Professional Documents

Culture Documents

Assessment of Transformer Mineral Oil

Uploaded by

BalajiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assessment of Transformer Mineral Oil

Uploaded by

BalajiCopyright:

Available Formats

1544 L. V. Badicu et al.

: Assessment of Transformer Mineral Oil Condition Based on dc and ac Conductivity

1070-9878/12/$25.00 2012 IEEE

Assessment of Transformer Mineral Oil Condition

Based on dc and ac Conductivity

L. V. Badicu, B. Gorgan, L. M. Dumitran and P. V. Notingher

University Politehnica of Bucharest

313 SplaiulIndependentei Street

Bucharest, 060042, Romania

ABSTRACT

Due to the increase of electrical energy consumption, the power transformers are loaded

beyond nameplate rating. The degradation of their insulation systems is intensified and the

dielectric properties are worsened. Therefore, the interest of asset managers, regarding the

condition of their transformers is a very important topic. Electrical conductivity is strongly

influenced by the high operating temperatures and catalysis products (water, gases, acids)

that appear as a result of oil and paper degradation reactions during transformer operation.

The present paper is focused on an experimental study regarding the influence of water,

acids and gases (hydrogen, acetylene, ethylene, methane etc.) resulted from degradation

processes on electrical conduction phenomena of mineral oil. For that, the frequency/time

variation curves of ac/dc conductivity for different concentrations of water, acids and gases

are drawn. Finally, the correlation between ac and dc conductivity and the possibility to

assess the ageing state of the mineral oil based on these quantities are analyzed.

Index Terms Mineral oil, conduction phenomena, electrical conductivity, dielectric

response function.

1 INTRODUCTION

POWER transformers are one of the most important parts

of equipment from the electrical grid, due to their operational

role, on one hand (step-down or step-up transformer), and to

financial reasons, on the other hand [1-4]. The operating

transformers are subjected to thermal, electrical, mechanical

and environmental stresses, which especially affect their

insulation systems, leading to their failure and further to

transformer failure.

Premature shut-down of a transformer produces important

losses to both manufacturers and electrical consumers.

The effective maintenance strategies must allow lowering

the operations that are not necessary, as well as finding the

optimal moment in time for the transformer to be taken out of

service in a controlled way. The maintenance plans are

established based on the results of monitoring diagnostic

factors, which are related to power transformers condition.

The diagnostic factors are chemical, electrical, mechanical,

thermal etc. Nowadays, condition monitoring and diagnosis of

transformers are based more and more on the electrical

properties of their insulation systems, which play an important

role in terms of life expectancy of these assets [5-6]. Mineral

oils used in transformers are stable only at lower temperatures,

their stability being determined by the energy of C-C, C-H

simple or double links. At higher temperatures, these links are

split in a series of compounds based on carbon and hydrogen.

Thus, the decomposition may be the source of new

hydrocarbons (CH

4

, CH

2

, C

2

H

6

, C

2

H

4

) as well as of other

secondary products, namely acids, CO, H

2

and even water.

Moreover, the resulting products from the depolymerisation

process of the paper (CO, CO

2

, H

2

O, H

2

, CH

4

) also accelerate

the degradation reactions of the mineral oil.

The secondary products resulted from oil and paper

degradation water, gases, and acids influence the ageing

processes of mineral oils, by creating direct chemical links

(oxidation) with their molecules. The oil oxidation reaction

starts with the formation of hydro-peroxides, from which

result oxides and ketones. Next, carboxylic acids and other

soluble or insoluble substances are formed and have a negative

effect on the oils properties. The kinetic of oxidation reaction

depends on the chemical structure of oil, on the oxidation

conditions (temperature, pressure, contact surface with air)

and on the presence of oxidation promoting or inhibiting

substances [7-8].

The oil oxidation favors the creation of acids, which, on

one hand, are dissociated in water increasing the H

+

ions

concentration and, on the other hand, increasing the

water absorption capacity of the oil. That is the reason

why water solubility in oil is higher in the case of

degraded oils. Water can be found in oil, depending on its

concentration, in three forms: dissolved water (creates

physical links with oil molecules), linked water (creates

chemical links with oil molecules) and free water. Water

solubility in mineral oil depends on temperature, but also

on the concentration of aromatic hydrocarbons and polar Manuscript received on 13 January 2012, in final form 1 June 2012.

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 19, No. 5; October 2012 1545

molecules (controlled concentrations through refining

process) etc. [9].

According to IEC standards (60076-7), the insulation

systems degradation process is an irreversible chain of

reactions, under the action of several stress factors. The most

important stress factors affecting the mineral oil condition are

the temperature, moisture, oxygen (and acids, which appear

after the degradation reactions inception of paper and oil). The

stress factors activity can be assessed by electric diagnostic

factors (electrical conductivity, loss factor,

absorption/resorption currents, partial discharge etc), and

chemical diagnostic factors (gases concentration, number of

solid particles, total acidity number TAN).

In the present paper, the electrical conductivity is used in

order to assess the mineral oil condition and to evaluate the

ageing state. According to IEC 60422:2005 the limit values (at

20 C) of electrical conductivity are 250 pS/m for power

transformers with a nominal system voltage below 170 kV and

50 pS/m for power transformers with a nominal system

voltage above 170 kV. The reason why the electrical

conductivity of mineral oil was chosen as a diagnostic factor is

explained below.

It is known that, for the paper-oil insulation, the parameter

which reflects the dielectric losses contains two terms, a term

proportional with the imaginary part of complex susceptibility

(parameter which evaluates the polarization losses) and a

term based on the steady-state conductivity of the insulation

system

0

(parameter which evaluates the conduction losses):

/ ) ( ) (

0 0

' ' ' '

+ =

r

(1)

where = 2f is the angular frequency of the electric field and

0

is the vacuum permittivity [10, 11].

