Professional Documents

Culture Documents

Chassis Air Guide

Uploaded by

strangelove91Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chassis Air Guide

Uploaded by

strangelove91Copyright:

Available Formats

Chassis Air Guide (CAG)

Design Guide

September 2003

Revision 1.1

R

2

INTEL CORPORATION (AND ANY CONTRIBUTOR) IS PROVIDING THIS INFORMATION AS A CONVENIENCE AND

ACCORDINGLY MAKES NO WARRANTIES WITH REGARD TO THIS DOCUMENT OR PRODUCTS MADE IN

CONFORMANCE WITH THIS DOCUMENT.

THIS DOCUMENT IS PROVIDED "AS IS" AND INTEL DISCLAIMS ALL EXPRESS AND IMPLIED WARRANTIES,

INCLUDING THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE. IN ADDITION,

INTEL (AND ANY CONTRIBUTOR) DOES NOT WARRANT OR REPRESENT THAT THIS DOCUMENT OR ANY

PRODUCTS MADE IN CONFORMANCE WITH IT WILL OPERATE IN THE INTENDED MANNER, ARE FREE FROM

ERRORS OR DEFECTS, OR ARE SAFE FOR USE FOR ITS INTENDED PURPOSE. ANY PERSON USING THIS

DOCUMENT OR MAKING, USING, OR SELLING PRODUCTS IN CONFORMANCE WITH THIS DOCUMENT DOES SO AT

HIS OR HER OWN RISK.

INTEL DISCLAIMS ALL LIABILITY ARISING FROM OR RELATED TO USE OR IMPLEMENTATION OF THE INFORMATION

PROVIDED IN THIS DOCUMENT, INCLUDING LIABILITY FOR INFRINGEMENT OF ANY INTELLECTUAL PROPERTY

RIGHTS RELATING TO THE INFORMATION OR THE IMPLEMENTATION OF INFORMATION IN THIS DOCUMENT. INTEL

DOES NOT WARRANT OR REPRESENT THAT SUCH DEVICES OR IMPLEMENTATION WILL NOT INFRINGE SUCH

RIGHTS.

INTEL IS NOT OBLIGATED TO PROVIDE ANY SUPPORT, INSTALLATION OR OTHER ASSISTANCE WITH REGARD TO

THE INFORMATION OR PRODUCTS MADE IN ACCORDANCE WITH IT. THE INFORMATION IN THIS DOCUMENT IS

SUBJECT TO CHANGE WITHOUT NOTICE.

THE INFORMATION REFERRED TO IN THIS DOCUMENT IS INTENDED FOR STANDARD COMMERCIAL USE ONLY.

CUSTOMERS ARE SOLELY RESPONSIBLE FOR ASSESSING THE SUITABILITY OF THE INFORMATION FOR USE IN

PARTICULAR APPLICATIONS. THE INFORMATION IS NOT INTENDED FOR USE IN CRITICAL CONTROL OR SAFETY

SYSTEMS, MEDICAL OR LIFE SAVING APPLICATIONS, OR IN NUCLEAR FACILITY APPLICATIONS.

NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS

GRANTED HEREIN.

Intel is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

*Other names and brands may be claimed as the property of others.

Copyright 2002, 2003 Intel Corporation

3

Contents

1 Introduction ......................................................................................................................... 6

1.1 Scope ..................................................................................................................... 6

1.2 Overview................................................................................................................. 6

1.3 Recommended Chassis for Chassis Air Guide...................................................... 7

1.4 Reference Documents............................................................................................ 7

2 Chassis Considerations ...................................................................................................... 8

2.1 Chassis Air Guide Description ............................................................................... 8

2.2 Chassis Air Guide Typical Airflow Pattern.............................................................. 9

2.3 Chassis Air Guide Assembly Stack...................................................................... 10

2.4 Separation Distance............................................................................................. 10

2.5 System Fans......................................................................................................... 11

2.6 CAG Venting Location.......................................................................................... 12

2.7 System Venting .................................................................................................... 13

2.8 Attach Mechanisms.............................................................................................. 13

3 Dynamics .......................................................................................................................... 14

