Professional Documents

Culture Documents

HeatExchanger Report

Uploaded by

Nur Izzati KamrulnizamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HeatExchanger Report

Uploaded by

Nur Izzati KamrulnizamCopyright:

Available Formats

HEAT EXCHANGER SPECIFICATION SHEET

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 Customer Address Plant Location Service of Unit: Size Surf/unit (eff.) Fluid allocation Fluid name Fluid quantity, Total Vapor (In/Out) Liquid Noncondensable Temperature (In/Out) Dew / Bubble point Density (Vap / Liq) Viscosity Molecular wt, Vap Molecular wt, NC Specific heat Thermal conductivity Latent heat Pressure Velocity Pressure drop, allow./calc. Fouling resist. (min) Heat exchanged Transfer rate, Service PV Engineering Waterloo, ON Hot oil heater 17 / 96 213.7 ft2 Job No.: Reference No.: Proposal No.: Date: August 24, 2010 Rev. 2 Item No: E-101 Type BEM Hor Connected in 1 1 parallel Shells/unit 1 213.7 ft2 Surf/shell (eff.) PERFORMANCE OF ONE UNIT Shell Side Tube Side lb/h lb/h lb/h lb/h 10443 10443 0 0 10443 0 116667 116667 0 116667

in

series

572.59 F 572.59 F lb/ft3 2.625 / cp 0.0215 / 18.01

571.2 572.59 / 44.755 / 0.0953

380 578.38 / 53.323 / 0.3576

479.19 578.38 / 50.581 / 0.2262

BTU/(lb*F) 1.4586 / / 1.1674 / 0.5199 / 0.5641 BTU/(ft*h*F) 0.039 / / 0.301 / 0.079 / 0.071 BTU/lb psi 1250 1249.96 30 26.86 ft/s 2.93 6.5 psi 13.95 0.05 10 3.14 ft2*h*F/BTU 0.0005 0.001 0.0012 Ao based MTD corrected 6273921 BTU/h 140.31 F 209.93 Dirty 209.91 Clean 326.28 BTU/(h*ft2*F) CONSTRUCTION OF ONE SHELL Sketch Shell Side Tube Side Design/Vac/Test pressure FV 150 psi 1400 / / / / Design temperature 650 650 F Number passes per shell 4 1 Corrosion allowance 0.0625 0.0625 in 6 900 ANSI 1 Connections 4 In in 1 / / 300 ANSI Size/rating Out 3 900 ANSI 1 4 1 / / 300 ANSI Nominal Intermediate 900 ANSI / / 300 ANSI Tube No. 104 TksAvg 0.083 Length 96 in Pitch 1.25 in OD 1 in Tube type Plain Material Carbon Steel Tube pattern 30 Shell Carbon Steel ID 17.25 OD 19 in Shell cover Channel or bonnet Carbon Steel Channel cover Tubesheet-stationary Carbon Steel Tubesheet-floating Floating head cover Impingement protection Rods Baffle-crossing Carbon Steel Type Single segmental Cut(%d) 24.7 V Spacing: c/c 15.5 in Baffle-long Seal type Inlet 15.9375 in Supports-tube U-bend Type Bypass seal Tube-tubesheet joint Exp. 2 grv Expansion joint Carbon Steel Type Flange and flued (TEMA) RhoV2-Inlet nozzle 98 Bundle entrance 14 Bundle exit 38 lb/(ft*s2) Gaskets - Shell side Spiral-Wound Metal Fib Tube Side Spiral-Wound Metal Fib Floating head Code requirements ASME Code Sec VIII Div 1 TEMA class B - chemical service Weight/Shell 3709.1 Filled with water 4554.4 Bundle 1198.5 lb Remarks

T2 S3 T1 S2 S1

Page

HC Heat Transfer Solutions Inc. www.hcheattransfer.com 1-877-542-1214

of 5

HEAT EXCHANGER SPECIFICATION SHEET

1 2 3 4 5 Customer Address Plant Location Service of Unit: PV Engineering Waterloo, ON Hot oil heater 17 / 213.7 96 in ft2 Type BEM Shells/Unit 1 Hor Job No.: Reference No.: Proposal No.: Date: August 24, 2010 Item No: E-101 Connected in Surf/Shell(eff) 1 parallel 213.7