Because mineral oil is a non-polar dielectric, the term

dependent on the imaginary part of the complex susceptibility

becomes negligible, and consequently the polarization losses

are negligible compared to the conduction losses. Therefore, it

can be said that practically the entire amount of losses

developed inside the mineral oil exists because of the

conduction phenomena [12]. From this point of view, the

electrical conductivity is an important diagnostic factor for the

assessment of mineral oil condition.

In the studies [13-17], the power transformers insulation

systems condition using dc conductivity is analyzed. In this

paper, a study concerning ac and dc conductivity of mineral

oil samples contaminated with water, acids and gases is

presented. At the end, a correlation between ac and dc

conductivity is also shown.

2 ELECTRICAL CONDUCTION OF LIQUIDS

The electrical conduction of a dielectric liquid is due to the

movement of the positive and/or negative ions (which appear

as a result of impurities dissociation), ionized liquid molecules

and free electrons. Moreover, the solid particles in suspension

can also participate to the conduction phenomenon [18]. The

dissociation phenomenon of the impurities depends on both

physico-chemical structure of the liquid and liquid permittivity

value. The dissociation constant K

d

can be characterized by

the equation [18]:

(

=

+

+

) (

ln exp

-

-

0 0

r r kT

q q

C K K

r

d

(2)

where K

0

and C

0

represent material constants, q

+

, q

-

, r

+

, r

-

are

the charges and the radius of the formed ions, T is the

temperature and

r

is the relative permittivity of the liquid, and

k is the Boltzmann constant [18]. The increase of T and

r

favors the dissociation process of the impurities, which

implies the increase of charge carriers concentration.

The electrical conductivity of a liquid that contains n

species of charge carriers can be determined with the equation:

=

=

n

j

j j j

M q N

1

(3)

where N

j

, q

j

and M

j

are the concentration, the electrical charge

and, respectively, the mobility of j type charge carriers [18].

The mobility of a charge carrier M

j

can be expressed by:

T

D k

M

j j

j

=

(4)

) / exp( T B A D

j j j

=

(5)

where D

j

is the diffusion coefficient, A

j

, B

j

and K

j

are constants

which characterize the charge carrier of type j [19-21].

If a dc voltage is applied between two electrodes submerged

into the liquid, an absorption current i

a

(t) appears (Figure 1),

which has four components:

) ( ) ( ) ( ) ( ) ( t i t i t i t i t i

c ss p i a

+ + + =

(6)

where i

i

(t) is the capacitor charge component, i

p

(t) is the

polarization component, i

ss

(t) is the space charge component

and i

c

(t) is the steady-state conduction component [22].

Figure 1.General form of time variation of absorption i

a

(t) and resorption i

r

(t)

currents.

1546 L. V. Badicu et al.: Assessment of Transformer Mineral Oil Condition Based on dc and ac Conductivity

If the capacitor is short-circuited at t = t

c

, a resorption

current i

r

(t) can be measured, which has three components

(equation (7)).

) ( ) ( ) ( ) (

'

t i t i t i t i

ss dp d r

+ + =

(7)

where i

d

(t) is the capacitor discharge component, i

dp

(t) is the

depolarization component and i

ss

(t) is the space charge

component.

If i

i

(t) = i

d

(t), i

p

(t) = i

dp

(t) and i

ss

(t) = i

ss

(t), the conduction

current i

c

(t) can be written:

c r a c

I t i t i t i = = ) ( ) ( ) (

(8)

and the dc conductivity

dc

can be calculated with the

equation:

A

d

U

I

c

dc

=

0

(9)

where d is the distance between the electrodes, A is the

electrodes area and I

c

is the conduction current.

Generally, i

p

(t) i

dp

(t), i

ss

(t) i

ss

(t) and the dc conductivity

is:

A

d

U

t i t i

t

r a

dc

=

0

) ( ) (

) (

(10)

and it has two components [25]:

) ( ) (

0

t t

v dc

+ =

(11)

where

0

is the steady-state component of dc conductivity and

corresponds to the conduction current I

c

, while

v

(t) is the time

variable component of dc conductivity (which becomes zero

for a long measurement time t) corresponding to the i

p

(t) and

i

ss

(t) currents.

Assuming that the time for the voltage application T

c

is

sufficiently long, so that f(t + T

c

) 0, the dielectric response

function of the liquid f(t) might be calculated, like in case of

the solid dielectrics, based on the resorption current i

r

(t)

[23]:

0 0

) (

) (

U C

t i

t f

r

~

(12)

function which, in the case of mineral oil, can be

approximated by:

c t a t f

b

+ = ) (

(13)

where a, b, c are coefficients resulted from (12).

The function f(t) allows the calculation of some diagnostic

factors with regard to the frequency domain, respectively, the

components of the complex relative permittivity

r

,

r

and the

loss factor tg:

}

+

+ =

0

'

) cos( ) ( 1 ) ( dt t t f

r

(14)

}

+

+ =

0 0

0 ' '

) sin( ) (

) ( dt t t f

r

(15)

'

' '

tg

r

r

=

(16)

Currently, there are no experimental set-ups, which permit

to separate the electric conduction phenomena losses from the

electric polarization losses. For this reason, the term L

1

=

0

/

0

was added in equation (15) [11]. Thus, the first term

L

1

from equation (15) is related to the conduction losses while

the second term L

2

is related to the polarization losses.

The components of complex conductivity ( ' o , " o ) can be

calculated based on the components of complex relative

permittivity [24-25]:

) ( ) (

) ( ) (

'

0

' '

' '

0

'

e = e

e = e

r

r

(17)

It must be noted that due to the non-polar character of the

mineral oil, the real part of the complex relative permittivity

and the imaginary part of the complex conductivity

do

not offer relevant information with respect to the degradation

state of the oil [26].

As dc conductivity

dc

(t), the ac conductivity

() has two

components [25]:

) ( ) (

' '

0

'

v

+ = (18)

where

0

is the steady-state component (independent on

frequency), while

) (

'

e o

v

is the component dependent on the

electric field frequency.