3.1 Shock Test............................................................................................................ 14

3.2 Vibration Test ....................................................................................................... 14

3.3 Pass Criteria......................................................................................................... 14

4 Process Selection ............................................................................................................. 15

4.1 Vacuum Forming Process.................................................................................... 15

4.2 Injection Molding Process .................................................................................... 15

5 Regulatory Considerations................................................................................................ 16

5.1 Electromagnetic Interference Radiation............................................................... 16

5.2 Safety ................................................................................................................... 17

5.3 Ecology................................................................................................................. 17

6 Mechanical Drawings........................................................................................................ 18

6.1 Flange, Chassis Air Guide.................................................................................... 19

6.2 Upper Duct, Chassis Air Guide ............................................................................ 20

6.3 Lower Duct, Chassis Air Guide ............................................................................ 21

6.4 Duct Assembly, Chassis Air Guide ...................................................................... 22

6.5 Vent Pattern, Chassis Air Guide .......................................................................... 23

6.6 Chassis Air Guide Center Location...................................................................... 24

4

Figures

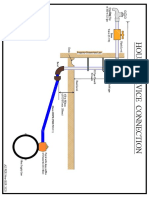

Figure 1. Typical Tower Platform With Chassis Air Guide.................................................. 8

Figure 2. Chassis Air Guide Typical Airflow Pattern........................................................... 9

Figure 3. Chassis Air Guide Exploded View With Screws................................................ 10

Figure 4. Separation Distance From Active Fan Heatsink................................................ 11

Figure 5. Chassis Side Panel Venting .............................................................................. 12

Figure 6. Flange, Chassis Air Guide................................................................................. 19

Figure 7. Upper Duct, Chassis Air Guide.......................................................................... 20

Figure 8. Lower Duct, Chassis Air Guide.......................................................................... 21

Figure 9. Duct Assembly Chassis Air Guide..................................................................... 22

Figure 10. Vent Pattern, Chassis Air Guide...................................................................... 23

Figure 11. Chassis Air Guide Center Location ................................................................. 24

5

Revision History

Revision

Number

Description Revision Date

1.0 Initial Release. May 2002

1.1 System vent pattern optimization September 2003

Introduction

6

1 Introduction

1.1 Scope

This design guide explores the design, implementation and performance of a ducting solution to

cool the internal components of a personal computer enclosure. Design recommendations are

presented for implementation within a mid-tower desktop style enclosure. The target audiences

for this document are: computer enclosure engineers, designers, and system integrators.

1.2 Overview

The newest personal computer technologies, including those for processor, chipset, memory, and

graphics, pose significant thermal challenges to the system designer. As the market transitions to

faster computing speeds and enhanced features in reduced platform sizes, both the heat and heat

density generated by these devices will continue to increase. Such increases in component-level

power force the designer to reconsider the thermal solutions used at the chip, package, board and

system-level. Active heatsinks have proven to be a reliable and relatively economical solution to

keep pace with an increasingly challenging thermal environment. To continue using these

heatsink technologies, consideration to the system-level thermal solution must be given.

In the past, system designers focused on improving system thermal environments by adding fans

and optimizing vent locations. This remains a very important aspect of system thermal design.

However, the increasing costs and complexities of package-level thermal solutions requires more

advanced system level technologies in order to find a more balanced and cost-effective approach

for the system. If the computer enclosure can provide cooler internal temperatures much of this

expense can be mitigated. With the proper balance of system and package solutions, the

integrator can minimize the overall system cost.

In an environment of increasing thermal loads, the processor is generally the most demanding

component in terms of system thermal design. Processor thermal solutions commonly use a

copper or aluminum heatsink with an active fan providing airflow. The processor die temperature

can be directly correlated to the temperature of the air flowing into the active fan and heatsink.

The lower the temperatures, the lower processor die temperature. Most computer enclosures

typically provide an internal thermal environment of approximately 40-45 C, at a 35 C room

temperature. This document provides a reference design of one solution to lower the processor

thermal environment to approximately 38 C. The reference design, or duct, is called the Chassis

Air Guide (CAG).

