Professional Documents

Culture Documents

5 Axis Manual

Uploaded by

pfonsecapOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 Axis Manual

Uploaded by

pfonsecapCopyright:

Available Formats

MACH3 5 axis CNC interface board instruction

Functions and Features

1Completely support MACH3 and the other softs that use LPT port. 2USB Power supply and external power supply separatefor protecting your PC. 3 Wide range external power supply voltage 12 - 24V and has preventing reverse connection function 4All the input signals are separated by photocouplerscan be connected to EstopProbe and Limit switchs. To make your computer safe. 5 One relay output ,can be conneted to spindle switch Using P17. 60-10V photocoupler separated analog voltage output, can be connected to Frequency converterusing to control the spindle speed Using P1. 7All 17 LPT ports are availablecan be connected to stepping motor drivers,can control five stepping motor. 8 P1 can be used to output PWM signal and can control the spindle Speed Regulator that has a photocoupler for input. 9 Can be connected to stepping motor drivers using common anode or common cathode input connection . 10All of the LPT port names are printed on board,Easy to be used.

BlueSky_TEC Mach3 5 axis CNC interface board (BL-MACH-V1.1) instruction

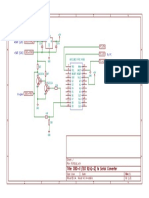

Funtion Wiring diagram:

Noteall the stetings below is for common anode connection between this interface board and the stepping motor drivlers

MACH3 soft setting

AFirst check MACH3 driver is install well

note Mach3 Drivercant

has or

BSoft setting 1Unit select Select uniton menuconfigselect native units--- select MM.

BlueSky_TEC

Mach3

5 axis CNC interface board (BL-MACH-V1.1) instruction

2Ports and pins: 1 Port setup and axis selectionnote--make sure you have save your changes.

2 Motor outputsset as the below diagram

note the motor turning direction is relevant to its connection if the direction is not right you can adjustDir LowActive as on the diagram 3 input signalsset as belowthen click the confirm button

BlueSky_TEC

Mach3

5 axis CNC interface board (BL-MACH-V1.1) instruction

4 Output signalsset as belowthen click the confirm button

BlueSky_TEC

Mach3

5 axis CNC interface board (BL-MACH-V1.1) instruction

Enable1setpping motor enable setting--p14 Output #1spindle relay switch setting--P17 5 Spindle setup

Using PWM to control the spindle speedalso need to set spindle pulleys as below:

BlueSky_TEC

Mach3

5 axis CNC interface board (BL-MACH-V1.1) instruction

3Motor turning This is relate to the screw pitch and the excitation mode of the motor driver. The below diagram seting is base on 5MM screw pitch and excitation mode is 8.

Steps permeans how many steps it need for moving 1 MM. The seting of YZA axis is similar to Xand have to save the settings after all. 4System hotkeys setup

Set the hotkeys of on the keyboard.

X Y Z axis as this diagram then you can control the motors by this hotkeys

BlueSky_TEC

Mach3

5 axis CNC interface board (BL-MACH-V1.1) instruction

You might also like

- CNC Interface Board CM101 ManualDocument17 pagesCNC Interface Board CM101 ManualZorica SolunacNo ratings yet

- Datasheet - M542H Stepper Motor DriverDocument10 pagesDatasheet - M542H Stepper Motor DriversthollanderNo ratings yet

- Step by Step Procedure FOR Stepper Motor ControlDocument5 pagesStep by Step Procedure FOR Stepper Motor ControlMohd Abdul RahmanNo ratings yet

- Stepper Motors CatalogDocument35 pagesStepper Motors Catalogapi-3700604100% (1)

- Adafruits Raspberry Pi Lesson 4 Gpio SetupDocument17 pagesAdafruits Raspberry Pi Lesson 4 Gpio SetupJuan BuitragoNo ratings yet

- XBT Xk700eDocument92 pagesXBT Xk700evalentincaciorNo ratings yet

- Motor Shield AdafruitDocument51 pagesMotor Shield AdafruitengrodeNo ratings yet

- Control Servo Motors With JoystickDocument9 pagesControl Servo Motors With Joystickaurumstar20000% (1)