3 EXPERIMENTS AND SAMPLES

The experiments were carried out using mineral oil samples

with 8 ppm initial water content. The samples were subjected

to a degassing treatment and contaminated with different

gases, water and naphthenic acid. In order to examine the

reproducibility of the results, each measurement has been

performed on three identical samples.

The characteristics of the used mineral oil samples are

presented in Table 1. The samples AH have been prepared

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 19, No. 5; October 2012 1547

in the laboratory, while the samples I were taken out from a

transformer with the rated power of 400 kVA which was in

service for 25 years. In order to obtain oil samples with an

acidity number of TAN = 0.19 mg KOH/g oil, a volume of

125 l naphthenic acid was added to a volume of 170 ml

mineral oil, while for a TAN = 0.57 mg KOH/g oil, a volume

of 375 l was added to the same oil volume (170 ml).

For determining the ac and dc conductivities, the Dirana

monitoring system was used [27]. Time domain experiments

have involved absorption and resorption currents

measurements applying a dc voltage (U

0

= 200 V) for 3600 s.

With respect to frequency domain spectroscopy, the time

variable applied voltage was U = 100 V peak. The frequency

took values between (1 mHz and 1 kHz).

The experiments were done at ambient temperature (25 C)

and at 90 C (1 C), according to standards IEC 60247 and

IEC 61620. A climatic chamber has been used in order to

ensure the permanent control of the environmental humidity.

The samples water content was determined by Karl Fischer

method (coulometric titration) and the acidity number was

determined with Methrom - 702 SM Titrino titrator according

to [28].

4 RESULTS AND DISCUSSIONS

4.1 WATER CONTENT INFLUENCE

Figures 2 and 3 present the variations of the dc conductivity

(equation (10)), for mineral oil samples, A, D and F, as a

function of measurement time at the two temperatures (25 and

90

o

C). At T = 25

o

C, the electrical dc conductivity of oil is not

significantly influenced by the increase of water content (Figure

2). For these concentration values (like samples A, D and F),

water is completely dissolved in oil (the molecules of the two

mediums being connected through the hydrogen molecules) and

no longer has the initial physical properties [29].

In Figure 2, for t< 200 s, the lowering tendency of

conductivity with water content can be noticed. For such a

short period, the dissolved water molecules might block the

charge carriers migration under the electric field action,

leading to a temporary decrease of conductivity for samples

with higher water concentration.

On the other hand, for t< 40 s the dc conductivity curves

slightly increase over the measuring time (Figure 2). An

explanation might be that the amount of added water increases

the oil relative permittivity and consequently the dissociation

phenomenon leading to the increase of charge carriers

concentration.

For t > 40 s the dc conductivity curves decrease due to

neutralization and recombination phenomena of charge

carriers.

Figure 2. Time variation curves of the dc conductivity for oil samples with

different water contents c

w

: 1 c

w

= 8 ppm (A); 2 c

w

= 20 ppm (D);

3 c

w

= 30 ppm (F) (TAN = 0.03 mg KOH/g, T = 25 C, U

0

= 200 V).

1 10 100 1000

1x10

-11

5x10

-11

5x10

-12

1 2

3

D

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Time (s)

Figure 3. Time variation curves of the dc conductivity for oil samples with

different moisture contents c

w

: 1 c

w

= 8 ppm (A); 2 c

w

= 20 ppm (D);

3 c

w

= 30 ppm (F) (TAN = 0.03 mg KOH/g, T = 90 C, U

0

= 200 V).

The conductivity increases with the increase of the

temperature (Figure 3) due to the intensification of the

dissociation phenomena (equation (2)) and to the growing of

the charge carriers mobility.

4.2 CARBOXYLIC ACIDS INFLUENCE

Due to oil degradation, important quantities of acids

(formic, naphthenic, acetic etc.) - quantified by the total

acidity number TAN [28] can appear.

Figures 4 and 5 present the time variation curves of the dc

conductivity

dc

(t) at T = 25

o

C and T = 90 C, for the samples

A, B and C. It can be seen that the dc conductivity

dc

(t)

increases with TAN number regardless the measurement

temperature.

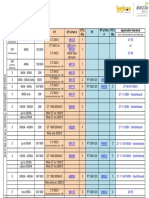

Table 1. Oil samples characteristics.

Samples A B C D E F G H I

Water content c

w

(ppm) 25 C 8 8 8 20 20 30 30 30 22

Acidity number TAN (mg KOH/g oil) < 0.03 0.19 0.57 < 0.03 0.58 < 0.03 0.57 0.57 0.16

Hydrogen content c

h

(ppm) - - - - - - - 2500 -

Acetylene content c

a

(ppm) - - - - - - - 100 -

1548 L. V. Badicu et al.: Assessment of Transformer Mineral Oil Condition Based on dc and ac Conductivity

10

0

10

1

10

2

10

3

1x10

-13

1x10

-12

1x10

-11

1x10

-10

1

3

2

D

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Time (s)

Figure 4. Time variation curves of the dc conductivity for oil samples with

different acidity numbers TAN: 1 TAN < 0.03 mg KOH/g (A);

2 TAN = 0.19 mg KOH/g (B); 3 TAN = 0.57 mg KOH/g (C) (c

w

= 8 ppm,

T = 25 C, U

0

= 200 V).

10

0

10

1

10

2

10

3

1x10

-11

5x10

-11

5x10

-12

2

3

1

D

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Time (s)

Figure 5. Time variation curves of the dc conductivity for oil samples with

different acidity numbers TAN: 1 TAN < 0.03 mg KOH/g (A);

2 TAN = 0.19 mg KOH/g (B); 3 TAN = 0.57 mg KOH/g (C) (c

w

= 8 ppm,

T = 90 C, U

0

= 200 V).