Rev. 1 ft2

2 series

6 Size 7 Surf/Unit(eff) 8 9 10 11 12 13

Shell Side Nozzle Table

Nozzle Service Mark S1 S2 S3 No. 1 1 1 Size (inch) 6 3 2 SCH XXH XXH XXH Class (psig) 900 ANSI 900 ANSI 900 ANSI FACE RF RF RF TYPE WN WN WN COMMENT located on the side located on the bottom located on the top

14 15 Steam Inlet 16 Condensate Outlet 17 Vent 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 Inlet Outlet Drain Vent

Tube Side Nozzle Table

Nozzle Service Mark T1 T2 T3 T4 No. 1 1 1 1 Size (inch) 4 4 1 1 SCH 40 40 80 80 Class (psig) 300 ANSI 300 ANSI 300 ANSI 300 ANSI FACE RF RF RF RF TYPE WN WN WN WN COMMENT located on the bottom located on the top located at rear end located at rear end

Mean Metal Wall Temperature

Temperature Conditions Normal Operating Mean Wall Temperature Maximum Operating Mean Wall Temperature Startup Mean Wall Temperature Upset Mean Wall Temperature Steam Out Mean Wall Temperature Other Operating Mean Wall Temperature Shell 573 480 Tube 535.89 394 Tubesheet 463 240 Units F F F

HC Heat Transfer Solutions Inc. www.hcheattransfer.com 1-877-542-1214

Page

of 5

HEAT EXCHANGER SPECIFICATION SHEET

1 2 Customer 3 Address 4 Plant Location 5 Service of Unit: 6 Size 7 Surf/Unit(eff) Hot oil heater 17 213.7 / 96 in ft2 Type Shells/Unit BEM 1 Hor PV Engineering Waterloo, ON Job No.: Reference No.: Proposal No.: Date: Item No: August 24, 2010 E-101 1 parallel 213.7 1 ft2 series Rev. 2

Connected in Surf/Shell(eff)

NOTES 1234Two (2) rows of impingement rods on a 30 deg layout are to be used for impingement protection Baffles to have a 1" V notch at the bottom The shell inlet nozzle is to be located on the side Dummy tubes (6) are to be installed in the horizontal pass partition lane.

HC Heat Transfer Solutions Inc. www.hcheattransfer.com 1-877-542-1214

Page

of 5

HEAT EXCHANGER SPECIFICATION SHEET

1 2 Customer 3 Address 4 Plant Location 5 Service of Unit: 6 Size 7 Surf/Unit(eff) Hot oil heater 17 213.7 / 96 in ft2 Type BEM 1 Hor Shells/Unit PV Engineering Waterloo, ON Job No.: Reference No.: Proposal No.: Date: Item No: August 24, 2010 E-101 1 parallel 213.7 1 ft2 series ser s eri er ies Rev. 2

Connected in Surf/Shell(eff)

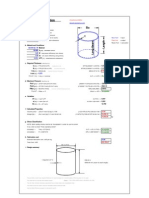

Tubesheet Layout

Shell inside diameter F ront head inside diameter Outertube limit T ube number T ube O.D. T ube pitch T ube pattern T ube passes T ie rod number T ie rod diameter Sealing strips (pairs) Baffle type Impingement protection T ube length Shell Side Inlet Nozzle Inside Diameter Shell Side Outlet Nozzle Inside Diameter Shell Side Outlet Nozzle Inside Diameter

Cu stome r: H&C H eat Tra nsfe r So l utions Ad dres s: Sarni a , O N Se rvice o f U n it: Ite m No.:E-10 1

in in in

17.25 17.25 16.8125 104

in in

1. 1.25 30 4 -1

in

0.376 0 Single segmental Rods

in in in in

96. 5.761 3.068 2.067

Aspen Shell & Tube

Tube Layout

Design Codes ASME Code Sec VIII Div 1 T E MA B - chemical service

1.0 0

24

28

Drawing Number

Custom erSpecifications

1.2 5 24 28

Revision

Date 24/08/2010

Dwg.

App.

