Professional Documents

Culture Documents

30120140502017

Uploaded by

IAEME PublicationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30120140502017

Uploaded by

IAEME PublicationCopyright:

Available Formats

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING 6340(Print), ISSN

N 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

AND TECHNOLOGY (IJMET)

ISSN 0976 6340 (Print) ISSN 0976 6359 (Online) Volume 5, Issue 2, February (2014), pp. 149-161 IAEME: www.iaeme.com/ijmet.asp Journal Impact Factor (2014): 3.8231 (Calculated by GISI) www.jifactor.com

IJMET

IAEME

MOLDING PROCESS INDUCED ANISOTROPY EFFECT ON BUCKLING ANALYSIS OF FIBER- FILLED PLASTIC CRC PUSH ROD

R. Joseph Bensingh, M. Santhosh, S. Ilangovan

Advanced Research School for Technology and Product Simulation (ARSTPS), Central Institute of Plastics Engineering and Technology, Guindy, Chennai-600032

ABSTRACT Fiber-filled plastic materials are commonly used in metal replacement applications. The combination of low weight and high stiffness makes fiber-filled plastics ideal for high-performance applications. The key to unlocking the potential of these plastics lies in the orientation of the fibers. The orientation direction and the degree of orientation of the fibers determine the mechanical properties of the molded part. The injection moluding process for fiber-filled parts can cause great variation in strength throughout a part, the effects of the injection process should be considered in the design of such a part. In order to enable product designers to incorporate the strength variations of fiber filled, injection-molded components into mechanical analyses of those components by coupling of Moldflow injection molding simulation tools together with finite element analysis (FEA) software. By using this approach Design engineer can explore different design scenarios that will produce cheaper parts, while ensuring sufficient strength in highly loaded areas. In this paper, a Non Linear Anisotropic buckling analysis is carried out on CRC push rod component of hydraulic clutch actuation systems by coupling Moldflow with ANSYS. A comparison is made between the results from non linear isotropic and non linear anisotropic analysis with experimental results to understand the mechanical performance of the part. Simulation results are able to predict the observed mechanical behavior of fiber filled plastic components when the anisotropy of the material is taken into consideration. Traditional approach of treating the material property as isotropy overestimates the stiffness of the part. Also, modeling of flow is able to quantify the anisotropy generated in the part during its fabrication process. Keywords: Fiber Filled Plastic, Anisotropic, Buckling Analysis, CRC Push Rod, ANSYS Moldflow Interface.

149

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

ABBREVIATIONS CAD CAE CRC MISO MPI Computer-Aided Design Computer-Aided Engineering Clutch Release Cylinder Multi linear Isotropic material Moldflow Plastics Insight

1. INTRODUCTION Because of the many advantages of using plastic materials, there is an ongoing trend of replacing metal with injection-molded plastic parts in variety of applications. Plastics are lightweight, durable and corrosion-resistant; have a high strength-to-weight ratio; and, when used in transportation applications, for example, offer one of the easiest ways to increase fuel savings by making vehicles more lightweight. Lightweight plastics allow automotive designers and engineers the freedom to deliver innovative concepts cost effectively. From an aesthetic perspective, plastics and plastic composites offer the automotive designers distinct advantages in many applications. Fiber-filled plastic materials are commonly used in metal replacement applications. When glass or carbon fibers are added to plastics, the elastic modulus can increase significantly with a negligible effect on part weight. This combination of low weight and high stiffness makes fiber-filled plastics ideal for high-performance applications. The key to unlocking the potential of these plastics lies in the orientation of the fibers. The orientation direction and the degree of orientation of the fibers determine the mechanical properties of the molded part. In areas where fibers are strongly aligned, the material will have higher strength characteristics in that direction, but will be relatively weak in the perpendicular direction (across the fibers). In areas where the fibers are more randomly oriented, the material will not achieve maximum strength, though the strength properties will not depend as much on the loading direction, creating a more isotropic like material. But fiber reinforced plastics typically show anisotropic mechanical, thermal and rheological properties. Therefore, prediction of fiber orientation during the transient mold filling is important for the prediction of such anisotropic properties of final plastic part. During the injection molding process, the fibers in the plastic melt will orient in different directions under the influence of shear forces that are driven by the flow patterns .Figures 1 and 2 show the velocity profile and fiber orientation for a melt flow across thickness. The degree of orientation and the dominant direction of the fibers change throughout the part. The fibers in the mix get oriented along the local velocity vector and because of the variation of velocity across the thickness the fiber orientation also varies across the thickness of the part. This will result in material properties being different at different locations of the part i.e. anisotropy of modulus of the part based on the local orientation of the fibers.