Moreover, the conductivity increase is more important for

TAN values close to the maximum admissible limit (0.5 mg

KOH/g oil according to IEC 62021). One of the reasons why

the dc conductivity

dc

(t) increases with the acidity number

might be the high volume of acid (in comparison with water,

for instance) which must be added to get a desired value of

TAN. The samples C(0.57 mgKOH/g oil) was obtained

combining 170 ml mineral oil and 0.375 ml naphthenic acid,

which means, an acid concentration value around 2200 ppm in

the tested oil. At 90 C the dc conductivity takes also higher

values for higher values of TAN. In this case, the increase of

conductivity is more obvious when TAN is close to its limit

value, as well (according to IEC 62021).

4.3 THE SIMULTANEOUS INFLUENCE OF WATER,

ACIDS AND GASES

During transformer operation, the stress factors act

simultaneously and the resulted degradation process is

strongly influenced by the temperature. For this reason, it is

important to know the electrical conductivity evolution under

the simultaneous action of water, acid and gases. Figures 6

and 7 show the time variation curves of the dc conductivity

dc

(t) for mineral oil samples with constant acidity

number(TAN = 0.57 mg KOH/g oil) and different water and

dissolved gases concentration (C, E, G, H samples) and for

10

0

10

1

10

2

10

3

1x10

-12

1x10

-11

5x10

-11

5

4

1

2

3

D

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Time (s)

Figure 6. Time variation curves of the dc conductivity for C(1), E(2), G (3),

H(4) and I(5) samples (T = 25 C, U

0

= 200 V).

10

0

10

1

10

2

10

3

1x10

-11

1x10

-10

5x10

-11

2

3

5

1

4

D

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Time (s)

Figure 7. Time variation curves of the dc conductivity for C(1), E(2), G (3),

H(4) and I(5) samples (T = 90 C, U

0

= 200 V).

mineral oil samples from a transformer taken out of service

after 25 years (I samples).

If the samples have the acidity number TAN 0.03 mg

KOH/g oil, the water concentration has no significant

influence on the electrical conductivity (Figure 2). In case of

TAN = 0.57 mg KOH/g oil, the conductivity is influenced by

the increased water content, even at ambient temperature

(Figures 6 and 7 - C, E, G samples). The combined action of

water and acid influences the value of the dc conductivity at

room temperature, but especially at 90 C. The main cause of

this phenomenon is, probably, the increase of H

+

ions, due to

acid molecules dissociation in the presence of water [7].

The conductivity

dc

(t) has been significantly increased

after the contamination of G samples with hydrogen and

acetylene (resulting the H samples). The values for the gases

contents were chosen close to the critical ones imposed by the

IEEE C57.104 in view to cause significant changes,

respectively c

h

= 2500 ppm and c

a

= 100 ppm.

For a realistic evaluation, the electrical conductivities of the

artificially aged samples (by controlled contamination with

water, acids and gases) were compared with the electrical

conductivity of the oil samples aged during transformer

operation (I samples, Figures 6 and 7). It can be seen that, for

the samples I, the quantity

dc

(t) takes very high values, even

though it has a water concentration lower than samples G and

H and its acidity number is lower than the admissible limits

imposed by IEC 62021. These differences may be due to the

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 19, No. 5; October 2012 1549

high concentration of charge carriers and solid particles found

in suspension in oil, which, together with the dissociation of

the oil and impurities molecules lead to a high conductivity

value of the samples I, especially at 90

o

C.

Figures 8 10 present the variation curves of ac

conductivity (

) with the frequency of the electric field for the

samples C, E, G, H and I. It can be seen that, for a high acidity

number (0.57 mg KOH/g oil), the increased water content

(from 8 ppm for samples C to 30 ppm for samples H) leads to

the increase of the quantity

, both at 25

o

C (Figure 8) and at

90

C (Figure 9). The growing tendency is much more obvious

at low frequencies of the electric field and at 90

o

C. This

increase is due to the increase of contaminants concentration

and the intensification of the dissociation phenomenon

catalyzed by the naphthenic acid.

Figure 10 shows frequency variation curves of the ac

conductivity

() (equation (17)) at 25 C and 90 C for

samples I. By extending the curves until the intersection with

the vertical axis, the steady-state values

0(25)

(for T = 25

o

C)

and

0(90)

(for T = 90

o

C) are obtained.

It can be seen that the ac conductivity takes important

values for higher temperatures.

10

-3

10

-1

10

1

10

3

1x10

-12

1x10

-11

1x10

-10

1x10

-9

5 4 3 2 1

A

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Frequency (Hz)

Figure 8. Frequency variation of the real part of complex conductivity for the

samples C(1), E(2), G(3), H(4) and I(5) at T = 25

o

C.

10

-3

10

-1

10

1

10

3

1x10

-12

1x10

-11

1x10

-10

1x10

-9

2 3 4 5 1

A

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Frequency (Hz)

Figure 9. Frequency variation of the real part of complex conductivity for the

samples C(1), E(2), G(3), H(4) and I(5) at T = 90 C.

10

-3

10

-1

10

1

10

3

10

-11

1x10

-10

1x10

-9

2

1

o

0

'

(90)

o

0

'

(25)

A

C

c

o

n

d

u

c

t

i

v

i

t

y

(

S

/

m

)

Frequency (Hz)

Figure 10. Frequency variation curves of ac conductivity at T = 25 C (1) and

T = 90 C (2) for samples I (c

w

= 22 ppm, TAN = 0.16 mg KOH/g).

Table 2 shows the values of steady-state components of dc

(

0

) and ac conductivities (

0

), at 25 C and 90 C, for

samples I. It can be noticed that, for f = 1 mHz, the differences

between the values of

0

and

0

are relative small, regardless

the temperature values.

Consequently, at low frequencies,

(f0)

0

dc

(t ) =

0

, respectively:

) ( lim

'

0

0

f

f

o = o

(19)

Table 2. The values of steady-state components of dc (

0

) and ac (

0

)

conductivity.

