Professional Documents

Culture Documents

FDA FSM A Explained All Candy 0119111

Uploaded by

Jessica AngelinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FDA FSM A Explained All Candy 0119111

Uploaded by

Jessica AngelinaCopyright:

Available Formats

PHILIP C.

OLSSON

RICHARD L. FRANK

DAVID F. WEEDA (1948-2001)

DENNIS R. JOHNSON

ARTHUR Y. TSIEN

JOHN W. BODE*

STEPHEN D. TERMAN

MARSHALL L. MATZ

MICHAEL J. O'FLAHERTY

DAVID L. DURKIN

NEIL F. O'FLAHERTY

BRETT T. SCHWEMER

TISH E. PAHL

ROBERT A. HAHN

EVAN P. PHELPS

GARY H. BAISE

DAVID A. BIEGING

KATHRYN E. BALMFORD

FREDERICK H. BRANDING*

BRUCE A. SILVERGLADE

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

ATTORNEYS AT LAW

SUITE 400

1400 SIXTEENTH STREET, N.W.

WASHINGTON, D.C. 20036 (202) 789-1212

w w w . ofw law .c om

JOLYDA O. SWAIM

JONATHAN M. WEINRIEB

NANCY W. MATHEWSON

COUNSEL

ROGER R. SZEMRAJ

ANSON M. KELLER

CASPER E. ULDRIKS*

OF COUNSEL

KENNETH D. ACKERMAN

MARK L. ITZKOFF

ELLIOT BELILOS

SENIOR POLICY ADVISORS

MEMORANDUM

January 19, 2011

JOHN R. BLOCK

CHARLES W. STENHOLM

GEORGE McGOVERN

SALLY S. DONNER

BRENT W. GATTIS

BARBARA J. MASTERS

*PRACTICE WITHIN THE DISTRICT OF COLUMBIA

IS LIMITED TO MATTERS AND PROCEDURES

BE FORE FE DE RAL COURT S AND AGE NCI E S

BY ELECTRONIC MAIL

FROM:

Olsson Frank Weeda Terman Bode Matz PC

RE:

The FDA Food Safety Modernization Act

The FDA Food Safety Modernization Act of 2010 (Public Law 111-353) (FSMA) was

enacted on January 4, 2011. The new legislation represents a major reform of the food safety

provisions of the Federal Food, Drug, and Cosmetic Act (FD&C Act) and significantly expands

the powers of the Food and Drug Administration (FDA) with respect to food. This memorandum

provides a brief summary of this landmark legislation, focusing on provisions relevant to the

chocolate industry.1

I.

SUMMARY

The FDA Food Safety Modernization Act represents the most significant expansion of

food safety requirements and FDA food safety powers since the original enactment of the FD&C

Act in 1938. The FSMA requires FDA to undertake more than a dozen rulemakings and issue at

least 10 guidance documents, as well as a host of reports, plans, strategies, standards, notices,

and other tasks. Therefore, implementation of the legislation is likely to take several years.

However, it should be noted that some provisions of the new law became effective immediately

upon enactment. This memorandum highlights the effective dates of provisions relevant to the

chocolate industry, and a summary at the end of this memorandum identifies which provisions of

the law are self-implementing and which provisions will require FDA regulations to implement.

Major provisions include:

1

A copy of the new law is available at: http://www.gpo.gov/fdsys/pkg/BILLS-111hr2751eas/pdf/BILLS111hr2751eas.pdf. This link is temporary. A copy of the law should be available soon on the Library of Congress

website (http://thomas.loc.gov) under its Public Law number.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 2

Registration and Inspection

Food facilities are required to register with FDA biennially.

Food from an unregistered facility may not be imported into the United States or

introduced into interstate or intrastate commerce.

Food facilities will be inspected with greater frequency, and domestic facilities

will be inspected at least once every 5 years.

Hazard Analysis and Preventive Controls Plans

Registered food facilities are required to conduct hazard analyses and to develop

and implement written preventive controls plans.

Imported Foods

Food importers are required to implement Foreign Supplier Verification Programs

and to take steps to verify that the food they import is safe.

FDA will establish a Voluntary Qualified Importer Program that will provide

expedited importation for foods imported by eligible importers (i.e., importers

that import food from facilities certified by an accredited third-party auditor).

Recordkeeping and Records Access; Traceability

Registered food facilities are required to maintain additional records, including

copies of their hazard analyses and preventive controls plans and related records,

and to make these records available to FDA upon request.

Food importers are required to maintain additional records, including their

Foreign Supplier Verification Programs and related records, and to make these

records available to FDA upon request.

FDA will establish a product tracing system within FDA to improve the agencys

ability to effectively and rapidly track and trace food, and FDA will establish

additional recordkeeping requirements for high-risk foods.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 3

Fees

Food facilities and food importers are subject to new fees, including a fee to be

paid by each domestic food facility or importer that undergoes a re-inspection

because of a material non-compliance identified during an initial inspection.

New FDA Powers

FDA has the authority to order a recall of food, but FDA must first provide the

responsible company with the opportunity to voluntarily recall the food and an

informal hearing.

FDA has the authority to administratively detain food based only on a reason to

believe that the food is adulterated or misbranded.

FDA has the power to suspend a facilitys registration, and thereby suspend its

operations, if FDA determines that food manufactured, processed, packed, or held

at that facility has a reasonable probability of causing serious adverse health

consequences or death.

FDA has the power to require that an article of food offered for import be

accompanied by a safety certification from an accredited third-party auditor as a

condition of granting admission into the United States.

The FSMA can be said to move FDA regulation of food closer to the U.S. Department of

Agriculture (USDA) regulatory model in significant ways. For example, FDA now has the

power to suspend a food facilitys registration, and thereby suspend its operations, similar to

USDAs power to suspend inspection. FDA has the authority to set performance standards for

contaminants as USDA has done for pathogens in meat and poultry. Food facilities registered

with FDA will have to perform hazard analyses and implement preventive controls plans similar

to the HACCP (Hazard Analysis and Critical Control Points) plans required of meat and poultry

establishments.

II.

REGISTRATION

What

Registration Frequency

Whereas food facilities had been required to register with FDA on a one-time basis, the FSMA

requires food facilities to register with FDA biennially, between October 1 and December 31 of

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 4

each even-numbered year. FDA is to provide an abbreviated renewal process for facilities that

have had no changes in their registration information since the previous renewal.

Registration Information

In addition to the registration information already required, the FSMA requires the

following new registration information: (1) a consent to permit FDA inspection of the

registered facility; (2) the email address for the facilitys contact person (or, in the

case of a foreign facility, the email address of the facilitys U.S. agent); and (3) in the

section requiring the food product categories manufactured, processed, packed, or

held at the facility, any other food categories determined by FDA to be appropriate.

Suspension of Registration (see New FDA Enforcement Powers in Sec. X below)

When

Biennial registration will begin in 2012.