Fig. 1: Velocity and shear rate profile of melt

150

Fig. 2: Fiber orientations along thickness

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

In normal Design engineers typically solve this kind of problem by using highly non isotropic materials by applying generous safety factors to their designs, making them thicker than is actually required. This led to not only waste of raw materials and cost, but also on cycle time. A simple rule of thumb for injection molding is that when the thickness is doubled, the production time quadruples. For effective design of short-fiber reinforced polymer based composites; CAE (Computer Aided Engineering) can play an important role. Characteristics of polymer and particle-contained suspensions being highly nonlinear and complex, only CAE can provide reasonable solutions. This technique offers a detailed and accurate simulation of processes in shorter time and lesser cost than traditional experiments and tests. The results can be used to identify the areas where orientation of the fibers is not suitable for a design. However, most commercial packages use rather simplified models and approximate numerical algorithms to calculate fiber orientation distribution. Refinement in modeling and numerical prediction of fiber suspension for better prediction is one area of focus for current research activities. 2. LITERATE REVIEWS A number of researchers have studied the flow induced anisotropy in fiber-filled plastics employing analytical and experimental methods. Recently, linear orthotropic analysis is carried out on ash tray door component by coupling Moldflow with ANSYS by [1] P. Satheesh Kumar, S. Srikari, N. S. Mahesh, S. Reddy. Based on there work the following points are drawn from there paper. 1) A finite element modeling approach can be used to predict the influence of process induced anisotropy in fiber-filled plastic parts. 2) Anisotropy induced due to manufacturing process has a major impact on mechanical performance of a component. 3) In a molded part, fiber orientation and density, both governed by flow pattern in the mold, result in modulus value different at different points in the part, and also, different in three principle directions at the same point. 4) Anisotropy can change the stiffness characteristics of a part by more than 50%. 5) Material anisotropy is affected by the flow pattern in mold. Hence, change in mold design can be used to tailor the stiffness characteristics of a part. [2] Ashok K Kancharla, Harindranath Sharma K, and Paul Nugent are carried outed the Experimental techniques and numerical studies to compare the isotropic and anisotropic behaviors of a fiber-filled plastic bolt. They conducted flow and structural analysis on a plastic bolt, using Moldflow and Abaqus. Their results showed that the simulation results with anisotropic property were within 4% of experimental results (Fig. 3). According to them this proves the capability of anisotropic structural analysis in predicting the results accurately for a short fiber filled thermoplastic material.