Version 1.1 of the Chassis Air Guide Design Guide includes information on a larger diameter

upper duct and includes guidance on other system vents. The larger duct allows for more airflow

demanded by active fan heatsinks. The balancing of vents that control the internal airflow is

critical to satisfy the other subsystem thermal targets as well as processor ambient temperature.

Version 1.1 provides a system level cooling approach.

Introduction

7

1.3 Recommended Chassis for Chassis Air Guide

This design guide refers to a chassis with the features listed below. However, the ingredients and

design techniques described here could be adapted to other chassis:

Fits a standard ATX or microATX motherboard

Supports two external 5.25-inch peripheral bays, one external 3.5-inch peripheral bay and

one or two internal 3.5-inch peripheral bays

Includes one standard PS/2-sized power supply or PS/3-size for smaller chassis

Includes up to seven add-in card slots including a graphics card

Does not use a single-piece chassis cover

Provides single system-fan cooling with provision for at least one 92-mm rear exhaust fan

(Note that this statement excludes the fan in the Power Supply)

Internal power supply with fan exhausting system enclosure

Accommodates standard ATX I/O shield

Provides for front connector I/O compliant with the Front Panel I/O Connectivity Design

Guide

1.4 Reference Documents

Document Document

No./Location

ISO 7779-AcousticsMeasurement of Airborne Noise Emitted by

Information Technology and Telecommunications Equipment

http://www.iso.ch/

ATX Thermal Design Suggestions http://www.formfactors.org

EMC Design Suggestions http://www.formfactors.org

microATX Motherboard Interface Specification 1.0 http://www.formfactors.org

ATX Motherboard Specification http://www.formfactors.org

Performance microATX Thermal Design Suggestions v1.0 http://www.formfactors.org

Chassis Considerations

8

2 Chassis Considerations

2.1 Chassis Air Guide Description

The following design is intended to achieve a temperature rise (T

rise

) of less than 3 C to standard

ATX and microATX tower style chassis. The design focus is to lower the processor thermal

environment temperature while allowing for some core (processor and chipset) area movement

based on varying motherboard layout designs. The overall goal is to provide a cooling solution

that can be easily integrated into current and future chassis designs while being adaptable for

different motherboards at a minimum cost and integration impact.

Figure 1 is a chassis that is similar to many microATX chassis platforms currently available. The

three-piece Chassis Air Guide is shown attached to the chassis side panel. The Chassis Air Guide

consists of a hollow tube with a flared end that guides cool room ambient air towards the

processor. It has no fans and is therefore a completely passive cooling solution. It relies entirely

on the internal systems fans to guide air to the processor and other system components. To

properly function, it requires a ventilation opening on the chassis side panel. This is discussed

further in Section 2.6. The design of the Chassis Air Guide limits the use of one-piece chassis top

and side covers. A side panel as seen in Figure 1 is recommended for ease of installation.

Figure 1. Typical Tower Platform With Chassis Air Guide

Chassis Considerations

9

2.2 Chassis Air Guide Typical Airflow Pattern

Figure 2 depicts one example of the airflow pattern expected when using the Chassis Air Guide.

This system platform has a typical 92 mm rear system fan and a 80 mm fan on the power supply.

Both fans exhaust (blow out) from the chassis, thereby providing airflow for system component

cooling. This fan configuration causes a slight depressurization of the chassis interior with

respect to the outside atmosphere. As a result, all other chassis openings become intake vents.

The primary intake vents are now the front bezel openings, the add-in card side panel venting,

and the Chassis Air Guide. The processor fan heatsink combination is now able to draw outside

air directly and remains a vital part of processor cooling.

Airflow balancing remains very important to ensure the adequate cooling of other system

components. This involves providing the proper amount of open area in the front and side of the

enclosure so that all components will receive the required airflow volume. Without proper

balancing, some components may operate cooler than required while others may operate in a

higher temperature environment. Airflow balancing is difficult to manage, but done properly,

will allow all system components to operate within the recommended temperature range.

