Professional Documents

Culture Documents

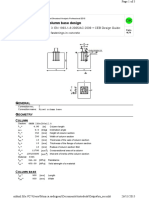

Steel Design Connection of A SHS Type Beam

Uploaded by

SlevinKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Design Connection of A SHS Type Beam

Uploaded by

SlevinKCopyright:

Available Formats

327

Autodesk Robot Structural Analysis Professional 2012

Ratio

0,06

EN 1993-1-8:2005/AC:2009

GENERAL

Connection no.:

Connection name:

Structure node:

Structure bars:

29

Tube

216

2948, 192, 191

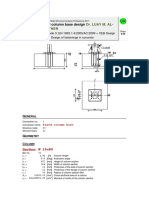

GEOMETRY

BARS

Bar no.:

Section:

h

bf

tw

tf

r

Material:

fy

fu

Angle

Length

Chord

2948

SHSH 120x120x5

120

120

5

5

5

S275

275,00

430,00

0,0

1000

OFFSET

e0 =

-35

[mm]

Offset

Diagonal 1

191

SHSH 80x80x5

80

80

5

5

5

S275

275,00

430,00

51,7

1976

Diagonal 2

192

SHSH 80x80x5

80

80

5

5

5

S275

275,00

430,00

51,7

1976

Post

mm

mm

mm

mm

mm

MPa

MPa

Deg

mm

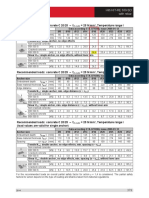

328

SPACINGS

g2 =

-62

[mm]

Spacing of 2nd diagonal

[mm]

Thickness of welds of diagonals and posts

WELDS

ad =

LOADS

Case: 21: COMB7 (1+2)*1.00+(7+10+13)*1.50

CHORD

N01,Ed = -2,65

[kN] Axial force

M01,Ed = 0,10 [kN*m] Bending moment

N02,Ed = -6,93

[kN] Axial force

M02,Ed = 0,10 [kN*m] Bending moment

DIAGONAL 1

N1 =

M1 =

-3,15

[kN] Axial force

0,00 [kN*m] Bending moment

DIAGONAL 2

N2 =

M2 =

3,76

[kN] Axial force

0,00 [kN*m] Bending moment

RESULTS

CAPACITY VERIFICATION EUROCODE 3: EN 1993-1-8:2005

M5 =

1,00

Partial safety factor

[Table 2.1]

FAILURE MODES FOR JOINTS (RHS CHORD MEMBERS) [Table 7.10] for Ni,Rd

GEOMETRICAL PARAMETERS

= 0,67

= 12,00

Coefficient taking account of geometry of connection bars

Coefficient taking account of geometry of the chord

=(b2+b1)/(2*b0) [1.5 (6)]

= b0/(2*t0) [1.5 (6)]

TUBE BRACE FAILURE

DIAGONAL 2

ov =

be,ov =

61,25

[%]

Value of the overlap of bars

50 [mm] Effective width for the overlapping diagonal

be,ov = [10/(b1/t1)] * [fy1*t1/(fy2*t2)]

* b2

beff = [10/(b0/t0)] * [fy0*t0/(fy2*t2)] *

b2

33 [mm] Effective width in the connection of the

diagonal to the chord

N2,Rd = 307,08 [kN] Tension capacity

N2,Rd = fy2*t2* [beff + be,ov + 2*h2-4*t2] /M5

|3,76| < 307,08

(0,01)

verified

|N2| N2,Rd

beff =

DIAGONAL 1

ov =

be,ov =

61,25 [%] Value of the overlap of bars

50 [mm] Effective width for the overlapping

be,ov = [10/(b1/t1)] * [fy1*t1/(fy2*t2)] * b2

ov =

61,25

329

[%]

Value of the overlap of bars

diagonal

33 [mm] Effective width in the connection of the

beff =

beff = [10/(b0/t0)] * [fy0*t0/(fy2*t2)] * b2

diagonal to the chord

N1,Rd = 307,08 [kN] Compression capacity

N2,Rd = fy2*t2* [beff + be,ov + 2*h2-4*t2] /M5

|-3,15| < 307,08

(0,01)

verified

|N1| N1,Rd

Longitudinal weld

1,19 [MPa] Normal stress in a weld

=

1,19 [MPa] Perpendicular tangent stress

=

1,33 [MPa] Tangent stress

II =

|1,19| < 309,60

|| 0.9*fu/M2

2

2

2

3,30 < 404,71

[ + 3*( +II )] fu/(w*M2)