Fig. 3: Variation of deflection with pressure

151

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

[3] Chung and Kwon carried out finite element analysis for fiber suspensions using Pseudo Concentration method as a melt-front capturing technique. They found that including fountain flow effect induces wide core layers of orientation distributions and consequently simulation results match experimental data. Also, the coupling effect between fluid and fiber is important near the core and transition layers, even far downstream in the flow direction. The numerical studies of viscoelastic polymer dynamics must accompany with general 3D geometry because of the importance of melt front or gate region on the orientation states. Also, experimental data for various complex geometries must be obtained to understand detailed orientation dynamics and rheology. It was stated that suspension rheology and particle dynamics must be understood for more highly concentrated suspensions in the near future, then fiber to fiber interaction could be better understood The literature reveals the need for analysis of flow induced anisotropy for improving design and performance of fiber-filled material. Due to the complex flow behavior very few computational studies have been reported previously. In the current work, numerical simulations of a CRC push rod component of hydraulic clutch actuation have been carried out to provide an insight into the physics of the flow characteristics and structural performance of a filled material. There is only some simulation technique available for the simulation of thermoplastics because of their material nonlinearity. In this paper repeated use will be made of the finite element method to identify significant issues and provide evidence of the accuracy with which engineering analysis of plastic parts can be conducted. Although it is not within the scope of this work to provide a detailed description of this analysis approach, some general level of understanding of this analysis method will be useful. There is a significant difference between simulation and test results for thermoplastics necessitating comparison studies as in the scope of this paper to increase the correlation between test and simulation. In this paper, results of modeling and simulation of fiber-filled plastics with process induced anisotropy have been presented. Moldflow has been used to simulate the manufacturing process (injection molding) and ANSYS has been used to simulate the structural Buckling performance of the CRC push rod component At Two different cases, as described below, and results have been compared with test results. Case 1: Simulation technique based on material models (Multi-linear isotropic material model) Case 2: Simulation technique based on interface based simulation tools (Mold flow-ANSYS interface) 3. GEOMETRIC MODELS AND ANALYSIS METHODOLOGY The model used for this study is a push rod which is the part of the Clutch release Cylinder (CRC) of a hydraulic clutch activation system show in Fig 4. The Function of Push rod is to transfermation the motion from CRC cylinder piston to clutch Fork .Push rod is subjected to only axial loads so it behave like column. In normal short column under the action of an axial load will fail by direct compression before it buckles, but a long column loaded in the same manner will fail by buckling (bending), the buckling effect being so large that the effect of the direct load may be neglected. Buckling is characterized by a sudden failure of a structural member subjected to high compressive stress, where the actual compressive stress at the point of failure is less than the ultimate compressive stresses that the material is capable of withstanding.

152

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

Fig. 4: Location of push rod in Clutch release Cylinder The Geometric model of the push rod is created in CATIA V5 as for the dimensions as shown in Fig.5.

Fig. 5: Geometric model of the CRC Push Rod Figure 6 shows the Details of the analysis methodology to conduct the flow and structural analysis in the first case of the methodology, CAD model was imported into ANSYS and loading, boundary conditions are applied for isotropic material model for find out the buckling load. In the Second case material Flow Simulation of the component is carried out by using Moldflow. The result of this analysis, which includes information about fiber orientation, is then exported to ANSYS where finite element model for structural analysis is created. For anisotropic analysis, Information about fiber orientation, obtained from Moldflow analysis, is used to determine the buckling load of push rod.

Fig .6: Methodology for Push rod buckling analysis

153

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

3.1 Details of the numerical models for analysis ANSYS was used to carry out the structural analysis. The CAD model was imported into ANSYS and meshed with solid 187 tetrahedral elements. Boundary conditions were specified in ANSYS and first an analysis with Multi-linear isotropic material model was carried out to get the Buckling load (Case 1). The material specified for the analysis was PA66 GF50% (Zytel73G50 HSLABK416) from DUPONT engineering polymers with a elastic modulus of 11688 MPa at temperature of 230. 3.2 Boundary conditions for analysis Boundary condition used for non linear buckling analysis of push rod are described below and are shown in Fig .7 1) At pilot node UZ displacement is applied axially and all other DOF are locked to achieve the buckling load. 2) At bottom face of the push rod all DOF are locked. 3) For reducing the computational time of analysis, some disturbance load is applied in positive x and negative y direction to initiate the buckling. To determine the buckling load, axial displacement is applied instead of force on the pilot node. Based on reaction force that is developed on the pilot node buckling load is determined.

Fig .7: Boundary Conditions used for structural analysis 4. STRUCTURAL ANALYSIS AND FLOW SIMULATION 4.1 Case 1: Simulation technique based on material models Thermoplastic exhibit complex behavior when subjected to constant, increasing or cyclical mechanical loads. As these materials begin to be used more in load-bearing designs, we must be able to predict the structural performance of actual modeled parts. The design element involves creating geometry and performing analysis to predict part performance. Engineering design requires mechanical properties to define material behavior adequately and accurate analysis techniques to predict generic part performance based on those data. For this type of simulation technique the material property provided for simulation, will be taken from standard data provided by the manufacturers after conducting some tests on the standard specimen. Simulation technique based on material model is given below.