Figure 2. Chassis Air Guide Typical Airflow Pattern

Chassis Considerations

10

2.3 Chassis Air Guide Assembly Stack

The Chassis Air Guide seen in Figure 3 is shown as a three-piece design.

The three parts of the Chassis Air Guide are:

Upper Duct

Flange

Lower Duct

This design has advantages over a single or two-piece design. The three-piece design can be

elongated by hand to allow for different chassis widths. This allows for one tool to be used for

many chassis sizes. The Flange can be molded or stamped in plastic or metal, with plastic having

some weight and cost advantages. The Flange piece can be screwed into place on the chassis side

panel, allowing for support of the Upper Duct and holding it in position.

With this configuration, the Lower Duct can be installed by sliding onto the Upper Duct. It is

recommended that the Upper and Lower Ducts have corrugation ribs or other device to hold the

two pieces firmly in place after final system assembly has taken place.

Figure 3. Chassis Air Guide Exploded View With Screws

2.4 Separation Distance

The Chassis Air Guide should not be in direct contact with the processor heatsink and fan. A

separation distance is necessary in order to improve ease of assembly and cool other system

components. The separation distance shown in Figure 4 is not only critical to the processor

thermal performance but also the overall system cooling. If the separation distance is greater than

20 mm, the cooling performance for the processor will suffer as the cool air will disperse before

reaching the processor fan heatsink. If the separation distance is less than 12 mm, other system

components may not get adequate cool airflow, as the processor will receive the majority of the

intake air.

Chassis Considerations

11

Figure 4. Separation Distance From Active Fan Heatsink

2.5 System Fans

Rear Chassis System Exhaust Fan:

The system fans have proven to remain a very valuable part of the overall system solution. The

system fans create a low-pressure environment in the system relative to the external system

pressure. This creates a pressure gradient that forces cooler external air to flow into the system

through the air guide. A 92-mm or larger rear fan providing a minimum of 55 CFM (in free air)

of flow is recommended to exhaust the chassis in conjunction with the Chassis Air Guide. Using

the rear fan to pressurize the chassis should not be done when using the Chassis Air Guide and

will render this solution completely ineffective.

Note: Some duct instantiations may utilize a system pressurizing rear fan. This will be a design choice

based on overall system and ducting solution design.

Power Supply Fan:

The power supply fans seen in the market today have shown to be adequate to support the chassis

air guide as defined in this document. A power supply fan should exhaust the chassis to assist

with system cooling. A power supply fan that pressurizes the chassis with warm air will reduce

the effectiveness of the Chassis Air Guide. No changes or special considerations are needed in

this area to support the Chassis Air Guide.

Processor Active Fan Heat Sink:

Much the same as the rear system exhaust fan, the processor cooling fan remains a critical piece

of the overall cooling solution. An active fan heatsink is needed to maintain airflow to properly

Chassis Considerations

12

cool the processor when using the Chassis Air Guide. Do not use a passive processor cooling

solution with the Chassis Air Guide. The Chassis Air Guide is intended to only provide the path

for cool air to be drawn to the processor core area. The air guide will not push cool air; rather the

chassis system fans draw the cooler, external air to themselves.

2.6 CAG Venting Location

The Chassis Air Guide requires a side vent as seen in Figure 5. It is highly recommended that

this vent have an open effective area of 60% or greater with a minimum diameter of 80 mm. This

will maximize the thermal performance gains and still contain EMI effectively. The holes can be

any shape but care should be taken to ensure proper EMI containment. The vent should protrude

from the chassis side panel as shown in Figure 5 to mitigate vent blocking if the system should be

placed against a wall, desk or other obstruction. This is only one implementation and many other

possibilities exist to prevent vent blocking.

The vent for this ducting solution is best located with respect to the standard ATX mounting holes

as defined in the ATX Specification. Refer to Section 6.6 for the mechanical drawing

demonstration the proper location of this ducting solution.