Transverse inner weld

1,31 [MPa] Normal stress in a weld

=

0,32 [MPa] Perpendicular tangent stress

=

0,00 [MPa] Tangent stress

II =

|1,31| < 309,60

|| 0.9*fu/M2

2

2

2

1,42 < 404,71

[ + 3*( +II )] fu/(w*M2)

Transverse outer weld

0,32 [MPa] Normal stress in a weld

=

1,31 [MPa] Perpendicular tangent stress

=

0,00 [MPa] Tangent stress

II =

|0,32| < 309,60

|| 0.9*fu/M2

2

2

2

2,29 < 404,71

[ + 3*( +II )] fu/(w*M2)

Longitudinal weld

-1,23 [MPa] Normal stress in a weld

=

-1,23 [MPa] Perpendicular tangent stress

=

-1,37 [MPa] Tangent stress

II =

|-1,23| < 309,60

|| 0.9*fu/M2

2

2

2

3,42 < 404,71

[ + 3*( +II )] fu/(w*M2)

Transverse outer weld

-1,08 [MPa] Normal stress in a weld

=

-1,72 [MPa] Perpendicular tangent stress

=

0,00 [MPa] Tangent stress

II =

|-1,08| < 309,60

|| 0.9*fu/M2

2

2

2

3,17 < 404,71

[ + 3*( +II )] fu/(w*M2)

verified

verified

(0,00)

(0,01)

verified

verified

(0,00)

(0,00)

verified

verified

(0,00)

(0,01)

verified

verified

(0,00)

(0,01)

verified

verified

(0,00)

(0,01)

0,06

You might also like

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Anonymous 0x2pwMCWgjNo ratings yet

- Base Plate Shear Concrete Edge FailureDocument5 pagesBase Plate Shear Concrete Edge FailureJoel Nolan de Carvalho0% (1)

- Eurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in ConcreteDocument5 pagesEurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in ConcretegunasekaranNo ratings yet

- Eurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in ConcreteDocument5 pagesEurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in Concretegunasekaran100% (1)

- Punching of Flat Slab Acc. DIN EN 1992-1-1: Benchmark Example No. 31Document19 pagesPunching of Flat Slab Acc. DIN EN 1992-1-1: Benchmark Example No. 31Sri RamNo ratings yet

- Declaratie de Conformitate Ancore MTH PDFDocument3 pagesDeclaratie de Conformitate Ancore MTH PDFFerencz ZsoltNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- SPT I30 01 Failed ReportDocument10 pagesSPT I30 01 Failed ReportmalikasalNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXDocument8 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXTeomnerCabreraNo ratings yet

- Punching of Flat Slab Acc. DIN EN 1992-1-1: Benchmark Example No. 31Document19 pagesPunching of Flat Slab Acc. DIN EN 1992-1-1: Benchmark Example No. 31Alexandru PintilieNo ratings yet

- Engineering Calculations For Cox's Walk Footbridge Alternative Repair Proposal - July 2020 - RevBDocument23 pagesEngineering Calculations For Cox's Walk Footbridge Alternative Repair Proposal - July 2020 - RevBDennis DorcooNo ratings yet

- Fixed Column Base Design: EneralDocument5 pagesFixed Column Base Design: Eneralamanpreet_ahujaNo ratings yet

- Base Plate Calculations IDocument5 pagesBase Plate Calculations Ivarshasdm1987No ratings yet

- Steel Connection Design - Tension ElementsDocument5 pagesSteel Connection Design - Tension ElementsSimon LsmNo ratings yet

- Bolted Connection ToolDocument56 pagesBolted Connection ToolPrakash Singh RawalNo ratings yet

- Assemblage Poteau-Semelle IsoléeDocument11 pagesAssemblage Poteau-Semelle IsoléeFrancklinMeunierM'ondoNo ratings yet

- ConnectionDocument16 pagesConnectionHimura_No ratings yet

- Company Name: Calculation SheetDocument7 pagesCompany Name: Calculation SheetVenkatesha HebbarNo ratings yet

- Autodeskrobotstructuralanalysisprofessional2013 190105071907 PDFDocument9 pagesAutodeskrobotstructuralanalysisprofessional2013 190105071907 PDFmaheshbandhamNo ratings yet

- ETABS 2013 Concrete Frame DesignDocument2 pagesETABS 2013 Concrete Frame DesignGabriel LagunaNo ratings yet

- SloofDocument2 pagesSloofAl-Fatih Kids ChannelNo ratings yet

- Column Base Plate Eurocode Ods FileDocument7 pagesColumn Base Plate Eurocode Ods FileSimon LsmNo ratings yet