Candy Specific

NCA will be glad to provide advice to members regarding whether their facilities (domestic or

foreign) are required to register with FDA, how to register, and how to defend themselves

against suspension of registration.

III.

HAZARD ANALYSIS AND PREVENTIVE CONTROLS

What

Hazard Analysis and Preventive Controls Plans

The FSMA requires registered facilities to perform a hazard analysis and implement a preventive

controls plan. The owner, operator, or agent in charge of each registered facility is required to

conduct a hazard analysis and develop and implement a written preventive controls plan to

ensure that food is not adulterated under FD&C Act Section 402 or misbranded under FD&C Act

Section 403(w) (allergen labeling). Under the Bioterrorism Act, the last foreign facility to

process the food (including packaging, but not including labeling or other de minimis

processing), and any subsequent foreign facility that packs or holds the food, is required to

register with FDA. Since FDA considers fumigation of cocoa beans to be processing, port

facilities in origin countries where cocoa beans are fumigated and then stored prior to shipment

to the U.S. must register with FDA. However, upstream foreign facilities that handle the beans

prior to reaching the port are exempt from FDA registration. The written plan must include the

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 5

following elements: hazard analysis, preventive controls (including preventive controls at critical

control points, if any), monitoring, verification, corrective actions, and recordkeeping.

Required Elements

Hazard analysis: Must identify and evaluate all known or reasonably foreseeable hazards

that may be associated with the facility as well as the incoming food materials (including

biological, chemical, physical, and radiological hazards as well as natural toxins,

pesticides, drug residues, decomposition, parasites, allergens, and unapproved food and

color additives) and prepare a written hazard analysis.

Preventive controls: Must identify and implement preventive controls (including at

critical control points, if any) to provide assurances that (a) hazards identified in the

hazard analysis are significantly minimized or prevented; (b) hazards that may be

intentionally introduced are significantly minimized or prevented; and (c) the food

manufactured, processed, packed, or held by the facility will not be adulterated under

Section 402 of the FD&C Act or misbranded under Section 403(w) (allergen labeling).

Preventive controls may include the following:

Sanitation procedures for food contact surfaces and utensils;

Supervisor, manager, and employee hygiene training;

An environmental monitoring program to verify the effectiveness of

pathogen controls in processes where food is exposed to a potential

contaminant in the environment;

A food allergen control program;

A recall plan;

Current Good Manufacturing Practices under 21 C.F.R. Part 110; and

Supplier verification activities related to food safety.

Monitoring: Must monitor the effectiveness of preventive controls.

Corrective actions: Must establish procedures to ensure that, if preventive controls are

not properly implemented or are found to be ineffective: (a) all affected food is evaluated

for safety; (b) all affected food is prevented from entering commerce if the owner,

operator, or agent in charge cannot ensure it is not adulterated under Section 402 or

misbranded under Section 403(w); and (c) appropriate action is taken to reduce the

likelihood of a recurrence.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 6

Verification: Must verify that the facilitys preventive controls are adequate to control the

hazards identified in the hazard analysis, that monitoring is being performed, that

appropriate decisions about corrective actions are being made, and that periodic

reanalysis of the plan is conducted. Verification is required to include environmental and

product testing programs.

Recordkeeping and records access: Must maintain a copy of the facilitys written

preventive controls plan. It also must maintain, for at least 2 years, records of

monitoring, instances of nonconformance material to food safety, corrective actions,

verification, and the efficacy of preventive controls and corrective actions. Such records

must be made available to FDA promptly upon oral or written request.

Requirement to Reanalyze

The owner, operator, or agent in charge of the facility must reanalyze the hazard analysis at least

once every 3 years and before any significant change is made in the activities conducted at the

facility if such change creates a reasonable potential for a new hazard or a significant increase in

a previously identified hazard. FDA also may require a reanalysis to respond to new hazards,

developments in scientific understanding, or results of a Department of Homeland Security

(DHS) terrorism risk assessment.

Exemptions

Section 418 does not apply to certain types of facilities, including:

o Very small businesses designated as qualified facilities, which are defined as either:

o A facility that, including any subsidiary or affiliate of the facility, is

collectively a very small business (to be defined by FDA regulations); or

o A facility for which both: (a) the average annual monetary value of food sold

by the facility during the 3-year period preceding the applicable calendar year

was less than $500,000, adjusted for inflation; and (b) the average annual

monetary value of the food manufactured, processed, packed, or held at the

facility and sold directly to qualified end-users (i.e., consumers, restaurants,

or retail food establishments located either in the same state as the facility or

not more than 275 miles from the facility) exceeded the average annual

monetary value of the food manufactured, processed, packed, or held at the

facility and sold to all other purchasers during the 3-year period preceding the

applicable calendar year.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 7

o FDA may, by regulation, exempt or modify the requirements of Section 418 for

facilities that are solely engaged in the storage of raw agricultural commodities (other

than fruits and vegetables) intended for further distribution or processing or facilities

that are solely engaged in the storage of packaged foods that are not exposed to the

environment. It is worth noting that FDA historically has not considered cocoa beans

that have been dried, fermented, and fumigated to be a raw agricultural commodity.

When

By July 2012, FDA is required to promulgate regulations to establish science-based minimum

standards for conducting a hazard analysis, documenting hazards, implementing preventive

controls, and documenting implementation of preventive controls. The FDA regulations are

required to provide sufficient flexibility to be practicable for all sizes and types of facilities and

may not require a facility to hire a consultant or other third party to identify, implement, certify,

or audit preventive controls (except where required by a consent decree). Section 418 will

become effective on July 4, 2012, except that it will become effective for small businesses 6

months after the effective date of FDA implementing regulations, and for very small businesses,

18 months after the effective date of FDA implementing regulations.

Candy Specific

NCA plans to hold a workshop for confectioners on food safety and GMP best practices in 2011,

as it did in 2009 and 2010 in anticipation of this new law.

IV.

INSPECTIONS

What

Frequency

FDA is required to:

Inspect all domestic facilities at least once every 5 years.

Inspect domestic high-risk facilities at least once during the 5-year period following the

date of enactment, and at least once every 3 years thereafter.

Inspect domestic facilities that are not high-risk facilities at least once during the 7-year

period following the date of enactment, and at least once every 5 years thereafter.

Inspect at least 600 foreign facilities during the first year following enactment, and at

least twice the number inspected during the previous year in each of the next 5 years. 2 In

2

Unless FDA receives substantial additional funding, we believe the agency is unlikely to meet these targets.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 8

targeting inspections of foreign facilities, FDA will consider participation in the

Voluntary Qualified Importer Program and third-party certification.

