Professional Documents

Culture Documents

M HACCP

Uploaded by

Aki EspaldonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M HACCP

Uploaded by

Aki EspaldonCopyright:

Available Formats

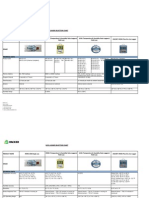

m-HACCP template Company/ Client Name: Product: Phase/ Dosage format: Start date: End date: Organization HACCP

Team and roles 1. 2. 3. 4. 5. Noted by: _______________________________________ CEO/ COO

Approved by: _______________________________________ VP-Manufacturing and Operations Cc: HACCP Team, VP-Mfg & Operations

Checklist for information prior to review and analysis 1. Pre-formulation and stability studies, materials characterization 2. Formulation, unit dose 3. List of suppliers and alternate suppliers used in manufacturing with complete CAs, route of synthesis, impurities, solvents, intermediates, starting materials 4. Manufacturing process 5. All equipment used, its design and operational specifications, calibration and maintenance history 6. Construction or review of PFD (process flow diagram) and P&ID if necessary (piping and instrumentation diagram), check if updated or an option for a walk-thru

Table1: The 12-step HACCP programme Features Descriptions 1) 2) 3) 4) 5) 6) Preliminary Tasks Define scope of system and risk question Assemble HACCP team consisting of R&D, manufacturing, QA and define scope Describe/ review product and process, equipment properties, characteristics etc. (in short, all information about productprocess-equipment-utility, PPEU) Identify intended use Challenge/ Review/ Refine PFD (process flow diagram) as well as P&ID Verify PFD and P&ID onsite but it must be updated frequently Risk Assessment, Monitoring, Control and Communication 1) Conduct Hazard Analysis 2) Determine CCPs 3) Establish critical limits for each CCP 4) Establish monitoring and control system for each CCP 5) Establish corrective actions for each CCP 6) Establish verification procedures to confirm if HACCP is working 7) Establish documentation and record keeping

Table2. Hazard identification, Critical Control Points, Limits and Actions Processing Step Dispensing Hazard identification (classification matrix: Equipment, Manpower, RM, Utility, Facility Microbiological, chemical and physical) F- Mechanical disturbances M-Dispensing the wrong ingredient (i.e. vitamin E-SD, vitamin E) M- Dispensing the wrong quantity (i.e. 0.1 grams vs. 0.01 grams of F&DC Red) M- Dispensing an expired lot Addition of pre-dispensed materials to inCritical control Points Critical Limits Corrective Action Cost Resp.

process containers F- Static charges M- Operator error R - Raw material debris from supplier Sifting of raw materials Damage or fracture on sieve during sifting. Cross contamination with products of previous batch during sifting. Exposure of materials to contamination during sifting Incorrect dry mixing time and speed of mixing blade Quantity of water in binder solution Mixing time Rotational speed of impeller Disheveled gown of operator, insufficient cleaning of equipment The loading of the processing bowl Incorrect outlet air temperature Improper air flow in the inlet-air plenum and velocity of airflow Incorrect choice of container and air distributor Blockage of filter bag Filter bag shaking Damage of inlet-air filter, damage of thermometer

Dry-Mixing Wet mixing Granulation Spray Granulation Drying

Compression Coating Packaging Summary

Three hazards ( note: RISK = HAZARD x DOSE/ EXPOSURE TIME ) Physical High and low Temperature operation, steam, glycols etc. High pressure compressed air, nitrogen, steam etc. Vacuum High pressure fluidizing air x-rays, radiation Electricals, Static charges Sources of ignition Rotating impellers, motors Removable parts (big and small) of equipment Small instruments, devices, fixtures near product, RM Elevated storage, platform Dust particles People Air, water Earthquakes Organic solvents (liquid-state) used in production (coacervation microencapsulation), maintenance, cleaning etc. All other solid-state raw materials, chemicals both and not GRAS used in production, maintenance, cleaning etc. Pesticides Personnel/ human wastes Microorganisms, viruses, parasites Insects , rodents Multi-cellular organisms Other unknown microbiological particles

