Professional Documents

Culture Documents

WPS Pqrchecklist

Uploaded by

rodofgodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS Pqrchecklist

Uploaded by

rodofgodCopyright:

Available Formats

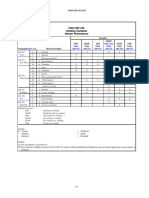

ASME SECTION IX-2010 -WPS & PQR CHECKLIST

VARIABLES QW-402 - JOINTS

.1 in groove design .4 - of backing in single sided weld .5 + of backing and chemical composition .10 in root spacing .11 nonfusing retainers QW-403 - BASE METAL .5 in group number QW-422 .6 T Limits impact .7 T/t Limits > 8 in. (203 mm) .8 T Qualified .9 t pass > 1/2 in. (13 mm) .10 T Limits Qualified (Short Circuit Arc) .11 P-N Qualified .13 P-N 5/9/10 QW-404 - FILLER METALS .3 Size .4 F-N .5 A-N .6 Diameter .7 Diameter > 1/4 in. (6 mm) .9 Flux/Wire Classification .10 Alloy flux .12 AWS classification .14 Filler .22 Consumable insert .23 Filler metal product form (Solid/metal or fluxcored) .24 Supplemental Filler Metal .25 Supplemental Powder Filler metal .26 > Supplemental Powder Filler metal .27 Alloy elements .29 Flux designation .30 t .32 t Limits (Short Circuit Arc) .33 AWS Classification .34 Flux Type .35 Flux/Wire Classification .36 Recrushed Slag .50 Flux QW-405 - POSITION .1 + Position .2 Position .3 Vercal Welding QW-406 - PREHEAT .1 Decrease > 100F (56C) .2 Preheat maintenance .3 Increase > 100F (56C) (IP) S S E E E E E E E E E E N N N N S S E E E E E E N N N N S S E E N N N N S S N N N N N SMAW SAW GMAW / FCAW GTAW

ASME SECTION IX-2010 -WPS & PQR CHECKLIST -CONT'D

VARIABLES

QW-407 - PWHT .1 PWHT .2 PWHT ( Time & Temperature Range) .4 T Limits QW-408 - GAS .1 Trailing or composition .2 Single, mixture or % .3 Flow rate .5 or Backing flow .9 - Backing or composition .10 Shielding or trailing E S E E

SMAW

E

SAW

GMAW / FCAW

E E S E N E N N E E E E S E E E

GTAW

N N N

QW-409 - ELECTRICAL CHARACTERISTICS

E E N .1 .2 .3 .4 > Heat input Transfer Mode Pulsing I Current or Polarity S S S N N N N N N N N N S S E N N E E N N N E N N N E N N N N N

N N

N N

N N

E E N S

E E N E E S

E E N

E E

S E

S N

E E E E E N E N E S E N E N E E N E E E E

.8 I & E Range .12 Tungsten electrode QA-410 - TECHNIQUE .1 String/Weave .3 Orifice cup, or nozzle size .5 Method of cleaning .6 Method of back gouge .7 Oscillation .8 Tube to Work distance .9 Multi to single pass per side .10 Single to multi electrodes .11 Closed to out of chamber welding .15 Electrode spacing .25 Manual or Automatic .26 Peening .64 Use of Thermal Process

N N N

N N N N N N N

N N N N N N N

S S

S S

E N

LEGEND + Addition / - Deletion / > Increase /Greater than / < Decrease / Less than Uphill / Downhill / Forehand / Backhand / Change E = Essential Variables which must be indicated on both the WPS and recorded on the PQR. Any changes to these variables

N N S N E N S S E N S E N S N S N E N S N N

require requalification of WPS. S = Supplementary Essential Variables must be indicated on the WPS and Recorded on the PQR when Impact Testing is required. Changes to these variables when Impact testing is performed require requalification of WPS. ( QW-403.6-Where notch toughnes required min. base Metal Thk. qualified is 16mm ).