High Risk

FDA is required to allocate resources for inspection according to risk, and to identify high-risk

facilities based on the following factors:

The known safety risks of the food manufactured, processed, packed, or held at the

facility;

The facilitys compliance history including recalls, outbreaks, and violations;

The rigor and effectiveness of the facilitys hazard analysis and preventive controls;

Whether the facility or its food have been certified by an accredited third-party auditor;

whether the food manufactured, processed, packed, handled, prepared, treated,

distributed, or stored at the facility meets the criteria for priority under FD&C Act section

801(h)(1) (i.e., possible intentional adulteration); and

Any other criteria deemed appropriate by FDA.

When

While the law requires FDA to increase inspection frequency immediately, the agencys ability

to do so will largely depend on how much funding it receives from Congress in each of the next

several appropriations cycles.

Candy Specific

Traditional FDA inspection priorities for candy products include Salmonella and other pathogen

contamination of raw materials (e.g., cocoa, milk, eggs, peanuts, tree nuts); filth in raw materials

and molding starch; handling of rework; foreign objects; undeclared or unapproved color

additives; and undeclared major food allergens. Confectionery facilities that use major food

allergens, that roast peanuts or tree nuts, and/or that have had a Class I recall in the past few

years may be more likely to be classified by FDA as high risk facilities. To gauge whether or

not FDA may consider a facility as high risk, consider the following:

Has the facility had a Class I recall in recent years?

Were safety violations found during recent FDA or state inspections?

Does the facility have a HACCP plan in place?

Does the facility have an allergen control plan in place?

Does the facility have a validated kill step for raw materials that may be vulnerable to

pathogen contamination (e.g., cocoa beans, peanuts, tree nuts)?

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 9

Is the facility audited by a third party?

Note that there is no exemption from inspection frequency based on company or facility size.

In 2011 and 2012, NCA will offer a variety of educational tools to help member companies

prepare for increased FDA oversight. Look for more information on what to expect and how to

prepare for an FDA inspection.

V.

IMPORTS

What

Inspection of Imports

FDA is required to allocate resources to inspect imported foods according to their risk

profile, based on the following factors:

The known safety risks of the imported food;

The known safety risks of the countries or regions of origin and transport of the imported

food;

The importers compliance history including recalls, outbreaks, and violations;

The rigor and effectiveness of the importers Foreign Supplier Verification Program (see

below);

Whether the importer participates in the Voluntary Qualified Importer Program (see

below);

Whether the food is a likely candidate for possible intentional adulteration

Whether the food or the facility that manufactured, processed, packed, or held the food

has been certified by an accredited third-party auditor; and

Any other criteria deemed appropriate by FDA.

Inspection of Foreign Facilities; Effect of Refusal

FDA is required to inspect at least 600 foreign facilities during the first year following

enactment, and at least twice the number inspected during the previous year in each of the

next 5 years. FDA is authorized to enter into agreements with foreign governments to

facilitate inspection of foreign food facilities.

In targeting inspections of foreign facilities, FDA will consider participation in the

Voluntary Qualified Importer Program and third-party certification.

If the owner, operator, or agent in charge of a foreign factory, warehouse, or other

establishment, or the government of a foreign country, refuses to permit entry of FDA-

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 10

designated inspectors, food from that foreign establishment shall be refused admission

into the United States.

An inspection request will be considered to be refused if an inspection is not permitted

during the 24-hour period after a request is made, or after such other time period as

agreed upon by FDA and the foreign establishment.

Voluntary Qualified Importer Program

FDA is required to establish a Voluntary Qualified Importer Program to expedite movement of

food through the import process.3

To be eligible to participate in the Voluntary Qualified Importer Program during a given

fiscal year, an importer must be importing food from a facility that has been certified by an

accredited third-party auditor under Section 808 (see Sec. VII below) and such certification

must accompany the imported food.

An importer that wishes to participate must submit a notice and application to FDA at the

time and in the manner established by FDA.

In reviewing applications, FDA shall consider the risk of the food to be imported by the

importer based on such factors as: the known safety risks of the food, the compliance history

of the foreign suppliers used by the importer, the importers Foreign Supplier Verification

Program and food safety practices, the importers regulatory history, the regulatory system in

the country of export, the potential risk of intentional adulteration, and such other factors as

FDA deems appropriate.

FDA is required to reevaluate participating importers at least once every 3 years.

When

FDAs ability to increase inspection frequency is questionable unless Congress increases

funding.

FDA is required to issue a guidance document by July 4, 2012 explaining how to participate in

the Voluntary Qualified Importer Program.

Candy Specific

FDA Import Alerts may provide some indication of the products, regions, and importers that may

receive increased inspection scrutiny. Current Import Alerts include all foods from China

containing milk due to melamine (Import Alert # 99-30) and cocoa beans from Indonesia,

Malaysia and Brazil due to live insects (Import Alert # 34-01). FDA may also target inspections

3

For purposes of Section 806, an importer is defined as the person that brings food, or causes food to be brought,

from a foreign country into the customs territory of the United States. 21 U.S.C. 386(g).

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 11

of foreign facilities and imported foods based on the following factors: use of major food

allergens (e.g., tree nuts); and use of ingredients at potential risk of pathogen or pesticide

contamination.

Confectionery manufacturers that rely on imported supplies may want to urge their suppliers to

participate in the Voluntary Qualified Importer Program, once it is established, in order to ensure

a steady supply. NCA plans to alert members when FDAs guidance document on this program

is available.

VI.

IMPORTS NEW REQUIREMENTS

Foreign Supplier Verification Program

What

Every U.S. importer4 will be required to perform risk-based foreign supplier verification

activities to verify that the food it imports is (a) produced in compliance with the requirements of

Section 418 (hazard analysis and preventive controls) or Section 419 (produce standards); and

(b) is not adulterated under Section 402 or misbranded under Section 403(w) (allergen labeling).

Each importer will be required to perform foreign supplier verification activities, which

may include monitoring records of shipments, lot-by-lot certification, annual on-site

inspections of foreign suppliers, checking the hazard analysis and prevent controls plans

of foreign suppliers, and periodic sampling and testing of shipments.

Each importer will be required to maintain records related to its Foreign Supplier

Verification Program for at least 2 years and to make them available to FDA upon

request.

FDA is required to maintain on its website a current list of the names, locations, and other

information deemed necessary about importers that are in compliance with Section 805.

FDA is required to establish, by Federal Register notice, an exemption for articles of

food imported in small quantities for research and evaluation purposes (i.e., product

samples) or for personal consumption, provided that such foods are not intended for

resale and are not sold or distributed to the public.

A food offered for import will be refused admission if it appears that the importer does

not have a Foreign Supplier Verification Program.

For purposes of Section 805, the term importer means, with respect to an article of food, either: (a) the U.S.

owner or consignee of the article of food at the time of entry into the United States; or (b) if there is no U.S. owner

or consignee, the U.S. agent or representative of a foreign owner or consignee at the time of entry into the United

States. 21 U.S.C. 385(a)(2).