Chemical

Microbiological

Hazard Identification and Critical Point Matrix Microbiological RM MOs - contamination Chemical Moisture microbial growth Physical Debris - contamination Particle size-dust explosion

Product Equipment Utility Facility Insects Insects, rodents High pressure compressed air, nitrogen, steam

References: 1. FAO (1998), Food Quality and safety system: A training manual on Food Hygiene and the Hazard Analysis Critical Control Points (HACCP) system, Food and Agriculture Organization of the United Nations, Rome. 2. The application of HACCP and risk management in the pharmaceutical process, Glory Bansal, Bharat Parashari, Dept. of pharmacyDEPT. OF PHARMACY, MANAV BHARTI UNIVERSITY, SOLAN (H.P.), INDIA. 1 Ph.d., Head, Dept. of Pharmacy, Manav Bharti University, SOLAN (H.P.), INDIA,2DEPT. OF PHARMACY, MANAV BHARTI UNIVERSITY, SOLAN (H.P.), INDIA

You might also like

- Guide Mqa 005 008Document7 pagesGuide Mqa 005 008B112m4No ratings yet

- Using Preliminary Hazard Analysis To Determine Equipment and Instrument Requalification FrequencyDocument7 pagesUsing Preliminary Hazard Analysis To Determine Equipment and Instrument Requalification Frequencyrodcam1No ratings yet

- Advent 200 Manual 2005Document20 pagesAdvent 200 Manual 2005Cristian Pedraza Beltran100% (1)

- USP1058 - Analytical - Instruments Qualification PDFDocument8 pagesUSP1058 - Analytical - Instruments Qualification PDFSrinivasNo ratings yet

- FMEA - Improving Quality Risk Manag During Qualific, Validation, and Change ControlDocument15 pagesFMEA - Improving Quality Risk Manag During Qualific, Validation, and Change ControlLuis Gustavo PachecoNo ratings yet

- Water For Pharmaceutical Use: Commissioning, Qualification and ValidationDocument16 pagesWater For Pharmaceutical Use: Commissioning, Qualification and ValidationAndy RojasNo ratings yet

- Reduced-Method Robustness Testing of Analytical Methods Driven by A Risk-Based Approach (Phil Borman Et Al., PharmTech, 2010) PDFDocument8 pagesReduced-Method Robustness Testing of Analytical Methods Driven by A Risk-Based Approach (Phil Borman Et Al., PharmTech, 2010) PDFMostafa AfifyNo ratings yet

- 3812-Article Text-10914-1-10-20170219Document7 pages3812-Article Text-10914-1-10-20170219harini_kNo ratings yet

- Oq Faw1005Document66 pagesOq Faw1005vijayns_250355172No ratings yet

- Product Development Handout MA SolivenDocument84 pagesProduct Development Handout MA SolivenJackielou MaquisoNo ratings yet

- Leseprobe FundamentalsDocument14 pagesLeseprobe FundamentalsDinesh SenathipathiNo ratings yet

- Installed Filter Test ProcedureDocument5 pagesInstalled Filter Test ProcedureDoan Chi ThienNo ratings yet

- Iso Astm 52701-13 PDFDocument10 pagesIso Astm 52701-13 PDFAhmed LabibNo ratings yet

- ArticleDocument7 pagesArticleRamachandra Bhat HireNo ratings yet

- Materi Workshop CAPA BPOMDocument53 pagesMateri Workshop CAPA BPOMRidwan ArifandiNo ratings yet

- Limites Microbianos Por PoissonDocument10 pagesLimites Microbianos Por PoissonJavier GalvanNo ratings yet

- Canada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1Document34 pagesCanada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1atulbsNo ratings yet

- Article Wjpps 1386003302Document21 pagesArticle Wjpps 1386003302Andrey VychegzhaninNo ratings yet