154

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

Multi-linear isotropic material model The non linear buckling analysis carried out for multi-linear isotropic material model with the following Stress vs Strain curve data at 230 C for the material PA66 GF50% (Zytel73G50 HSLABK416) is shown in fig .8 and the stress strain data is listed in table 1.

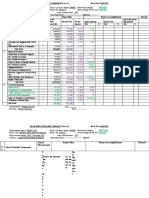

Fig. 8: Stress vs Strain curve for MISO material model Table .1 Stress vs Strain values for the MISO material model Strain Stress 0.0032 37.4 0.0051 57.3 0.0066 72.2 0.008 84.4 0.0093 94.4 0.0121 112 0.0149 127 0.0165 134 0.0182 141 0.0218 152 0.0366 167 Buckling load obtained from this analysis was about 7255 N is shown in fig.9 .This curve is draw for the reaction force obtained at pilot against to the displacement at the pilot node in z direction

Fig .9: Displacement vs. Load curve at pilot node for MISO material model

155

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

Buckling mode shape of the push rod for MISO material model is shown fig.10

Fig .10: buckling mode shape of push rod for MISO material model Von mises stress contour for push rod is shown in Fig.11.From this contours we can see that the max von mises stress of push rod reached max stress value definde by stress vs strain curve. After this value the part will strart get fail (plastic defromed).

Fig. 11: Von mises stress contour MISO material model 4.2 Case 2: simulation technique based on interface based simulation tools (Mold flow-ANSYS interface) The results of a Moldflow simulation include calculations of material properties with fiber orientation and residual stresses in the plastic part. These data's are given as a input for structural analysis in Ansys. The work flow of this interface is shown in below Fig.12

156

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

Fig .12: Work Flow between Moldflow and ANSYS 4.2.1 Flow Simulation The CAD model of the Push rod is imported in Hypermesh and surface of the push rod was meshed very fine and after checking quality, exported in Moldflow readable format. The surface meshed model from Hypermesh is imported in to Moldflow insight software for the mouldflow simulation. In Mold flow the Push rod with 2D surface mesh is converted into 3D mesh to do flow simulation. The meshed Push rod model with The injection gate location used for flow stimulation is show in Fig 13.

Fig.13: Injection gate location for Push rod mold stimulation Process boundary condition like filling time, packing pressure, holding pressure, injection time, velocity etc. are directly affect the component material properties in molding process .So proper process condition are needed to accurate mold flow stimulation. The process boundary condition used for CRC push rod mold flow stimulation are listed in Table 2 Table 2: Moldflow process boundary conditions for Push rod molding Material PA66 GF50% (Zytel70G50 HSLA BK039B) Melt temperature 2870c Mold temperature 100 0c Injection time 0.6 s Switch-over Velocity/Pressure ( By %volume filed) 99 Packing/Holding Pressure Packing Pressure Time 50Mpa 7s

157

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

The material processing of the Push rod component for the specified process boundary conditions is simulated using Moldflow (MPI). Mold flow has the capability to predict the fiber orientations and then calculate the mechanical properties based on these orientations. The random fiber orientation of the push rod after the molding stimulation are shown in Fig.14

Fig: 14: Random fiber orientation tensor contour of the push rod The stimulation results generated by MPI are binary files. In order to be used in ANSYS, these files need to be converted to ASCII format. An API script is available that automatically converts the necessary result and mesh files into a format that ANSYS can use. API uses the mpi2ans.vbs, command to convert the files for ANSYS readably format. The MPI results are exported in *.mts,* ist format the 3D mesh is exported in ANSYS input *.cdb format. The exported files are imported in to ANSYS to do the Buckling analysis. For this material model the Von mises stress contour shown in fig.15.Based on Von misses failure criteria. The von misses stress of push rod is reached failure stress value (250) at displacement 0.699 mm and the corresponding load that is cause this displacement is consider as buckling load.

Fig. 15: Von mises stress contour for interface material model The obtained Buckling load for causing of 0.699mm displacement was about 5732 N is shown in fig.16.This curve is draw for the reaction force obtained at pilot against to the displacement at the pilot node in z direction.