Figure 5. Chassis Side Panel Venting

Chassis Considerations

13

2.7 System Venting

Other system venting plays an important role in delivering overall thermal performance. An add-

in card side vent, as shown is Figure 5, is a new addition to the Chassis Air Guide Design Guide,

Version 1.1. This vent acts as a system inlet and provides air through the add-in cards. High

performance graphics cards benefit by having this lower temperature air as inlet to their cooling

solution.

The front of the system also requires an inlet vent to provide the needed air flow for the system

sub-components. The front bezel must allow adequate airflow into the front sheet metal vents for

this inlet to be effective.

2.8 Attach Mechanisms

The design guide demonstrates using four screws to hold the Chassis Air Guide securely in place.

Platform designers may use other attach mechanisms but special attention should be made with

regards to shock and vibration and ease of installation.

Dynamics

14

3 Dynamics

The basic structural requirement is that the duct must survive shipping without damage to itself or

any other system ingredient. Because the shipping environment involves mechanical shock loads,

the duct should be designed for impact resistance. The following mechanical testing describes the

recommended minimum shock and vibration environment a duct should be able to survive when

installed in a computer enclosure.

3.1 Shock Test

Unpackaged

25 g, 11 ms trapezoidal; ~ 170 in/s

Two drops in each of the six directions applied to each of the samples

3.2 Vibration Test

Unpackaged

Sine sweep: 5 Hz to 500 Hz @ 0.5 g 10%; @ 0.5 octaves/min; Dwell 15 min at each of three

resonant points

Random Profile: 5 Hz @ 0.01 g

2

/Hz to 20 Hz @0.02 g

2

/Hz (slope up)

20 Hz to 500 Hz @ 0.02 g

2

/Hz (flat)

Input acceleration: 3.13 g RMS

10 min/axis for all axes on all samples

Random control limit tolerance is 3 dB

3.3 Pass Criteria

No visible damage.

No displaced or dislodged components of the duct.

No damage caused by the duct to any other system components.

Process Selection

15

4 Process Selection

The process by which the parts for a duct design are produced are numerous and varied with each

having advantages and disadvantages. Below are two processes that have proven to be cost

effective and produce the quality needed for a system platform duct. The three-piece Chassis Air

Guide can be constructed in high volume for a relatively low cost using the processes listed

below. The Upper Duct and Lower Duct (see Section 2.3) would best be constructed using a

Vacuum Forming process while the Flange is best suited for an injection molding process.

There may be other processes or materials available that deserve taking the time to explore. New

processes or process improvements may become available that will aid in the manufacturability

and production of a ducting solution.

4.1 Vacuum Forming Process

The vacuum forming process utilizes the natural atmospheric pressure to force heat softened

thermoplastic sheet into or over a molding form. After the sheet has cooled on the molding form

(tool) it retains its shape. The trim is then removed. Parts can be large or small using material

less then 1 mm thick up to 10 mm or more. Vacuum forming is a very cost effective method for

producing small or large quantities of molded plastic parts.

4.2 Injection Molding Process

Injection molding is the most widely used polymeric fabrication process. It evolved from metal

die casting, however, unlike molten metals; polymer melts have a high viscosity and cannot

simply be poured into a mold. Instead a large force must be used to inject the polymer into the

hollow mold cavity. Identical parts are produced through a cyclic process involving the melting

of a pellet or powder resin followed by the injection of the polymer melt into the hollow mold

cavity under high pressure.

Regulatory Considerations

16

5 Regulatory Considerations

The unit and its design must meet a number of regulatory Safety, EMC and Ecology concerns.

Specific requirements for Information Technology Equipment vary somewhat by country,

however, the overall standards are somewhat unified and are based upon the following standards:

Note: Certain countries may require formal certifications and many require a Declaration of

Conformance (DOC) be placed in the manual or on the box. In Europe the CE mark and a DOC

is required for every computing device.