N = Nonessential variables must be indicated on the WPS but when changed do not require requalification of WPS. NOTE: WPSs are to indicate all Essential, Nonessential and Supplementary Essential variables. Do not indicate variables which are not used as NA they are applicable and should be entered on the WPS as None or Not used.

You might also like

- Shell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)Document2 pagesShell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)trijaya landscapeNo ratings yet

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- Inspection RoleDocument18 pagesInspection Rolesribd9128No ratings yet

- Visual Inspection Checklist PipingDocument2 pagesVisual Inspection Checklist PipingshifaNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Witness Joint ChecklistDocument1 pageWitness Joint ChecklistAustin J AlfredNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Flange Tracking LogDocument5 pagesFlange Tracking Logcorey jacobsNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportmujahed_muhammedNo ratings yet

- API 570 Pipeline Inspection PDFDocument1 pageAPI 570 Pipeline Inspection PDFKhalidMoutarajiNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- SEIP for Claus Waste Heat Boiler InspectionDocument6 pagesSEIP for Claus Waste Heat Boiler InspectionThinh NguyenNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- M 4 D1.1 2015 Form PDFDocument1 pageM 4 D1.1 2015 Form PDFDabbar TaherNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Surface Preparation and Painting PlanDocument13 pagesSurface Preparation and Painting PlanRido100% (1)

- Maintaining ExperienceDocument5 pagesMaintaining ExperienceIvan KryskoNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- Wps PQR FormatDocument1 pageWps PQR FormatVarun MalhotraNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Supplier Pre-Qualification Document - September 2020Document23 pagesSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesNo ratings yet

- ACG 22 Requirements For Lifting Equipment Inspection BodiesDocument14 pagesACG 22 Requirements For Lifting Equipment Inspection BodiesramodNo ratings yet

- Hydrotest Ansi b31.3 2017Document13 pagesHydrotest Ansi b31.3 2017Bangkit SusiloNo ratings yet

- Job Procedure For Hot Insulation Work of Piping & Equipment1Document13 pagesJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- List of Inspection Tools (Qaqc)Document7 pagesList of Inspection Tools (Qaqc)saffririzal4237No ratings yet

- Radiograph Acceptance Criteria ChartDocument1 pageRadiograph Acceptance Criteria ChartTURNO100% (2)

- Sultanate's ultrasonic flowmeter standardsDocument3 pagesSultanate's ultrasonic flowmeter standardsaltipatlarNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- Water Soluble Penetrant Test ProcedureDocument7 pagesWater Soluble Penetrant Test ProcedureTahseen Ahmed100% (1)

- JHF 610-Xgat-Mm (2006 Ac)Document1 pageJHF 610-Xgat-Mm (2006 Ac)Arya Bayu WibisonoNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Nioec SP 90 02Document77 pagesNioec SP 90 02aminNo ratings yet

- SOLENOID VALVE ASCO LowPower - Gseries - R8 PDFDocument14 pagesSOLENOID VALVE ASCO LowPower - Gseries - R8 PDFNUR AFIFAHNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- SCP004-MS30-QA-PLN-00002 A01 - ITP Cleaning and GaugingDocument4 pagesSCP004-MS30-QA-PLN-00002 A01 - ITP Cleaning and GaugingAbdulkadir Berk MalkoçNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFMohamad RifkiNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- DANEM ENGINEERING INSPECTION PLAN FOR MAIN STACK FABRICATIONDocument4 pagesDANEM ENGINEERING INSPECTION PLAN FOR MAIN STACK FABRICATIONRejoy babyNo ratings yet

- Inspection & Test Plan For Nozzle Replacement On VS ShellDocument1 pageInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDocument2 pagesWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiNo ratings yet

- Essar Constructions Ltd. Hazira.: List of FormatsDocument68 pagesEssar Constructions Ltd. Hazira.: List of Formatsravi00098No ratings yet

- PTS-1012 - RA Hardness Test ReportDocument1 pagePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNo ratings yet

- WPMP NDT Request FormDocument7 pagesWPMP NDT Request FormVimin PrakashNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- 18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFDocument19 pages18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFOscar Miguel Fuquen SanabriaNo ratings yet