HC Heat Transfer Solutions Inc. www.hcheattransfer.com 1-877-542-1214

Page

of 5

HEAT EXCHANGER SPECIFICATION SHEET

1 2 Customer 3 Address 4 Plant Location 5 Service of Unit: 6 Size 7 Surf/Unit(eff) Hot oil heater 17 213.7 / 96 in ft2 Type Shells/Unit BEM 1 Hor PV Engineering Waterloo, ON Job No.: Reference No.: Proposal No.: Date: Item No: Connected in Surf/Shell(eff) August 24, 2010 Rev. E-101 1 parallel 213.7 1 ft2 series ser s eries es 2

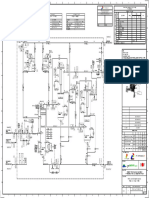

Setting Plan

V iews on arrow A 3.25 T2

A

11.125 7.125 T2 6.5 S3

131.125 Overall 81.0

3.25

T1

S1 S3

T1

S2 16

S2 19.1875 57.625

S1

7.125 Pul li ng Length 79

2.0

2.0

4.0 2 Bolts Fi xed

4.0 2 Bolts Sliding

Ref S1 S2 S3 T1 T2

OD 6.625" 3.5" 2.375" 4.5" 4.5"

W all 0. 432" 0. 216" 0. 154" 0. 237" 0. 237"

Nozzle Data Standard 900 ANSI W eld 900 ANSI W eld 900 ANSI W eld 300 ANSI W eld 300 ANSI W eld

Notes neck ck neck eck neck ck neck neck

Design Data Design Pressure Design T emperature F ull Vacuum Corrosion Allowance T est P ressure Number of Passes Radiography PWHT Internal V olum e

Units psi F in psi

Shell 1399.99 650. 0. 0625 1

Channel 150. 650. 0.0625 4

C u sto me r : H&C H ea t Tr a n sfe r So lutio n s Ad dr e s s : Sar n ia , O N Se r vic e o f Un it: Ite m N o .:E- 10 1 D a te: Au g 20 1 0 R ev N o .: 1 J ob N o .:

Aspen Shell & Tube Exchang er

Setting Plan BEM 17 - 96

Drawing Number

Design Codes ASME Section VII I Div. 1 T EMA B Customer Specificat ions

ft

12. 5125

4.4291

Empty 3709 lb

W eight Summary F looded 4554 lb

Bundle 1198 lb

Revision

Date 24/ 08/2010

Dwg.

Chk.

App.

HC Heat Transfer Solutions Inc. www.hcheattransfer.com 1-877-542-1214

Page

of

You might also like

- Shaper Gear CuttingDocument4 pagesShaper Gear Cuttingnevadablue100% (4)

- Stored EnergyDocument38 pagesStored EnergySajid SattarNo ratings yet

- Silhouette Training NotesDocument33 pagesSilhouette Training NotesMichael Lester67% (3)

- Sagana Kutus 132kv Transmission Line and SubstationDocument324 pagesSagana Kutus 132kv Transmission Line and Substationshivvaram-1100% (1)

- 7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionDocument2 pages7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionJitender Kumar GuptaNo ratings yet

- Feild Inspection of Shell and Tube Heat ExchangersDocument4 pagesFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNo ratings yet

- Selection of TEMA Class of Heat ExchangerDocument10 pagesSelection of TEMA Class of Heat ExchangerBalkundeNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168No ratings yet

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Compressor Head Calculations Design GuideDocument30 pagesCompressor Head Calculations Design GuideDavid Gustavo Duran TangoNo ratings yet

- BBS 10 P1 PID 0045 ModelDocument1 pageBBS 10 P1 PID 0045 ModelAdianto RahmanNo ratings yet

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanNo ratings yet

- Guide To Petrophysical Interpretation PDFDocument147 pagesGuide To Petrophysical Interpretation PDFDwiandaru DarmawanNo ratings yet

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocument4 pagesToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument5 pagesShell and Tube Heat Exchanger DesignDominic CareoNo ratings yet

- (Conectores) SandhaasC Munch-AndersenJ DietschP DesignofConnectionsinTimberStructures PDFDocument332 pages(Conectores) SandhaasC Munch-AndersenJ DietschP DesignofConnectionsinTimberStructures PDFClaudio Ignacio Zurita MillónNo ratings yet

- Shell Thickness CalcDocument1 pageShell Thickness CalcDidi KurniadiNo ratings yet

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocument35 pages6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Catalogue For AutoDocument22 pagesCatalogue For Autosentimiento azulNo ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Propane Storage TankDocument1 pagePropane Storage TankMarakanaMaheshNo ratings yet