- Pharmaceutical Cleaning & Cleaning ValidationDocument31 pagesPharmaceutical Cleaning & Cleaning ValidationManish BhatkarNo ratings yet

- Kitain Mikhail Clean RoomDocument39 pagesKitain Mikhail Clean RoomshrinivastNo ratings yet

- # Observations Corrective Actions: Manufacturing ControlsDocument4 pages# Observations Corrective Actions: Manufacturing ControlsMasthan GMNo ratings yet

- ActiveCount Manual Rev.1.4Document30 pagesActiveCount Manual Rev.1.4Anonymous hISvHbfiB1100% (1)

- Animal Cell CultureDocument74 pagesAnimal Cell CultureMarcelo Andrés Ortiz BentoNo ratings yet

- IPQA A Beginner's GuideDocument170 pagesIPQA A Beginner's GuideGoran MickoNo ratings yet

- Forced DegradationDocument8 pagesForced DegradationBiyaya San PedroNo ratings yet

- USFDA Guidelines For PharmaceuticalsDocument5 pagesUSFDA Guidelines For PharmaceuticalsemranNo ratings yet

- Validation of Mixer Double Cone BlenderDocument6 pagesValidation of Mixer Double Cone BlenderSyed RizviNo ratings yet

- Premises As Per GMPDocument15 pagesPremises As Per GMPdivvelaNo ratings yet

- sg3 PD n18-r8Document26 pagessg3 PD n18-r8elighiNo ratings yet

- T309 - Microbiological Quality Control Requirements in An ISO 17025 Laboratory PDFDocument26 pagesT309 - Microbiological Quality Control Requirements in An ISO 17025 Laboratory PDFПламен ЛеновNo ratings yet

- A Guide To ATP Hygiene MonitoringDocument32 pagesA Guide To ATP Hygiene MonitoringGaganpreet KaurNo ratings yet

- Scale-Up Using QBD Webinar ISPE-cjp v3Document20 pagesScale-Up Using QBD Webinar ISPE-cjp v3MohammadNo ratings yet

- Cleaning and Cleaning Validation PDFDocument6 pagesCleaning and Cleaning Validation PDFedgar palominoNo ratings yet

- FOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsDocument10 pagesFOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsmaghraouiNo ratings yet

- An Inside Look at USP71Document22 pagesAn Inside Look at USP71Dante IulliNo ratings yet

- COLIPA-NITROSAMINAS - Technical Guidance Document On Minimising and Determining Nitrostamines in Cosmetics - 2009 PDFDocument13 pagesCOLIPA-NITROSAMINAS - Technical Guidance Document On Minimising and Determining Nitrostamines in Cosmetics - 2009 PDFcgannauNo ratings yet

- Data Logger Selection Chart Vacker Dubai UAEDocument10 pagesData Logger Selection Chart Vacker Dubai UAEVacker Group UAENo ratings yet

- TR65 TocDocument7 pagesTR65 TocDhaval ShahNo ratings yet

- GMP For Facility Design References April06Document17 pagesGMP For Facility Design References April06madhubiochemNo ratings yet

- Rota 940 - OqDocument39 pagesRota 940 - Oqsamar elrobyNo ratings yet

- SHP Laboklav Manual PDFDocument35 pagesSHP Laboklav Manual PDFAntoni Gandia100% (1)

- Nvironmental Onitoring: Omprehensive AndbookDocument7 pagesNvironmental Onitoring: Omprehensive Andbookdavincicode888No ratings yet

- GLP or Good Laboratory PracticesDocument35 pagesGLP or Good Laboratory Practicesningsih rezekiNo ratings yet

- Eudragit Rspo PDFDocument2 pagesEudragit Rspo PDFKimberlyNo ratings yet

- Handling of Out of Specification Results: International Journal of Pharmaceutical Quality Assurance April 2015Document8 pagesHandling of Out of Specification Results: International Journal of Pharmaceutical Quality Assurance April 2015Pavana KharwalNo ratings yet