- Hydro test report for 750mm dismantling jointDocument2 pagesHydro test report for 750mm dismantling jointAnonymous a8oga83No ratings yet

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- How To Calculate Hydrostatic Test Height in TanksDocument4 pagesHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNo ratings yet

- WPS and PQR ChecklistDocument2 pagesWPS and PQR Checklistshabbir626No ratings yet

- Asme Ix Wps PQR ChecklistDocument0 pagesAsme Ix Wps PQR ChecklistaghussrNo ratings yet

- ASME SEC. IX WPS & PQR Check ListDocument2 pagesASME SEC. IX WPS & PQR Check Listsajeed76740No ratings yet

- Dschx400 HG enDocument175 pagesDschx400 HG enrodofgodNo ratings yet

- Welding Tantalium s304Document17 pagesWelding Tantalium s304rodofgodNo ratings yet

- ASTM E797 - Practice For ME - Pulse Echo PDFDocument7 pagesASTM E797 - Practice For ME - Pulse Echo PDFLuciano RezendeNo ratings yet

- Sony Camcorder ManualDocument32 pagesSony Camcorder Manualnp484No ratings yet

- Complying With ISO 17025 A Practical GuidebookDocument122 pagesComplying With ISO 17025 A Practical Guidebookyes17025100% (8)

- Installation Guidelines for Integrally Reinforced Branch FittingsDocument7 pagesInstallation Guidelines for Integrally Reinforced Branch FittingsrodofgodNo ratings yet

- Rights and Obligations of European Union Membership Print VersionDocument100 pagesRights and Obligations of European Union Membership Print VersionrodofgodNo ratings yet

- Nimonic Alloy 90Document20 pagesNimonic Alloy 90akashrambharosNo ratings yet

- ISO 6520 Defect Classification GuideDocument27 pagesISO 6520 Defect Classification Guidealinor_tn100% (4)

- Pro-Forma Invoice: VAT NO. GB 827 4395 05Document1 pagePro-Forma Invoice: VAT NO. GB 827 4395 05rodofgodNo ratings yet

- WABO Welder Qualification StandardDocument77 pagesWABO Welder Qualification StandardJuan Martinez100% (1)

- Flux Cored Arc WeldingDocument5 pagesFlux Cored Arc WeldingPatrick DominguezNo ratings yet

- Vacuum Technology Book II Part 2Document140 pagesVacuum Technology Book II Part 2bracio100% (1)

- Ally PorocityDocument8 pagesAlly PorocityrodofgodNo ratings yet

- M227 Oper Manual Rev EDocument86 pagesM227 Oper Manual Rev ErodofgodNo ratings yet

- Elgacore DWA 50 Flux Cored Wire for Mild Steel WeldingDocument2 pagesElgacore DWA 50 Flux Cored Wire for Mild Steel WeldingrodofgodNo ratings yet

- Form P6Document1 pageForm P6rodofgodNo ratings yet

- Detect Leaks with Vacuum and Helium TechniquesDocument14 pagesDetect Leaks with Vacuum and Helium TechniquesSavij_ChouhanNo ratings yet

- F9J1102 8820ed00841 N600 UkDocument48 pagesF9J1102 8820ed00841 N600 UkrodofgodNo ratings yet

- CSWIP-WI-6-92 12th Edition May 2012Document17 pagesCSWIP-WI-6-92 12th Edition May 2012Shaju ShamsudheenNo ratings yet

- LNG WeldingDocument12 pagesLNG Weldingrodofgod100% (1)

- Ultrasonic Testing: Weld Inspection Using AWS D1.1Document65 pagesUltrasonic Testing: Weld Inspection Using AWS D1.1CLIFFORDPANo ratings yet

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Document58 pagesFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000No ratings yet

- Welding MetricsDocument63 pagesWelding MetricsgenergiaNo ratings yet

- Welding PreheatDocument2 pagesWelding PreheatsjmudaNo ratings yet

- Cheng WentaoDocument289 pagesCheng WentaorodofgodNo ratings yet

- WABO Welder Qualification StandardDocument77 pagesWABO Welder Qualification StandardJuan Martinez100% (1)