Temperature (C)

0

(pS/m)

0

(1 mHz)(pS/m)

25 (C) 18.6 19.6

90 (C) 48.8 53.6

4.4 LOSSES EVALUATION BASED ON DC

CONDUCTIVITY

Keeping in mind that the ac conductivity

depends on

r

(equation (17)) and that, at small frequencies

(f) tends to

0

(equation (19)), it results that, for small frequencies (e.g. 10

-3

Hz), the imaginary part of complex relative permittivity

' '

rsf

can be calculated using the steady-state component of dc

conductivity

0

[27]:

0

0 ' '

=

rsf

(20)

Table 3 presents the values of

' '

rsf

at frequency of 1 mHz,

obtained by direct measurement on one hand, and

calculation(using equation (20)), on the other hand. It can be

noticed that the calculated quantity

' '

rsf

takes different values

than its measured values.

The main cause of these differences is due to the fact that,

at frequency of 1 mHz, the

0

value is slightly different from

0

value.

1550 L. V. Badicu et al.: Assessment of Transformer Mineral Oil Condition Based on dc and ac Conductivity

Table 3. The measured and calculated values of quantity

' '

rsf

Samples A B C D E F G H I

' '

rsf

measured (1 mHz, 25 C)

5.1 19.5 25.4 11.6 58.0 14.3 67.3 178.2 288.1

' '

rsf

calculated (1 mHz, 25 C)

3.5 18.4 36.8 11.8 64.9 9.4 77.4 314.2 257.4

' '

rsf

measured (1 mHz, 90 C)

33.6 104.6 189.9 85.1 239.2 176.6 384.1 625.3 950.1

' '

rsf

calculated (1 mHz, 90 C)

41.6 118.2 209.6 98.2 263.3 194.1 368.8 502.0 877.1

For frequencies lower than 1 mHz, probably

0

0

, and the

differences between calculated

' '

rsf

and measured

' '

rsf

are smaller.

The dielectric response functions f(t) were calculated based

on the resorption currents (equation (12)) for the samples A and

I at ambient temperature. The time variation curves of these

functions have been fitted using equation (13). The coefficients

of the above equation are presented in Table 4.

Using equation (15), the values of the imaginary part of

complex relative permittivity were calculated, for frequency of

1 mHz. According to this relation, the contribution of the

conduction and polarization losses to the total dielectric losses

(reflected by

' '

rsf

) in oil can be determined. Table 5 presents the

values of the imaginary part of relative permittivity

' '

rsf

, of the

term related to dielectric losses due to conduction phenomena

(L

1

=

0

/

0

, equation (15)) and the term related to dielectric

losses due to the polarization phenomena (L

2

=

}

+

0

) sin( ) ( dt t t f

,

equation (15)), at ambient temperature of 25

o

C. Thus, it can be

said that the term related to dielectric losses due to the electrical

polarization phenomena is negligible comparing to the term

related to dielectric losses due to the conduction phenomena. It

results that, for the evaluation of the dielectric losses in mineral

oil and for its condition assessment it is necessary to know

the steady-state component of dc conductivity

0

, which might

be an important diagnostic factor to assess the mineral oil

condition from power transformers.

Table 4. Function coefficients f(t).

Samples A (T = 25 C) Samples I (T = 25 C)

a 0.008374 0.002113

b -1.513 -0.5214

c 0.0000534 0.0001101

Table 5. Losses contribution by conduction (L

1

) and polarization (L

2

) to the

total losses reflected by

' '

rsf

Samples A (T = 25 C) Samples I (T = 25 C)

"

rsf

c

3.5 250

L

1

3.42 249.05

L

2

0.08 0.95

5 CONCLUSIONS

At ambient temperature, the steady-state component of dc

conductivity

0

is not strongly influenced by water content,

when the oil acidity number takes low values. The water

influence becomes important when the acidity number and the

concentration of oil gases take high values. Moreover, the oil

samples aged in service shows high values of

0

electrical

conductivity because of the high number of contaminants.

The condition of mineral oil might also be evaluated using the

ac conductivity, but at low frequency, the steady-state component

of ac conductivity

0

tends to the steady-state component of dc

conductivity

0

.

The steady-state component of dc conductivity

0

allows the

evaluation of the imaginary part of relative permittivity of the

mineral oil (related to the dielectric losses). This method is very

important for oil diagnosis, due to the large accessibility of

mineral oil dc conductivity measurement, which can be made

with non-substantial investment equipment, directly on in-service

power transformers.

ACKNOWLEDGMENTS

The work has been funded by the Sectoral Operational

Programme Human Resources Development 2007-2013 of the

Romanian Ministry of Labour, Family and Social Protection

through the Financial Agreement POSDRU/88/1.5/S/60203,

POSDRU/89/1.5/S/62557. Also, this paper has been possible with

a great contribution of Institute for Power Transmission and High

Voltage Technology University of Stuttgart.

REFERENCES

[1] S. Tenbohlen, F. Vahidi, J. Gebauer, M. Krger and P. Mller,

Assessment of power transformer reliability, XVII Intl.Sympos. High

Voltage Engineering (ISH), Paper G-026, 2011.

[2] M. Wang, A. J. Vandermaar and K. D. Srivastava, Review of condition

assessment of power transformers in service, IEEE Electrical Insulation

Magazine, Vol.18, No.6, pp.1225, 2002.

[3] M. A. G. Martins, Vegetable Oils, an Alternative to Mineral Oil for

Power Transformers-Experimental Study of Paper Aging in Vegetable

Oil Versus Mineral Oil, IEEE Electrical Insulation Mag., Vol. 26, No.

6, pp. 7-13, 2010.

[4] R. J. Liao, L.-J. Yang, J. Li and S. Grzybowski, Aging Condition

Assessment of Transformer Oil-paper Insulation Model based on Partial

Discharge Analysis, IEEE Transactions on Dielectrics and Electrical

Insulation, Vol. 18, pp. 303-311, 2011.