- Guía Revisión Periódica (Anual) de ProductoDocument18 pagesGuía Revisión Periódica (Anual) de ProductoNerito MONo ratings yet

- 11.4159 USD2755 Remote Control Palltronic Flowstar IV Using OPC IFUDocument16 pages11.4159 USD2755 Remote Control Palltronic Flowstar IV Using OPC IFUseinNo ratings yet

- Connectionsaqt For Empower 3: Requirements Before Qualification BeginsDocument45 pagesConnectionsaqt For Empower 3: Requirements Before Qualification BeginsJorge MorenoNo ratings yet

- Microbiology Product Catalog EU enDocument94 pagesMicrobiology Product Catalog EU enArifin R HidayatNo ratings yet

- v2 Precision Accuracy and Total Analytical PDFDocument2 pagesv2 Precision Accuracy and Total Analytical PDFJie ChuNo ratings yet

- Asmf 01-00-2012 - ApDocument668 pagesAsmf 01-00-2012 - ApRogerioNo ratings yet

- Yang 2013Document9 pagesYang 2013Tanneru Hemanth KumarNo ratings yet

- Case Study: Beta-Lactam Decontamination and Cleaning Validation of A Pharmaceutical Manufacturing FacilityDocument5 pagesCase Study: Beta-Lactam Decontamination and Cleaning Validation of A Pharmaceutical Manufacturing FacilityМарина Рогоза100% (1)

- LabX Bro eDocument12 pagesLabX Bro eWalter BurtonNo ratings yet

- Apple Dylan Extensions and Framework ReferenceDocument714 pagesApple Dylan Extensions and Framework Referencepablo_marxNo ratings yet

- Sop of Disinfection, CoatingDocument27 pagesSop of Disinfection, CoatingAhmed Quadri0% (1)

- Accela CotaDocument5 pagesAccela CotaHassan HaniNo ratings yet

- Pharmaceutical Country Profile PeruDocument147 pagesPharmaceutical Country Profile PeruNethcy JapNo ratings yet

- Solutions To Exam#2Document4 pagesSolutions To Exam#2Aki EspaldonNo ratings yet

- Other Books For Home and Personal Care TechnologiesDocument1 pageOther Books For Home and Personal Care TechnologiesAki EspaldonNo ratings yet

- Formulation # 1329556-098 SD Dry Undeca-Ethyl Ester Ppg-26 Nacl Dimethyl Amido Pyrolido-Amine Oxide Alkyl Carboxy Ethoxylated SulfuonateDocument1 pageFormulation # 1329556-098 SD Dry Undeca-Ethyl Ester Ppg-26 Nacl Dimethyl Amido Pyrolido-Amine Oxide Alkyl Carboxy Ethoxylated SulfuonateAki EspaldonNo ratings yet

- Formulation-For SearchDocument1 pageFormulation-For SearchAki EspaldonNo ratings yet

- Solutions To SeatworkDocument3 pagesSolutions To SeatworkAki EspaldonNo ratings yet

- Rules of Thumb Properties of Gelatin For SoftgelsDocument1 pageRules of Thumb Properties of Gelatin For SoftgelsAki EspaldonNo ratings yet

- Gas Stoich AnswersDocument2 pagesGas Stoich AnswersAki EspaldonNo ratings yet

- Space Materials: Let's Get Started With The Essentials..Document3 pagesSpace Materials: Let's Get Started With The Essentials..Aki EspaldonNo ratings yet

- Novel Therapeutic DairyDocument5 pagesNovel Therapeutic DairyAki EspaldonNo ratings yet

- Pharmaceutical Manufacturing Elective University of San Carlos Chemical Engineering Format For Project # 2Document1 pagePharmaceutical Manufacturing Elective University of San Carlos Chemical Engineering Format For Project # 2Aki EspaldonNo ratings yet

- Delivery of Probiotic Microorganisms IntoDocument1 pageDelivery of Probiotic Microorganisms IntoAki EspaldonNo ratings yet