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 12

When

This requirement will become effective 2 years after the date of enactment, so cocoa bean

and chocolate importers should be in compliance by the end of 2012.

FDA is required to issue regulations specifying the content of importers Foreign

Supplier Verification Programs by the end of 2011.

FDA is also required to issue a guidance document to assist importers in developing their

Foreign Supplier Verification Programs by the end of 2011.

Candy Specific

Unless importers have in-house food safety capabilities, they are likely to turn to third-party

auditors to perform the requirements of the Foreign Supplier Verification Program. NCA plans

to participate in the rulemaking process to establish the content of the Foreign Supplier

Verification Program with the intent to make this requirement least burdensome.

Import Certificates

What

FDA is authorized to require, as a condition of granting admission to an article of food imported

or offered for import, that an agency or representative of the government of the country from

which the food originates or an accredited third-party auditor (see Sec. VII below) provide a

certification, or such other assurance as FDA deems appropriate, that the food complies with

FD&C Act requirements.

If required, the certification may be in the form of a shipment-specific certificate, a listing of

certified facilities, or such other form as FDA may specify.

In determining whether to require such certification, FDA shall consider such factors as: the

known safety risks of the food; the known safety risks of the country, territory, or region of

origin of the food; and a finding by FDA that the food safety programs, systems, and

standards in the country, territory, or region of origin are inadequate to ensure safety and that

certification would assist FDA in making an admissibility determination.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 13

If FDA determines that the food safety programs, systems, and standards in a foreign

country, territory, or region are inadequate to ensure safety, FDA is required to identify such

inadequacies and establish a process whereby the foreign country, territory, or region may

inform FDA of improvements to its food safety programs, systems, and standards and

demonstrate their adequacy. The information submitted to FDA under such a process must

be considered by FDA in determining whether to require an import certification.

FDA may refuse to accept an import certificate if FDA determines it is not valid or reliable,

and FDA may require renewal of an import certificate at any time. FDA is required to

provide for electronic submission of import certificates.

An imported food that is required to have an import certificate but fails to comply shall be

refused admission.

When

While FDA acquired the authority to require import certificates effective upon enactment, it will

likely take some time before the system for accrediting third-party auditors (see below) is up and

running.

Candy Specific

NCA is not aware of any reason why FDA would require import certificates for confectionery

ingredients or products. However, it is possible FDA may use the import certificate requirement

as an alternative to increased foreign facility inspections if it lacks sufficient resources to

increase foreign inspections.

VII.

ACCREDITATION OF THIRD-PARTY AUDITORS

What

FDA is required to create a system for FDA recognition of accreditation bodies that will accredit

third-party auditors to certify eligible entities.5 Importantly, third-party certification under new

FD&C Act Section 808 is limited to foreign entities. The term eligible entity is defined as a

foreign entity, including a foreign facility registered with FDA, in the food import supply chain

that chooses to be audited by an accredited third-party auditor.

5

A third-party auditor is defined as a foreign government, agency of a foreign government, foreign cooperative, or

any other qualified third party (including an individual), as FDA determines appropriate, that conducts audits of

eligible entities. An accredited third-party auditor is a third-party auditor accredited by an accreditation body. An

audit agent is an individual who is an employee or agent of an accredited third-party auditor and is qualified to

conduct food safety audits. 21 U.S.C. 388(a).

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 14

Accreditation Bodies

Each recognized accreditation body is required to submit to FDA a list of the accredited

third-party auditors it has accredited and their audit agents.

FDA is required to develop model accreditation standards, including requirements for

regulatory audit reports.

Prior to accrediting a foreign government or an agency of a foreign government, the

accreditation body (or FDA in the case of a direct accreditation) must perform such audits

of food safety programs, systems, and standards as FDA deems necessary.

Prior to accrediting a foreign cooperative that aggregates the products of growers or

processors, or any other third party, the accreditation body (or FDA in the case of a direct

accreditation) must perform such audits of the training and qualifications of audit agents

used by the cooperative or third party, conduct reviews of internal systems, and such

other investigations as FDA deems necessary.

An accreditation body may not accredit a third-party auditor unless such third-party

auditor agrees to issue a written and, as appropriate, electronic certification to accompany

each shipment of food for import into the United States from the eligible entities it

certifies.

Accredited Third-Party Auditors

An accredited third-party auditor may issue a food import certificate or a facility

certification only after conducting a regulatory audit and such other activities as may be

necessary to establish compliance.6

Within 45 days after conducting an audit, an accredited third-party auditor or its audit

agent must prepare an audit report in a form and manner specified by FDA.

FDA may at any time require an accredited third-party auditor to submit a report of a

regulatory audit to FDA, as well as such other documents and reports required as part of

the audit process, for any eligible entity certified by the third-party auditor.

FDA may not obtain reports of consultative audits except pursuant to FD&C Act Section

414 (i.e., where FDA has a reasonable belief that an article of food is adulterated and

presents a threat of serious adverse health consequences or death to humans or animals).

An accredited third-party auditor or its audit agent is required to immediately notify FDA

if it discovers a condition that could cause or contribute to a serious risk to public health.

Section 808 distinguishes between regulatory audits and consultative audits. A consultative audit is an audit

the results of which are for internal facility purposes only.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 15

FDA is required to issue regulations to protect against conflicts of interest between

accredited third-party auditors and eligible entities. Such regulations must require that

audits be unannounced.

FDA is required to withdraw accreditation from a third-party auditor under the following

circumstances: (a) if food certified by the third-party auditor, or food from a facility

certified by the third-party auditor, is linked to an outbreak of foodborne illness that has a

reasonable probability of causing serious adverse health consequences or death to

humans or animals;7 (b) if FDA determines the third-party auditor no longer meets

accreditation requirements; (c) following a refusal to allow U.S. officials to conduct such

audits and investigations as may be necessary to ensure continued compliance; or (d) if

the third-party auditor was accredited by an accreditation body whose recognition is

revoked and FDA determines there is good cause for the withdrawal.

FDA is required to evaluate the performance of each accredited third-party auditor at

least once every 4 years.

FDA may at any time conduct an onsite audit of any eligible entity certified by an

accredited third-party auditor, with or without the auditor present.

FDA is required to establish a public registry of accreditation bodies and accredited thirdparty auditors including their names and contact information.

Uses of Third-Party Certification

FDA is required to use third-party certifications for the following purposes:

To determine whether a foreign facility is eligible to import food under the Voluntary

Qualified Importer Program;

To provide an assurance of safety for designated food imports (see Import Certificates

above); and

To target foreign inspection resources.

An eligible entity is required to be re-certified annually by an accredited third-party auditor if it

participates in the Voluntary Qualified Importer Program or if it is required to provide an import

certificate for any of its products.