- StrainerDocument2 pagesStrainerRanjithNo ratings yet

- Procedures For Solar Electric (Photovoltaic Abbreviated As PV) System Design and InstallationDocument5 pagesProcedures For Solar Electric (Photovoltaic Abbreviated As PV) System Design and InstallationUmamaheshwarrao VarmaNo ratings yet

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjNo ratings yet

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocument1 pageC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNo ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- 00000-UDS-001 (Chemical Injection Unit) Rev 0Document2 pages00000-UDS-001 (Chemical Injection Unit) Rev 0sithulibraNo ratings yet

- Heat Exchanger CalcDocument34 pagesHeat Exchanger Calcميثة الغيثيةNo ratings yet

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- Limpet With Jacket Nozzle OrientationDocument1 pageLimpet With Jacket Nozzle OrientationArunkumar MyakalaNo ratings yet

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVANo ratings yet

- Datasheet For FiltersDocument13 pagesDatasheet For FiltersAntonio MendesNo ratings yet

- (E-104) Air Cooled Heat Exchangers - Rev1 PDFDocument13 pages(E-104) Air Cooled Heat Exchangers - Rev1 PDFmihir_jha2No ratings yet

- Pump and Line CalcDocument1 pagePump and Line CalcPRATIK P. BHOIRNo ratings yet

- Heat Exchanger Specification Sheet SI Units: C:/Users/thangtq/Desktop/new - HtriDocument1 pageHeat Exchanger Specification Sheet SI Units: C:/Users/thangtq/Desktop/new - HtriTrần Quang ThắngNo ratings yet

- Steam CondenserDocument2 pagesSteam CondenserAlphaEcc EngineeringTeamNo ratings yet

- Lesco TestDocument8 pagesLesco Testai khanNo ratings yet

- 8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothDocument15 pages8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothakashlogicNo ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- Shell Entrance Area Calculation-R0Document2 pagesShell Entrance Area Calculation-R0nagtummalaNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDocument3 pagesDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTORONo ratings yet

- bb1 DatasheetDocument14 pagesbb1 DatasheetMojtabaNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDocument3 pagesBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloNo ratings yet

- Nozzle LoadDocument8 pagesNozzle LoadDam VoNo ratings yet

- PV Enineering EHX - OutDocument144 pagesPV Enineering EHX - Out9913489806No ratings yet

- When Is An Expansion Bellows Required in A Heat ExchangerDocument3 pagesWhen Is An Expansion Bellows Required in A Heat ExchangerTiHoRNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- FOAMGLAS Cellular Glass InsulationDocument18 pagesFOAMGLAS Cellular Glass InsulationermizeNo ratings yet

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattNo ratings yet

- Datasheet For Side Entry MixerDocument4 pagesDatasheet For Side Entry Mixervinoj chandranNo ratings yet

- Calgary 2011 Nozzle Loads PresentationDocument10 pagesCalgary 2011 Nozzle Loads PresentationpexyNo ratings yet

- Air Cooled HX Data SheetDocument1 pageAir Cooled HX Data SheetHoney TiwariNo ratings yet

- 10P87-D0003-046-R0-WHRU by TEPLDocument23 pages10P87-D0003-046-R0-WHRU by TEPLjigarNo ratings yet

- Working Principle of Shell and Tube Heat ExchangerDocument8 pagesWorking Principle of Shell and Tube Heat ExchangersanjayNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh PatelNo ratings yet

- Filter CalculationDocument4 pagesFilter CalculationRashmi RanjanNo ratings yet

- Fluid Flow Basics OF Throttling ValvesDocument43 pagesFluid Flow Basics OF Throttling ValvesSandro AraújoNo ratings yet

- DAM DesuperheaterDocument4 pagesDAM DesuperheaterangeloNo ratings yet

- Heat Exchanger Specification Sheet: in FT FT Performance of One UnitDocument10 pagesHeat Exchanger Specification Sheet: in FT FT Performance of One UnitAnonymous Wd2KONNo ratings yet

- General Fabrication and Performance Information Section 3: FIGURE G-5.2 Heat Exchanger Specification SheetDocument1 pageGeneral Fabrication and Performance Information Section 3: FIGURE G-5.2 Heat Exchanger Specification SheetMoises Rodriguez SanchezNo ratings yet

- Flanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignDocument9 pagesFlanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignSaleh EttehadiNo ratings yet