- Adafruit CatalogDocument46 pagesAdafruit CataloggregguerreroNo ratings yet

- Adafruit Io Basics Temperature and HumidityDocument29 pagesAdafruit Io Basics Temperature and HumiditysyncasterNo ratings yet

- Iot Based Smart Irrigation System Using Nodemcu Esp8266 & Adafruit IoDocument6 pagesIot Based Smart Irrigation System Using Nodemcu Esp8266 & Adafruit IoSanthosh Kumar100% (1)

- User Guide - Air Quality Sensor Kit PDFDocument45 pagesUser Guide - Air Quality Sensor Kit PDFMR. TNo ratings yet

- Hb860h ManualDocument6 pagesHb860h ManualBayron Ospina MarinNo ratings yet

- Adafruit Cc3000 WifiDocument56 pagesAdafruit Cc3000 Wifilojain centerNo ratings yet

- Using Servo Motors With RPI PDFDocument11 pagesUsing Servo Motors With RPI PDFVictor Alexandru BusnitaNo ratings yet

- VEXTA PK Motor Only OverviewDocument21 pagesVEXTA PK Motor Only OverviewHerbert RodriguezNo ratings yet

- Adafruit - Feather m0 Wifi Atwinc1500Document67 pagesAdafruit - Feather m0 Wifi Atwinc1500Bobby100% (1)

- Arduino-TempHumidity-with-LCD-And-Web-Interface ALLSTEPSDocument12 pagesArduino-TempHumidity-with-LCD-And-Web-Interface ALLSTEPSKurniawan SusiloNo ratings yet

- M35160 Ug Rev 3Document19 pagesM35160 Ug Rev 3FreezzbyNo ratings yet

- Heidenhain TNC 151 BQ Conversational ProgrammingDocument371 pagesHeidenhain TNC 151 BQ Conversational ProgrammingFranGiga100% (1)

- BDF - AUT - 16 - 001 - Eng - TP 6 Poles To 8 Poles Motors - OPD and DSC - Rev1-1 PDFDocument10 pagesBDF - AUT - 16 - 001 - Eng - TP 6 Poles To 8 Poles Motors - OPD and DSC - Rev1-1 PDFDilanka RajithamalNo ratings yet

- Jpb2cvse A3 Sheet 01Document1 pageJpb2cvse A3 Sheet 01Juan PastorNo ratings yet

- Stepper Motor Driver DQ542MA DocumentDocument4 pagesStepper Motor Driver DQ542MA DocumentRenieNo ratings yet

- Tig 4300i AC/DC DetailsDocument24 pagesTig 4300i AC/DC DetailsaswanthNo ratings yet

- How To Control Servo Motors With An Arduino and JoystickDocument11 pagesHow To Control Servo Motors With An Arduino and Joystickkangazzam1984No ratings yet

- Cloud Connected Weather Station With The Arduino Yun and TembooDocument12 pagesCloud Connected Weather Station With The Arduino Yun and TembooMiguel Augusto Gutierrez MaldonadoNo ratings yet

- RN550-MRC PDFDocument2 pagesRN550-MRC PDFAR El Patron KadryNo ratings yet

- Node REDDocument11 pagesNode REDAshwani MauryaNo ratings yet

- JVL QuickStep Integrated Stepper Motor MIS34 Up To 9 NMDocument8 pagesJVL QuickStep Integrated Stepper Motor MIS34 Up To 9 NMElectromate100% (2)

- Faq Ad Update Mt8000ie Os enDocument3 pagesFaq Ad Update Mt8000ie Os enIvan KranticNo ratings yet

- RS232 To TCPip ManualDocument8 pagesRS232 To TCPip ManualMárton NagyNo ratings yet

- Dev Kit 8000 User ManualDocument78 pagesDev Kit 8000 User ManualPedro Antonio Duran CaneoNo ratings yet

- TSX17 20 SelectionDocument12 pagesTSX17 20 SelectionLuis Enrique PariapazaNo ratings yet