- Effect of Some Clinically Used Proteolytic Enzymes On Inflammation in RatsDocument1 pageEffect of Some Clinically Used Proteolytic Enzymes On Inflammation in RatsAki EspaldonNo ratings yet

- What Constitutes Good Documentation?: Documented, It Didn't Happen)Document1 pageWhat Constitutes Good Documentation?: Documented, It Didn't Happen)Aki EspaldonNo ratings yet

- Pharmaceutical cGMPs For The 21st CenturyDocument5 pagesPharmaceutical cGMPs For The 21st CenturyAki EspaldonNo ratings yet

- Table 2Document1 pageTable 2Aki EspaldonNo ratings yet

- Osmolality of Frequently Consumed Beverages.: Dini E de Abreu J López EDocument1 pageOsmolality of Frequently Consumed Beverages.: Dini E de Abreu J López EAki EspaldonNo ratings yet

- Ideo 1Document3 pagesIdeo 1Aki EspaldonNo ratings yet

- Problems For Flow MeasurementsDocument1 pageProblems For Flow MeasurementsAki EspaldonNo ratings yet

- USP 51 Antimicrobial Effectiveness TestDocument4 pagesUSP 51 Antimicrobial Effectiveness TestAki Espaldon100% (1)

- Prepared ByDocument1 pagePrepared ByAki EspaldonNo ratings yet

- Problems For Flow of Compressible FluidsDocument1 pageProblems For Flow of Compressible FluidsAki EspaldonNo ratings yet

- Problem Set 4 - FiltrationDocument3 pagesProblem Set 4 - FiltrationAki EspaldonNo ratings yet

- Stephen CoveyDocument2 pagesStephen CoveyAki EspaldonNo ratings yet

- List of References For Pharma Elective - 1st ListDocument1 pageList of References For Pharma Elective - 1st ListAki EspaldonNo ratings yet

- Assignment 1Document1 pageAssignment 1Aki EspaldonNo ratings yet

- QB DDocument1 pageQB DAki EspaldonNo ratings yet

- Answers To Examination # 1 With Corresponding Points/ MarksDocument1 pageAnswers To Examination # 1 With Corresponding Points/ MarksAki EspaldonNo ratings yet

- Medicinal Chemistry I Lectures ContentsDocument7 pagesMedicinal Chemistry I Lectures ContentsAki EspaldonNo ratings yet

- Excipient Brand NamesDocument1 pageExcipient Brand NamesAki EspaldonNo ratings yet

- Group 3: Micropumps and MicrovalvesDocument20 pagesGroup 3: Micropumps and MicrovalvesPhenias ManyashaNo ratings yet

- 10 Average Atomic Mass-SDocument5 pages10 Average Atomic Mass-S776pmsfq2fNo ratings yet

- Silver Nano Materials Technical DatasheetDocument9 pagesSilver Nano Materials Technical DatasheetTuấn Anh NguyễnNo ratings yet

- ATOM Class 7Document23 pagesATOM Class 7Eureka MaterialNo ratings yet

- Tutorial Sheets-CHEM2002-2017-2018 PDFDocument18 pagesTutorial Sheets-CHEM2002-2017-2018 PDFajali1957No ratings yet

- Soil Test Interpretation Guide: D.A. Horneck, D.M. Sullivan, J.S. Owen, and J.M. HartDocument12 pagesSoil Test Interpretation Guide: D.A. Horneck, D.M. Sullivan, J.S. Owen, and J.M. Hartabarrios78100% (1)

- Chemistry Class Xii Ut 1 Objective PaperDocument2 pagesChemistry Class Xii Ut 1 Objective Papergojo satoruNo ratings yet

- Kun Fang Dissertation-Thin Film Multichip Packaging For High Temperature Geothermal ApplicationDocument130 pagesKun Fang Dissertation-Thin Film Multichip Packaging For High Temperature Geothermal ApplicationThu KhaNo ratings yet