- Engineering DrawingsDocument70 pagesEngineering Drawingsjohn_kadier651No ratings yet

- House Down EtonDocument4 pagesHouse Down EtonrodofgodNo ratings yet

- CROCI Focus Intellectual CapitalDocument35 pagesCROCI Focus Intellectual CapitalcarminatNo ratings yet

- Design of Hydraulic Structures Seepage TheoryDocument13 pagesDesign of Hydraulic Structures Seepage TheorySuleman FaisalNo ratings yet

- CommunicationDocument5 pagesCommunicationRyan TomeldenNo ratings yet

- Course-PM SSY135 Wireless Communications 21-22Document7 pagesCourse-PM SSY135 Wireless Communications 21-22Amirhossein MohsenianNo ratings yet

- EtomDocument1 pageEtomarthryxNo ratings yet

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNo ratings yet

- Crafting and Executing StrategyDocument33 pagesCrafting and Executing Strategyamoore2505No ratings yet

- Designers' Guide To Eurocode 7 Geothechnical DesignDocument213 pagesDesigners' Guide To Eurocode 7 Geothechnical DesignJoão Gamboias100% (9)

- It 7sem Unit Ii IotDocument10 pagesIt 7sem Unit Ii IotMaitrayee SuleNo ratings yet

- India An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)Document437 pagesIndia An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)soumadri.2023.1301No ratings yet

- HR MasterlistDocument6 pagesHR MasterlistLeychelle AnnNo ratings yet

- CD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesDocument26 pagesCD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesMAC CONSULTORESNo ratings yet

- Mil B 49430BDocument36 pagesMil B 49430Bparam.vennelaNo ratings yet

- Action Plan On GadDocument1 pageAction Plan On GadCherish Devora ArtatesNo ratings yet

- Test Unit 7 m.2Document6 pagesTest Unit 7 m.2Petchara SridakunNo ratings yet

- Understanding Logistics and Supply Chain Management ConceptsDocument12 pagesUnderstanding Logistics and Supply Chain Management Conceptsarfat kabraNo ratings yet

- History of Computer AnimationDocument39 pagesHistory of Computer AnimationRanzelle UrsalNo ratings yet

- 5 Grade - Lesson 1.3 Dissolving and Back Again: ObjectiveDocument4 pages5 Grade - Lesson 1.3 Dissolving and Back Again: ObjectiveManushka ThomasNo ratings yet

- Admission:Discharge Criteria in Speech-Language Pathology - ASHADocument16 pagesAdmission:Discharge Criteria in Speech-Language Pathology - ASHANádia MarquesNo ratings yet

- SO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BDocument15 pagesSO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BATMMOBILISNo ratings yet

- REFLEKSI KASUS PLASENTADocument48 pagesREFLEKSI KASUS PLASENTAImelda AritonangNo ratings yet

- Display TFT SPI ST7735Document6 pagesDisplay TFT SPI ST7735Adlene DenniNo ratings yet

- Language II Module 2 Adjectives and AdverbsDocument25 pagesLanguage II Module 2 Adjectives and AdverbsCarla Arredondo MagnereNo ratings yet

- Writing A Spooky Setting DescriptionDocument4 pagesWriting A Spooky Setting DescriptionAayan AnjumNo ratings yet

- Pnas 1703856114Document5 pagesPnas 1703856114pi. capricorniNo ratings yet

- Information HandoutsDocument6 pagesInformation HandoutsPooja Marwadkar TupcheNo ratings yet

- Chapter 6 - 31-05-2023Document163 pagesChapter 6 - 31-05-2023Saumitra PandeyNo ratings yet

- Sinavy Pem Fuel CellDocument12 pagesSinavy Pem Fuel CellArielDanieli100% (1)

- Ziva RWW ManuscriptDocument3 pagesZiva RWW ManuscriptroderunnersdNo ratings yet

- ISO 17000 2004 Terms & DefintionsDocument6 pagesISO 17000 2004 Terms & DefintionsSelvaraj SimiyonNo ratings yet