5.1 Electromagnetic Interference Radiation

The Electromagnetic Interference (EMI) performance of a system is determined by the degree of

noise suppression designed into the system motherboard and the provisions for EMI containment

in the chassis design, including placement of internal subsystems and cables. Requirements call

for compliance to stringent electromagnetic compatibility (EMC) limits such as the CISPR-22

European standard or the FCC B United States standard. Open chassis requirements for board

manufacturers suggest that most EMI needs to be suppressed at the board level. The chassis,

however, should provide at least 6 dB of EMI attenuation or Shielding Effectiveness (SE)

throughout the spectrum. The goal of 6 dB assumes board complies with FCC Part 15 (Open Box

Test). Boards that have higher expected emissions will likely require additional containment.

These standards, along with higher processor and video frequencies, call for additional chassis

containment provisions. Basic design principles have not changed, but as frequencies continue to

increase, the shorter wavelengths require more frequent ground contacts and smaller apertures in

the chassis design. At very high frequencies, this becomes impractical because the ground points

become so close that continuous gaskets would be needed, and vent holes would need to be so

small that they would impede airflow.

EMC Standards:

47 CFR Parts 2 and 15 (USA)

ICES-003 (Canada)

EN55022:1998 (European Union Emissions)

EN55024:1998 (European Union Immunity)

Other International requirements based upon CISPR 22

Regulatory Considerations

17

5.2 Safety

This design guide is not intended to cover all safety aspects that may pertain to different countries

and regulatory bodies. The safety standards listed below are a starting point for your reference;

however, the manufacturer is ultimately responsible to ensure that safety standards are adhered to.

Safety Standards:

IEC 60590 (International)

UL/CSA 60950 (USA and Canada)

EN60590 (European Union)

5.3 Ecology

This design guide is not intended to cover every aspect of designing a product to meet every

International regulation, however, the following standards and programs may cover Ecology

issues that may or may not apply to your product.

Ecological Standards

ECMA TR70:

Energy Star

TCO '99, Blue Angel

Ecological Programs

Participation in waste electronics recycling program.

Participation in a packaging-recycling program.

18

6 Mechanical Drawings

Mechanical Drawings

19

6.1 Flange, Chassis Air Guide

Figure 6. Flange, Chassis Air Guide

Mechanical Drawings

20

6.2 Upper Duct, Chassis Air Guide

Figure 7. Upper Duct, Chassis Air Guide

Mechanical Drawings

21

6.3 Lower Duct, Chassis Air Guide

Figure 8. Lower Duct, Chassis Air Guide

Mechanical Drawings

22

6.4 Duct Assembly, Chassis Air Guide

Figure 9. Duct Assembly Chassis Air Guide

Mechanical Drawings

23

6.5 Vent Pattern, Chassis Air Guide

Figure 10. Vent Pattern, Chassis Air Guide

Mechanical Drawings

24

6.6 Chassis Air Guide Center Location

Figure 11. Chassis Air Guide Center Location

You might also like

- NCRDocument120 pagesNCRsam7939No ratings yet

- Education Manual: The Raspberry PiDocument137 pagesEducation Manual: The Raspberry Pidr7zyqNo ratings yet

- How-To Post Test A Motherboard - Power On Self Test GuideDocument16 pagesHow-To Post Test A Motherboard - Power On Self Test Guidestrangelove91No ratings yet

- The Final Fiblet - Peter WattsDocument2 pagesThe Final Fiblet - Peter Wattsstrangelove91No ratings yet

- How To - Hackintosh A Dell Mini 9 Into The Ultimate OS X NetbookDocument9 pagesHow To - Hackintosh A Dell Mini 9 Into The Ultimate OS X Netbookstrangelove91No ratings yet

- The Tomb of Vlad TepesDocument9 pagesThe Tomb of Vlad Tepesstrangelove91No ratings yet

- Top 37 Things You'll Regret When You're OldDocument4 pagesTop 37 Things You'll Regret When You're Oldstrangelove91No ratings yet

- Engel Hammar - Magnetic Tape HistoryDocument10 pagesEngel Hammar - Magnetic Tape HistoryEvilásio SouzaNo ratings yet

- Apple Samsung LawsuitDocument373 pagesApple Samsung LawsuitPedro_ApfNo ratings yet

- Nuclear Reactor Analysis PDFDocument668 pagesNuclear Reactor Analysis PDFstrangelove91100% (2)