When

FDA may make an exception where FDA conducts an investigation and determines the accredited third-party

auditor was not at fault.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 16

By the end of 2012, FDA is required establish a system for recognizing accreditation bodies,

to accredit third-party auditors to certify eligible entities.

FDA is authorized to directly accredit third-party auditors itself if FDA has not recognized

any accreditation bodies within 2 years after the accreditation system is established.

FDA is required to develop model accreditation standards, including requirements for

regulatory audit reports, no later than July 2012.

FDA is also required to issue regulations to protect against conflicts of interest between

accredited third-party auditors and eligible entities by July 2012.

Candy Specific

If companies use accredited third-party auditors, they should be aware that: (1) FDA will have

access to audit reports and related records for any regulatory audits; (2) FDA may conduct its

own onsite audit at any time of the companys facilities; and (3) accredited third-party auditors

will be obligated to notify FDA immediately if they discover any condition that could pose a

serious risk to public health.

VIII. LABORATORY ACCREDITATION; DIRECT SUBMISSION OF LAB TESTS

TO FDA

What

FDA is required to establish a program for the testing of food by accredited labs.

This laboratory accreditation program would encompass independent private laboratories;

foreign laboratories; and laboratories operated by Federal, State, and local government

agencies.

FDA is directed to work with recognized accreditation bodies to increase the number of

accredited labs beyond the number in existence on the date of enactment.

FDA is required to establish a publicly available registry of accreditation bodies recognized

by FDA and labs accredited by a recognized accreditation body. The registry is to include

contact information for accredited labs and indicate the sampling and/or analytical methods

for which each lab is accredited.

Beginning not later than 30 months after the date of enactment, all testing of food by or on

behalf of its owner or consignee for the purposes listed below must be conducted by either a

Federal laboratory or a non-Federal laboratory that has been accredited by a recognized

accreditation body:

o To support the admission of an imported food;

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 17

o To support removal from an Import Alert;

o To comply with a specific testing requirement under the FD&C Act or FDA

regulations to address an identified or suspected food safety problem; and

o As otherwise required by FDA to address an identified or suspected food safety

problem.

In general, the results of such tests must be sent directly to FDA.

FDA is required to develop model standards that laboratories must meet to be accredited to

perform specified sampling and analytical testing methods.

When

FDA is required to establish the system for lab accreditation by the end of 2012). By June 2013,

all testing of food by or on behalf of its owner or consignee for regulatory purposes must be done

by a Federal lab or an accredited lab.

Candy Specific

This lab accreditation system may help industry by making it easier for FDA to accept test

results from private labs.

IX.

TRACEABILITY; RECORDKEEPING; RECORDS ACCESS

What

Product Tracing System

FDA is required to establish a product tracing system within FDA to receive information that

improves their capacity to effectively and rapidly track and trace food that is in the United States

or offered for import into the United States.

Prior to establishing this tracing system, FDA is required to conduct at least 2 pilot projects (1 or

more for processed foods, and 1 or more for fresh produce) to evaluate methods for improving

traceability and report its findings to Congress. FDA is also required to engage in additional data

gathering, including assessing the costs and benefits of several different product tracing

technologies and evaluating domestic and international tracing practices in commercial use.

Additional Recordkeeping Requirements for High-Risk Foods

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 18

FDA is also required to issue regulations containing new recordkeeping requirements applicable

to facilities that manufacture, process, pack, or hold high-risk foods.8 FDA is required to

designate high-risk foods subject to additional recordkeeping based on the following factors:

Known safety risks of a particular food, including the history and severity of outbreaks

attributed to such food;

The likelihood that a particular food has a high potential risk for microbiological or chemical

contamination or would support growth of pathogens;

The point in the manufacturing process where contamination is most likely to occur;

The likelihood of contamination and steps taken during the manufacturing process to reduce

the risk of contamination;

The likelihood that consuming a particular food will result in foodborne illness; and

The likely or known severity of foodborne illness attributed to a particular food.

FDA is required to publish a list of high-risk foods on its website. FDA may add or remove

foods from the list of high-risk foods by publishing a notice in the Federal Register.

The new recordkeeping requirements for high-risk foods are subject to a number of limitations.

For example, such requirements shall:

Not require a full pedigree of a food (i.e., a complete record of the foods previous

distribution history from point of origin);

Not require records of recipients of a food beyond the immediate subsequent recipients;

Not require product tracking to the case level;

Not require use of specific technologies for the maintenance of records; and

Include a process whereby FDA may issue a waiver of the recordkeeping requirements if

FDA determines they would result in economic hardship for an individual facility or type of

facility.

There are also specific limitations applicable to farms and commingled raw agricultural

commodities.9 If FDA determines the additional recordkeeping requirements for high-risk

8

For foods that are not high-risk, the recordkeeping requirements of FD&C Act Section 414 (21 U.S.C.

and FDA regulations at 21 C.F.R. Part 1, Subpart J will continue to apply. FSMA, 204(d)(7).

9

350c)

A commingled raw agricultural commodity is any commodity that is combined or mixed after harvesting, but

before processing. FSMA, 204(d)(6)(D)(ii).

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 19

foods are not needed to protect public health, FDA may, by Federal Register notice, exempt or

modify the requirements with respect to a particular food or type of facility.

An article of food offered for import shall be refused admission if the recordkeeping

requirements of Section 204 (except those applicable to farms) have not been complied with

regarding such article.

FDA Expanded Records Access Authority

FDAs records access authority is expanded in a number of ways, including the following:

If FDA has a reasonable belief that a particular article of food is adulterated and presents a

threat of serious adverse health consequences or death to humans or animals, FDA may have

access to all records relating to that article of food and any other article of food that the

Secretary reasonably believes is likely to be affected in a similar manner.

Registered food facilities required to have a preventive controls plan are required to make

such plan and related records (including records of monitoring, verification, and corrective

actions) available to FDA upon written or oral request.

Importers are required to maintain records related to their Foreign Supplier Verification

Program for at least 2 years and to make them available to FDA upon request.

When

There is no deadline by which FDA must establish a product tracing system for food. However,

FDA must report to Congress on its pilot projects for product tracing by July 2012.

FDA is required to publish a proposed rule to establish new recordkeeping requirements for

high-risk foods by the end of 2012.10 FDA is required to designate high-risk foods by the end of

2011.

Candy Specific

It is too early to tell whether or how the product tracking system to be developed by FDA will

impact the confectionery industry. NCA will monitor the FDA pilot projects and resulting report

to Congress.

10

No deadline is specified for the final rule. However, any final rule will apply to small businesses beginning 1 year

after the effective date of the final rule, and to very small businesses beginning 2 years after the effective date of the

final rule.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 20

NCA believes it is unlikely that finished candy products would be considered high-risk foods

subject to special new recordkeeping requirements, but we will monitor FDAs deliberations to

ensure such products are not included. However, given the outbreaks of foodborne illness

associated with pathogens on peanuts and FDAs subsequent treatment of peanuts as a high risk

food, it is conceivable that FDA will consider cocoa beans a high risk food due to the presence of

Salmonella and the need for a kill step in the processing of beans. In the event that cocoa beans

are designated as a high-risk food by FDA, NCA would seek to exempt them from any new

recordkeeping requirements as commingled raw agricultural commodities.

