellanos BallesterosNo ratings yet

- Chapter (4 Retaining Wall)Document28 pagesChapter (4 Retaining Wall)Henok YalewNo ratings yet

- Kerala University B SC Physics SyllabusDocument78 pagesKerala University B SC Physics SyllabusDawn DavidNo ratings yet

- Jee MainsDocument32 pagesJee Mainsjhaayushbhardwaj9632No ratings yet

- Filtration Handbook: Awareness of FluidsDocument22 pagesFiltration Handbook: Awareness of Fluidsmatteo_1234No ratings yet

- Process Measurement Instrumentation GuideDocument27 pagesProcess Measurement Instrumentation Guideappril26No ratings yet

- POF 100 Specifications and Requirements For ILI - Nov 2021Document62 pagesPOF 100 Specifications and Requirements For ILI - Nov 2021Fernando ViurquesNo ratings yet

- IctionDocument7 pagesIctionFullo Flores MarviloneNo ratings yet

- CONJUGATE BEAM METHODDocument26 pagesCONJUGATE BEAM METHODGodwin AcquahNo ratings yet

- Aakash Kaliraman Seminar Presentation-1Document18 pagesAakash Kaliraman Seminar Presentation-1Ajay PGI/15/CV/006No ratings yet

- VCR System For Low Temperature Applications: (Cascaded VCRS)Document10 pagesVCR System For Low Temperature Applications: (Cascaded VCRS)Akshay GeraNo ratings yet

- TEWI AnalysisDocument63 pagesTEWI Analysismirali74No ratings yet

- NMR Spectroscopy Daily AssignmentDocument1 pageNMR Spectroscopy Daily AssignmentSandipan SahaNo ratings yet