158

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

Fig .16: Displacement vs. Load curve at pilot node for interface material model 4.3 Experimental test The experimental test is carried out on the UTM (universal testing machine) for the push rod component. Sample parts for testing are prepared by injection moulding. Then those test sample parts are placed in UTM and compression load is gradual applied to find out the buckling load of the push rod. After experimental Tested push rod parts are sown in Fig .17.

Fig. 17: push rod mode shapes after experimental test Average buckling load obtained for this experimental test is about 6120 N shown in Fig 18.This curve is drawn against the time vs applied load

Fig. 18: Time vs applied load curve for the experimental test

159

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

5. RESULTS AND DISCUSSIONS Buckling load obtained for two cases with two different material models are compared with test results is shown in table 3 and Fig. 19 Table.3: Comparison of buckling load with test result for different material models

Fig. 19: Comparison of buckling load for different material models From above results following observation is drawn. 1) The buckling load is varying for different material models to cause the same amount of displacement. 2) From curve we can also observe that in MISO material model the load is decreasing with respect displacement after buckling load is reached .This is due to the plasticity affect of the non liner material model. 3) But in anisotropic material the load is increase linear with displacement after buckling load Because of the material strength in other direction are capable of carrying load even through the material get plastic deformation in one direction Results presented above demonstrate the necessity and accuracy of Anisotropy Buckling analysis over isotropic buckling analysis for glass fiber filled thermoplastics. Precise modeling of the experimental setup is necessary to predict the results accurately. The CAE analysis results considering Anisotropy material properties, closely match with the experimental data within a variation of 6%. This proves the capability of Anisotropy Buckling analysis in predicting the results accurately for a glass fiber filled thermoplastic material.

160

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online), Volume 5, Issue 2, February (2014), pp. 149-161, IAEME

6. CONCLUSIONS Based on above results, it can be observed that the simulation tools, for molding process and for structural analysis with anisotropic material properties, can be successfully used in tandem to predict the Buckling behavior of molded components made out of glass fiber filled thermoplastic material. It is important that this approach is used, rather than designing the component assuming the material property to be isotropic, because the approximation can be very erroneous. Based on the simulation results presented above, the following conclusions were drawn 1) As analyzed, it will be inappropriate to consider isotropic material properties for the simulation of short fiber filled thermoplastics. 2) By using the interface simulation technique we can accurately predict the structural analysis occurs. 3) A finite element modeling approach can be used to predict the influence of process induced anisotropy in fiber-filled plastic parts. 4) Anisotropy induced due to manufacturing process has a major impact on mechanical performance of a component. 5) Material anisotropy is affected by the flow pattern in mold. Hence, change in mold design can be used to tailor the stiffness characteristics of a part. REFERENCES 1. P. Satheesh Kumar, S. Srikari, N. S. Mahesh, S. Reddy, structural analysis of fiber- filled plastics With moulding process induced anisotropy, SASTECH Journal Volume 9, Issue 2, September 2010. Ashok K Kancharla, Harindranath Sharma K, and Paul Nugent, Orthotropic Structural Analysis of Short Fiber Filled Thermoplastics: Abaqus- Moldflow Interface, Experimental Validation, SIMULIA India Regional Users Meet, 2009. Du Hwan Chung and Tai Hun Kwon, Fiber Orientation in the Processing of Polymer Composites, Korea-Australia Rheology Journal Vol. 14, No. 4, pp. 175-188, December 2002. Jos Luis Manzanares Japn, Ignacio Hinojosa Snchez-Barbudo, Non-linear plastic analysis of steel arches under later buckling, journal of construction steel research volume 67, Issue 12, December 2011, Pages 1850-1863. Santhosh M, Joseph Bnsingh R, Structural analysis of fiber- filled plastics with molding process induced anisotropy: Ansys - Mold flow Interface and Experimental Validation International conference ANTEC Mumbai 2013 held on December 06-07, 2012 at Mumbai. Autodesk, Moldflow reference manuals and help files, Autodesk Moldflow 2010. Ramesh Chandra Mohapatra, Antaryami Mishra and Bibhuti Bhushan Choudhury, Investigations on Tensile and Flexural Strength of Wood Dust and Glass Fibre Filled Epoxy Hybrid Composites, International Journal of Mechanical Engineering & Technology (IJMET), Volume 4, Issue 4, 2013, pp. 180 - 187, ISSN Print: 0976 6340, ISSN Online: 0976 6359. M.G. Rathi and Manoj D. Salunke, Reduction of Short Shots by Optimizing Injection Molding Process Parameters, International Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 3, 2012, pp. 285 - 293, ISSN Print: 0976 6340, ISSN Online: 0976 6359.