- Pet Geo 1Document5 pagesPet Geo 1api-347509160No ratings yet

- Photons Part 2Document10 pagesPhotons Part 2noullithuanNo ratings yet

- A 983 - A 983M - 01 - Qtk4my0wmqDocument5 pagesA 983 - A 983M - 01 - Qtk4my0wmqhoangNo ratings yet

- Applied Thermodynamics C211 PDFDocument173 pagesApplied Thermodynamics C211 PDFSubham AcharyaNo ratings yet

- Trans-Dichlorobis (Ethylenediamine) Cobalt (III) Chloride: The Synthesis ofDocument9 pagesTrans-Dichlorobis (Ethylenediamine) Cobalt (III) Chloride: The Synthesis ofANA MARIA VERA ESCAMILLANo ratings yet

- Laser Cutting ParametersDocument55 pagesLaser Cutting ParametersQasim Ali100% (3)

- Reaction RateDocument96 pagesReaction RateSoh Ming LunNo ratings yet

- Meja 1Document17 pagesMeja 1sdpNo ratings yet

- Biokimia Farmasi Asam Amino, Oligopeptida, Protein Serta Metabolisme Asam Amino Dan ProteinDocument52 pagesBiokimia Farmasi Asam Amino, Oligopeptida, Protein Serta Metabolisme Asam Amino Dan ProteinCHEISY ANASTASYA GRATIA LENGKONG100% (1)

- Simulation Study of Cryogenic Air Separation PDFDocument58 pagesSimulation Study of Cryogenic Air Separation PDFAHMEDNo ratings yet

- TRP Engineering College, Irunglaur, Trichy - 621 105 Cycle Test - I TRP Engineering College, Irunglaur, Trichy - 621 105 Cycle Test - IDocument1 pageTRP Engineering College, Irunglaur, Trichy - 621 105 Cycle Test - I TRP Engineering College, Irunglaur, Trichy - 621 105 Cycle Test - IChockalingamNo ratings yet

- Material Safety Data Sheet Material Safety Data Sheet Material Safety Data Sheet Material Safety Data SheetDocument7 pagesMaterial Safety Data Sheet Material Safety Data Sheet Material Safety Data Sheet Material Safety Data Sheetmiketyson11No ratings yet

- Acrylic Sheets Roofing: Group Members: Priyal Mittal Anuj Nandanwar Shubham Parekh Sanket PanditDocument18 pagesAcrylic Sheets Roofing: Group Members: Priyal Mittal Anuj Nandanwar Shubham Parekh Sanket PanditPriya ManeNo ratings yet

- Determination of Tap Density of Metallic Powders and CompoundsDocument2 pagesDetermination of Tap Density of Metallic Powders and CompoundsLuigi HernándezNo ratings yet

- Energy Integration of A HydrotreatmentDocument43 pagesEnergy Integration of A Hydrotreatmentvarun kumarNo ratings yet

- Answers To Further Questions: For The StudentDocument4 pagesAnswers To Further Questions: For The StudentRumana KhanNo ratings yet

- Epoxy-Coated Prefabricated Steel Reinforcing Bars: Standard Specification ForDocument17 pagesEpoxy-Coated Prefabricated Steel Reinforcing Bars: Standard Specification ForNada KhlifNo ratings yet

- NET CaterpillarDocument29 pagesNET CaterpillarnatalioNo ratings yet

- 06 d-BlockElementsDocument55 pages06 d-BlockElementsuser 12No ratings yet

- Lecture Guide 3 Conduction-through-a-Homogenous-Cylinder-WallDocument8 pagesLecture Guide 3 Conduction-through-a-Homogenous-Cylinder-WallCllyan ReyesNo ratings yet

- Foundry Technology: Reference BooksDocument34 pagesFoundry Technology: Reference BooksGowtham VishvakarmaNo ratings yet

- PiDocument30 pagesPiSai Praneethtej SaspretNo ratings yet