[5] M. Arshad and S. M. Islam, Significance of Cellulose Power

Transformer Condition Assessment, IEEE Transactions on Dielectrics

and Electrical Insulation, Vol. 18, No. 5, pp. 1591-1598, 2011.

[6] C57.91-1995 IEEE guide for loading mineral-oil-immersed

transformers, 1996.

[7] L. E. Lundgaard, W. Hansen, D. Linhjell and T. J. Painter, Aging of

Oil-Impregnated Paper in Power Transformers, IEEE Transactions on

Power Delivery, Vol. 19, pp. 230-239, 2004.

[8] Gh. Radulescu, M. Ilea, Fizico-Chimia si Tehnologia Uleiurilor

Lubrifiante, Editura Tehnica, Bucuresti, Romania, 1982 (in Romanian).

[9] M. Koch and S. Tenbohlen, Diagnostic Application of Moisture

Equilibrium for Power Transformers, IEEE Transactions on Power

Delivery, Vol. 25, pp. 2574-2581, 2010.

[10] S. M. Gubanski, J. Blennow, B. Holmgren, M. Koch, A. Kuechler, R.

Kutzner, J. Lapworth, D. Linhjell, S. Tenbohlen and P. Werelius,

Dielectric Response Diagnoses for Transformer Windings, CIGRE

Technical Brochure, No. 414, 2010.

[11] W. S. Zaengl, Dielectric Spectroscopy in Time and Frequency Domain

for HV Power Equipment, Part I: Theoretical considerations, IEEE

Electrical Insulation Mag., Vol. 19, No. 5, pp. 5-19, 2003.

IEEE Transactions on Dielectrics and Electrical Insulation Vol. 19, No. 5; October 2012 1551

[12] R. Bartnikas, Some general remarks on the dielectric loss mechanisms in

mineral oils, IEEE Transactions on Dielectrics and Electrical Insulation, Vol.

16, pp. 1506-1510, 2009.

[13] L. V. Badicu, P. V. Notingher, L. Dumitran, B. Gorgan and G. Tanasescu,

Assessment of mineral oil condition based on water content, Electrical

Machines Symposium, paper L17, 2010.

[14] A. A. Shayegani,H. Borsi, E. Gockenbach and H. Mohseni, "Application of low

frequency dielectric spectroscopy to estimate condition of mineral oil", IEEE

Intl. Conf. Dielectr. Liquids, pp. 285-288, 2005.

[15] T. K. Saha and P. Purkait, "Investigation of Polarization and Depolarization

Current Measurements for the Assessment of Oil-paper Insulation of Aged

Transformers", IEEE Transactions on Dielectrics and Electrical Insulation ,Vol.

11, pp. 144-154, 2004.

[16] I. Fofana, H. Hemmatjou, M. Farzaneh, E. Gockenbach and H. Borsi,

"Polarization and Depolarization Current Measurements of Oil impregnated

Paper insulation System under Thermal Runaway", IEEE Intl. Conf. Solid

Dielectrics, pp. 1-4, 2010.

[17] N. A. Muhamad, B. T. Phung, T. R. Blackburn and K. X. Lai, "Polarization and

Depolarization Current (PDC) Tests on Biodegradable and Mineral

Transformer Oils at Different Moisture Levels", Proc. Power Eng. Conf., pp. 1-

6, 2009.

[18] P.V. Notingher, Insulation Systems, Bucharest, Romania, Printech, 2002.

[19] B. Abedian and K. N. Baker, Temperature effects and the electrical

conductivity of dielectric liquids, IEEE Transactions on Dielectrics and

Electrical Insulation, Vol. 15, pp. 888-892, 2008.

[20] L. M. Dumitran, Sisteme de izolatie electrica (Electrical Insulation Systems),

Editura Printech, Bucuresti, Romania, 2008 (in Romanian).

[21] N. F. Schmidt, Liquid state electronics of insulating liquids, New York, USA,

CRC Press, 1997.

[22] P. V. Notingher, C. Stancu, L. M. Dumitran, P. P. Notingher, A. Rakowska and

K. Siodla, Influence of the ageing state of insulation systems on

absorption/resorption currents, Revue Roumaine des Science Techniques,

Serie Electrotehnique et Energetique, Vol. 53, No. 2, pp. 163-177, 2008.

[23] A. A. Shayegani, E. Gockenbach and H. Borsi, Investigation on the

Transformation of Time Domain Spectroscopy Data to Frequency Domain

Data for Impregnated Pressboard to Reduce Measurement Time, Springer-

Verlag, Electr. Eng., Vol. 89, No. 1, pp. 11-20, 2006.

[24] Novocontrol equipment, User manual, 2008.

[25] P. V. Notingher, C. Stancu and I. Enescu, Electrical Conductivity of Wood-

polymer Composites, Revista Materiale Plastice, Vol. 2, pp. 170-175, 2011.

[26] S. M. Gubanski, P. Boss, G. Cspes, V. Der Houhanessian, J. Filippini, P.

Guuinic, U. Gfvert, V. Karius, J. Lapworth, G. Urbani, P. Werelius and W.

Zaengl, Dielectric Response Methods for Diagnostics of Power Transformers

IEEE Electrical Insulation Magazine, Vol. 19, No. 3, pp. 12-18, 2003.

[27] M. Koch, Reliable Moisture Determination in Power Transformers, Ph.D.

Dissertation, University of Stuttgart, Germany, 2008.

[28] M. Jovalekic, S. Tenbohlen and M. Koch, The influence of carboxylic acids on

the dielectric performance of oil-paper insulations, 16

th

Intl.Sympos. High

Voltage Eng., pp. 1071-1075, 2009.

[29] V.G. Arakelian and I. Fofana, "Water in Oil-Filled High-Voltage Equipment

Part I: States, Solubility, and Equilibrium in Insulating Materials", IEEE

Electrical Insulation Magazine, Vol. 23, No.4, pp. 15-27, 2007.