2.

3. 4.

5.

6. 7.

8.

161

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cash and Cash Equivalents ReviewerDocument4 pagesCash and Cash Equivalents ReviewerEileithyia KijimaNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDocument6 pagesSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDocument5 pagesA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDocument6 pagesEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationNo ratings yet

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDocument7 pagesFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationNo ratings yet

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDocument10 pagesIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationNo ratings yet

- Cape 2 Biology - Homeostasis &excretionDocument9 pagesCape 2 Biology - Homeostasis &excretionTamicka BonnickNo ratings yet

- Full Bridge Phase Shift ConverterDocument21 pagesFull Bridge Phase Shift ConverterMukul ChoudhuryNo ratings yet

- Mapeh 9 Aho Q2W1Document8 pagesMapeh 9 Aho Q2W1Trisha Joy Paine TabucolNo ratings yet

- 348 - Ct-Tol Toluene TdsDocument1 page348 - Ct-Tol Toluene Tdsonejako12No ratings yet

- Ecg Quick Guide PDFDocument7 pagesEcg Quick Guide PDFansarijavedNo ratings yet

- CL Analyzer: Coagulometric, Chromogenic and Immunological AssaysDocument2 pagesCL Analyzer: Coagulometric, Chromogenic and Immunological AssaysEdwinNo ratings yet

- Grain Silo Storage SizesDocument8 pagesGrain Silo Storage SizesTyler HallNo ratings yet

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventDocument8 pagesEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumNo ratings yet

- Calculation Condensation StudentDocument7 pagesCalculation Condensation StudentHans PeterNo ratings yet

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- AcquaculturaDocument145 pagesAcquaculturamidi64100% (1)

- Denagard-CTC US Knowledge ReportDocument4 pagesDenagard-CTC US Knowledge Reportnick224No ratings yet

- 感應馬達安裝、保養使用說明書31057H402E (英)Document17 pages感應馬達安裝、保養使用說明書31057H402E (英)Rosyad Broe CaporegimeNo ratings yet

- Complete Renold CatalogueDocument92 pagesComplete Renold CatalogueblpNo ratings yet

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsNo ratings yet

- High CarbonDocument2 pagesHigh CarbonKarisoNo ratings yet

- Ineffective Breastfeeding - NCPDocument10 pagesIneffective Breastfeeding - NCPJullian PloyaNo ratings yet

- Ransport and Installation Instructions CTX 510 EcoDocument32 pagesRansport and Installation Instructions CTX 510 EcoMiliano FilhoNo ratings yet

- Practical Cookery 14th Edition SAMPLEDocument16 pagesPractical Cookery 14th Edition SAMPLETendaiNo ratings yet

- Senographe Crystal: The Choice Is Crystal ClearDocument7 pagesSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirNo ratings yet

- Technical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsDocument380 pagesTechnical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsJairo Manzaneda100% (2)

- Narrative ReporDocument3 pagesNarrative ReporMARK LUKE ULITNo ratings yet

- CampingDocument25 pagesCampingChristine May SusanaNo ratings yet

- Final Manuscript GROUP2Document102 pagesFinal Manuscript GROUP222102279No ratings yet

- Qualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific ApproachDocument23 pagesQualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific Approachmicrobioasturias100% (4)

- II092 - Horiz & Vert ULSs With Serial InputsDocument4 pagesII092 - Horiz & Vert ULSs With Serial InputsJibjab7No ratings yet

- RCM Design and ImplementationDocument34 pagesRCM Design and ImplementationRozi YudaNo ratings yet

- Mental Status ExaminationDocument34 pagesMental Status Examinationkimbomd100% (2)

- Soil Chapter 3Document67 pagesSoil Chapter 3Jethrone MichealaNo ratings yet