- NPS711B9Document504 pagesNPS711B9funkyznNo ratings yet

- 13Document81 pages13Rodriguez JohannNo ratings yet

- Jehnert 45140 EBA Engl WebDocument10 pagesJehnert 45140 EBA Engl Webpost8713No ratings yet

- ISO9141 To Serial SchematicDocument1 pageISO9141 To Serial SchematicAnderson Lopes100% (2)

- Mpi 11002Document21 pagesMpi 11002alkesh.eng0% (1)

- HBS86 HDDocument7 pagesHBS86 HDLuis Flores0% (1)

- Euromap 12 PDFDocument2 pagesEuromap 12 PDFBruce0% (1)

- UP5135 DC20v 100A MeterDocument1 pageUP5135 DC20v 100A Meterdanielstancu883296No ratings yet

- The DB9-USB Family of UART Converter Modules: DatasheetDocument26 pagesThe DB9-USB Family of UART Converter Modules: DatasheetScoundrel ByteNo ratings yet

- FTP Server With Letter HeadDocument25 pagesFTP Server With Letter HeadPham LongNo ratings yet

- Tnc 135 Точка По ТочкаDocument21 pagesTnc 135 Точка По ТочкаaLexusNo ratings yet

- THGT Series: Cylindrical Cased Axial Flow FansDocument42 pagesTHGT Series: Cylindrical Cased Axial Flow Fanszeljkogr100% (1)

- Servo Motor Speed and Direction ControlDocument7 pagesServo Motor Speed and Direction Controltazeb100% (1)

- M542 Stepper Motor DriveDocument8 pagesM542 Stepper Motor DriveElvio JungesNo ratings yet

- C ps416 1Document12 pagesC ps416 1Henrique PortesNo ratings yet

- User Manual 5 Axis Breakout BoardDocument10 pagesUser Manual 5 Axis Breakout BoardSonia SantamaríaNo ratings yet

- 一、Detailed description of 6-axis engraving machine interface boardDocument6 pages一、Detailed description of 6-axis engraving machine interface boardIvan HerreraNo ratings yet

- USB MACH3 Interface Board (BL-UsbMACH-200-V3.1) InstructionDocument14 pagesUSB MACH3 Interface Board (BL-UsbMACH-200-V3.1) InstructionAnnaLangerVittorioGigliottiNo ratings yet

- MACH3 Interface Specification V2.1-21719148761417912066Document24 pagesMACH3 Interface Specification V2.1-21719148761417912066Виктория ФаріонNo ratings yet

- User Manual 5 Axis Breakout BoardDocument10 pagesUser Manual 5 Axis Breakout BoardDavid FernandezNo ratings yet

- Arduino DC Motor ControlDocument4 pagesArduino DC Motor ControlKathryn WorkmanNo ratings yet

- Profi4 Main Board ManualDocument15 pagesProfi4 Main Board ManualCarlos TerrazaNo ratings yet

- Driver Capy C11G Cnc4pcDocument19 pagesDriver Capy C11G Cnc4pccastellano_rNo ratings yet

- TB6560 3axis DriverDocument11 pagesTB6560 3axis DriverPHQ1910No ratings yet

- CNC Instructables PDFDocument13 pagesCNC Instructables PDFNadim AhmedNo ratings yet

- Final Report On Line Follower RobotDocument44 pagesFinal Report On Line Follower RobotAjay Verma50% (4)

- Changzhou Wantai Electrical Appliance Co., LTD: User Guide For 4 Axis TB6560 Driver BoardDocument11 pagesChangzhou Wantai Electrical Appliance Co., LTD: User Guide For 4 Axis TB6560 Driver BoardP BNo ratings yet

- Effect of Lithium Doping Concentration On The Structural, Morphological and Optical Properties of NiO NanoparticlesDocument4 pagesEffect of Lithium Doping Concentration On The Structural, Morphological and Optical Properties of NiO NanoparticlesIRJAESNo ratings yet

- Merit - Le Thi Linh - BKC1924 - Innovation Commercialization - Assignment1 - Btec Bit01k11Document14 pagesMerit - Le Thi Linh - BKC1924 - Innovation Commercialization - Assignment1 - Btec Bit01k11Linh LêNo ratings yet