Laurentiu Viorel Badicu was born in Romania on

20 October 1984. He received the Dipl.-Eng.

degree in electrical engineering in 2008 and the

Ph.D, degree in electrical engineering at University

Politehnica of Bucharest (UPB), Bucharest,

Romania in 2011. His research interests include

ageing mechanisms of electrical insulation,

insulation systems testing especially cellulose-

based insulation and mineral oil.

Bogdan Gorgan was born in Romania, on 6

December 1985. He received the B.Sc. degree in

electrical engineering from the University

Politehnica of Bucharest (UPB) in 2009. At present,

he is enrolled for the Ph.D. degree sponsored by the

University Politehnica of Bucharest, Romania. His

technical field of interest includes ageing

mechanisms of electrical insulation, insulation

systems testing, especially cellulose-based

insulation and mineral oil, power transformer lifetime modeling.

Laurentiu Marius Dumitran was born in Romania

on 1 March 1973. He received the M.S. degree in

electrical engineering from the University

Politehnica of Bucharest, Romania, in 1996, and the

jointly sponsored Ph.D. degree in electrotechnical

materials and physics from the University

Politehnica of Bucharest and the University Joseph

Fourier, Grenoble, France, in 2001.He is currently a

Lecturer in Electrical Engineering Faculty,

University Politehnica of Bucharest. His present research interests

include the electrical properties of dielectric materials, the

characterization of insulating systems, as well as the numerical and

experimental modeling of electrostatic separation and precipitation

processes.

Petru V. Notingher (M91) was born in Romania on

18 February 1946. He received the M.S. and Ph.D.

degrees in electrical engineering from the University

Politehnica of Bucharest (PUB), Bucharest, Romania.

He is a Professor in the Department of Electrical

Machines and Materials at the University Politehnica of

Bucharest and the Director of Electrical Materials

Laboratory of PUB. His research interests include

ageing mechanisms of electrical insulation, insulation

systems testing, electrical and water treeing, and materials (dielectrics,

composites). He has published over 340 scientific papers and books. Prof.

P.V. Notingher is a member of CIGRE.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- WEF Making Affordable Housing A Reality in Cities ReportDocument60 pagesWEF Making Affordable Housing A Reality in Cities ReportAnonymous XUFoDm6dNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Practice HSC Papers General 2Document47 pagesPractice HSC Papers General 2DarrenPurtillWrightNo ratings yet

- Lifeboat Engine Operation Manual 380JDocument29 pagesLifeboat Engine Operation Manual 380JDuarte100% (2)

- Welding and Gas CuttingDocument2 pagesWelding and Gas CuttingKrishna Patil100% (1)

- Effect of Temperature and Pressure On The DensityDocument7 pagesEffect of Temperature and Pressure On The DensityDrSaurabh TewariNo ratings yet

- Kris Gethin Muscle Building - Nutrition OverviewDocument8 pagesKris Gethin Muscle Building - Nutrition OverviewLuisLopezNo ratings yet

- Cutting Torch InstructionDocument2 pagesCutting Torch Instructionfoxtrot mikeNo ratings yet

- He - 02 - 2020 PDFDocument92 pagesHe - 02 - 2020 PDFMarco Antonio Guevara MartínezNo ratings yet

- 13 - Piping Sample ReportDocument5 pages13 - Piping Sample ReportS Surya Dharma100% (3)

- Chapter 5 (2nd Law of ... )Document64 pagesChapter 5 (2nd Law of ... )yohannes lemiNo ratings yet

- Lechler Brochure Tank Equipment Cleaning enDocument84 pagesLechler Brochure Tank Equipment Cleaning enAnonymous lswzqloNo ratings yet

- Banjanin 2019Document5 pagesBanjanin 2019BalajiNo ratings yet

- Dtec 2016 7731298Document7 pagesDtec 2016 7731298BalajiNo ratings yet

- Martinez - Lightning Performance Analysis of Overhead Transmission Lines Using The EMTP PDFDocument11 pagesMartinez - Lightning Performance Analysis of Overhead Transmission Lines Using The EMTP PDFDiego AcostaNo ratings yet

- Insulation Coordination of HV Lines Resumo Alargado - Linhas Aereas - Final PDFDocument6 pagesInsulation Coordination of HV Lines Resumo Alargado - Linhas Aereas - Final PDFEdward Baleke SsekulimaNo ratings yet

- Tower Grounding Improvement vs. Line Surge Arresters: Comparison of Remedial Measures For High-BFOR Subtransmission LinesDocument8 pagesTower Grounding Improvement vs. Line Surge Arresters: Comparison of Remedial Measures For High-BFOR Subtransmission LinesBalajiNo ratings yet

- A Simple Simulation Model For Analyzing Very Fast Transient Overvoltage in Gas Insulated SwitchgearDocument6 pagesA Simple Simulation Model For Analyzing Very Fast Transient Overvoltage in Gas Insulated SwitchgearPuchi RománNo ratings yet

- Research On The Characteristics of TEV When Disconnector Operating in UHV GISDocument7 pagesResearch On The Characteristics of TEV When Disconnector Operating in UHV GISBalajiNo ratings yet

- Zero Sequence Behaviour of A Double-Circuit Overhead LineDocument8 pagesZero Sequence Behaviour of A Double-Circuit Overhead LineBalajiNo ratings yet

- V/ K 22 GKFKH Pyye Pyye: Ikb VK/KKFJR Iz'UDocument4 pagesV/ K 22 GKFKH Pyye Pyye: Ikb VK/KKFJR Iz'UBalajiNo ratings yet

- 2006 International Conference on Power System Technology Overvoltage Analysis and Events in ThailandDocument7 pages2006 International Conference on Power System Technology Overvoltage Analysis and Events in ThailandBalajiNo ratings yet

- NCERT Books & Worksheets Single Click File Class 1Document4 pagesNCERT Books & Worksheets Single Click File Class 1BalajiNo ratings yet