Within the statute, there is also an option for commodities to be exempted if they are subjected to

a validated kill step, such as is the case with cocoa beans and chocolate. This is an alternative

argument NCA could make to minimize additional traceability requirements on cocoa.

All registered facilities and importers that handle cocoa beans and chocolate products should

familiarize themselves with FDAs expanded records access authority.

X.

NEW FDA ENFORCEMENT POWERS

Mandatory Recall Authority

What

The FSMA adds a new Section 423 (21 U.S.C. 350l) to the FD&C Act giving FDA, for the

first time, mandatory recall authority with respect to all FDA-regulated foods.

If FDA determines there is a reasonable probability that an article of food is

adulterated under FD&C Act Section 402 or misbranded under Section 403(w) (allergen

labeling) and that use of, or exposure to, such article will cause serious adverse health

consequences or death, FDA is required to give the responsible party 11 the opportunity to

cease distribution and recall the product.

If the responsible party does not voluntarily cease distribution and recall the food within the

time and in the manner prescribed by FDA, FDA may issue an order requiring the

responsible party to immediately cease distribution and notify other persons to immediately

cease distribution of the food.

o Such notification must be given to: (a) all persons manufacturing, processing,

packing, transporting, distributing, receiving, holding, or importing and selling such

food; and (b) all persons to which the food has been distributed, transported, or sold.

11

For purposes of Section 423, the term responsible party is defined as it is defined in FD&C Act Section 417 (21

U.S.C. 350f).

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 21

If, after providing an opportunity for an informal hearing, FDA determines the food should

be removed from commerce, FDA is required to order a recall. The authority to order a

recall or vacate a recall order may not be delegated by the FDA Commissioner.

FDA is authorized to assess a civil fine for failure to comply with a recall order. Any person

who fails to comply with a recall order is liable for a civil penalty not to exceed $50,000 for

an individual, $250,000 for a corporation. 21 U.S.C. 333(f)(2)(A).

In conducting a recall, FDA is required to ensure that a press release is issued and to post an

image of the recalled food, if one is available, on the FDA website.

FDA is required to create a user-friendly search engine on the FDA website that enables

members of the public to find relevant information about recalled foods, including whether a

recall is ongoing or has been completed.

When

FDA has mandatory recall authority now, effective immediately upon enactment. Within 90

days after the date of enactment, FDA is required to create a user-friendly search engine on the

FDA website for the public to find information about food recalls.

Candy Specific

NCA believes mandatory recall authority will rarely be invoked, because most industry members

will continue to voluntarily recall products when requested to do so by FDA. However,

mandatory recall authority may increase FDA leverage in negotiations over the scope of a recall.

Administrative Detention Authority

What

The FSMA significantly expands FDAs power to administratively detain foods.

Under current law, FDA must have credible evidence or information that an article

of food presents a threat of serious adverse health consequences or death to humans

or animals to detain that article of food.

The new law gives FDA the authority to administratively detain an article of food if

FDA has reason to believe that the article of food is adulterated or misbranded.

When

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 22

FDA is required to issue an interim final rule implementing this amendment not later than 120

days after the date of enactment, and the expanded administrative detention authority will

become effective 180 days after the date of enactment.

Candy Specific

This change is likely to have little impact. Administrative detention is still a stopgap measure to

prevent a product from moving in commerce until FDA can bring a seizure action, so FDA is

unlikely to use this remedy except in extreme situations.

Suspension of Registration

What

If FDA determines there is a reasonable probability that food from a facility could cause serious

adverse health consequences or death, FDA may suspend the registration of: (a) any facility that

created, caused, or is otherwise responsible for such reasonable probability; or (b) any facility

that packed, received, or held such food and that knew of, or had reason to know of, such

reasonable probability. The authority to suspend registration, or vacate a suspension order, may

not be delegated by the FDA Commissioner.

FDA is required to provide the registrant an opportunity for an informal hearing on the

actions required for reinstatement of the facilitys registration, to be held not later than 2

business days after issuance of the suspension order, or such other time as agreed upon by

FDA and the registrant.

If FDA determines the suspension remains necessary, the registrant must submit a corrective

action plan, and FDA is required to review the plan within 14 days of submission or such

other time period as determined by FDA.

If FDA determines adequate grounds do not exist to continue the suspension, FDA is

required to promptly vacate the suspension order and reinstate the facilitys registration or

modify the order, as appropriate.

Effect of suspension will be to force a facility to cease operations.

o No person may import, offer to import, or introduce into interstate or intrastate

commerce food from a facility whose registration has been suspended.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 23

o An article of food offered for import shall be refused admission if it is from a facility

whose registration has been suspended.

When

FDA must issue regulations on suspension of registration but may do so on an interim final basis.

This new authority will become effective on the date that FDA issues implementing regulations

or June 2011, whichever is earlier.

Candy Specific

NCA anticipates that FDA will suspend registration only in cases where a facility has very

serious violations and is incapable of ensuring the safety of product. Examples might include a

facility that knowingly distributes unsafe products or that cannot validate a kill step for roasting

of cocoa beans or tree nuts.

XI.

FEES

What

The FSMA imposes the following new industry fees:

An annual fee from the responsible party12 for each domestic facility, and the U.S. agent for

each foreign facility, that is subject to a re-inspection 13 in that fiscal year in an amount

sufficient to cover 100% of FDAs total re-inspection-related costs (up to a total of not more

than $25 million for any fiscal year).

12

The responsible party with respect to an article of food is the person that submits the registration under section

415(a) for a food facility that is required to register under section 415 (a), at which such article of food is

manufactured, processed, packed, or held. 21 U.S.C. 350f(a)(1).

13

For purposes of these fees, the term re-inspection means: (a) for domestic facilities, one or more

inspections conducted subsequent to an inspection that identified non-compliance materially related to a food safety

requirement, specifically to determine whether compliance has been achieved to FDAs satisfaction; and (b) for

importers, one or more examinations conducted subsequent to an examination that identified non-compliance

materially related to a food safety requirement, specifically to determine whether compliance has been achieved to

FDAs satisfaction.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 24

An annual fee from the responsible party for any domestic facility and any importer that fails

to comply with a recall order in that fiscal year sufficient to cover 100% of FDAs food recall

activities associated with such recall order (up to a total of not more than $20 million for any

fiscal year).

An annual fee from each importer participating in the Voluntary Qualified Importer Program

in that fiscal year sufficient to cover 100% of FDAs administrative costs of operating the

Voluntary Qualified Importer Program (see discussion below).