- Design of A Non-Contact Vibration Measurement and Analysis System For Electronic Board TestingDocument136 pagesDesign of A Non-Contact Vibration Measurement and Analysis System For Electronic Board TestingNur Izzati KamrulnizamNo ratings yet

- Choudhary Anurudh A: Career ObjectiveDocument3 pagesChoudhary Anurudh A: Career ObjectiveNur Izzati KamrulnizamNo ratings yet

- Manufacturing Firms' Performance and Technology Commitment The Case of The Electronics Industry in ChinaDocument8 pagesManufacturing Firms' Performance and Technology Commitment The Case of The Electronics Industry in ChinaNur Izzati KamrulnizamNo ratings yet

- How Successfully Does JIT Handle Machine Breakdowns in An Automated Manufacturing System?Document16 pagesHow Successfully Does JIT Handle Machine Breakdowns in An Automated Manufacturing System?Nur Izzati KamrulnizamNo ratings yet

- Free For Life: Percuma Sepanjang HayatDocument4 pagesFree For Life: Percuma Sepanjang HayatNur Izzati KamrulnizamNo ratings yet

- Cimb Balance TransferDocument2 pagesCimb Balance TransferNur Izzati KamrulnizamNo ratings yet

- Earthquake in TaguigDocument4 pagesEarthquake in TaguigDianca Zyra Rodil-CabanelaNo ratings yet

- OurLocalExpert Exeter 2013-14Document15 pagesOurLocalExpert Exeter 2013-14Nick HallNo ratings yet

- Service Manual: Model Code - Kib19Bp3-CmgDocument11 pagesService Manual: Model Code - Kib19Bp3-Cmgpravin jadavNo ratings yet

- Design of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundDocument24 pagesDesign of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundKakula SasidharNo ratings yet

- Feslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vDocument19 pagesFeslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vraulUTCNNo ratings yet

- CHEG320 Electrochemistry LecturesDocument114 pagesCHEG320 Electrochemistry LecturesqalanisNo ratings yet

- Csi Sap2000 Example 1-008Document4 pagesCsi Sap2000 Example 1-008Juan Pablo González CarballoNo ratings yet

- Drainage Sewerage Piping Work Risk AssessmentsDocument5 pagesDrainage Sewerage Piping Work Risk Assessmentsboa jean marieNo ratings yet

- Paper: Theory/Week: Credits: Mobile Application Development Using Android Hours: IA: ExamDocument1 pagePaper: Theory/Week: Credits: Mobile Application Development Using Android Hours: IA: ExamHaseeb MogralNo ratings yet

- InsulinDocument6 pagesInsulinJorelle-Nickolai RodriguezNo ratings yet

- Teodoriu 2010Document13 pagesTeodoriu 2010JhormanNo ratings yet

- K.analysis of The Articulated Robotic Arm (TITLE DEFENCE)Document22 pagesK.analysis of The Articulated Robotic Arm (TITLE DEFENCE)sky4sterNo ratings yet

- DP Misc Wnt5 x86-32 ChangelogDocument5 pagesDP Misc Wnt5 x86-32 ChangelogBrandal KalocyNo ratings yet

- Java Swing Demo (Class Name Test)Document2 pagesJava Swing Demo (Class Name Test)bejarunNo ratings yet

- Zaštita Transformatora Osiguračima - Nadstrujna - Zaštita PDFDocument4 pagesZaštita Transformatora Osiguračima - Nadstrujna - Zaštita PDFKristian MevželjNo ratings yet

- Manual Multisim 2001 (Ingles)Document72 pagesManual Multisim 2001 (Ingles)Anonymous W1QQcbA4sWNo ratings yet

- Inspection & Maintenance of Dams: Dam Safety GuidelinesDocument79 pagesInspection & Maintenance of Dams: Dam Safety Guidelinesvishu1909100% (1)

- Worksheet # 7 - Free Body DiagramDocument2 pagesWorksheet # 7 - Free Body DiagramyabalabahiyaNo ratings yet

- Dating Torrential ProcessesDocument29 pagesDating Torrential ProcessesJulio Montenegro GambiniNo ratings yet

- L3 - Hardening Soil Models in PlaxisDocument33 pagesL3 - Hardening Soil Models in PlaxisOng Tai BoonNo ratings yet