- Simulation of VFTO by ATP/EMTP With Various Arc Models, Liu XiaofanDocument6 pagesSimulation of VFTO by ATP/EMTP With Various Arc Models, Liu XiaofanBalajiNo ratings yet

- Research on Arc Model of Disconnector for Conductive Interference of Electronic TransformerDocument5 pagesResearch on Arc Model of Disconnector for Conductive Interference of Electronic TransformerBalajiNo ratings yet

- Higl - Pressure Gas As A DielectricDocument4 pagesHigl - Pressure Gas As A DielectricBalajiNo ratings yet

- Nasa Ntrs Archive 19800022965Document6 pagesNasa Ntrs Archive 19800022965BalajiNo ratings yet

- 05447777Document4 pages05447777BalajiNo ratings yet

- Weibull Statistical Analysis of Impulse-Driven Surface Breakdown DataDocument5 pagesWeibull Statistical Analysis of Impulse-Driven Surface Breakdown DataBalajiNo ratings yet

- Comparison of Universal Circuit Breaker Arc Representation With EMTP Built-In ModelDocument6 pagesComparison of Universal Circuit Breaker Arc Representation With EMTP Built-In ModelBalajiNo ratings yet

- Fielding A Current Idea Exploring The Public Health Impact of Electromagnetic RadiationDocument12 pagesFielding A Current Idea Exploring The Public Health Impact of Electromagnetic RadiationBalajiNo ratings yet

- EVS QuestionsDocument3 pagesEVS QuestionsBalajiNo ratings yet

- The Effect of Gas-Cell DiameterDocument7 pagesThe Effect of Gas-Cell DiameterBalajiNo ratings yet

- On The Statistical Testing of Solid DielectricsDocument6 pagesOn The Statistical Testing of Solid DielectricsBalajiNo ratings yet

- Aging Effect On Insulation Reliability Evaluation With Weibull Distribution For Oil-Immersed TransformersDocument8 pagesAging Effect On Insulation Reliability Evaluation With Weibull Distribution For Oil-Immersed TransformersBalajiNo ratings yet

- Is 9335 3 4 1984Document9 pagesIs 9335 3 4 1984BalajiNo ratings yet

- Estimation of Partial Discharge Inception Voltages in The Ambient Medium of SF 6Document4 pagesEstimation of Partial Discharge Inception Voltages in The Ambient Medium of SF 6BalajiNo ratings yet

- Exploring The Feasibility of An Aging Model For Paper Insulation Based On The Repetition Frequency of TransientsDocument5 pagesExploring The Feasibility of An Aging Model For Paper Insulation Based On The Repetition Frequency of TransientsBalajiNo ratings yet

- Fielding A Current Idea Exploring The Public Health Impact of Electromagnetic RadiationDocument12 pagesFielding A Current Idea Exploring The Public Health Impact of Electromagnetic RadiationBalajiNo ratings yet

- Automatic Circuit RecloserDocument16 pagesAutomatic Circuit RecloserFarraziNo ratings yet

- 1.3.6.6.8. Weibull DistributionDocument5 pages1.3.6.6.8. Weibull DistributionBalajiNo ratings yet

- EVALUATICtO OF TRANSFORMER LOADING ABOVE NAMEPLATE RATINGDocument10 pagesEVALUATICtO OF TRANSFORMER LOADING ABOVE NAMEPLATE RATINGBalajiNo ratings yet

- FisicaDocument352 pagesFisicaCg Tonio100% (1)

- Final Examination in Thermodynamics IDocument3 pagesFinal Examination in Thermodynamics IChristopher AlcarazNo ratings yet

- Kaise Batera Agm 12v 200ahDocument2 pagesKaise Batera Agm 12v 200ahJOHN FREDY IBAÑEZ HERNANDEZNo ratings yet

- Compare Energy Sources & Their Environmental EffectsDocument2 pagesCompare Energy Sources & Their Environmental Effectsamit shuklaNo ratings yet

- CT Essential Products EN PDFDocument159 pagesCT Essential Products EN PDFXavier DomenechNo ratings yet

- 3.electromagnetic Theory NET-JRF VKSDocument31 pages3.electromagnetic Theory NET-JRF VKSSijil SalimNo ratings yet

- MODULE I - 10 Marks Basic Laboratory TechniquesDocument18 pagesMODULE I - 10 Marks Basic Laboratory TechniquesArun KumarNo ratings yet

- Small, High Efficiency, Recuperated Ceramic Turboshaft EngineDocument1 pageSmall, High Efficiency, Recuperated Ceramic Turboshaft EngineU.S. Naval Research LaboratoryNo ratings yet

- Fcu Pressure Drop PDFDocument18 pagesFcu Pressure Drop PDFvishalNo ratings yet

- CT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhaseDocument1 pageCT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhasePrabakar PNo ratings yet

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocument3 pagesACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002No ratings yet

- Parandoush 2017Document18 pagesParandoush 2017diego9723No ratings yet

- EMUA Connection PDFDocument12 pagesEMUA Connection PDFBilly Eka Dharmala PutraNo ratings yet

- Bum 60 S: Single Power UnitDocument62 pagesBum 60 S: Single Power UnitBruno CardosoNo ratings yet

- Profile ForgingDocument17 pagesProfile ForgingMahipal ChandanNo ratings yet

- Pharmaceutical Refrigerators with Built-In FreezerDocument2 pagesPharmaceutical Refrigerators with Built-In FreezerEslam HassanNo ratings yet

- AZ E-Lite LED Lighting CatalogDocument2 pagesAZ E-Lite LED Lighting CatalogsujiNo ratings yet

- Greece WasteDocument64 pagesGreece WasteYiannis AntonopoulosNo ratings yet

- Installation: Residential/Light Commercial Generator SetsDocument64 pagesInstallation: Residential/Light Commercial Generator SetsJackNo ratings yet