An annual fee from each importer that is subject to a re-inspection in that fiscal year

sufficient to cover 100% of FDAs re-inspection-related costs at ports of entry (up to a total

of not more than $25 million for any fiscal year).

FDA is also authorized to collect a fee for issuing export certificates for food.

When

FDA will publish the fee amounts for each fiscal year, as well as the time and manner in which

fees will be collected, in the Federal Register not later than 60 days before the start of such fiscal

year. Within 180 days after the date of enactment of the FSMA, FDA is required to publish

proposed guidelines in consideration of the burden of fee amounts on small business, which

may include reduced fees for small businesses. However, FDA may reduce fees for small

businesses only through notice-and-comment rulemaking.

Candy Specific

Fees for re-inspections may be considerable, since FDA may send several investigators to

conduct a re-inspection.

XII.

AUTHORITY TO ESTABLISH PERFORMANCE STANDARDS

What

FDA is required to review relevant health data, including toxicological and epidemiologic

studies, to determine the most significant foodborne contaminants. Based on its findings, FDA is

required to issue, by regulation or guidance document, contaminant-specific performance

standards, which may include action levels.

When

FDA is required to conduct its review of health data at least once every 2 years, and to establish

performance standards when appropriate.

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 25

XIII. OTHER PROVISIONS OF INTEREST

Whistleblower Protection

The FSMA adds a new Section 1012 to the FD&C Act (21 U.S.C. 399c) that provides

whistleblower protections to any employee of an entity engaged in the manufacture,

processing, packing, transporting, distribution, receipt, holding, or importation of food.

Whistleblower protections may not be waived by any agreement, policy, form, or condition of

employment.

Sanitary Transportation of Food

Within 18 months after the date of enactment, FDA is required to issue regulations on the

sanitary transportation of food, as required by Section 416(b) of the FD&C Act. FDA is also

required to conduct a study of the transportation of food for consumption in the United States,

including transportation by air and an examination of the unique needs of rural and frontier areas.

Compliance with International Agreements

The FSMA provides that it may not be construed in a manner inconsistent with the agreement

establishing the World Trade Organization or any other treaty or international agreement to

which the United States is a party.

Food Allergy and Anaphylaxis Voluntary Guidelines (Section 112)

Within 1 year after the date of enactment, FDA, in consultation with the Department of

Education, is required to develop voluntary guidelines for managing the risk of food allergy and

anaphylaxis in schools and early childhood education programs. The guidelines are required to

address, among other issues, strategies to reduce the risk of exposure to allergens in classrooms

and cafeterias.

XIV.

PROVISIONS NOT IN FINAL LEGISLATION

A number of provisions in earlier versions of this legislation did not survive the legislative

process and are not included in the new law. These include the following:

Annual registration fees for food facilities and food importers;

Mandatory FDA registration for food importers;

FDA authority to quarantine food;

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 26

FDA authority to levy civil fines for any prohibited act;

New country-of-origin labeling requirements;

Broad subpoena power; and

Full pedigree traceability requiring farm to fork tracking by all companies in the supply

chain.

XV.

SUMMARY OF TIMEFRAMES

Effective Immediately Upon Enactment

Section 101 Inspection of Records

Section 102 Registration of Food Facilities

o Requirement to register biennially

o Additional registration information required

Section 107 Fees

Section 115 Port Shopping

o Requirement that FDA notify DHS when FDA refuses to admit a food

Section 201 Inspections

o Inspection frequency

o Identification of high-risk facilities

Section 206 Mandatory Recall Authority

Section 303 Authority to Require Import Certifications for Food

Section 402 Whistleblower Protection

Effective at a Later Date

Section 103 Hazard Analysis and Preventive Controls Plan (July 2012; longer for small

and very small businesses)

o Requirement of hazard analysis and preventive controls plan

o Recordkeeping requirements

o Requirement to reanalyze

Section 202 Laboratory Accreditation (End of 2012)

Section 204 Traceability

o FDA pilot projects (not later than 270 days after date of enactment) and product

tracing system (report to Congress by July 2012)

Section 301- Foreign Supplier Verification Program (End of 2012)

Section 307 Accreditation of Third-Party Auditors

{00226256.DOC v1}

OLSSON FRANK WEEDA

TERMAN BODE MATZ PC

January 19, 2011

Page 27

o Establishment of system (not later than end of 2012)

o Development of model accreditation standards (by July 2012)

Provisions Requiring FDA Rulemaking or Guidance to Implement

Section 102 Registration of Food Facilities

o Suspension of registration

Section 103 Hazard Analysis and Preventive Controls

o Establishment of standards for hazard analysis and preventive controls

Section 104 Performance Standards

Section 111 Sanitary Transportation of Food

Section 204 Traceability

o Additional recordkeeping requirements for high-risk foods

Section 207 Administrative Detention of Food

Section 301 Foreign Supplier Verification Program

Section 302 Voluntary Qualified Importer Program

Section 307 Accreditation of Third-Party Auditors

o Conflict of interest prevention

o Fees to be paid by accredited third-party auditors

{00226256.DOC v1}

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Lunch 2Document1 pageLunch 2Jessica AngelinaNo ratings yet

- Monthly Sales Report TemplateDocument1 pageMonthly Sales Report TemplateShady R. NicolasNo ratings yet

- Profit and Loss Forecast v1.0Document4 pagesProfit and Loss Forecast v1.0Jessica AngelinaNo ratings yet

- Sample Budget Worksheets For A Restaurant 12 Month BudgetDocument5 pagesSample Budget Worksheets For A Restaurant 12 Month BudgetBabyBabyAngel100% (1)

- Cash Flow Worksheet: Cash in (Record When Actually Recieved)Document53 pagesCash Flow Worksheet: Cash in (Record When Actually Recieved)Jessica AngelinaNo ratings yet

- 3 Years Stavanger Northumbria Alberta Oldenburg Ljubljana TotalDocument2 pages3 Years Stavanger Northumbria Alberta Oldenburg Ljubljana TotalJessica AngelinaNo ratings yet

- CDL v8Document16 pagesCDL v8Jessica AngelinaNo ratings yet

- Cashflow Statement SampleDocument9 pagesCashflow Statement SampleJessica AngelinaNo ratings yet

- HargaDocument30 pagesHargaSyarifudinNo ratings yet

- Brosur Channel ReloadDocument2 pagesBrosur Channel ReloadJessica AngelinaNo ratings yet

- Elcomreload: Tata Cara Transaksi Acs Pulsa (Format SMS)Document5 pagesElcomreload: Tata Cara Transaksi Acs Pulsa (Format SMS)Jessica AngelinaNo ratings yet

- Duties: Pilotage: Eta: Etd: Port: - Pilot: +pilotDocument2 pagesDuties: Pilotage: Eta: Etd: Port: - Pilot: +pilotJessica AngelinaNo ratings yet