- Beam Column+Splice+and+End+Plate+ +connectionDocument5 pagesBeam Column+Splice+and+End+Plate+ +connectionSeifeldin Ali MarzoukNo ratings yet

- Table of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3Document7 pagesTable of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3Nicholas FeatherstonNo ratings yet

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNo ratings yet

- ETABS 2015 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument1 pageETABS 2015 Concrete Frame Design: ACI 318-14 Beam Section DesignJohan SonNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- Column Base Plate (Eurocode)Document4 pagesColumn Base Plate (Eurocode)_at_to_No ratings yet

- Circular Hollow Concrete ColumnDocument3 pagesCircular Hollow Concrete ColumnUttam Kumar GhoshNo ratings yet

- SB - A20 - 04 Rev 1Document10 pagesSB - A20 - 04 Rev 1malikasalNo ratings yet

- STR Report 1Document9 pagesSTR Report 1firasslmn50% (2)

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- CB01 AXIS 27-K Change 800x800Document11 pagesCB01 AXIS 27-K Change 800x800Reab SimanthNo ratings yet

- En Column Base Plate 1.0Document7 pagesEn Column Base Plate 1.0Ali AlomyNo ratings yet

- Column Design With Base Plate and Stiffeners PDFDocument7 pagesColumn Design With Base Plate and Stiffeners PDFAhmed AlmayaliNo ratings yet

- Assemblage Poteau-Semelle IsoléeDocument9 pagesAssemblage Poteau-Semelle IsoléeFrancklinMeunierM'ondoNo ratings yet

- RCC Design SheetsDocument9 pagesRCC Design SheetsBabu SundararamanNo ratings yet

- EmtDocument9 pagesEmtWaleed Mohammed FekryNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Document1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Sham TajasNo ratings yet

- THRUMAXX ZPL DoP 30551rev1 EngDocument3 pagesTHRUMAXX ZPL DoP 30551rev1 EngRicardo MagalhãesNo ratings yet

- 5501 Temp. GaugeDocument5 pages5501 Temp. GaugehnvrajrahNo ratings yet

- Pinned Column Base Design: Eurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in ConcreteDocument6 pagesPinned Column Base Design: Eurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in Concreteismet mehmetiNo ratings yet

- How To Import Staad Model To XsteelDocument11 pagesHow To Import Staad Model To XsteelBenchNo ratings yet

- Steel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDDocument12 pagesSteel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDmalikasalNo ratings yet

- Hilti D16Document1 pageHilti D16Ina RoseNo ratings yet

- 06.TOPIC 3 - Taking Off Quantities For Building - Civil Engineering Works - BeamSlabDocument23 pages06.TOPIC 3 - Taking Off Quantities For Building - Civil Engineering Works - BeamSlabMUHAMMAD IKHWAN NAIM ASRINo ratings yet

- Joint Welding Method PHC D600A-100Document2 pagesJoint Welding Method PHC D600A-100sochealaoNo ratings yet

- Mathcad V1 BDocument11 pagesMathcad V1 BDoğan ArslanNo ratings yet

- Base Plate RobotDocument8 pagesBase Plate RobotinoNo ratings yet

- SpliceDocument17 pagesSpliceSh MNNo ratings yet

- Base PlateDocument8 pagesBase PlateIMJ JNo ratings yet

- Designing A Reinforced Concrete Column Acc. DIN EN 1992-1-1: Benchmark Example No. 33Document13 pagesDesigning A Reinforced Concrete Column Acc. DIN EN 1992-1-1: Benchmark Example No. 33Sri RamNo ratings yet

- Thuyết minh kttc1 lần xongDocument6 pagesThuyết minh kttc1 lần xongTran TinhNo ratings yet

- RHS & SHS Welding DesignDocument1 pageRHS & SHS Welding DesignMyat Thu Zar KhineNo ratings yet

- Design of Slab For Bending: Benchmark Example No. 1Document6 pagesDesign of Slab For Bending: Benchmark Example No. 1Sri RamNo ratings yet

- Aftershock Risk EvaluationDocument1 pageAftershock Risk EvaluationSlevinKNo ratings yet

- Aftershock MainshockDocument1 pageAftershock MainshockSlevinKNo ratings yet

- Nietsche Part 2Document2 pagesNietsche Part 2SlevinKNo ratings yet

- Ideology 10Document4 pagesIdeology 10SlevinKNo ratings yet

- Treasure 6Document5 pagesTreasure 6SlevinKNo ratings yet

- Examination 4Document3 pagesExamination 4SlevinKNo ratings yet

- Examination 4Document3 pagesExamination 4SlevinKNo ratings yet

- The Marriage3Document3 pagesThe Marriage3SlevinKNo ratings yet

- Catalans 2Document3 pagesCatalans 2SlevinKNo ratings yet

- Father and Son1Document2 pagesFather and Son1SlevinKNo ratings yet

- Hilbert Huang TransformationDocument3 pagesHilbert Huang TransformationSlevinKNo ratings yet