- CL-21Z50MQ K16CDocument73 pagesCL-21Z50MQ K16CRonald CastellarNo ratings yet

- Basic Pecvd Plasma Processes (Sih Based) : Pecvd Sinx: Sih + NH (+H) or Sih + N (+H)Document36 pagesBasic Pecvd Plasma Processes (Sih Based) : Pecvd Sinx: Sih + NH (+H) or Sih + N (+H)Anonymous lidok7lDiNo ratings yet

- Motherboard Voltage Regulator CircuitDocument22 pagesMotherboard Voltage Regulator Circuitleon_sfNo ratings yet

- Panasonic BT-LH1710-1760 (E-MC) PDFDocument116 pagesPanasonic BT-LH1710-1760 (E-MC) PDFboroda2410100% (1)

- Sipmos: DS D DS (On)Document8 pagesSipmos: DS D DS (On)JuanLoveraNo ratings yet

- LM1117LDocument21 pagesLM1117LfreddyNo ratings yet

- Mems SyllabusDocument2 pagesMems SyllabusSony RamaNo ratings yet

- DIY Short Circuit Overcurrent Protection PDFDocument6 pagesDIY Short Circuit Overcurrent Protection PDFsarath39438No ratings yet

- On Semiconductor - mtd20p06hdl-dDocument8 pagesOn Semiconductor - mtd20p06hdl-dshohratNo ratings yet

- Magnetism - Molecules To Materials III - Nanosized Magnetic Materials - Miller - Wiley 2002Document399 pagesMagnetism - Molecules To Materials III - Nanosized Magnetic Materials - Miller - Wiley 2002Samira Gama ReisNo ratings yet

- Characteristics of A Rectangular WaveguideDocument4 pagesCharacteristics of A Rectangular WaveguideRavinderNo ratings yet

- Commander SE Product DataDocument23 pagesCommander SE Product Dataramon navaNo ratings yet

- Temperature Control Utilizing SSRDocument2 pagesTemperature Control Utilizing SSRAtakan OzturKNo ratings yet

- DIY Laser Burner TutorialDocument24 pagesDIY Laser Burner TutorialArnaldo Canelas67% (3)

- DAC CompleteDocument9 pagesDAC CompleteNashrul HaqNo ratings yet

- Intro KeramerDocument26 pagesIntro Keramertv009334No ratings yet

- Direct On Line DOL Motor Starter PDFDocument7 pagesDirect On Line DOL Motor Starter PDFVasudev AgrawalNo ratings yet

- MJ 11032 G Hyundai BlowerDocument4 pagesMJ 11032 G Hyundai BlowerDragan LugonićNo ratings yet

- Floyd CH 5Document40 pagesFloyd CH 5aishahsuciutomo100% (1)

- Electronic CKT Simulator ManualDocument11 pagesElectronic CKT Simulator ManualSuraj SinghNo ratings yet

- Sequential CircuitsDocument11 pagesSequential CircuitsGoutham RamakrishnanNo ratings yet

- Infineon To Acquire Wolfspeed-Investor PresentationDocument25 pagesInfineon To Acquire Wolfspeed-Investor Presentationspeedybits100% (1)

- BEEE Unit I MaterialDocument93 pagesBEEE Unit I MaterialK Praveen KumarNo ratings yet

- Light Dependent Resistance Project Report PhysicsDocument23 pagesLight Dependent Resistance Project Report Physicsapi-342687563100% (1)

- Seccionadores ABB PDFDocument8 pagesSeccionadores ABB PDFLuisManuelTrujilloMartínezNo ratings yet

- Enhancement MOSFET: Biasing Techniques of MosfetDocument10 pagesEnhancement MOSFET: Biasing Techniques of MosfetNaveen ReddyNo ratings yet

- LG OLED Lighting User GuideDocument23 pagesLG OLED Lighting User GuidePuni Maina Hutabarat100% (2)

- Ballantine 3440 Boonton 952001 1.2ghz 1,5pf RF Probe SMDocument4 pagesBallantine 3440 Boonton 952001 1.2ghz 1,5pf RF Probe SMIvo MFNo ratings yet