- Pricelist Rudi ModivDocument4 pagesPricelist Rudi ModivJessica AngelinaNo ratings yet

- Master List RevDocument1,329 pagesMaster List RevJessica AngelinaNo ratings yet

- Greenschool Donation Payments MethodDocument1 pageGreenschool Donation Payments MethodJessica AngelinaNo ratings yet

- AirDocument3 pagesAirJessica AngelinaNo ratings yet

- Inspect 050114Document116 pagesInspect 050114Jessica AngelinaNo ratings yet

- 0293daftar Billing Provider - IndDocument2 pages0293daftar Billing Provider - IndAndhika Hantyo PermadiNo ratings yet

- Pulsa DoanDocument2 pagesPulsa DoanJessica AngelinaNo ratings yet

- Price List 07 03 13Document8 pagesPrice List 07 03 13Jessica AngelinaNo ratings yet

- National Combustion Turbine List: Region 9 - CaliforniaDocument1 pageNational Combustion Turbine List: Region 9 - CaliforniaJessica AngelinaNo ratings yet

- Chity AlDocument318 pagesChity AlJessica AngelinaNo ratings yet

- OAP Database 8 2011Document97 pagesOAP Database 8 2011Jessica AngelinaNo ratings yet

- Compressed Air Best Practice ToolDocument17 pagesCompressed Air Best Practice TooljokishNo ratings yet

- Laporan Curah Hujan 2011Document15 pagesLaporan Curah Hujan 2011Jessica AngelinaNo ratings yet

- Calc CACDocument5 pagesCalc CACJessica AngelinaNo ratings yet

- APSAWC201213Document92 pagesAPSAWC201213Jessica AngelinaNo ratings yet

- Seperate List of Recognised J.B Schools in TRIPURA (As On 31-08-2013)Document134 pagesSeperate List of Recognised J.B Schools in TRIPURA (As On 31-08-2013)Jessica Angelina100% (1)

- SumatraDocument34 pagesSumatraJessica AngelinaNo ratings yet

- Rab MasterDocument71 pagesRab MasterFrengky MaskNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Review Process of Discharge Planning: by Janet BowenDocument11 pagesReview Process of Discharge Planning: by Janet BowenAfiatur RohimahNo ratings yet

- ResearchDocument10 pagesResearch999saitama 999No ratings yet

- Renal Calculi Concept Map PathophysiologyDocument3 pagesRenal Calculi Concept Map PathophysiologySharon TanveerNo ratings yet

- CH 06Document21 pagesCH 06amir nabilNo ratings yet

- GenogramDocument10 pagesGenogrammohamadNo ratings yet

- G2 CHAPTER 2finalDocument15 pagesG2 CHAPTER 2finalMike AntolinoNo ratings yet

- Case Analysis: Medical Surgical NursingDocument7 pagesCase Analysis: Medical Surgical NursingMaria ThereseNo ratings yet

- CATCH UP FRIDAY - March 22 2024Document2 pagesCATCH UP FRIDAY - March 22 2024jeffersonmanalo787No ratings yet

- Implementing Mechanism For EO 141 Presentation For NGAs - Asof15July 1 2Document35 pagesImplementing Mechanism For EO 141 Presentation For NGAs - Asof15July 1 2Reyan ArintoNo ratings yet

- 2018 Jordanian Conference BookletDocument51 pages2018 Jordanian Conference BookletAurelian Corneliu MoraruNo ratings yet

- Medical Claim Form (Reimbursement Only)Document2 pagesMedical Claim Form (Reimbursement Only)Muhammad Rizwan Tariq100% (1)

- Dri - English - 113 Driver Risk InventoryDocument6 pagesDri - English - 113 Driver Risk Inventoryminodora100% (1)

- 2023 Revised Reviewed Exam of All Hesi Fundamentals 2022 Exam Test Bank PDFDocument264 pages2023 Revised Reviewed Exam of All Hesi Fundamentals 2022 Exam Test Bank PDFCeciliaNo ratings yet

- GEMS Presentation: Health Market InquiryDocument47 pagesGEMS Presentation: Health Market InquiryYash RohiraNo ratings yet

- How Many Implants Are Necessary To Stabilise An Implant-Supported Maxillary Overdenture?Document2 pagesHow Many Implants Are Necessary To Stabilise An Implant-Supported Maxillary Overdenture?Erick Brañes EspinozaNo ratings yet

- Modern Drummer 08 2022Document84 pagesModern Drummer 08 2022milanamNo ratings yet

- Infection Control Measures in Dental Clinics in Kingdom of Saudi ArabiaDocument4 pagesInfection Control Measures in Dental Clinics in Kingdom of Saudi Arabiaاحمد القحطانيNo ratings yet

- Chapter 4 MayangDocument12 pagesChapter 4 MayangJames FulgencioNo ratings yet

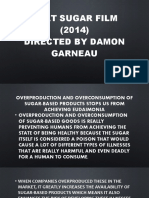

- That Sugar Film (2014) Directed by Damon GarneauDocument7 pagesThat Sugar Film (2014) Directed by Damon GarneauBai Fatima LumanggalNo ratings yet

- Research-Group-5-Ughhh NiniwDocument39 pagesResearch-Group-5-Ughhh NiniwTaguno ChrisNo ratings yet

- Community Project Funds 2008-09Document5,191 pagesCommunity Project Funds 2008-09New York SenateNo ratings yet

- Nutrient Requirements of Egg Laying Chickens: Feed ConsumptionDocument3 pagesNutrient Requirements of Egg Laying Chickens: Feed ConsumptionEzikawa Kirt100% (1)

- Exploring The Multifaceted Dimensions of Placemaking: From Theory To PracticeDocument33 pagesExploring The Multifaceted Dimensions of Placemaking: From Theory To Practiceecho10131105No ratings yet

- 11 Strategies To Fight CancerDocument73 pages11 Strategies To Fight CancerPayal Nandwana100% (1)

- Reikalingi ISO StandartaiDocument2 pagesReikalingi ISO StandartaiIndreNo ratings yet

- FluidDocument190 pagesFluidAndrias OzNo ratings yet

- Design and Implementation of An Expert System On Diagnosis of Communicable DiseasesDocument9 pagesDesign and Implementation of An Expert System On Diagnosis of Communicable DiseasesDominic MaryNo ratings yet

- Transcranial Magnetic Stimulation - Jasper AzzarelloDocument2 pagesTranscranial Magnetic Stimulation - Jasper AzzarelloJasper AZZARELLONo ratings yet

- Regulatory Bodies of Nursing in India: Dr. Maheswari JaikumarDocument75 pagesRegulatory Bodies of Nursing in India: Dr. Maheswari Jaikumarkalla sharonNo ratings yet

- Leaflet Writing TasksDocument10 pagesLeaflet Writing TasksNeal ColpittsNo ratings yet