- Glossary of English-Greek Enginnering Terms by Dr. DritsosDocument3 pagesGlossary of English-Greek Enginnering Terms by Dr. DritsosSlevinKNo ratings yet

- 1st Puc Physics Chapter14-Oscillations Notes by U N SwamyDocument9 pages1st Puc Physics Chapter14-Oscillations Notes by U N Swamyashwinikumari b100% (1)

- 2 - Quantum InfoDocument24 pages2 - Quantum InfoSusie101No ratings yet

- Physics 3204: Part A: Multiple ChoiceDocument4 pagesPhysics 3204: Part A: Multiple ChoiceVasile NicoletaNo ratings yet

- ISO 12572 Vapour TransmissionDocument36 pagesISO 12572 Vapour TransmissionAK100% (5)

- Calculating Pump HeadDocument6 pagesCalculating Pump HeadAshok Kumar PillaiNo ratings yet

- Robot Actuators:: Actuators Are Used For Converting The Hydraulic, Electrical orDocument12 pagesRobot Actuators:: Actuators Are Used For Converting The Hydraulic, Electrical orNani KumarNo ratings yet

- Q4 WK3 Weather PatternsDocument66 pagesQ4 WK3 Weather PatternsSherwin PhillipNo ratings yet

- Indian Standard: Guide For Lateral Dynamic Load Test On PilesDocument21 pagesIndian Standard: Guide For Lateral Dynamic Load Test On PilesSubodh SontakkeNo ratings yet

- Accelerated Aging and Thermal-Mechanical Fatigue MDocument27 pagesAccelerated Aging and Thermal-Mechanical Fatigue MQUALITY LABORATORYNo ratings yet

- Preformulati ON: By: Abhishek D. DeshmukhDocument33 pagesPreformulati ON: By: Abhishek D. DeshmukhSuraj WasankarNo ratings yet

- Aakash Test Planner: Aiats Test For Class-Xi (Medical)Document3 pagesAakash Test Planner: Aiats Test For Class-Xi (Medical)Bharat GelotNo ratings yet

- LNG - Storage - Tank - Rollover PDFDocument7 pagesLNG - Storage - Tank - Rollover PDFchemsac20% (1)

- Single Shear Steel ConnectionDocument36 pagesSingle Shear Steel ConnectionNatalie WestNo ratings yet

- Laporan Soil Investigation Pertamina PanjangDocument60 pagesLaporan Soil Investigation Pertamina PanjangAlex SudrajatNo ratings yet

- Why Coiled Tubing Fails and HowDocument56 pagesWhy Coiled Tubing Fails and HowArdita S IrwanNo ratings yet

- g7 3j04 Lab - FinalDocument46 pagesg7 3j04 Lab - Finalyliu8877100% (1)

- Polarization 2Document34 pagesPolarization 2Legend ProNo ratings yet

- Edgcse TTPP Cc1-2 SB AnswersDocument5 pagesEdgcse TTPP Cc1-2 SB Answersegcarty1009No ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- CE 101: Analytical Mechanics: KineticsDocument11 pagesCE 101: Analytical Mechanics: KineticsRaquib AhsanNo ratings yet

- DPI General CatalogueWeb PDFDocument149 pagesDPI General CatalogueWeb PDFsunny_boy73No ratings yet

- Night Vision SystemDocument12 pagesNight Vision SystemAnshul Aggarwal100% (1)

- 10elementary SurveyingDocument2 pages10elementary SurveyingAljay MontereyNo ratings yet

- Equillibrium of Coplanar Concurrent ForcesDocument17 pagesEquillibrium of Coplanar Concurrent Forcessalman husainNo ratings yet

- Study Unit 1Document8 pagesStudy Unit 1Mphoka SalomeNo ratings yet

- Modelling Shear Strength of Compacted SoilsDocument5 pagesModelling Shear Strength of Compacted SoilsSothoan Pro ÐGNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Automatic Transmission 42REDocument121 pagesAutomatic Transmission 42REmtaylor030% (7)

- EXP6 - Laminar and Turbulent Flow ReportDocument4 pagesEXP6 - Laminar and Turbulent Flow ReportPoochi DougNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (4)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 3.5 out of 5 stars3.5/5 (22)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildFrom EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildRating: 5 out of 5 stars5/5 (5)