- MS-7091 M-ATX MainboardDocument25 pagesMS-7091 M-ATX Mainboardstrangelove91No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NSBI 2022-2023 FormsDocument16 pagesNSBI 2022-2023 FormsLove MaribaoNo ratings yet

- GRT9165 Product GuideDocument23 pagesGRT9165 Product GuideEslamAldenAbdoNo ratings yet

- BSC Ag Syllabus 5th DeanDocument150 pagesBSC Ag Syllabus 5th Deansaurabh rNo ratings yet

- Kerr Injection WaxesDocument1 pageKerr Injection WaxesmarosnaxNo ratings yet

- Surface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweDocument9 pagesSurface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweEdwinNo ratings yet

- Rec2009 025 PDFDocument172 pagesRec2009 025 PDFEkaStaVTVNo ratings yet

- Tabel Benkelman Beam Baru - AsisDocument21 pagesTabel Benkelman Beam Baru - AsisAsisNo ratings yet

- Week 2 - Risk AssessmentDocument35 pagesWeek 2 - Risk AssessmentTahir BashirNo ratings yet

- W2AEW Videos (Apr 29, 2017) Topics Listed NumericallyDocument12 pagesW2AEW Videos (Apr 29, 2017) Topics Listed Numericallyamol1agarwalNo ratings yet

- Connorized Classical CatalogDocument37 pagesConnorized Classical CatalogPablo Olea RodríguezNo ratings yet

- A Community School: Research Aspect 2 ReportDocument13 pagesA Community School: Research Aspect 2 ReportMarsha MianNo ratings yet

- ADAMHAND8A4Document11 pagesADAMHAND8A4Elker José Camargo100% (1)

- A Project Report On: "Recreation Club"Document80 pagesA Project Report On: "Recreation Club"Appz100% (2)

- Understanding the Process of OogenesisDocument52 pagesUnderstanding the Process of OogenesisBharat ThapaNo ratings yet

- Din en 50155 (Vde 0115-200) - 2008-03Document42 pagesDin en 50155 (Vde 0115-200) - 2008-03Collins Akhimien100% (1)

- Product Information: Traffic Management AccessoryDocument12 pagesProduct Information: Traffic Management AccessoryCORAL ALONSONo ratings yet

- Crusher Type Part Number Description Weight (KG)Document3 pagesCrusher Type Part Number Description Weight (KG)Juvenal CorreiaNo ratings yet

- Therapeutic Drug Monitoring GuideDocument12 pagesTherapeutic Drug Monitoring GuidePromise NcubeNo ratings yet

- Hoa ReviewerDocument3 pagesHoa ReviewerRachel Mae BahoyNo ratings yet

- 21734Document67 pages21734Jeef100% (4)

- Renal Cortical CystDocument2 pagesRenal Cortical Cystra222j239No ratings yet

- GMSARN Conf: Design Criteria on Substation ProtectionDocument6 pagesGMSARN Conf: Design Criteria on Substation Protectionbdaminda6701No ratings yet

- House Service Connection NEW BSR 2020-1Document1 pageHouse Service Connection NEW BSR 2020-1Deshraj BairwaNo ratings yet

- Discourse on Colonialism and CivilizationDocument48 pagesDiscourse on Colonialism and CivilizationEmir özerNo ratings yet

- Op-Amp Comparator: Astable (Or Free-Running) Multivibrators Monostable MultivibratorsDocument5 pagesOp-Amp Comparator: Astable (Or Free-Running) Multivibrators Monostable MultivibratorsYuvaraj ShanNo ratings yet

- Potensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliDocument8 pagesPotensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliNuyul FaizahNo ratings yet

- Geneaid DNA Reagent Plant GR200Document4 pagesGeneaid DNA Reagent Plant GR200Gandi SogandiNo ratings yet

- Sports AcousticsDocument43 pagesSports Acousticssiddhant raoNo ratings yet

- Sap MRP ConfigDocument23 pagesSap MRP Configsharadapurv100% (1)

- Tests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Document1 pageTests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Lorna BacligNo ratings yet